Professional Documents

Culture Documents

Makrolon 2558 - en - 56977523 00009646 19213466

Makrolon 2558 - en - 56977523 00009646 19213466

Uploaded by

rajha vikneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Makrolon 2558 - en - 56977523 00009646 19213466

Makrolon 2558 - en - 56977523 00009646 19213466

Uploaded by

rajha vikneshCopyright:

Available Formats

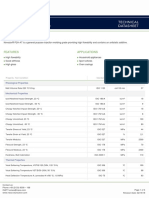

Makrolon® 2558

Grades / Medical devices MVR (300 °C/1.2 kg) 14 cm³/10 min; medical devices; suitable for ETO and steam sterilization at 121

°C; biocompatible according to many ISO 10993-1 test requirements; medium viscosity; easy release;

injection molding - melt temperature 280 - 320 °C; available in transparent and opaque colors

ISO Shortname PC

Property Test Condition Unit Standard typical Value

-

Rheological properties

C Melt volume-flow rate 300 °C/ 1.2 kg cm³/10 min ISO 1133 14

Melt mass-flow rate 300 °C/ 1.2 kg g/10 min ISO 1133 15.5

C Molding shrinkage, parallel 60x60x2 mm/ 500 bar % ISO 294-4 0.65

C Molding shrinkage, normal 60x60x2 mm/ 500 bar % ISO 294-4 0.7

Molding shrinkage, parallel/normal Value range based on general % b.o. ISO 2577 0.6 - 0.8

practical experience

Mechanical properties (23 °C/50 % r. h.)

C Tensile modulus 1 mm/min MPa ISO 527-1,-2 2400

C Yield stress 50 mm/min MPa ISO 527-1,-2 66

C Yield strain 50 mm/min % ISO 527-1,-2 6.1

C Nominal strain at break 50 mm/min % ISO 527-1,-2 > 50

Stress at break 50 mm/min MPa ISO 527-1,-2 70

Strain at break 50 mm/min % b.o. ISO 527-1,-2 130

C Tensile creep modulus 1h MPa ISO 899-1 2200

C Tensile creep modulus 1000 h MPa ISO 899-1 1900

Flexural modulus 2 mm/min MPa ISO 178 2400

Flexural strength 2 mm/min MPa ISO 178 97

Flexural strain at flexural strength 2 mm/min % ISO 178 7.1

Flexural stress at 3.5 % strain 2 mm/min MPa ISO 178 73

C Charpy impact strength 23 °C kJ/m² ISO 179/1eU N

Charpy impact strength -60 °C kJ/m² ISO 179/1eU N

Charpy notched impact strength 23 °C/ 3 mm kJ/m² ISO 21305/based on ISO 70P

179/1eA

Charpy notched impact strength -30 °C/ 3 mm kJ/m² ISO 21305/based on ISO 16C

179/1eA

Izod notched impact strength 23 °C/ 3 mm kJ/m² ISO 21305/based on ISO 65P

180/A

Izod notched impact strength -30 °C/ 3 mm kJ/m² ISO 21305/based on ISO 15C

180/A

C Puncture impact properties - maximum force 23 °C N ISO 6603-2 5400

C Puncture impact properties - maximum force -30 °C N ISO 6603-2 6300

C Puncture energy 23 °C J ISO 6603-2 60

C Puncture energy -30 °C J ISO 6603-2 65

Ball indentation hardness N/mm² ISO 2039-1 115

Thermal properties

C Glass transition temperature 10 °C/min °C ISO 11357-1,-2 144

C Temperature of deflection under load 1.80 MPa °C ISO 75-1,-2 124

C Temperature of deflection under load 0.45 MPa °C ISO 75-1,-2 136

C Vicat softening temperature 50 N; 50 °C/h °C ISO 306 144

Vicat softening temperature 50 N; 120 °C/h °C ISO 306 145

C Coefficient of linear thermal expansion, parallel 23 to 55 °C -4

10 /K ISO 11359-1,-2 0.65

C Coefficient of linear thermal expansion, normal 23 to 55 °C -4

10 /K ISO 11359-1,-2 0.65

C Oxygen index Method A % ISO 4589-2 28

Thermal conductivity, through-plane 23 °C; 50 % r. h. W/(m·K) ISO 8302 0.20

Resistance to heat (ball pressure test) °C IEC 60695-10-2 138

Flash ignition temperature °C ASTM D1929 480

Self ignition temperature °C ASTM D1929 550

Page 1 of 3 pages

Edition 13.09.2021 ISO Datasheet

Makrolon® 2558

Property Test Condition Unit Standard typical Value

-

Electrical properties (23 °C/50 % r. h.)

C Relative permittivity 100 Hz - IEC 60250 3.1

C Relative permittivity 1 MHz - IEC 60250 3.0

C Dissipation factor 100 Hz 10

-4 IEC 60250 5.0

C Dissipation factor 1 MHz 10

-4 IEC 60250 90

C Volume resistivity Ohm·m IEC 60093 1E14

C Surface resistivity Ohm IEC 60093 1E16

C Electrical strength 1 mm kV/mm IEC 60243-1 34

C Comparative tracking index CTI Solution A Rating IEC 60112 250

Other properties (23 °C)

C Water absorption (saturation value) Water at 23 °C % ISO 62 0.30

C Water absorption (equilibrium value) 23 °C; 50 % r. h. % ISO 62 0.12

C Density kg/m³ ISO 1183-1 1200

Bulk density Pellets kg/m³ ISO 60 660

Material specific properties

Refractive index Procedure A - ISO 489 1.586

Haze for transparent materials 3 mm % ISO 14782 < 0.8

Luminous transmittance (clear transparent materials) 1 mm % ISO 13468-2 89

C Luminous transmittance (clear transparent materials) 2 mm % ISO 13468-2 89

Luminous transmittance (clear transparent materials) 3 mm % ISO 13468-2 88

Luminous transmittance (clear transparent materials) 4 mm % ISO 13468-2 87

Processing conditions for test specimens

C Injection molding - Melt temperature °C ISO 294 290

C Injection molding - Mold temperature °C ISO 294 80

C Injection molding - Injection velocity mm/s ISO 294 200

Recommended processing and drying conditions

Melt temperatures °C - 280 - 320

Standard Melt temperature °C - 300

Barrel Temperatures - Rear °C - 250 - 260

Barrel Temperatures - Middle °C - 270 - 280

Barrel Temperatures - Front °C - 280 - 290

Barrel Temperatures - Nozzle °C - 290 - 300

Mold Temperatures °C - 80 - 120

Hold Pressure (% of injection pressure) % - 50 - 75

Plastic Back Pressure (specific) bar - 50 - 150

Peripheral Screw Speed m/s - 0.05 - 0.2

Shot-to-Cylinder Size % - 30 - 70

Dry Air Drying Temperature °C - 120

Dry Air Drying Time h - 2-3

Moisture Content max. (%) % - <= 0,02

Vent Depth mm - 0.025 - 0.075

C These property characteristics are taken from the CAMPUS plastics data bank and are based on the international catalogue of basic data for

plastics according to ISO 10350.

Impact properties: N = non-break, P = partial break, C = complete break

Page 2 of 3 pages

Edition 13.09.2021 ISO Datasheet

Makrolon® 2558

Disclaimer

Typical value

These values are typical values only. Unless explicitly agreed in written form, the do not constitute a binding material specification or warranted values. Values may be affected by the design of the

mold/die, the processing conditions and coloring/pigmentation of the product. Unless specified to the contrary, the property values given have been established on standardized test specimens at

room temperature.

General

The manner in which you use and the purpose to which you put and utilize our products, technical assistance and information (whether verbal, written or by way of production evaluations), including

any suggested formulations and recommendations are beyond our control. Therefore, it is imperative that you test our products, technical assistance, information and recommendations to determine

to your own satisfaction whether our products, technical assistance and information are suitable for your intended uses and applications. This application-specific analysis must at least include

testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by Covestro. Unless we otherwise agree in

writing, all products are sold strictly pursuant to the terms of our standard conditions of sale which are available upon request. All information and technical assistance is given without warranty or

guarantee and is subject to change without notice. It is expressly understood and agreed that you assume and hereby expressly release us from all liability, in tort, contract or otherwise, incurred in

connection with the use of our products, technical assistance, and information. Any statement or recommendation not contained herein is unauthorized and shall not bind us. Nothing herein shall be

construed as a recommendation to use any product in conflict with any claim of any patent relative to any material or its use. No license is implied or in fact granted under the claims of any patent.

With respect to health, safety and environment precautions, the relevant Material Safety Data Sheets (MSDS) and product labels must be observed prior to working with our products.

Covestro Medical Grades

For more information on Covestro products in Medical Applications, please request from your sales support contact our Guidance document: GUIDANCE ON USE OF COVESTRO PRODUCTS IN

A MEDICAL APPLICATION.

Recommended Processing and Drying Conditions

Barrel temperatures are valid for a standard 3-zone barrel. Temperature set-up for different barrel types may change according to configuration. Values for hold pressure as percentage of

injection pressure may vary depending on, amongst others, part geometry, injection molding machine and injection mold. Drying conditions are for dry air dryers only. Drying times and drying

temperatures may differ depending on valid dryer type. Further information is provided by your local Covestro support as well as in the following brochures: Injection Molding of High Quality

Molded Parts - Drying; Determining the Dryness of Makrolon by TVI Test; The fundamentals of shrinkage in thermoplastics; Shrinkage and deformation of glass fiber reinforced thermoplastics [...].

https://www.plastics.covestro.com/Library/Overview.aspx

Covestro AG

Polycarbonates Business Unit

Kaiser-Wilhelm-Allee 60

51373 Leverkusen

Germany

plastics@covestro.com

www.plastics.covestro.com

Page 3 of 3 pages

Edition 13.09.2021 ISO Datasheet

You might also like

- ESS AudioDrive ES688 UserGuideDocument86 pagesESS AudioDrive ES688 UserGuideGregNo ratings yet

- RF Welding of PVC and Other Thermoplastic CompoundsDocument5 pagesRF Welding of PVC and Other Thermoplastic CompoundsRushyanth KRNo ratings yet

- No. M.1642/COLREG 1: The Merchant Shipping (Distress Signals and Prevention of Collisions) Regulations 1996Document32 pagesNo. M.1642/COLREG 1: The Merchant Shipping (Distress Signals and Prevention of Collisions) Regulations 1996Polaris BridgemanNo ratings yet

- Ficha Makrolon 2607 ISO enDocument4 pagesFicha Makrolon 2607 ISO enPatriciaNo ratings yet

- Makrolon 2405 ISO enDocument4 pagesMakrolon 2405 ISO enJuan Daniel Ledezma Alonso100% (1)

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroNo ratings yet

- Makrolon® 1952: Flame Retardant Grades / Medium ViscosityDocument3 pagesMakrolon® 1952: Flame Retardant Grades / Medium ViscosityDiegoTierradentroNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- Makrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityDocument4 pagesMakrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityagungNo ratings yet

- Makrolon 2607 - en - 56977671 00009617 18538954Document4 pagesMakrolon 2607 - en - 56977671 00009617 18538954MulyadiNo ratings yet

- PC Makrolon 2458 - 2006Document4 pagesPC Makrolon 2458 - 2006countzeroaslNo ratings yet

- 202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018Document3 pages202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018obeckoneNo ratings yet

- Makrolon 6557 - TDSDocument4 pagesMakrolon 6557 - TDSCassianNo ratings yet

- Bayer Makrolon - AL2447 - LensDocument4 pagesBayer Makrolon - AL2447 - LensLeandro LacerdaNo ratings yet

- Flow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Document4 pagesFlow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Guilherme Dos Santos SouzaNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- Makrolon Rx3440 - en - 87242367 05124840 21462211Document3 pagesMakrolon Rx3440 - en - 87242367 05124840 21462211MamdouhNo ratings yet

- Makrolon AL2447 - en - 56978848 00009654 19215151 2Document4 pagesMakrolon AL2447 - en - 56978848 00009654 19215151 2optoyhamelNo ratings yet

- Makrolon LED2245 - en - 81038415 00003726 19218403Document4 pagesMakrolon LED2245 - en - 81038415 00003726 19218403dave judayaNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Makrolon OD2015: Grades For / Optical Storage MediaDocument3 pagesMakrolon OD2015: Grades For / Optical Storage MediamarioNo ratings yet

- Makrolon SF800 - en - 56979992 00009671 17283484Document3 pagesMakrolon SF800 - en - 56979992 00009671 17283484Shinichi SuzukiNo ratings yet

- Lanxess Durethan Bkv130h2.0 901510 Iso enDocument3 pagesLanxess Durethan Bkv130h2.0 901510 Iso enRICARDONo ratings yet

- LANXESS Durethan BKV35H2.0 901510 ISO ENDocument3 pagesLANXESS Durethan BKV35H2.0 901510 ISO ENcristinamss33No ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- TDS - TS004 - Durethan BKV30H2.0Document3 pagesTDS - TS004 - Durethan BKV30H2.0oberta.andrzejNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Durethan BKV240 H20 XCP901510 ISOinternetDocument3 pagesDurethan BKV240 H20 XCP901510 ISOinternetshahin_723No ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- TDS - TS002 - Durethan AKV30H3.0Document3 pagesTDS - TS002 - Durethan AKV30H3.0oberta.andrzejNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Makrolon UV: Solid Polycarbonate SheetDocument2 pagesMakrolon UV: Solid Polycarbonate SheetKIMIKA Industrial CorporationNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- PA66-GF30LANXESS Durethan AKV30 000000 ISO ENDocument3 pagesPA66-GF30LANXESS Durethan AKV30 000000 ISO ENKalipse FerreiraNo ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- SABIC® PP - 108MF97 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 108MF97 - Global - Technical - Data - Sheetkhaloud.alkaabi98No ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Sabic PC 10 Mfi pc1003rDocument3 pagesSabic PC 10 Mfi pc1003rChu ChuNo ratings yet

- Barcoding RequirementsDocument21 pagesBarcoding RequirementsRushyanth KRNo ratings yet

- Company Visit ReportDocument6 pagesCompany Visit ReportRushyanth KRNo ratings yet

- Reveos BrochureDocument16 pagesReveos BrochureRushyanth KRNo ratings yet

- Factory Visit Report - CVRDE, AvadiDocument4 pagesFactory Visit Report - CVRDE, AvadiRushyanth KRNo ratings yet

- PTT, Maleinized ABS BlendDocument7 pagesPTT, Maleinized ABS BlendRushyanth KRNo ratings yet

- Materials Science and Engineering ADocument10 pagesMaterials Science and Engineering ARushyanth KRNo ratings yet

- DBMS Queries OverviewDocument98 pagesDBMS Queries OverviewAbhinay YadavNo ratings yet

- L2-Characteristics and Importance of Tourism IndustryDocument5 pagesL2-Characteristics and Importance of Tourism Industryraymart fajiculayNo ratings yet

- Overview of Active Directory Domain Services: Lesson 1Document34 pagesOverview of Active Directory Domain Services: Lesson 1Deepak MalusareNo ratings yet

- Manuel Operatoire Four 1Document33 pagesManuel Operatoire Four 1Ayoub MagroudNo ratings yet

- Types of Extrusion and Extrusion Equipment: NPTEL - Mechanical Engineering - FormingDocument8 pagesTypes of Extrusion and Extrusion Equipment: NPTEL - Mechanical Engineering - FormingtechopelessNo ratings yet

- Dhaka Bank UncompleteDocument40 pagesDhaka Bank UncompleteAbir HasanNo ratings yet

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDocument4 pagesBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniNo ratings yet

- Results For Sai Teja Traders - Rajahmundry - ZonalinfoDocument4 pagesResults For Sai Teja Traders - Rajahmundry - ZonalinfoManoj Digi LoansNo ratings yet

- Perovskite SemiconductorDocument5 pagesPerovskite SemiconductorAkil SundarNo ratings yet

- HCDocument2 pagesHCSashikant SharmaNo ratings yet

- Objective QSNR ITG MDRA BA 2024Document12 pagesObjective QSNR ITG MDRA BA 2024neerejdev.sjcNo ratings yet

- Aircraft Lighting RequirementsDocument1 pageAircraft Lighting Requirementsdonnal47100% (1)

- DUI INstall Manual 232ci - 6516-3Document2 pagesDUI INstall Manual 232ci - 6516-3EdwinNo ratings yet

- Written Digests105 124Document845 pagesWritten Digests105 124Hoven MacasinagNo ratings yet

- A Comparative Study of BCG & McKinseyDocument18 pagesA Comparative Study of BCG & McKinseypunya.trivedi20030% (1)

- 5 A Case Study: The Domino PuzzleDocument6 pages5 A Case Study: The Domino PuzzleqwqqwwNo ratings yet

- ePDQ DirectLink en OriginalDocument24 pagesePDQ DirectLink en Originalsoleone9378No ratings yet

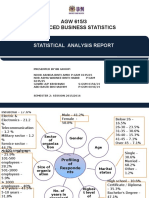

- AGW 615/3 Advanced Business Statistics: Statistical Analysis ReportDocument10 pagesAGW 615/3 Advanced Business Statistics: Statistical Analysis ReportNida AmriNo ratings yet

- Topic 7. X-Ray, Luminescent and Transilluminating Diagnostics: The Indication ToDocument2 pagesTopic 7. X-Ray, Luminescent and Transilluminating Diagnostics: The Indication ToHERO RescueNo ratings yet

- 2008 - Aecom - UK AirportTerminals - CM - 1aug08Document6 pages2008 - Aecom - UK AirportTerminals - CM - 1aug08Yi JieNo ratings yet

- Mother Tongue LessonsDocument6 pagesMother Tongue LessonsPrincess CuevasNo ratings yet

- Adventure Park in Bukidnon Where A Vast Plantation of Seems To Be A Golden Crown Fruit Is LocatedDocument8 pagesAdventure Park in Bukidnon Where A Vast Plantation of Seems To Be A Golden Crown Fruit Is Locateddindin mariz s. tangenteNo ratings yet

- Microstructure and Mechanical Properties of Resistance Upset Butt Welded 304Document11 pagesMicrostructure and Mechanical Properties of Resistance Upset Butt Welded 304Ashkaan OzlatiNo ratings yet

- Ospf Basic Lab WalkthroughDocument7 pagesOspf Basic Lab WalkthroughAek BenabadjaNo ratings yet

- 10.1016@B978 0 12 814580 7.00014 9Document6 pages10.1016@B978 0 12 814580 7.00014 9BALAI BESAR MKG WIL III BALINo ratings yet

- Biosphere Vector Control Bahan Kuliah OnlnineDocument21 pagesBiosphere Vector Control Bahan Kuliah OnlnineFikri AlghifariNo ratings yet

- Anti Inflammatory DietDocument6 pagesAnti Inflammatory DietHW GomarNo ratings yet

- Ethiopia 7th Version DRM Policy 2009Document52 pagesEthiopia 7th Version DRM Policy 2009abk1234No ratings yet