Professional Documents

Culture Documents

PREFASE

Uploaded by

John PavalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PREFASE

Uploaded by

John PavalCopyright:

Available Formats

M Series Reach Truck Operation and Maintenance Manual

PREFACE

Thanks for purchasing M-series 1-2t reach truck manufactured by Maximal forklift

Co., Ltd.

M-series reach truck adopts the best design. It characterizes the strong output of

torque, mast for wide view, the whole hydraulic steering and the forward and reverse

with hydraulic control, upon which, it owns the following advantages, such as

comfortable operation, flexible steering, easy charging, the tight grab of the drive wheel

on the accidented ground and so on.

FBR-10~20 series reach truck appears an attractive feature, low noise, power shift,

and advanced design. So it has been widely used in many industry fields, such as

merchandise, medicine, meat, water-producing machine and the materials handling in

freezing warehouse. So it is the best tool to improve the labor efficiency and to realize

the work for high place in a three-dimensional warehouse.

The performance index this manual offer is for the standard models. Now the

M-series reach truck equipped the high mast is specially fit in a high place and

three-dimensional warehouse. The maximal lifting height is 7.2 m, while we can offer

the models with the height that the customers request.

M-series truck will be improved with the market request and the customer’s

demand. So it will be some difference between what the manual said and the real

products and we will make a continuous revise and complements, but it will not be

informed for the improvement of the small part.

In order to help the operator get a knowledge of the working principle of the forklift,

the manual offer a brief instruction of performance and the structure, operation,

maintenance and so on. It is hoped that the forklift is operated according to the manual

and make sure the forklift work normally. It is necessary to obey the rules carefully when

concerning the safety of the people and the security of the forklift.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

CONTENT

1、M-Series Reach Truck Appearance Diagram………………………………………… 2

2、The Main Technical Characteristic …………………………………………… 4

(Ⅰ)Performance Parameter…………………………………………………………… 4

(Ⅱ)Dimension Parameter …………………………………………………………… 4

(Ⅲ)Weight Parameter………………………………………………………………… 4

(Ⅳ)Main Outside Fittings ………………………………………………………… 5

3、The Configuration of Reach Truck ………………………………………………… 5

(Ⅰ)Driving System ………………………………………………………………… 5

1、Summary ………………………………………………………………… 5

2、Gear Box ………………………………………………………………… 7

3、Wheel……………………………………………………………………… 9

(Ⅱ)Steering System………………………………………………………………… 11

(Ⅲ)Braking System………………………………………………………………… 13

(Ⅳ)Lifting System ……………………………………………………………… 15

(Ⅴ)Hydraulic System …………………………………………………………… 17

(Ⅵ)Electrical System……………………………………………………………… 23

(Ⅶ)Forward & Backward Device of Battery……………………………………… 27

4、Operation Introduction and Note Items…………………………………………… 27

5、Fault and Resolution ……………………………………………………………… 30

6、Maintenance………………………………………………………………………… 31

7、Specification Form of some Standard Parts & Wearing Parts …………………… 32

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、M series appearance of reach battery truck

Chart 1-1 FBR10~13 appearance of the reach truck

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart 1-2 FBR15~20 appearance of the reach truck

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

2、The main technical characteristic

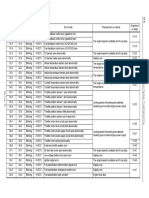

(Ⅰ)、Performance parameter

Parameter

Item FBR10 FBR13 FBR15 FBR18 FBR20

MC MJZ MC MJZ MC MJZ MC MJZ MC MJZ

Rated load

1000 1300 1500 1800 2000

capacity(kg)

Load center

500 500 500 500 500

(mm)

The max lifting

3000 3000 3000 3000 3000

height(mm)

Free Lift Height

330 330 330 330 330

(mm)

Max lifting speed

160 175 160 175 230 240 220 230 210 220

(㎜/s)

Travel speed

(full/no load) 7.7/8.0 8/8.5 7.5/7.8 8/8.5 9.5/10 8.8/9.3 9.2/10 8.5/9.3 8.5/9 9.1/9

(km/h)

The distance of

mast forward 550 600 500 550 600

movement(mm)

Mast forward 30 30 30 30 30

Tilt

Angle backward 50 50 50 50 50

Min turning

1430 1500 1580 1660 1700

radius(mm)

Max gradeability

12 12 12 12 10

(laden)%

System of speed

CurTis DC/ZAPI AC

control

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

(Ⅱ)、Dimension parameter

Parameter

Item

FBR10 FBR13 FBR15 FBR18 FBR20

Overall Length(mm) 1790 1870 2057 2107 2187

Overall width(mm) 1020 1020 1200 1200 1200

Height of overhead

2160 2160 2160 2160 2160

guard(mm)

Height of mast, lowered

2080 2080 2120 2120 2120

(mm)

(Ⅲ)、Weight parameter

Parameter

Item

FBR10 FBR13 FBR15 FBR18 FBR20

Service weight(kg) 1700 1800 2550 2650 2800

3、The Configuration of Reach Truck

(Ⅰ) Drive system

1. Summary

The drive system of FBR 10-20 series consists of drive motor (9), gear plate (3) and

gear box (1). It utilizes the hinge between higher & lower bracket(6、7)、pin(10、13), base

on the spring effect, the truck body’s weight transfer to the drive wheel, ensure the

maximal attraction, drive on the rough ground, the upside and downside brackets have

the effect which could auto regulated. At the end of the motor, loads the brake wheel (8),

according the foot brake, execute the whole truck braking. Between the gear plate and

the gear box, loads the plane bearing. We should ensure the weight loading, and the

drive wheel could rotate where it is.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、gear Box 2、big steering gear 3、gear plate 4、higher spring 5、pin

6、lower bracket 7、higher bracket 8、brake wheel 9、drive motor 10、higher pin

11、hydraulic motor 12、steering box 13、lower pin 14、lower spring

Chart 2 Drive System

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

2. Gear box

The Configuration of gear box FBR10~20, illustrated in the figure 3-1, gear box

connect with the steering main axes bearing、big steering gear and cover, and ensure

the drive wheel rotates where it is. When the truck turns, the steering wheel could

accomplish the size adjustment of steering and turning radius, according to the gear

drives the gear axes circumrotating, and then drives the big steering gear

circumrotating, engaged with the small gear on the gear axes.

The gear box achieves duplicate decelerating through four gears. The power from

motor fan-out drives small gear through the spline joint cover; transfer to the bevel drive

gear through the big gear and pinion gear in the big gear. In the end, drive wheel

circumrotating through the drive axle. The reach truck forward and backward, speed

change, all achieved by the handle accelerator gives the speed signal through the

controller. Due to the drive wheel and steering wheel combines, and high precision

cylindrical helical gear transmission is laid on the high-level, bevel gear transmission is

laid on the low-level, so the transmission is special balanced, noise is greatly reduced,

the structure is very small.

The note of system maintenance:

(I)The bottom of the gear box, please infuse 3 liters gear oil (SY1103-62/HL-20),the

liquid level height should be standardized by the flooding plug floods when open it.

(II)The clearance adjustment of the gear box bevel gear pair achieves through the

gasket regulation, ensure there is no block when it joggles. When installing the bevel

drive gear, make use of regulating the gasket, ensure the center spacing size between

the bevel pinion gear and the bevel drive gear. And then, installing the bevel pinion gear,

make use of the bolt and gasket regulating, ensure the joggle point along the gear width

is not less than 70%, the joggle clearance is 0.13-0.31.after installing, each

transmission part should freely,no blocking and axial float. The easiest method is

exhausting over the gear oil in the transmission, remove the cover, fetch the pinion gear,

and then install the cover, infuse the gear oil. After half or one year using the truck,

customer should check the joggle clearance of bevel gear pair. If the clearance exceeds

0.25-0.3, you should adjust again. After adjust the clearance every time, the brake

should be loosened before the motor starts, use the hand turns the brake wheel 6

circles, there should not happen tighten at any position.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

The configuration of FBR15-20 drive unit shows in the chart3-2, 4 gears in the drive

unit achieve duplicate deceleration. The power from motor fan-out transfers to the small

gear(1), then drives the big gear(2) through the spline joint cover; Through the

pedestal of spline bevel drive gear (4), bevel pinion gear(5),in the end, drive wheel

circumrotating through the spline drive axle. The reach truck forward and backward,

speed change, all achieved by the handle accelerator gives the speed signal through

the controller.

An adjust nut installed on the spline drive axle in the gear box, which adjusts the

clearance between the bevel drive gear and the bevel pinion gear. According to screw

the adjust nut, two gears` clearance maintains in the range of 0.10-0.15, no tightened,

no looser clearance, screw the bevel drive gear, feel easy.

The gear box divides into upside & downside, inject 18# hyperbola gear oil into the

box. The oil level of box’s higher half should accord with the tow sides of gear plane, the

oil level of lower half should accord with oil flooding, after loosen the middle plug which

locates on the side cover of flooding box.

1、big steering gear 2、little gear 3、big gear 4、drive gear pedestal

5、drive gear 6、adjusting gasket 7、drive axle 8、pinion gear pedestal

9、pinion gear

Chart3-1 Gear Box

9

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、pinion gear 2、big gear 3、drive gear pedestal

4、bevel drive gear pedestal 5、bevel pinion gear

6、pinion gear pedestal 7、drive axle

8、adjustint nut 9、drive wheel

Chart3-2 Gear Box

3、Wheel

All wheels of Maximal reach truck are using the special broadside solid tire,this

kind of tire bears to whet, oil and low temperature,and it fits Maximal 4 wheel truck’s tire.

Due to the drive wheel designed and installing in one side of truck’s body, for guarantee

the body balance and the stability of complete truck, there should dispose a set of

balance wheel, this shows in the chart 4.The balance wheel and drive wheel play an

effect of complete truck’s balance according to the lever principle & spring. When the

truck runs on the bumpy and tilting ground, the balance wheel loading increasing, and

10

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

transmits the loading to the drive wheel which loading decreasing, this according to

spring as a result of lever principle. The drive wheel should have enough adhesive force

and to make the running truck no skid in any situation.

The Configuration of front wheel shows in the chart 5.The wheels fixed on the two

sides of the front part of truck’s body. Due to front wheel fixed by two bearing and axle, it

is flexible and reliable when it runs. When installing it, please note to hold the clearance

not less than 2mm between wheel and the plane of forward arm, if it is undersize, not

only accelerate the tire wearing, but also decrease the complete truck’s efficiency.

Flange links the drive wheel and transmission axle, easy to remove or maintain it.

1、bracket shaft 2、balance wheel 3、balance wheel bady

4、bracket 5、axle

Chart4 Balance Wheel

11

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart5 Front Wheel

(Ⅱ) steering system (chart 6-1, 6-2)

1、 Drive wheel steering

The FBR10~13 series reach truck steering through the deflected steering wheel.

The front wheel is stationary type engaged wheel. When steering, the driver operates

the steering wheel (1) by single hand, it drives the input shaft (2) turning, through two

big gears (9) drive the output shaft, then through the gimbal joint (7) connects the spline

shaft (6) and coupling sleeve (4), the gear shaft (5), the big steering gear on the gear

box, the whole gear box & drive wheel deviated and realized the demand of steering.

Compared to the normal truck, the steering system and drive system of FBR10~

13 series truck is integrative. Due to the big steering gear is rigidity connecting with the

gear box, and drive axle as steering axle, only has one drive wheel, there is no travel

different of L&R wheel, so the compensating gear is not used when running and

steering, and make the configuration of gear box so simply.

The transmission from steering wheel to shaft is using the gear’s., it is accurate,

reliable, high efficiency, simply structure and easy operating, so decrease the driver’s

weariness greatly.

The simple cross gimbal joint with the output shaft and gear shaft & spline,overcome

two shaft centering owing to the inaccurate installing and frame distortion, not only easy

to install, but also make the up and down shafts running freely after joint it.

The instant steering centre loads the crossing point of front tyre line and truck’s

12

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

lengthways centre line,this insure the min. turning radius when the reach truck

forward 、backward and speed change, improves the truck’s flexibility. when the truck

go forward, the steering wheel’s turning direction is the same as the truck’s, namely, the

steering wheel turn tight, the truck turn right, the same as left( drive wheel max. left

turning angle is 77°46′,steering wheel turns right 3.3 circles, the max. right turning angle

is 102°13′,steering wheel turns left 4 circles.)

2、Entire hydraulic steering

The FBR10~13 series reach truck using the entire hydraulic steering、together

pumps technology, steering and lifting using the same motor, front wheel is stationary

type engaged wheel. When you operating, open the start switch, stamp the brake pedal,

pump motor starts to work, driver operates the steering wheel by single hand, when

steering, through the hydraulic redirector changes the direction of oil channel. Along

with the redirector’s oil channel changed, the drive motor turns L&R, the turning power

transmits to the drive gear(3) 、middle gear(10) ,through the spline to gear shaft(4),the

gig pinion gear(6) drive the gear box turn L&R 360°,to achieve dependable turning

efficiency.

Compared to the normal truck, the steering system and drive system of FBR15~20

series truck is integrative. Due to the big steering gear is rigidity connecting with the

gear box, and drive axle as steering axle, only has one drive wheel, there is no travel

different of L&R wheel, so the compensating gear is not used when running and

steering.

When the big steering gear turns, the upper extreme of left turn big gear installed the

special bearing inside band(8) 、bearing upper band(5) and bearing lower band(7),use

the cylindrical roller to make cross installing, big load capacity,reduce the gear box

steering load efficaciously. Due to the truck use the entire hydraulic steering, turning

transmission through the gear joggle. Steering accurately, high efficiency and flexibly.

The steering wheel、direct lever installed with hydraulic redirector on the same axial

lead. This overcomes two shaft centering owing to the inaccurate installing and frame

distortion, not only easy to install, but also make the up and down shafts running freely

after joint it. When the truck go forward, the steering wheel’s turning direction is the

same as the truck’s, namely, the steering wheel turn right, the truck turn right, the same

13

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

as left. Drive wheel max. left turning angle is 77°(steering wheel turns right 2.5 circles)

the max. right turning angle is 108°(steering wheel turns left 3.5 circles.)

1、steering wheel 2、input shaft 3、middle shaft 4、coupling sleeve 5、gear shaft

6、spline shaft 7、gimbal joint 8、output shaft 9、big gear

Chart6-1 Steering System

1、hydraulic motor 2、steering box 3、drive gear 4、gear shaft

5、bearing upper band 6、pinion gear 7、bearing lower band 8、bearing inside

band 9、gear box 10、control dial 11、connecting pedal 12、

redirector

14

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart6-2 Steering System

(Ⅲ)Brake system (Chart 7)

The brake system is type of NC (normally closed) band, designed be integrative with

drive system. The system is made up of contracting brake、brake shoe(4)、brake

cam(3) 、pedal(1) and other levers. The brake shoe is directly installed on the drive

motor of drive system; the brake wheel is installed on the shaft tip of drive motor’s tail.

The motor has high speed and little torque, so need little brake torque, braking steadily,

reliability, operation easily.

When the truck stops, brake shoe clasps the brake wheel closely; and when need

the truck runs, driver stamps brake pedal, through one pair of lever, control the cam

circumrotating, expanding the contracting brake, brake shoe separates with the brake

wheel. At the time of brake shoe separated, the lever of brake system turn on the travel

switch on the drive motor, through the operating switch makes the drive motor electrifies

and circumrotating, then the whole truck runs. Oppositely, if you need brake urgently,

driver only need loose the foot pedal, due to the function of the spring in the brake

system, the lever returns and closes the travel switch, the drive motor lose the power. At

the same time, the truck brakes and stops rapidly due to the brake shoe returns.

The clearance adjustment of contracting brake and brake shoe has much to do with

the brake effect. When adjusting, loose the nuts of cam’s two sides, located the suitable

position, makes the brake shoe clasps brake wheel, then adjusts the pressure spring

nut, until the hand could not turn the brake wheel. When the truck has max speed and

fully loaded, the distance of urgent braking should not more than 3m, we can also

increase longer appropriately base on the customer’s requirement, to prevent unwound

goods slides when the truck braking urgently. The pressure spring should not adjust

closer, to prevent increasing unnecessary pedal pressure and raising the driver’s weary.

Brake shoe should change if the wearing capacity is more than 1.5mm.

15

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、brake pedal 2、pull rod 3、brake cam

4、brake shoe 5、rocking plate 6、link lever bolt

Chart7 Brake System

16

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

(Ⅳ) Lifting System (Chart 8)

The system is made up of inner & outer mast、fork bracket、fork、sheave、chain、

lifting cylinder、forward cylinder and tilting cylinder.

1、outer mast 2、inner mast 3、head plate 4、compound roller

5、lifting cylinder 6、lifting chain 7、fork bracket 8、fork bracket

Chart8 Lifting System

The forward cylinder’s extension makes the whole lifting system through the 4

rollers under the outside mast, along the truck’s lead rail forward or backward, travel

route is 500mm.There is a regulating spacer on the roller’s surface, contacts with the

inner surface of truck’s lead rail. You should note the lateral symmetry and suitable

tightness when installing it. If too tight, it’s easy to lock and cause exceptional sound, if

too loose, it’s make the mast falter. Please note the clearance size when use it and

regulate it in duty time. Through adjusting the bolt advance and retreat, then change the

clearance size.

The move roller of fork bracket and inner mast is the compound roller (chart 10), the

side roller (6) installed in the compound one, the side clearance adjustment between

17

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

compound roller and mast lead rail could achieve through changing the regulating

shim’s thickness in the compound roller. Please note injecting the lubrication in the mast

lead rail regularly in service; maintain the compound roller works flexibly. The two lifting

chains should have the same tightness,no distortion; the max length of chain should

adjust when the fork lifting on the highest position(as the lifting cylinder’s piston rod

rises on the top).After adjusting, the chain should not too tight, two sheaves should run

flexibly.

1、compound roller pedestal 2、adjusting bolt 3、inner roller 4、inner roller shaft

Chart9 Roller

1、roller shell 2、end cover 3、end cover 4、supporting pedestal

5、side roller 6、shaft 7、washer 8、snap ring

9、bearing 10、column pin 11、adjusting washer

Chart10 Compound Roller

18

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

The move roller of inner mast & ouster’s adopted two pairs of compound one. The

side ones all installed in the main roller. The compound one (chart 10) under the inner

mast has adjusted the clearance when assembling it. You can adjust it through

changing the regulating shim’s thickness if necessary. After assembling and in service,

the compound roller on the top of outer mast, you can adjust it through the tighten nut

base on the circs of mast swinging,make the mast more steadily.

The tilting cylinder effects the fork bracket directly, makes the fork moves forward or

backward. Please note the L&R cylinder be parallel、the same height、distance of piston

rod extending、etc., to prevent single cylinder got pressure. The distance between two

forks, you can adjust it base on the goods size.

(Ⅴ)Hydraulic System

1、Hydraulic System

The reach truck’s hydraulic system has two parts: hydraulic lifting、 forward、tilting &

hydraulic steering system. Hydraulic lifting、 forward、tilting system is made up of lifting

cylinder (1) 、lifting cylinder (2) 、tilting cylinder(3)、motor(5)、oil box (8) 、multi- unit

valve (9) 、percolator (10) 、percolator (7).The flow and theory show in the chart 11.

Oil box fixed under the seat’s right side, capacity is 25 L, and magnetic plug is fixed

on the bottom, and adsorbs the scrap iron. The oil screen in each oil filler hole and oil

inlet should clean at regular times.

The pipeline adopts rubber hose H.P and 60°pyramidal face hard hose joint by

standard JB1885-77, it has simple structure、good sealability、standing H.P、high

reliability、using stably and easy operating.

19

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、lifting cylinder 2、governor valve 3、tilting cylinder

4、forward cylinder 5、motor 6、pump

7、percolator 8、oil box 9、multi- unit valve

10、percolator

Chart11 Hydraulic System

2、main parts

A .pump & motor

The motor adopts XQD-8.2 AC ones, the gear pump adopts

DSG05A18F9H1-R004C, they connects directly with flange,installs on the truck’s

upside. When you need maintain it, remove the meter and do it.

B. Hydraulic motor & redirector

the motor is BM-100H gerotor motor ,delivery capacity is 100ml/r,the redirector

adopts Eaton 403-7981-33,including the preferential valve, delivery capacity is 80ml/r.

Oil motor installs on the plate of drive system, open the door and you can disassemble

it, redirector and direct lever is cross connecting and installed under the direct lever.

20

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

C. multiple unit valve

The model is CDB2-F15DC; it is made up of oil injecting valve、reversing valve and

oil return valve, P is one point pressure oil inlet connects with oil pump outlet. O is one

point oil return port connects with the oil box’s ones, A joints the back cavity, B closed, C

& D joint the back cavity of tilting cylinder, E & F joint the back cavity of forward

cylinder, multi- unit valve’s spillover valve adjusted and achieves the 10% over loading

capacity, ensure the relevant rated capacity and lifting to 3 m. The multi- unit valve’s

pressure has fixed before leaving factory, do not maintain it on working.

D. Lifting cylinder (chart 13)

This model is single action piston’s structure, made up of piston lever(1)、guide

sleeve(6) 、body(7).In using, the piston internal leaking with the hydraulic oil of body’s

inner wall, oil returns from cylinder upside’s port to oil box. If the inner leaking is large,

the cylinder lifting pressure will go down, this time, change the Yx seal.

E. Forward Cylinder & Tilting Cylinder

Their model all is double action structure, show in (chart 14,15)

F. Single governor valve

The valve fixed on the oil inlet of lifting cylinder, the configuration shows in the chart

16. The valve makes use of pressure difference between the spring and valve hole,

controls the oil return, and achieves the purpose of limit the dropping speed.

3、Hydraulic oil

Choose the oil, mainly due to oil’s solidifying point. Whereas nowadays Chinese

oil’s fact and engineering machine’s test on the low temperature condition, the

solidifying point should better lower 30℃ than the using temperature, to prevent the oil

more sticky, and make operating difficultly. This series truck working ground is mainly

low temperature storage, the meal、aquatic product storage below 0℃ choose the

following standard hydraulic oil:

21

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

standard 13# machine oil(SYB1206-56)

12# voyage liquid

value Composed spindle oil SY1220-68

(SY1181-76)

character (GB442-64)

Movement con.(m 2/s) Not less than

(12-14)×10-6 12×10-6

-6

18×10

flash point℃(not less

163 160 100

than)

freezing point℃ ( not

-45 -40 -70

higher than)

Now series trucks of Maximal forklift use the SY1220-68 hydraulic oil.

Fruit storage chooses the 20-1 hydraulic oil (freezing point-30℃、50℃, movement

concentration is 12.5×10-6m2/S), normal storage can choose HJ-20 hydraulic oil or

spindle oil.

Different models of hydraulic oil could not be using combined, you must clear the

oil box when add the oil. For reduce oil system fault, must restrict the oil’s impurity

content exactly. You should replace the oil per 1500h and note clear the screen in

normally using.

22

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、holding valve 2、relief valve shell 3、relief valve

4、lifting slide valve 5、tilting slide valve 6、forward slide valve

7、oil return shell 8、forward valve shell 9、tilting valve shell

10、lifting valve shell

Chart12 Multiple Unit Valve

23

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1

2

3

4

5

7

8

10

11

12

1、piston lever 2、wiper seal 3、O-ring seal 4、Yx ring seal

5、O-ring seal 6、guide sleeve 7、cylinder 8、pivot ring

9、Yx ring seal 10、spring 11、single spacer 12、iron ball

Chart13 Lifting Cylinder

24

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、cylinder body 2、piston 3、pivot ring 4、Yx-ring seal

5、piston lever 6、guide sleeve 7、O-ring seal 8、Y x- ring seal

9、wiper seal 10、O-ring seal

Chart14 Tilting Cylinder

1、piston lever 2、wiper seal 3、Yx -ring seal 4、O-ring seal

5、guide sleeve 6、cylinder body 7、piston 8、Yx-ring seal

9、pivot ring 10、cylinder pedestal 11、O-ring seal 12、bushing

Char15 Forward Cylinder

25

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

1、valve body 2、slide valve 3、spring 4、O-ring seal 5、joint

Chart16 Single Governor Valve

(Ⅵ)Electrical System

The electrical control system of reach forklift comprises the drawing controller,

pump controller, travel motor, oil pump motor, instrument accelerator, battery and

various of switches. The principle of electrical system is available in picture 17-1、17-2.

1、the preparation for operating

①、insert the pin of battery into the power and then put on the emergency cut-off

switch.

②、turn the key switch on and the instrument display the quantity of battery power

and the starting working state

2、the control of the driving motor

①、step down the brake pedal and put the motor braking switch, which is prepared

for the making a star

②、you can move forward or backward the accelerator handle to realize the travel

direction you want. the rate is depended on the degree of the accelerator handle

movement.

③、loosing the accelerator handle travel motor is made to stop by the controller

④、If emergency occurred , you can release the brake pedal and loose the

accelerator handle to make the forklift stop by mechanical and electromagnetic brake

controlled by braking switch and controller.

26

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

3、the pump motor controlling

The inching switch is cutting off when the hydraulic device is operated with the

control lever to realize the tile and lift and forward-reverse of the mast. And then

different movement signals are sent to by the controller cause the relevant voltages

which control the pump motor to realize the rate of lifting and tilting and forward-reverse.

The motor will be out of power and stop working when the control lever return neutral.

4、Battery

The sets of battery offer power for the forklift, it will make a great different

performance whether the forklift is operated and maintained in right way or not, so it is

necessary to maintain as required and you could find it detailedly in battery instruction

and related rules, the points as follow

①、check whether the battery is unbroken before charging, whether the line is in

good touch. Then clean the appearance and open the cover.

②、the temperature couldn’t surpass 45℃ when charging , or else you need to

decrease the source current and low the temperature with other methods.

③、the proportion of electrolyte should be 1:28 and stay the same in 2-3 hours

when the battery is fully charged. A lot of air bubble is produced.

④、please charge in time when voltage of one unit is decreased to 1.75V and the

proportion of electrolyte is below 1:15.

⑤、the height of electrolyte level is kept higher than plate when the battery work all

the time .

⑥、the first charging affect the battery life greatly, the charging will be operated by

special person when the first charging technology and equipment is not offered.

27

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart17-1 FBR Series Forklift Electrical Principle (DC)

28

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart 17-2 FBR Series Forklift Electrical Principle(AC)

29

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

(Ⅶ) Forward & Backward Device of Battery

FBR15~20 series of forklifts: the work principle introduction of battery exchange,

maintenance and charge:

There’re two groups of active vanes loading on a gate ledger. On the body

footboard is loaded with the active hook board. Before the operation you should turn

over the vane, and hang the battery onto the vane( make sure the hanging position

should be in the center). The operator should also move the forward cylinder backward,

because there is a hook plate equipped behind the battery box. When the battery is

backed to the right position, the body hook plate and active plate will be connected

automatically through the spring. Then move the forward cylinder to the front, the

battery will be fixed in the right position to the forklift automatically. And then just put

down the mast active plate, the forklift can work now. When charging, you should pull

out the battery. The principle for it is that: turn up the mast active plate, move the

forward cylinder back, then thanks to the slant plate under the battery box, when to the

right position, because of the active plate and the slant plate, the battery will be lifted

and fixed on the mast active plate. Then operator can step on the hook plate, move the

cylinder to the front, and the battery can be taken into charge, maintenance, clean and

replacement.

4、Operation Introduction and Note items

(Ⅰ)Familiar with the instruments and operating institutions position(Chart 18)

(Ⅱ)Preparation before starting:

1. Check whether the battery voltage is normal.

2. Check whether the electric contactor and line is normal

3. Check the adequacy of hydraulic oil

4. Check for any leaks in the pipeline connecting joints.

5. Check the brake reliability, and should not turn the walking motor rotation axis

when stop.

6. Check whether there’re loose bolts site, and make sure the gas between every

part is suitable.

30

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

(Ⅲ)、Starting

1. Before starting the forklift, you should finish the electrical system preparation as

follows:

2. When starting, push the electrical manipulation handle with the right hand to

push the accelerator handle slowly, and then accelerate after slowly-starting.

3. Test forklift without load: check the battery voltage and observe the instrument.

When the electricity down to the 20%, it means it has reached the lowest discharge

voltage. You should recharge at once and don’t use the forklift, or it’ll do damage to the

battery.

(Ⅳ)Running Notes:

1. During operation, whether backward or forward, the accelerator should be

pushed slowly to avoid the sudden acceleration, to avoid the sudden force.

2. When starting, the pump motor can rotate automatically to provide impetus. The

power switch should be shut down when it stop, and to check the fault.

3. Pay attention to position of the accelerator handle when forward and backward

during the moving.

4. In order to enable the good stability of the operation of the forklift, after shoveling

the goods, the mast should be back to near the bodywork, the fork should incline, and

fall down to the floor as lower as possible. Moving the forklifts with the cargo high-lifted

is forbidden to avoid the accident and loss.

5. In high-speed operation, it’s not allowed to toggle the inverted-switch handle

directly. The direction should be changed after stopping the forklift.

6. Adjust the distance between the two forks by the size of cargo to make the

weight evenly distributed in the two forks so as not to partial set.

7. Strictly comply with truck load capacity according to the load curve of the table.

Overload is forbidden. The load centre is 500 mm in the front of shelf. If the actual use

of the tray laden is larger than the size of 1000 × 1000, Load should be reduced in

accordance with requirements of load curves

8. in order to ensure traffic safety, abrupt lane, high-speed turns and brake slams

should be avoided in the operation to prevent releases of persons and goods,

especially not on the slopes. It should be low speed when downgrade with heavy-duty.

31

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

And backward operation is suggested.

9. In the operation, if any abnormal noises and smells came out, you should stop

the forklift immediately and do the troubleshooting.

10. The power should be cut off and the switch key should be unplugged when you

left the forklift.

1、lifting lever 2、tilting lever 3、forward lever

4、accelerating knob 5、advance and retreat pedal, battery

6、brake pedal 7、steering wheel

Chart18 Position of Instrument and Operating Assembly

32

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Chart19 Transport Drawing

5、Fault and Resolution

No fault cause resolution

Instrument no re-shut the automatic switch

Automatic switch Released action

instruction and check the cause

Contactor not Do troubleshooting, replace

1 fuse broken

action the fuse

Bright lights do

Poor contact of battery power Recover the electrical plug

not work

The main circuit connections loose,

Contactor action

dynamic and static contact point is Restore connectors

2 Forklifts can not

bad

walk

Brush of motor contact poor Repair the motor

adjust the redirector

low pressure or damage of the

pressure or replace the

3 Heavy turning redirector

bearing spring

Damage of the transmission Replace the ball

33

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

turning bearing

Improper shoes gap adjustment Adjust the shoes gap

Brake

4 excessive worn of shoes replace the brake shoes

powerless

damage of brake pump replace the pump

Brake shoes Gas adjusted too tight Adjust the gas appropriately

5 separated

Return-spring valid Replace the spring

completely

noise of the rivets exposed of the shoes

6 replace the shoes

brake friction surface

Gear damage or surface adjust the gap of the bevel

spalling gear

Abnormal noise Gear gap too big Replace the gear

7

from the gear box Something-unknown in the box clean the box, fill oil

no oil in the box repair the oil-leak of the box

bearing broken replace the bearing

Pump motor fault Repair the motor

The oil pump gear and the pump

powerless lift body attrit excessively, the oversized Replace the attrition or oil pump

8

or lift inability gap creates seriously inner-leak

Up-down cylinder inner-leak Replace the Yx seal collar

multi-valve inner-leak repair the multi-valve

The hydraulic Inspect oil pipe connection seal

Oil suction pipe intake air

system and the situation, replace the seal

gate frame send hydraulic oil is in sufficient in

9 fill oil

out the abnormal the tank

sound Gate components worn out or the Exchanges gate components,

gap is too loose adjust the gap

34

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

6、Maintenance

(Ⅰ)Caution

1 、 Use the standard lube and hydraulic oil according to the environment

temperature and the various oil must not be mixed to used. The hydraulic oil must be

kept clean.

2、This series forklift must be used in adaptive temperature and the lube is required

to be the No. J-2 clay grease.

3、when the temperature stay all the same, the forklift should not be left in outdoors

all night along or in the freezing warehouse.

(Ⅱ)lubricated parts

Item Parts name lube filling time

Inside and outside

1 No.J-2 clay grease Twice a month

mast

2 Flexing transmit rail No.J-2 clay grease Twice a month

3 The mast bearing No.J-2 clay grease Once half a year

The direction chain

4 No.J-2 clay grease Twice a month

wheel

5 Steering axle gear No.J-2 clay grease Once a week

Twice a month(fill in the oil

6 Steering bearing 30#mechanical oil

hole)

supporting sleeve, U&D once a month(fill in the oil

7 No.J-2 clay grease

bracket hole,picture20)

Front wheel bearing

8 No.J-2 clay grease Spread when fixing

for balance roll

(Ⅲ)Maintenance

1、Daily maintenance

①you should clean the dirt and dust among the connecting leading after finishing

the work everyday.

②check whether the brake is normal.

③check whether the tightening parts in all the places and steering cross-axis

35

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

gimbal rivet is normal.

④check whether oil is leaked.

2、the first maintenance (once a week),the follow attention besides the daily

maintenance:

①add the lube as requested.

②adjust the roller of the inside and outside mast、transmit rail roller、the clearance

between the fork frame、tightening bolt so that make the cushion good performance.

3 、 the second maintenance (once a month ),attention more besides the first

maintenance:

①adjust clearance of the brake assembly, make sue it normal.

②add gear oil in the transmission box。

③adjust the degree of tightness of the lifting cylinder chain

④check the connecting points of the electrical system.

4、the third maintenance(once half a year),attention more besides the second

maintenance:

①change the oil in the oil system、clean the oil cleaner、oil tank、and change the seal

ring of cylinder.

②change the new tires(depend on the degree of wear).

③check overall electric appliance and change the electric fitting when problem.

④change the lube of the bearing and chain roller as requested.

⑤clean the redirector appearance of drive motor and pump motor using air

compressor, be attention to the situation of the redirector and redirecting light,check

whether the carbon brush is blocked and broken ,change carbon brush if the height is

less than 16mm(not fit for AC motor).

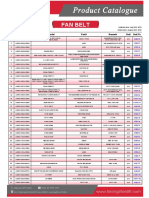

7、Specification Form of some Standard Parts & Wearing Parts

(Ⅰ)Bearing

Item standard model quantity Fixing position

1 GB292-86 bearing207 2 input gear of gear box

2 GB292-86 bearing109 2 counter gear of gear box

3 GB297-84 bearing 7206 2 bevel gear of gear box

4 GB276-84 bearing 7211 2 drive shaft in gear box

36

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

5 GB276-82 bearing 107 2 drive gear

6 GB276-82 bearing 207 2 idle gear

7 GB276-82 bearing 208 2 the seat for mast chain roller

8 GB276-82 bearing 60309 4 Bearing in the outside mast

9 GB276-82 bearing 111 4 compound roller ,inner & outer mast

10 GB276-82 bearing 210 4 compound roller, fork

bearing 208、

11 GB276-82 each 2 Front wheel bearing

209

12 GB276-82 bearing 60206 2 Balance wheel bearing

wimble handle bearing of balance

13 GB297-82 bearing 7207 1

wheel

(Ⅱ)Snap Ring

Item standard Specification material quantity Fixing position

1 GB893.1-86 72 65Mn 2 middle shaft, steering box

2 GB894.1-86 32 65Mn 1 upside, middle shaft

3 GB894.1-86 28 65Mn 1 rear of driving motor

45 lower bearing of outside

4 GB894-76 65Mn 4

mast

55 shaft of inside or outside

5 GB894-76 65Mn 4

mast

90 shaft of inside or outside

6 GB894-76 65Mn 4

mast

50 shell of inside or outside

7 GB893-76 65Mn 4

mast

8 GB893-76 90 65Mn 4 shell of fork

9 GB894-76 35 65Mn 2 sheave shaft

10 GB894-76 80 65Mn 2 sheave shaft

(Ⅲ) Oil Seal

Item Standard Specification Quantity Fixing position

1 GB9877.1-88 Oil seal B30×52×7D 1 upper bevel drive gear

2 GB9877.1-88 Oil seal B45×65×8D 1 lower bevel drive gear

37

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Oil seal

3 HG4-692-67 1 drive shaft

PD80×100×12

(Ⅳ)Yx Ring

Item Standard Specification Material Quantity Fixing position

D2(import) guide sleeve,

1 D32 polyurethane 1

forward cylinder

D1(import) piston, forward

2 D70 polyurethane 2

cylinder

guide sleeve, lifting

3 D40 polyurethane 1

cylinder

FH0613L0(import) piston, tilting

4 Osd50 polyurethane 1

cylinder

guide sleeve,

5 D28 polyurethane 2

tilting cylinder

piston, tilting

6 D50 polyurethane 4

cylinder

((Ⅴ)Hose H.P.

Item Standard Specification Quantity Fixing position

Hydraulic system to front core of

1 DIN3863-1995 6I-220 2

L&R tilting cylinder

Hydraulic system to rear core of

2 DIN3863-1995 6I-115 2

L&R tilting cylinder

3 DIN3863-1995 6I-2282 2 Hydraulic system to L&R winding hose

The joint of hydraulic system with

4 DIN3863-1995 8I-1120 2

body(tilting cylinder outlet)

The tube for entry and return of

5 DIN3863-1995 8I-1120 2

lifting cylinder

The tube from hydraulic system to

6 DIN3863-1995 13I-1120 1

lifting cylinder

The tube from oil pump to multi-way

7 DIN3863-1995 13II-1020 1

valve

38

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

The tube from hydraulic system to

8 DIN3863-1995 8I-1850 2

forward cylinder

The tube from hydraulic system to

9 DIN3863-1995 8I-700 2

oil motor

(Ⅵ)O-ring Seal

Item Standard Specification Quantity Fixing position

1 NOK LBH32 1 Forward cylinder

2 NOK USI32 1 Forward cylinder

3 NOK OSI60 1 Forward cylinder

4 GB1235-76 70×3.5 2 Forward cylinder

5 NOK LBH35 1 Lifting cylinder

6 NOK ISI35 1 Lifting cylinder

7 NOK P50 1 Lifting cylinder

8 NOK OSI45 1 Lifting cylinder

9 NOK OSI63 2 Tilting cylinder

10 GB1235-76 22×2.4 1 Tilting cylinder

11 GB1235-76 63×3.1 1 Tilting cylinder

12 NOK ISI28 1 Tilting cylinder

13 NOK LBH28 1 Tilting cylinder

(Ⅶ)Part of Electric Fittings

Item Name Model Quantity Remark

1 fuse plug RP1-RD5 5

2 Inching switch WK2-WK3 3

The switch of

3 CK 1

electrical system

4 The pin of battery CZ 1

The switch of metal

5 K1\K3 2

handle

6 Brake switch WK5 1

39

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

(Ⅷ)Port of Wearing Parts

Item Picture number Name Quantity Fixing place

Input gear of transmission

1 M15D-110003 Small gear 1

box

2 M15D-110005 Big gear 1 Input pinion gear, gear box

secondary axle gear, gear

3 M1D11-00-19 bevel drive gear 1

box

secondary pinion gear, gear

4 M1D11-00-20 bevel pinion gear 1

box

Input splicing sleeve, gear

6 M15D-120003 splicing sleeve 1

box

Input gear of the redirecting

7 M15D-120010 drive gear 1

box

Parallels side Compound roller, fork bracket

11 M1D32-00-05 4

roller body

12 M15D-51001 brake strap 2 contracting brake body

Compound

13 M1D11-00-12 2 Driving system

roller body

14 M15D-900000 Front wheel 2 The shaft of front wheel

Balance roller

15 M15D-802000 2 Balance roller bracket

body

40

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Little Gear

41

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Big Gear

42

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Bevel Drive Gear

43

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Bevel Pinion Gear

44

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

导轨侧滚轮

45

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

连接套

46

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

石棉刹车带

47

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Front Wheel

48

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Balance Wheel Bady

49

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Compound Roller

50

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

M Series Reach Truck Operation and Maintenance Manual

Drive Gear

51

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

You might also like

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them100% (6)

- 4D33 4D34T4 MTDocument266 pages4D33 4D34T4 MTwilmanes95% (20)

- ZL50H Manual PDFDocument77 pagesZL50H Manual PDFMasoodKan75% (4)

- Operation and Maintenance Manual of Container Reach-StackerDocument65 pagesOperation and Maintenance Manual of Container Reach-StackerIng Fermín67% (3)

- Fendt Vario 936 Service Manual 1/4Document822 pagesFendt Vario 936 Service Manual 1/4ciprian_dalvaru100% (15)

- Empilhadeira HeliDocument113 pagesEmpilhadeira HeliEdilson100% (1)

- Be30 (FB-11)Document422 pagesBe30 (FB-11)Phan Dung83% (6)

- Codigo de Falla - Toyota Serie 8Document7 pagesCodigo de Falla - Toyota Serie 8John Paval100% (2)

- BAOLI Soubor-1-3t-Cpd-58 PDFDocument124 pagesBAOLI Soubor-1-3t-Cpd-58 PDFJim Campbell De Castro100% (4)

- KALMAN DCF - 70 - 40 - 80 - 45 - 90 - 45 - 100 - 45 - enDocument5 pagesKALMAN DCF - 70 - 40 - 80 - 45 - 90 - 45 - 100 - 45 - ennam nguyenNo ratings yet

- Md500 SeriesDocument91 pagesMd500 SeriesFerreirarocha Ferreira Rocha100% (1)

- Field Assembly D155AX-6Document127 pagesField Assembly D155AX-6claudio100% (1)

- PC200-7 NoteDocument573 pagesPC200-7 NoteĐộngCơÔTô96% (57)

- Emp Combustao Serie7Document21 pagesEmp Combustao Serie7Fernando MoraesNo ratings yet

- Combilift LTD.: Operators & Service ManualDocument72 pagesCombilift LTD.: Operators & Service Manualmoviteknika100% (2)

- Boiler Reference Manual: Section 2 Feedwater TreatmentDocument53 pagesBoiler Reference Manual: Section 2 Feedwater TreatmentSaad Javed100% (2)

- Manual de Partes Catar Pillar Cargador Frontal 950 LDocument1,009 pagesManual de Partes Catar Pillar Cargador Frontal 950 Ljuan100% (4)

- Isuzu Engine Cooling SystemDocument21 pagesIsuzu Engine Cooling SystemToan100% (1)

- Volvo Penta MD 2020Document2 pagesVolvo Penta MD 2020Tullio Opatti100% (1)

- Mitsubishi's New 8-16 T Forklift Trucks Realize World-Class Environmental Efficiency and Operator ComfortDocument2 pagesMitsubishi's New 8-16 T Forklift Trucks Realize World-Class Environmental Efficiency and Operator Comfortalfan nashNo ratings yet

- Soubor 2 3 5 F Serie Ic Obsluha 66 PDFDocument102 pagesSoubor 2 3 5 F Serie Ic Obsluha 66 PDFjuanNo ratings yet

- 20D 7sa SMDocument80 pages20D 7sa SMmehdi100% (1)

- Stage V XF Series 1.5t-X5.5t Operation Manual 2020-06 ENDocument110 pagesStage V XF Series 1.5t-X5.5t Operation Manual 2020-06 ENmirko coppiniNo ratings yet

- Original Instruction : FB Battery Counterbalanced Forklift TruckDocument69 pagesOriginal Instruction : FB Battery Counterbalanced Forklift TruckSergio RecabarrenNo ratings yet

- Grendia Ex New-Generation Internal Combustion 3.5-5.5-Ton Forklift TruckDocument3 pagesGrendia Ex New-Generation Internal Combustion 3.5-5.5-Ton Forklift Truckryo asg3No ratings yet

- HoistDocument16 pagesHoistSenthilKumarNo ratings yet

- Kalmar DCF70-100, E4-E8 Empty Container Handlers 7 - 10 TonnesDocument16 pagesKalmar DCF70-100, E4-E8 Empty Container Handlers 7 - 10 TonnesNoer RachNo ratings yet

- Soubor 1 3t CPD 58 PDFDocument124 pagesSoubor 1 3t CPD 58 PDFJan Hendriks0% (1)

- Marine Harbor PDFDocument16 pagesMarine Harbor PDFMilos NikolicNo ratings yet

- Baoli 3ruote ACDocument87 pagesBaoli 3ruote ACmirko coppiniNo ratings yet

- 320C Perform Report (TEXR0335)Document10 pages320C Perform Report (TEXR0335)suwarjitechnicNo ratings yet

- Report Group 6Document17 pagesReport Group 6Muhammad AshirNo ratings yet

- Manitou MI 40 50 (EN)Document24 pagesManitou MI 40 50 (EN)ManitouNo ratings yet

- Kalmar DCE90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIIDocument12 pagesKalmar DCE90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIITungNo ratings yet

- Sef 0l6aeDocument144 pagesSef 0l6aezarni zarniNo ratings yet

- Soosung CatalogueDocument24 pagesSoosung Cataloguemaribella tvNo ratings yet

- SANY STC700T5 - Tabela de CargaDocument22 pagesSANY STC700T5 - Tabela de CargaDouglas MatsudaNo ratings yet

- FD70-FD100NH Sales ManualDocument42 pagesFD70-FD100NH Sales ManualLui DavidNo ratings yet

- Hiab XS 144 CLX Capacity 14 TM: Basic DataDocument2 pagesHiab XS 144 CLX Capacity 14 TM: Basic DataFabian RamirezNo ratings yet

- Hiab Xs 144 B-3 CLXDocument2 pagesHiab Xs 144 B-3 CLXsistemas msgruasNo ratings yet

- Caterpillar 14m16m Motor Grader Global Service LearningDocument10 pagesCaterpillar 14m16m Motor Grader Global Service Learningbelinda100% (47)

- Fuwa Crawler Cranes Spec D5e001Document24 pagesFuwa Crawler Cranes Spec D5e001ADI SUMARMONo ratings yet

- Combilift C3500 C10000 Forklift Trucks Operator's & Service Manual PDFDocument72 pagesCombilift C3500 C10000 Forklift Trucks Operator's & Service Manual PDFVüsal 1100% (2)

- Introducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmDocument120 pagesIntroducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmGerardo Marín100% (2)

- Introducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmDocument120 pagesIntroducing The D155AX-6 Crawler Dozer: Sigma Dozer + VMR + Cab + 560mmGerardo Marín100% (1)

- Method Statement For Cooling TowerDocument5 pagesMethod Statement For Cooling TowerWASIM MAKANDAR0% (1)

- Kalmar Dcg90 180Document12 pagesKalmar Dcg90 180slawny77No ratings yet

- Manual de Operação XZ40K - 1Document34 pagesManual de Operação XZ40K - 1DORIVAN JÚNIORNo ratings yet

- PS12 16 20 N PS16DN(压缩)Document4 pagesPS12 16 20 N PS16DN(压缩)Vitor HugoNo ratings yet

- CPDS15-18 3-Wheel-Operation & Service ManualDocument85 pagesCPDS15-18 3-Wheel-Operation & Service ManualKaran AroraNo ratings yet

- 4d33 TruckDocument262 pages4d33 Truckrifqihalvyan80% (5)

- GKD Company ProfileDocument23 pagesGKD Company ProfileWilly FandriNo ratings yet

- Very Narrow Aisle K: Capacity 1500 KG - Series 5231Document6 pagesVery Narrow Aisle K: Capacity 1500 KG - Series 5231Lực NguyễnNo ratings yet

- D375a-5eo Gen00054-02 PDFDocument167 pagesD375a-5eo Gen00054-02 PDFWill FrontNo ratings yet

- ZOOMLION Long Reach ExcavatorDocument1 pageZOOMLION Long Reach Excavatormohammed soaibul haque chowdhuryNo ratings yet

- Zoomlion LPG Forklift PDFDocument5 pagesZoomlion LPG Forklift PDFmohammed soaibul haque chowdhuryNo ratings yet

- 81-10-2194 Sherpa MDocument2 pages81-10-2194 Sherpa MАлександрNo ratings yet

- g3 SeriesDocument110 pagesg3 SeriesM NurusNo ratings yet

- Ss 8fbe 10 20 eDocument33 pagesSs 8fbe 10 20 eJA. AhadiNo ratings yet

- Fanuc Robot Brochure en 2017Document44 pagesFanuc Robot Brochure en 2017mimailuteNo ratings yet

- 7FG35Document21 pages7FG35fauzan datasheetNo ratings yet

- Bec08e1-01 A4Document403 pagesBec08e1-01 A4little khansa100% (2)

- Liebherr Complete Brochure enDocument24 pagesLiebherr Complete Brochure enناصرقوجيلNo ratings yet

- Boali CPCD30Document96 pagesBoali CPCD30Sittca MantenimientoNo ratings yet

- Overhead Traveling Crane, Hoist & Monorail System World Summary: Market Values & Financials by CountryFrom EverandOverhead Traveling Crane, Hoist & Monorail System World Summary: Market Values & Financials by CountryNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- FAJASDocument1 pageFAJASJohn PavalNo ratings yet

- Catalogo Uñas SMHDocument1 pageCatalogo Uñas SMHJohn PavalNo ratings yet

- Catalogo Asientos - SMHDocument12 pagesCatalogo Asientos - SMHJohn PavalNo ratings yet

- IC4 0-Mini5 0Document88 pagesIC4 0-Mini5 0John PavalNo ratings yet

- Ic1 0-4 0Document101 pagesIc1 0-4 0John PavalNo ratings yet

- 4wheel ElectricDocument76 pages4wheel ElectricJohn PavalNo ratings yet

- Filtros de Combustible - FOLANGSIDocument4 pagesFiltros de Combustible - FOLANGSIJohn PavalNo ratings yet

- Filtros Hidráulicos - FOLANGSIDocument3 pagesFiltros Hidráulicos - FOLANGSIJohn PavalNo ratings yet

- Ventiladores - FOLANGSIDocument3 pagesVentiladores - FOLANGSIJohn PavalNo ratings yet

- Alternadores - FOLANGSIDocument3 pagesAlternadores - FOLANGSIJohn PavalNo ratings yet

- 2012-9-14 New Forklift Alternators & Distributors 7Document2 pages2012-9-14 New Forklift Alternators & Distributors 7John PavalNo ratings yet

- Lambda Sensors: Quick and Easy Testing and ReplacementDocument12 pagesLambda Sensors: Quick and Easy Testing and ReplacementChinh HuuNo ratings yet

- Taijune Fire Tube Steam BoilerDocument8 pagesTaijune Fire Tube Steam BoilerAjay GoswamiNo ratings yet

- A - Case Method Introduction - OK35Document48 pagesA - Case Method Introduction - OK35Adeel AhmadNo ratings yet

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanNo ratings yet

- PPM TFC45 - HaishiDocument280 pagesPPM TFC45 - Haishicristian100% (3)

- PSV Thermal SizingDocument16 pagesPSV Thermal Sizingahmad santoso0% (1)

- Module 3: Mass Transfer Coefficients: Lecture No. 5Document3 pagesModule 3: Mass Transfer Coefficients: Lecture No. 5Anonymous Clbs7UkNo ratings yet

- AISC 13th - Table J3.3 Nominal Hole Dimensions PDFDocument1 pageAISC 13th - Table J3.3 Nominal Hole Dimensions PDFmuathNo ratings yet

- Week 4Document4 pagesWeek 4Waqar AhmadNo ratings yet

- SGP SyllabusDocument2 pagesSGP SyllabusPrathap VuyyuruNo ratings yet

- Mastering The Art of Pile TestingDocument15 pagesMastering The Art of Pile TestingLivian TeddyNo ratings yet

- I Unit PDFDocument5 pagesI Unit PDFgobardhan singhNo ratings yet

- F CH 4 PresentationDocument58 pagesF CH 4 PresentationTheødřøš ÄbNo ratings yet

- Slam ShutDocument5 pagesSlam ShutchemtrolsNo ratings yet

- Hyster 3 TONDocument738 pagesHyster 3 TONahmedaljamel433No ratings yet

- Alfa Romeo 146 Parts TableDocument53 pagesAlfa Romeo 146 Parts TableeephantomNo ratings yet

- Cad Cam SyllabusDocument4 pagesCad Cam SyllabuskrishrathoreNo ratings yet

- Instruction Manual: Small Cylinder DryerDocument20 pagesInstruction Manual: Small Cylinder DryerJohn Néstor Ramirez CalderónNo ratings yet

- Guideline For Energy Audit ReportDocument16 pagesGuideline For Energy Audit Reportashwini_kumar1984No ratings yet

- H-Pile Design 1518Document22 pagesH-Pile Design 1518Danny LamNo ratings yet

- UBCSAND UDM DocumentationDocument71 pagesUBCSAND UDM Documentationsujan95No ratings yet

- Economic Surge Tank DesignDocument6 pagesEconomic Surge Tank DesigncsimsekNo ratings yet

- Marine Propulsion English Status January 2011Document20 pagesMarine Propulsion English Status January 2011Jodiel CoelhoNo ratings yet

- Forces Otion: Forces and Motion at An Amusement ParkDocument30 pagesForces Otion: Forces and Motion at An Amusement ParkDave Khyl Josol BosqueNo ratings yet

- Ada 028794Document220 pagesAda 028794MOFEEZALAMNo ratings yet