Professional Documents

Culture Documents

167EC - Catc Metric Bulletin

Uploaded by

Jordy Alvarado0 ratings0% found this document useful (0 votes)

7 views16 pagesPingaaaaaa

Original Title

167EC.catc_metric_bulletin

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPingaaaaaa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views16 pages167EC - Catc Metric Bulletin

Uploaded by

Jordy AlvaradoPingaaaaaa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Bulletin 167-£¢

ree Roe Se

MaximumCapacity and

HighestQuality to the

AA Tale LE

ES Elis) dre ay

ince its founding in 1976, EVAPCO, Incorporated

has become an industry leader in the engineering

and manufacturing of quality heat transfer products

around the world. EVAPCO': mission is to provide fist

class service and quality products for the following markets:

= Industrial Refrigeration

= Commercial HVAC

= Industrial Process

= Power

m= District Energy

EVAPCO's powerful combination of financial strength and

technical expertise has established the company as a rece

ognized manufacturer of marketleading products on a

worldwide basis. EVAPCO is also recognized for the supe-

rior technology of their environmentally friendly product

Imovations in sound reduction and water management.

EVAPCO iis an employee owned company with a strong

‘emphasis on research & development and modern manu-

facturing plants. EVAPCO has earned a reputation for

technological innovation and superior product quality by

featuring products that are designed to offer these oper-

ating advantages:

= Higher System Efficiency

= Environmentally Friendly

= Lower Annual Operating Costs

© Reliable, Simple Operation and Maintenance

With an ongoing commitment to Research & Development

programs,EVAPCO provides the most advanced products in

the industry-Technology for the Future, Available

Today!

EVAPCO products are manufactured in 22 locations in 10

countries around the world and supplied through a sales

network consisting of over 170 offices.

2 ‘Goo APC

Advanced Technology

Condensers for

a Worldwide

‘The Containerized line of Evaporative Condensers has

been custom-engineered to ship in standard shipping

containers. This feature greatly reduces the transportation

costs associated with shipping. Customers around the

world will benefit from the Advanced Technology features

which are standard on the Containerized design:

= Low-Energy Consumption

m= Induced-Drafe Operation

1m Thermal-Pak® Coils

= ZM® Il Nozzles

PVC Water Distribution System

= WST Air Inlet Louvers

= Simple Operation and Maintenance

‘The Containerized Condensers have been designed for

simplified field assembly and rigging, while delivering the

quality and reliability of a factory-built unit. These units

provide the maximum capacity with the lowest ocean

shipping cost!

Designed to Lower Transportation and Installation Costs while

Delivering Advanced Technology, Superior Performance, Ease of

Maintenance and Long, Trouble-Free Operation.

A complete 2.24M x 2.74M (7.35 ft.x 9 ft) unit will fit

in a 20’ Shipping Container!

A complete 2.24M x 5.49M (7.35 ft.x |8 ft.) unit will fit

in a 40’ Shipping Container!

All Parts Required for Assembly Ship Inside the Basin.

Ine Lower

Optional Accessories

Ship Inside the

Container

Sloped Ladder

Motor Davie

Basin Heater Package

1 Vibration Cutout Switch

1 Electric Water Level Control

~ ran Moor

‘Covers

Easy Field Assembly

(See riing and assembly instructions for fully detailed procedure)

Mount Pump and Piping Mount Fan Motor

Product Applications

Design

EVAPCO Evaporative Condensers are of heavy-duty construc

tion and designed for long trouble-free operation, Proper

equipment selection, installation and maintenance fs, howev

necessary to ensure fll uni performance. Some of the major

considerations in the application of a condenser are presented

below. For additional information, contact the factory

Air Circulation

In reviewing the system design and unt location iti important

‘that proper air circulation be provided. The bast locaton is on

an unobstructed roof top or on ground level away from wall

and other barriers. Care must be taken when locating conden.

ers in wells or enclosures or next to high was. The potential

{or recirculation of hot, moist discharge air back into the fan

Ineake exists. Recirculation raises the wet bulb cemperature of

the entering air causing the tower pressure to rise above the

design. For these cases, a discharge hood or ducework should

be provided to raise the overall unt height even with the

adjacent wall, thereby reducing the chance of recirculation,

Good engineering practice dictates that the evaporative

condenser's discharge alt not be directed of located close to of

in the vicinity of building ar intakes. Enginecring assistance is

avilable from the factory to identify potential recirculation

problems and recommend solutions. For additional information

regarding layout of evaporative condencers, se EVAPCO

Bulletin entitled “Equipment Layout”

Piping

Condenser piping should be designed and installed in accor-

dance with generally accepted engineering practice. Al piping

should be anchored by properly designed hangers and supports

‘with allowance made for possible expansion and contraction

No external loads should be placed upon condenser connece

tions, nor should any of the pipe supports be anchored to the

Unie framework. For additional information concerning refriger-

ant pipe sing and layout, see EVAPCO Bulletin entitled “Piping

Evaporative Condensers

Maintaining the Recirculated Water System

“The heat rejection in a condenser is accomplished by the

evaporation of a portion of the recirculated spray water. As this,

water evaporates, icleaves behind all ofits mineral content and

Impurities. Therefore, it is important to bleed-off an amount of

water equal to chat which is evaporated to prevent the build-up

of these impurities, If this is not done, the mineral or the acidic

nature of the water will continue to increase, This will ukimate-

ly resul in heavy scaling ora corrasive condition

Bleed-off

Fach unit supplied with a pump mounted on the side i furnished

witha clear bleed line for visual inspection and a valve which

‘when fully open, will bleed-off the proper amount of water. If

the make-up water supplying the uni is relatively free of

impurities, fe may be possible to cue back the bleed, but the unit

must be checked frequently to make sure scale is not forming

Make-up water pressure should be maintained between 140 and

340KPa.

Water Treatment

‘A proper water trestmene program is an essential pare of

routine maintenance in order to help assure proper operation

and longevity of the unit. To help prevent the formation of

‘white rust, the interior ofthe unit should be passivated during

starcup and monitored periodially a part of the water

‘treatment program, For more information about white rust,

please request a copy of EVAPCO Engineering Bulletin 36, A

qualified water treatment company should be contacted £0

design a water treatment protocol specifically bared on

applicable location, water quality and unit material of construc:

tion, If acid i used for ereatment, it should be accurately

metered and the concentration properly controlled. The pH of

the water should be maintained between 6,5 and 8.0. Unis

constructed of galvanized steel operating with circulating water

having a pH of 80 or higher will require periodic passivation of

the galvanized steel to prevent the formation of “white rust.

Batch chemical feeding is not recommended because it does not

afford the proper degree of control, Ifaci cleaning is required

extreme caution must be exercised and only inhibited acids

recommended for use with galvanized construction should be

used,

NOTE: Operating the condenser below 6.0 pH for any period

of time may cause the removal ofthe protective zine coating on

the galvanized steel components

For more information see EVAPCO Bulletin entitled “Mainte-

nance Instructions

Control of Biological Contamination

‘Water quality should be checked regularly for biological

contamination. If belogical contamination is detected, a more

aggressive water treatment and mechanical clesning program

should be undertaken, The water treatment program should be

performed in conjunction with a qualfied water ereatment

company. [tis important tha all internal surfaces be kept clean

of accumulated dire and sludge, In adaltion, the dif eliminators

should be maintained in good operating condition.

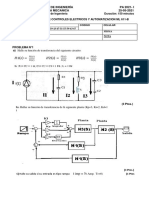

cATC Design and Construction Features

The cATC line of evaporative condensers reflects EVAPCO's continuing commitment to research and

development. Their advanced design provides owners with many operational and performance advantages.

For particularly corrosive environments, EVAPCO condensers are available with Type 304 or 316

Stainless Steel construction. Contact the factory for details on available options.

Principle of Operation

shecies rr Ena wae in

toe a fom at ce 2 ree i.

craw ropa rere The condone? nen

secre cdi ary 3 . “~

Fan Drive System

“The fan mocor and drive assombly is designed to allow

cexzy servicing ofthe motor and adjustment ofthe belt

‘tension from the exterior ofthe une. The totaly

enclosed fan cooled (TEFC) fan motor is mounted on

the outside for easy access. A protective cover swings

avy to allow servicing and bele adurtene

‘A large hinged access door witha “quick release” lech

provides access to the fan section for maintenance.

Fan Shaft Bearings

“The fan shaft bearings in ATC units are specially

selected for lng trouble-free He. They ae rated

for an L-10 fe of 75,000 to 135,000 hours and are

the heaviest plow block bearings availble.

Aluminum Alloy Pulleys

Fan pulleys located in the air stream are con-

structed of corrosion fee aluminum for long ie,

“The aluminum also helps bel st longer

Power-Band Drive Belt

“The Power Band isa sold-back, multigroove belt

system that has high eral rig. The belt con

structed of neoprene with polyester cords, The

deve bake is designed for 150 percen ofthe mator

nameplate horsepower for lng Me and durabiy,

Ho Sturt Dcharge Air

Jee Yep n

Jp Lid out

oa Or

emerge

emai Mtor Meant (Optenal Ladder Shown)

WST Air Inlet Louvers

‘Wacer and Sight Tight ai inlet louvers are designed

1 effectively eliminate spash-out and sunlight,

greatly reducing ce pocental fr alge formation

inside the condenser They are manufactured of

corresion‘ee

PVC and mounted

in light-weight

frames to alow

for easy removal

and convenient

access t0 the

basin section,

Type 304 Stainless

Steel Strainers

Subjected to excessive wear and corrosion, he

sump strainer crite! tothe succesful oper

‘ton of the condenser, EVAPCO uses only stain

less steel for this important component.

PVC Drift Eliminators

EVAPCO eliminators are constructed entirely of ner, corrosion:

free PVC. This patented design reduces dri rate to 0.001% and

tas been specially treated to resist damaging utravile light. The

climinazors are assembled in extilyhandled sections eo faclate

removal thereby exposing che upper portion of the unt and water

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SICREARG46 - Matriz IPERC (Mantenimiento de Torres de Enfriamiento)Document52 pagesSICREARG46 - Matriz IPERC (Mantenimiento de Torres de Enfriamiento)Jordy AlvaradoNo ratings yet

- Equilibrio 3dDocument6 pagesEquilibrio 3dJordy AlvaradoNo ratings yet

- Moldes de RTMDocument4 pagesMoldes de RTMJordy AlvaradoNo ratings yet

- Tablade Torque Segun Diamentro de PernoDocument1 pageTablade Torque Segun Diamentro de PernoJordy AlvaradoNo ratings yet

- Motores IP55Document1 pageMotores IP55Jordy AlvaradoNo ratings yet

- StdoutDocument1 pageStdoutJordy AlvaradoNo ratings yet

- El MacheteDocument1 pageEl MacheteJordy AlvaradoNo ratings yet

- PDF Ejercicios de Tornillos1 DLDocument14 pagesPDF Ejercicios de Tornillos1 DLJordy AlvaradoNo ratings yet

- Projet B2Document8 pagesProjet B2Jordy AlvaradoNo ratings yet

- Diseño de Elem. - Alva - Cap. 3 y 4Document66 pagesDiseño de Elem. - Alva - Cap. 3 y 4Jordy AlvaradoNo ratings yet

- Practica 1-SemaforosDocument9 pagesPractica 1-SemaforosJordy AlvaradoNo ratings yet

- CV ProyectosDocument2 pagesCV ProyectosJordy AlvaradoNo ratings yet

- CV Proyectos.Document2 pagesCV Proyectos.Jordy AlvaradoNo ratings yet

- Fila C Exam Parcial 20201-IDocument3 pagesFila C Exam Parcial 20201-IJordy AlvaradoNo ratings yet

- Solucion Ex Final 2020 IDocument8 pagesSolucion Ex Final 2020 IJordy AlvaradoNo ratings yet

- Solucion Ex Final 2020 IDocument8 pagesSolucion Ex Final 2020 IJordy AlvaradoNo ratings yet

- Examen Parcial de Control 2019 IIDocument3 pagesExamen Parcial de Control 2019 IIJordy AlvaradoNo ratings yet

- Fila C Exam Parcial 2020-IIDocument2 pagesFila C Exam Parcial 2020-IIJordy AlvaradoNo ratings yet

- Lab 1b.-Modelo Matem Sistema DinamcoDocument10 pagesLab 1b.-Modelo Matem Sistema DinamcoJordy AlvaradoNo ratings yet

- Solucion Examenes ParcialesDocument10 pagesSolucion Examenes ParcialesJordy AlvaradoNo ratings yet

- Álgebra Matricial y Geometría Analítica: Generales Ciencias Universidad CatólicaDocument2 pagesÁlgebra Matricial y Geometría Analítica: Generales Ciencias Universidad CatólicaJordy AlvaradoNo ratings yet

- Solucion Parcial Fila A 2020-IiDocument7 pagesSolucion Parcial Fila A 2020-IiJordy AlvaradoNo ratings yet

- Fila B Exam Parcial 2020-IiDocument2 pagesFila B Exam Parcial 2020-IiJordy AlvaradoNo ratings yet