Professional Documents

Culture Documents

Cat Oil Fdao Syn

Uploaded by

Desta 770 ratings0% found this document useful (0 votes)

40 views2 pagesOriginal Title

cat_oil_fdao_syn

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views2 pagesCat Oil Fdao Syn

Uploaded by

Desta 77Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

MAINTENANCE PRODUCTS & SERVICES

Final Drive and Axle Oil Synthetic (FDAO Syn)

For all Cat® Final Drives and Axles that previously specified the use of TO-4 oils, and that do not contain

friction material.

Cat Final Drive & Axle Oil Synthetic (FDAO Syn) is

an extended drain lubricant for final drives of Caterpillar FDAO Syn Characteristics*

Off-Highway Trucks, Track-Type Tractors* and certain

other machine models. It is specially formulated for use SAE Viscosity Grade Synthetic

in extremely high load, heavy duty operations and

applications where high temperatures cause a mineral oil Test or Specification

based lubricant to experience severe oxidation.

CAT FD-1

Recommended use ISO Viscosity Grade (ISO) Multigrade

Cat FDAO Synthetic is blended with a special formulation Gravity, @ API (ASTM D287) 33.4

of synthetic base stock and a unique additive package. It Appearance (Visual) Clear & Bright

may be used in any compartment in which FDAO is used.

Neither FDAO™ nor FDAO Synthetic are used in Flash Point, °C (°F) (ASTM D92) 246° (474°) minimum

compartments with friction materials unless FDAO has Pour Point, °C (°F) (ASTM D97) -36° (-38°)

been specified. NOT FOR USE IN ENGINES,

TRANSMISSIONS OR HYDRAULIC SYSTEMS. Viscosity (ASTM D445)

cP @ -20°C (ASTMD5293 37,000

Extended Drain Interval

cST @ 40°C (ASTM D445) 318

FDAO Synthetic has been proven to provide longer cST @ 100°C (ASTM D445) 31.7

drain intervals than either FDAO or Cat Transmission

& Drive Train Oil (TDTO™) in the final drives of Viscosity Index (ASTM D2270) 135

Caterpillar machines. FDAO has a recommended drain Brookfield Viscosity (ASTM D2983)

interval of 3,000 hours in the final drives of Cat Off-

Highway Trucks. TDTO has a recommended drain cP @ -30°C 130,000

interval of 2,000 hours in final drive applications. Copper Strip (ASTM D130, 2 hrs. @ 100°C) 1a

Whereas no specific drain interval is specified for

FDAO Synthetic, this outstanding product has been

proven to extend drain periods to 6,000 hours of * The values shown are typical values and should not be used as quality control parameters to either

accept or reject product. Specifications are subject to change without notice.

operation or more without significant oxidation or

depletion of additives.

Information Sources

We can help you determine the right oil for your Cat

machines and engines. You can also refer to your

"Operation and Maintenance Manual" or Service

Publication SEBU6250 (Caterpillar Machine Fluid

Recommendations). An electronic version of this

service publication is available at www.CAT.com.

Simply choose these selections: Products / Parts and

Service / Fluids / Machine Lubricant

Recommendations.

* Steel tracked machines with elevated final drives.

MAINTENANCE PRODUCTS & SERVICES

Final Drive and Axle Oil Synthetic (FDAO Syn)

Unique formula for improved life and performance Validation Tests

Cat Final Drive and Axle Oil Synthetic (FDAO Syn) is formulated for use in Cat equipment The performance of Cat FDAO Syn

final drives, axles, bevel gears and differentials in which gear and bearing loads and equaled or exceeded that of Cat TDTO

temperatures are high. Using FDAO Syn reduces contact fatigue, extending gear and bearing (an excellent lubricant) in the following

life. tests:

FDAO Syn is designed specifically for protection of highly loaded components. It does not

• Bearing Life

develop enough friction coefficient to satisfy the requirements of most brakes and clutches. It

• Seal Compatibility

should not be used in clutch and brake compartments unless those compartments are

• FZG Gear Pitting

specifically designated for FDAO use.

• FZG Scuffing

Cat FDAO Syn also: • D8N 4-Square

• Is compatible with TDTO oils and the seals for their compartments. • Lubricant Parameter

• Provides excellent protection against rust and copper corrosion. • Pour Point

• Minimizes foaming. • Rust

• Oxidizes at a low rate for improved oil life. • Copper Corrosion

• Extends oil change intervals, reducing downtime. • TO-4 Fluid Compatibility

• TO-4 Homogeneity

S·O·S SM Services for early detection • Foaming

• Flash Point

We recommend protecting your investment by using a scheduled fluid sampling program. • Pumpability

Our S·O·SSM Services program is the ultimate detection and diagnostic tool for your • High-Temperature Shear

equipment. It helps you head off potential problems before they can lead to major failures • KRL Shear

and costly unscheduled downtime. • Thermal Oxidation Stability

• High Torque, Low-Speed Axle

Proper use for health and safety

According to toxicology information, Cat FDAO Syn has little or no adverse effects if handled Developed by Caterpillar

and used properly. No special precautions are suggested beyond maintaining good personal

hygiene and avoiding prolonged, repeated skin contact. Caterpillar develops and tests Cat FDAO

Synthetic to meet or exceed the Caterpillar

For more information, refer to the Material Safety Data Sheet on the Caterpillar website, FD-1 standard, ensuring the best

www.catmsds.com protection and longest life for Caterpillar

final drive and axle components.

FDAO Syn Part Numbers

Package size Part Numbers

55 GAL (208 Liters) 198-7450

5 GAL (18.9 Liters) 208-2390

© 2001 Caterpillar

PEHP9570 www.CAT.com Printed in U.S.A.

You might also like

- Caterpillar C11 and C13 Industrial Engines Service ManualDocument98 pagesCaterpillar C11 and C13 Industrial Engines Service ManualDesta 77No ratings yet

- Caterpillar C11, C13, C15 and C18 Engines Troubleshooting ManualDocument188 pagesCaterpillar C11, C13, C15 and C18 Engines Troubleshooting ManualDesta 77100% (1)

- Jenny Randles - Mind Monsters - Invaders From Inner Space (1990)Document219 pagesJenny Randles - Mind Monsters - Invaders From Inner Space (1990)DirkTheDaring11100% (15)

- TITLE Technical Data Sheet for Shell Argina X 40Document2 pagesTITLE Technical Data Sheet for Shell Argina X 40HUM CIREBON DFLTS100% (1)

- Caterpillar C15 Engine SpecsDocument5 pagesCaterpillar C15 Engine SpecsDesta 77No ratings yet

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Caterpillar Diagnostic Tools - PDF CatalogDocument158 pagesCaterpillar Diagnostic Tools - PDF CatalogDesta 77No ratings yet

- Part Catalogue Engine Yanmar 3TNM72-GHFCLDocument26 pagesPart Catalogue Engine Yanmar 3TNM72-GHFCLDesta 77100% (1)

- CSIR NET December 2019 Admit CardDocument1 pageCSIR NET December 2019 Admit CardDevendra Singh RanaNo ratings yet

- BIGuidebook Templates - BI Logical Data Model - Data Integration DesignDocument12 pagesBIGuidebook Templates - BI Logical Data Model - Data Integration DesignShahina H CrowneNo ratings yet

- Blood Smear PreparationDocument125 pagesBlood Smear PreparationKim RuizNo ratings yet

- TDTO Pehp7506Document4 pagesTDTO Pehp7506ngilaNo ratings yet

- Vastu House PlanDocument187 pagesVastu House Planshilpa shahNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- Roto ZDocument3 pagesRoto Zjayakumar rajanNo ratings yet

- Shop Manual Sany SY 750HDocument525 pagesShop Manual Sany SY 750HDesta 77100% (2)

- Part Catalogue Mitsubishi Engine L3E SeriesDocument130 pagesPart Catalogue Mitsubishi Engine L3E SeriesDesta 77No ratings yet

- Cat TDTODocument4 pagesCat TDTOalexanderNo ratings yet

- Shell Gadus S2 High Speed Coupling Grease Technical Data SheetDocument3 pagesShell Gadus S2 High Speed Coupling Grease Technical Data Sheetjuan felipe diazgranados santosNo ratings yet

- Texamatic 7045EDocument3 pagesTexamatic 7045EIgor MitrovićNo ratings yet

- Canada Shell Spirax S6 GME 50 TDSDocument2 pagesCanada Shell Spirax S6 GME 50 TDSfdpc1987No ratings yet

- Cat-Tdto-10 30 50 PDFDocument4 pagesCat-Tdto-10 30 50 PDFEduardo Zamora100% (1)

- Taro 40Document2 pagesTaro 40Thiago MolverstetNo ratings yet

- TDTODocument2 pagesTDTOAndresCorrea100% (1)

- Cat Tdto-Tms: Caterpillar. The Difference CountsDocument2 pagesCat Tdto-Tms: Caterpillar. The Difference CountsMarcelo Monteiro Da CorreggioNo ratings yet

- MOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFDocument2 pagesMOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFFajar EkoNo ratings yet

- Chevron Regal RO PDSDocument4 pagesChevron Regal RO PDSVivekyathi BowanNo ratings yet

- Shell Rotella T5 Ultra 10w-30 TDSDocument2 pagesShell Rotella T5 Ultra 10w-30 TDSmdziubakNo ratings yet

- Shell Gadus S5 T460 1 5 TDSDocument2 pagesShell Gadus S5 T460 1 5 TDSSuresh RajanNo ratings yet

- Shell Spirax S3 G80WDocument2 pagesShell Spirax S3 G80WNokiabhre WijayaNo ratings yet

- Cat Arctic TDTO: Synthetic Blend Transmission and Drive Train OilDocument2 pagesCat Arctic TDTO: Synthetic Blend Transmission and Drive Train Oilanon_828943220No ratings yet

- Specs CI4Document2 pagesSpecs CI4Ignacio CanoNo ratings yet

- PDSDetail PageDocument3 pagesPDSDetail PageRSM FTLNo ratings yet

- Made in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnDocument2 pagesMade in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnsheilaNo ratings yet

- GPCDOC Local TDS Malaysia Shell Gadus S3 T220 2 (ms-MY) TDSDocument2 pagesGPCDOC Local TDS Malaysia Shell Gadus S3 T220 2 (ms-MY) TDSsyuhaimi82No ratings yet

- Hi-Perf 4T Super: High-Quality MineralDocument1 pageHi-Perf 4T Super: High-Quality MineralAwais A.No ratings yet

- Bpxe 9TQS2KDocument3 pagesBpxe 9TQS2KJayson VegillaNo ratings yet

- High Temp Grease for Heavy IndustryDocument2 pagesHigh Temp Grease for Heavy IndustryMudabbir Shan Ahmed100% (1)

- Total Quartz Ineo Long Life 5W-30: Key DataDocument2 pagesTotal Quartz Ineo Long Life 5W-30: Key DataVelibor KaranovicNo ratings yet

- Aral Hightronic 5w-40 Germany English PDB 467316Document2 pagesAral Hightronic 5w-40 Germany English PDB 467316Cristina OlaruNo ratings yet

- Synpower MST C4 5W-30-PI SheetDocument2 pagesSynpower MST C4 5W-30-PI SheetMaurizio StrokesNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- Geo Sng-4 Sae 40-Pi SheetDocument2 pagesGeo Sng-4 Sae 40-Pi SheetDana Group - Valvoline LubricantNo ratings yet

- GADUS S3 T220 2Document2 pagesGADUS S3 T220 2danielr.hanna93No ratings yet

- Hdax 5200 Low Ash Gas Engine Oil SAE 30, 40Document3 pagesHdax 5200 Low Ash Gas Engine Oil SAE 30, 40Hamid HasanNo ratings yet

- Triton 5005 EXDDocument3 pagesTriton 5005 EXDCarlosNo ratings yet

- Tema 5. Motores de Corriente AlternaDocument2 pagesTema 5. Motores de Corriente AlternaRichard ZapataNo ratings yet

- Mobilgrease HTR, HTM, HTS and HTF: GreaseDocument2 pagesMobilgrease HTR, HTM, HTS and HTF: GreaseCARLOS ALBERTO GalaNo ratings yet

- Aurelia: Trunk Piston Oil For Medium Speed EnginesDocument2 pagesAurelia: Trunk Piston Oil For Medium Speed EnginesFreddy FarukNo ratings yet

- GPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSDocument3 pagesGPCDOC GTDS Shell Gadus S5 T100 2 (En) TDSAlNo ratings yet

- PDS CALTEX Turbine OilDocument3 pagesPDS CALTEX Turbine OilAndaru Gunawan0% (1)

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- Cat Oil Filtros CodPartDocument2 pagesCat Oil Filtros CodPartKaly7No ratings yet

- Shell Gadinia S3 40: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadinia S3 40: Performance, Features & Benefits Main ApplicationssanathcgrNo ratings yet

- Bpxe 9m85vy PDFDocument2 pagesBpxe 9m85vy PDFzugniNo ratings yet

- Gear Atf Type D EngDocument1 pageGear Atf Type D EngTAREK HAMADNo ratings yet

- Gear Atf Type D EngDocument1 pageGear Atf Type D EngTAREK HAMADNo ratings yet

- PDS Castrol Trans C 10wDocument2 pagesPDS Castrol Trans C 10wepesanoNo ratings yet

- Shell Gadinia S3 40Document2 pagesShell Gadinia S3 40Jorge Arrieta TorresNo ratings yet

- Castrol Optigear Synthetic X 320 Wto - TDSDocument3 pagesCastrol Optigear Synthetic X 320 Wto - TDSHector JNo ratings yet

- Total Oil DetDocument2 pagesTotal Oil DetAwais A.No ratings yet

- Mobilfluid 428 Mobilfluid 428 Mobilfluid 428 Mobilfluid 428Document4 pagesMobilfluid 428 Mobilfluid 428 Mobilfluid 428 Mobilfluid 428Victor ZhicayNo ratings yet

- Shell Turbo Oil T 68 Technical Data SheetDocument2 pagesShell Turbo Oil T 68 Technical Data SheetAntonio CardosoNo ratings yet

- Shell Turbo Oil T 68 Technical Data SheetDocument2 pagesShell Turbo Oil T 68 Technical Data SheetMuhammad SaputraNo ratings yet

- Chevron Turbine Oil GST 68 DatasheetDocument3 pagesChevron Turbine Oil GST 68 DatasheetHaitham yousifNo ratings yet

- Shell Helix Ultra 5W-40: Performance, Features & BenefitsDocument2 pagesShell Helix Ultra 5W-40: Performance, Features & BenefitsMuhNo ratings yet

- Total Quartz 9000 Future FGC 5W-30: Key DataDocument2 pagesTotal Quartz 9000 Future FGC 5W-30: Key Datahoussem houssemNo ratings yet

- Shell Turbo T 68Document2 pagesShell Turbo T 68Eid EeidNo ratings yet

- Valvoline_Heavy_Duty_TDL_PRO_75W-90-PI_SheetDocument2 pagesValvoline_Heavy_Duty_TDL_PRO_75W-90-PI_SheetJUAN BAUTISTANo ratings yet

- Castrol EDGE 5W-40: DescriptionDocument2 pagesCastrol EDGE 5W-40: Descriptionvicky kNo ratings yet

- PSR As of 18.10.2023 - 13.56Document1 pagePSR As of 18.10.2023 - 13.56Desta 77No ratings yet

- PurgingFuel 2020Document1 pagePurgingFuel 2020Desta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- FIL FGP prodSpecPdfPgDocument1 pageFIL FGP prodSpecPdfPgDesta 77No ratings yet

- E Series ADT B35E B50E StageIIIA Broch18510316 June 2016englishwebDocument24 pagesE Series ADT B35E B50E StageIIIA Broch18510316 June 2016englishwebDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- Google Conversion Tracking CodeDocument1 pageGoogle Conversion Tracking CodeDesta 77No ratings yet

- FDocument1 pageFSebastián Riveros RodríguezNo ratings yet

- FDocument1 pageFDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- Oil Transynd 295Document2 pagesOil Transynd 295Desta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- TR 60Document526 pagesTR 60Desta 77No ratings yet

- 1298 EnuDocument2 pages1298 EnuDesta 77No ratings yet

- AutoresizeDocument6 pagesAutoresizeDesta 77No ratings yet

- FDocument1 pageFDesta 77No ratings yet

- Eni Rotra MP 85W-140 gear oil protects under heavy loadsDocument2 pagesEni Rotra MP 85W-140 gear oil protects under heavy loadsDesta 77No ratings yet

- Caterpillar C9 Engine SpecsDocument3 pagesCaterpillar C9 Engine SpecsDesta 77No ratings yet

- Shell Tellus S2 MX 100 Hydraulic Fluid Technical Data SheetDocument4 pagesShell Tellus S2 MX 100 Hydraulic Fluid Technical Data SheetDesta 77No ratings yet

- MA 7 TranscriptDocument82 pagesMA 7 TranscriptBob AndrepontNo ratings yet

- COT English 3rd PrepositionDocument14 pagesCOT English 3rd PrepositionGanie Mae Talde Casuncad100% (1)

- Characterization in Compound Semiconductor ProcessingDocument27 pagesCharacterization in Compound Semiconductor ProcessingMomentum PressNo ratings yet

- Function Apollo Amadeus: Sign In/OutDocument16 pagesFunction Apollo Amadeus: Sign In/OutMabs GaddNo ratings yet

- Regular expressions chapter 3 key conceptsDocument3 pagesRegular expressions chapter 3 key conceptsNabeel Ahmed0% (1)

- Dur - Ernakulam ReportDocument141 pagesDur - Ernakulam ReportArun SasiNo ratings yet

- I - Refracted EnergyDocument6 pagesI - Refracted EnergyAmmad Ali QureshiNo ratings yet

- Hve r13Document1 pageHve r13aleem_201sNo ratings yet

- Final Portfolio Cover LetterDocument2 pagesFinal Portfolio Cover Letterapi-321017157No ratings yet

- Bee Unit-IiDocument98 pagesBee Unit-IiHemant Ingale100% (1)

- Writing Visual Basic ProjectsDocument1 pageWriting Visual Basic ProjectsAmmuKuttyNo ratings yet

- Surface Wettability of Paper (Angle-of-Contact Method) : Standard Test Method ForDocument4 pagesSurface Wettability of Paper (Angle-of-Contact Method) : Standard Test Method ForfadjarNo ratings yet

- 07 FSM PDFDocument25 pages07 FSM PDFnew2trackNo ratings yet

- Public Authority CasesDocument11 pagesPublic Authority CasesAbhinav GoelNo ratings yet

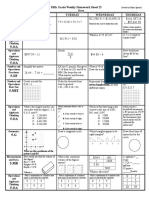

- 3 6 17weekly Homework Sheet Week 23 - 5th Grade - CcssDocument3 pages3 6 17weekly Homework Sheet Week 23 - 5th Grade - Ccssapi-328344919No ratings yet

- Call Log ReportDocument44 pagesCall Log ReportHun JhayNo ratings yet

- Types of FuseDocument10 pagesTypes of FuseRane SiddeshNo ratings yet

- How to Critique a Work in 40 StepsDocument16 pagesHow to Critique a Work in 40 StepsGavrie TalabocNo ratings yet

- The Reading Process PDFDocument1 pageThe Reading Process PDFAdy OliveiraNo ratings yet

- HYDRAULICSDocument1 pageHYDRAULICSOrland Son FactorNo ratings yet

- This Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCDocument81 pagesThis Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCabcdNo ratings yet

- CPC-COM-SU-4743-G External CoatingsDocument24 pagesCPC-COM-SU-4743-G External Coatingsaslam.amb100% (1)

- Filipinism 3Document3 pagesFilipinism 3Shahani Cel MananayNo ratings yet