0% found this document useful (0 votes)

125 views3 pagesFree Work Instruction Sample

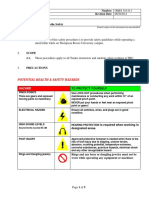

This work instruction provides the standard procedures for operating a new metal lathe machine at Bancroft Industries. It outlines pre-operational safety checks including ensuring familiarity with machine functions, having only one operator while two others check the machine and surroundings. It details operational safety procedures such as positioning the chuck and starting the machine while keeping body parts clear, and using cutting fluid to prevent overheating. The document was approved by the Safety Officer and Creative Director and is to be revised every two months.

Uploaded by

Mellifluence officialCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

125 views3 pagesFree Work Instruction Sample

This work instruction provides the standard procedures for operating a new metal lathe machine at Bancroft Industries. It outlines pre-operational safety checks including ensuring familiarity with machine functions, having only one operator while two others check the machine and surroundings. It details operational safety procedures such as positioning the chuck and starting the machine while keeping body parts clear, and using cutting fluid to prevent overheating. The document was approved by the Safety Officer and Creative Director and is to be revised every two months.

Uploaded by

Mellifluence officialCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd