Professional Documents

Culture Documents

Busakshamban Glyd Ring Piston Rings Product Catalogue Series S48044

Busakshamban Glyd Ring Piston Rings Product Catalogue Series S48044

Uploaded by

Frank Nunes0 ratings0% found this document useful (0 votes)

5 views23 pagesOriginal Title

busakshamban.glyd.ring.piston.rings.product.catalogue.series.S48044

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views23 pagesBusakshamban Glyd Ring Piston Rings Product Catalogue Series S48044

Busakshamban Glyd Ring Piston Rings Product Catalogue Series S48044

Uploaded by

Frank NunesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 23

SHAMBAN

Sealing Systems

Approach

continuing to develop

and build the best

sealing systems

in the world.

Slydring)

Giyd Ring® Assembly

Shamban provides optimum leakage control

to your engineered sealing applications.

Each seal component joins versatile seal

geometry with engineered high performance

materials. Individual elements are combined

for specific applications, resulting in the

most advanced sealing systems

ever introduced.

Component manufacturers around the world

rely upon quality SHAMBAN Sealing

Systems to resolve their toughest sealing

application problems. From the Seals

Division Headquarters in Fort Wayne,

Indiana, design engineers work directly with

Stepseal K®-R

in Tandem

‘Aa Sea, Tt, en, Gly Rng, Double Data, Seng, Exclude, Shambak, Stoseal K® and Tul are rgitore ademas of WS, SHAMBAN & Co

PreLok™ isa wademavk of W'S. Shaman & Co.

[AQ SEAL? US. Patont No 4,170,181 Stapsoa!K® US. Patent No. 4,440,718.

21880 8'S Snamten & Co,

customers to design sealing systems for

standard and specialized applications. CAD/

CAM (Computer Aided Design/Computer

Aided Manufacture), supported by extensive

testing in our lab assures accurate design,

rapid response and extended performance

in the field

The demands of rapidly expanding technolo-

gies continue to place increasing

requirements on product reliability, cost, and

performance. SHAMBAN helps you meet

these challenges by designing the most

versatile dynamic sealing systems available.

Excluder® 2

“=e

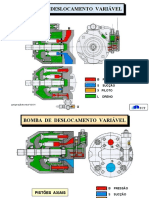

The Glyd Ring®

The Giyd Ring® is a two-piece, bi-directional

piston seal assembly designed for use in

hydraulic actuators, SHAMBAN engineers

have combined the dynamic performance

characteristics of Turcite® fluoroplastics, with

the positive sealing capabilities of Turel®

elastomer sealing elements to produce a

seal assembly that offers extended

performance at low and high pressure. The

Glyd Ring® is an economical, durable, low-

friction seal that assures longer life than

other fluid power seals and packings.

Glyd Ring’ Advantages:

+ Eifective bi-directional seal at high and

low pressure

+ Low friction, selt-lubricating

+ Consistent pressure distribution across

seal footprint

+ Performance at high and low temperature

‘+ Material compatibility for a wide range of fluids

+ Excellent extrusion resistance

+ Extended service life

+ Permits simple piston design

* Ease of installation

Series $48044 Giyd Ring®

Assembly utilized as a

piston seal component in a

typical example of a

SHAMBAN Heavy Duty

Cylinder sealing system.

0:00 an apt dl cranes ara us ont screen ass Psa beta dn

‘oermort fone sty ung arecrmarsed WS. SHA\OAN a Company sme To epOtEy Dea, eee

‘Simpl swans te reac crores mmr aera

‘ Radial Comp

Piston Rings _

Cutaway View of

Series 48044)

Cutaway View of

Series 28-42

Type 6 Type P

Uneut Stepcut

Giyd Ring” Radial Compression

Piston Rings with Notches

ression

Features

This section describes general characteristics of the Glyd

Ring” family. For more information about Giyd Rin

Series $48044, see Page 4, For Series 28-42, see Page 6.

Simple Two-Piece Design.

The dynamic component of the Giyd Ring® is made of

Turcite”, a specially modified fluorocarbon resin developed

exclusively by SHAMBAN, to provide the optimal sealing

element under both high and low pressure. The elastome

energizer (typically a Ture\elastomer square-ring or o-ring)

provides radial force necessary to energize the Glyd Ring”

and prevent leakage at low pressure.

Ease of Installation.

Using a stepcut Glyd Ring® facilitates installation. Uncut Giyd

Rings may require installation tools for assembly, depending

upon Glyd Ring® cross section and diameter, For installation

procedures of uncut Giyd Rings”, refer to Page 19.

‘To ofder Sories 28-42 Giyd Rings" with stepeut, include sutfix

'P" in appropriate position on the Glyd Ring® ordering code —

without, include a "G”. To order Series $48044 with stepcut,

include suffix "X" in appropriate position on ordering code.

To ofder without stepcut omit °X" suffix

Notches

Giyd Ring? Radial Compression Piston Rings are available

with sidewall notches. Notches provide instant pressurization

of the Glyd Ring® in rapid pressure reversal conditions to

prevent fluid “blow-by”.

e@

Turcite’ Material

TURCITE® is a family of tough, non-metallic low tition specially

‘moitied fluorocarbon resins developed by Shamban specially for

seals and bearings, Stitiontricton foroes are much lower with

Turcite® materials than rubber and urethane, Selected filers are

used in Turcite” compounds to “tailor the mechanical and physical

properties as needed to meet specific service conditions and

performance requirements.

Turel’ Material

“Ture!” is the Shamban family of high performance elastomers

developed by Shamban for use as energizers and elastomer contact,

‘components in Shamban seal assemblies. Turel® material

selections can be made to accommodate a wide range of fluid

sealing environments.

General Purpose

Hystaulc Fuds

Steal, Chrome,

‘Cast ron

sores | Ste Chane

anal Ciena

ra one

i, Ha

aeet Oy) ‘Anodized Aluminum:

Sea, nee Goon

fee aero

it) | ans te

TT iy

Sie Cass, Bre,

ee

a en

caer

Soe, Sree Creme,

ey ee ce

See" | er

cain, et

evra Pees | nur, Ht,

comer | mien es

a

Glyd Ring’

Working

Parameters

Pressure

Field proven pressure up to 5000 psi (345

bar). For applications above 5000 psi,

‘consult SHAMBAN Product Enginzering

for best product configuration and material

recommendation.

‘Temperature

Effective from 95°F (70°C) to 00°F

(260°0), (Continuous temperatures 10

‘50°F may reduco service life.) Selection

(of proper elastomer material wll vary

‘depending upon the temperature and fluid

‘medium of your application. Consult

‘materials Table | when ordering.

Running Friction’

‘Typical Coefcient of Runsing Friction of

Dynami¢ Seaing Suriace:

(0.07 lubricated

0.25 non-ubricated

Glyd Rings” are seif-lubricating and will

vitualy eliminate sip-sti

Velocity

Giyd Rings® are commonly utiized in

applications in excess of 120 fpm,

Ying effective leakage control and

extended service duration. Frequency up

toate

Bore Diameters

Offered for bore diameters from 1/2 inch to

46 inches. Diameters under 12 inch,

larger diameters to 150 inches, and

‘custom sizes are available. Contact

'SHAMBAN Product Engineering.

“Data based upon tests conducted by WS.

'SHAMBAN, using Turito® 48 on ground sice!

plate at 10-14 RMS ata surface speed of 30,

Tumin. Actual eoetcient of fiction, non

|Maricated at 200 pst-.28 — 25 cual, using

‘OW industrial ol a 600 psi: 08 — 07;

NOTE: For extreme applications that include

‘combinations of high pressures, clearances,

and fomporatures that are above recommended

{olorances, consutt SHAMEAN Product

Engineering for optimal material section

Series $48044 oe |

Glyd Ring” oO

Radial Compression Piston Ring

with Square-Ring Elastomer Energizer

Applications

The Series $48044 Glyd Ring" is a bi-directional piston seal, designed

for use in heavy and medium duty applications where the benefits of a |

stable seal footprint will be realized. The S48044 may be installed in re-

ciprocating, oscillating, and helically moving hydraulic systems. ‘Cutaway View of

Series $4e0de :

iva Ring”

1, $48044 Glyd Ring” Assembly consists of (1) Giyd

Ring” and (1) Square Ring Elastomer.

How To Order the * fic an ure gost mae

$48044 Glyd Ring 2 Uz he or addon xa ao by

Example: -|

xN

. i Fir Aasety

Jcepet Se

h te (TYP) ‘Size Dash No.

( aa

ee Sestrar Matarl Code

a eis Letter (See Note #2).

ee

r ae cyaing® Sal aor

saath BR | (See No #2)

84 x ve Optional Stepout (To Specity)

Optional ial Noches see page 2)

Ee ae

Series $48044 Giyd Ring” in piston

application with Slydring® pistan bearings

@

For maximum piston ring service

life, diametral clearances should

be held as emall as practical

Diametral clearances shown in

shaded area of Table Il require

the use of piston bearings,

Refer to Catalog # 1'C206 or

Consult Shamban Product

Enginoering for Slycring® Piston

Bearing recommendations,

9500

+0000

30500

1000

11500

+2000

32500

+3000

13500

14000

14500

15000

15500

16000

3190

3500

si

2om0

10130

10830

v0

11590

12190

| 12620

+3190

| 13630

410

| 14830

| 15190

MAX. RECOMMENDED DIAMETRAL,

CLEARANCE (E) - INCHES

DASH

Sue

(008/046

(048/082

084/196

144/256

Gea nies a

Radial Compression Piston Rings

with O-Ring Elastomer Energizers

Application:

Series 28-42 Glyd Ring” bi-directional piston seals are designed for

use in ight, medum, and heavy duty applications. I also recom-

mended in situations where installalon may be dificult. Series

28:42 Giyd Rings? may be installed in reciprocating. and helically

moving hydraulic systems. A large selection of cross sectional sizes

Offers voreatiity n'a wide range of applications. Cutaway View of

Series 28-42 Glyd Ring”

Series 28-42 Glyd Ring’ scare

features: J:

Chamfers

Series 28-42 Giyd Rings are chamfered to

ensure easy insertion of the piston into the

cylinder bore. A chamfer on the cylinder is

recommended but in some cases may not be

necessary. Remove burrs and smooth the edges

of the bore that come in contact with the Glyd

Ring during insertion of the piston.

Cross Sectional Sizes —

Series 28-42 Glyd Rings” have been engineered.

in eight different cross sectional sizes (See

Table.) to meet the unique requirements of

different sealing applications.

Selection of cross sections should be based

upon light, medium, or heavy duty conditions,

based upon service parameters. These include

required response, pressure, temperature, and

service life.

Sories 28-42 Glyd Ring® in piston applica

tion with Slydring® piston bearings

Series 28-42 Glyd Ring’ S

Standard Cross Sections

seseSe

SERIES26: SERIES20: SERIES 32: SERIES a S38

S38 hee

ys

a

~

How to Order Series 28-42 Glyd Rings

1. Use descriptive part numbers when EXAMPLE

ordering Glyd Ring” Piston Seals. ae

2, For recommendation of Glyd Ring* fetes Ne

materials and O-ring elastomer ma- ‘Type G or P.

terials, refer to Table | ibd canes

and Thousandths

3. Utilize the color-coded ordering ex-

ample at right by matching with

corresponding colors on the ordering Turcite Compound No.

charts. ‘With Notches

Elastomer Material Code Letter

“The part number used in the example is for a solid Type “G"

Glyd Ring® Set to fit a minimum bore of 2.000 inches, The

O-Ring material is a Ture!” ‘A’ suitable for air, or petroleum oil

This Glyd Ring® is made of Turcite 46 and is notched.

/PISTON BEARING OPTIONAL

u é / “my stgene cceanace

Dimensional Data

A PISTON DIAMETER B G

cnoove

j ( Cy ‘wie

anoove

(CYLINDER WITHOUT SLYDRING WITH SLYDRING DIA. +005 L

| geeomer | wamoureuenns | trokssaemas a

ox oe

sae ae Peat ceca boetedsatteel reo eetieiees fe

|

or 00 oo

500 |] 498 2 | 005 —_| 926 fm) 081 | 087 x]

cee roa oot 4

soo | 498 || 006 — | ame 8) 081 | 120

oor co al

362° 560 2° | 005 — | 208 8) 081 | 087 x]

}

= at oo

sez | 560/006 | — | — | 06 '22| 061 | 128 [x |

00% +000 | + oxo ¢

[ees =) 620 °°] 005 — [sr * 8) 081 | 087 rx]

25 $6) 620 72/008 — | 969 9) 081 | 128 |x|

=

Foal on 1 oa oan

[eer <2) cas 122] 00s — | sta) 081 | 87 |x|

os7 | 68s | 006 | — | aa 784) 081 | 128 |x|

[ea7 =| 605 +8] 008 | 065 ~2° | 026 | se9 °%%) 126 | 149 xt

Eg

{ 4.001 +000 +000) paneig

750-2) 748] 005 | — | — | 876 °°) 081 | 087 Px |

+.002| od

750°] 748 x]

~ 002) iad

750 * xy

“Replace X's appearing in Giyd Ring Piston Assombly No. columns with proper letter code as indicated. Eg,

‘2BGOOSOOAAG Is a 28G Serles Gyo Ring With Turel® A Elastomer end Turcite® 45 seal ring.

“Consult Catalog (C206 for Siyaring install dimensions.

Dimensional Data_

A Piston ovNeTER B 6

| a | enoove

c ‘wDTH

ort mwas | mem OF Ess i

SS Se ae

a2) a0 2! o05| —- | — | 638 °%| 061 | 087

| a2 | aio | 6 | — | — | see 24! oot | 128

Fare 2) e102) 006 | 700° | 008 | 514 8) 126 | 149

Fars <2 ars | 005] — | — | 701 °°] 001 | .087

as) ara | 006] —— | — | or9 =22) 001 | 120

3752) ars | 006 | 359 2% | 026 | s77 | 126 | 149

sor] 995 °° | 005 | —— | — | 760 “2%| 061 | 087

937 ~2) 935 '%| 006 | —— | — | oo | 061 | 126

ea7 | 935 2] 006 | ots 2 [026 | coo | sa | 140

+000 | 98 7%] 00s | — | — | see £2) 261 | oer

[000 =32| -se6 38 | oo | — | — | a4 “i 201 | 20

F000 | 998% | 006 | 97a "8 |.006 | 702 '@| 26 | 149

[1982 <'2i]1.000 33/008 | — | — | 06 “S| 281 | 087

}1.062 11.060 *22] oo | —— | — | 06 72%] 81 | .128

Foe 82) 4000 °% | 006 | 1.040 -%% | 026 | 764° 22) 28 | 140

Tyres [ates 22) 005 | —— | — | ost <2) 081 | 087

Tires [1123 82] 006] — | — | 969 *22) oer | 128

1125 ©4120 721 006 | 1.103 2% | o2e | ear =22) 126 | 140

1167 8") t4a5 7%) 005 | —— | — [ror °%9] 081 | 087

1407 “eases me | oo | —— | — | oar °98) 001 | 128

1187 “2/1185 82) 006 [1.165 “22 |.026 | veo °2%| 26 | 40

1250“) 1208 °%2/ 005 | —— | — [1076 “| 081 | 87

“Roplace X's appearing in Giyd Ring Piston Assembly No. columns wih proper letter code as indicated. Eg.

2BGOOSO0AA6 is a 28G Series Giyd Ring With Ture! A Elastomer and Turcite® 46 seal ring,

**Consult Catalog liC206 for Siydring install dimensions.

Standard Siz

A pron AMETER pa eae|

eoore

c Cy an

onoove

CYLINDER WITHOUT SLYDRING WITH SLYDRING DIA. +005 L

Sone | HevGwotwmes | ltowsdaands 233 |

Sa oo

tart [eee tlfss Ulear |More eld cel fom ewe '

| T a

1250 =| 1208 °2%] cos | —— | — | 904 -%%] oat | 126 |

1250 °] 1248 =] 006 [1.228 °% | 026 | 950°) 126 | 149

roi 2) aio 182) os | —— | — 1.198 2") 081 | 087

raz 11310 2) 006 | — | — | 1056 2%] 081 | 128

1312 72) 4310 006 | 1290 8 | os | 1014 120 | 149

rare) 1373 oos | —— | — | 1201 8" 061 | 87

1375 | 1373 6 | —— | — 1119 2 061 | 128

| 02 coo | sq +000 00 |

[ars “82 1973 19) 006 [1353 70 | oe | 1077 8) 126 | 148 ©

1437 22) 1495 22) ons | —— | — | 1268 |") 081 | 087

[sor Rg 495 2s) oe | —— | [aan 2) oer | ze

+ 002 000 Ee ooo nine 000 | eat

1.497 "| 1.435 3) | 006 1.415 fy | 026 | 1.199 thy) 126 | 149

1800!) 1400 2] 005 | —— | — | 1.006 °28) .061 | 087

5 pens +

1500 [1408 ©] cos | —— | — | 1.248 |) oa1 | 126

ial | = L i

1500'S) 1.498 "| 00s 1478 1% | 026 | 1.202 9 126 | 149

002] | 000)

1962 8% 1.560 198) 006 = — — | 1.264 |) 126 | 149

1562 '%) 1560 °%2| c06 | 1540 8 | 26 | 1.176 | 120 | 199

| 1560 ee 2

1562 *|1560 °%2| 007 [1.500 | 029 | 1.198 1 t66 | 212

Tyee 8/1623 2] cos) —— | — 1907 W126 | 140

T ona] i 000 1 00] a5 |

1628 S| 1.623 “98 ) 006 | 1.603 “Sp |.026 | 1.209 “tn) 120 | .193

1.625 3) 1.623 °°! 007 | 1.602 79% | 029 | 1.201 'O8) .166 | 212

1687 °%| 1.685] 008) —— | — | 1.989 | 126 | 149 @

~00e| ‘00 200 *000| |

1.687 “tho, 1.685" Sop | .006 | 1.665 “02 | .026 | 1.901 fp) 120 | 193

“Replace X's appearing in Glya Ring Piston Assembly No. columns with proper letter code as indicated,

28G00500A46 Is a 28G Series Glyd Ring With Turel” A Elastomer and Turcite® 46 seal ring.

a Consul Catalog 1JC206 for Siydring install dimensions.

PISTON DIAMETER B G |

a croove |

c Cy ‘WioTH

cnoove

‘CYLINDER, WITHOUT SLYDRING WITH SLYORING, DIAL +05 | Lb

‘BORE DIA. PISTON BEARINGS PISTON BEARINGS = 000 |

yea: aa] ae 7 000 | | T +00 |

[1687 2/165 | 007 [1.664 °% | 029 |1.263 ~%) 166 | o12

1750 “1748 °2"1 006 | —— | — |r4se °%) 126 | 149

[1750 M2) .748 °°) 006 | 1.728 ~% | 026 [1.964 ° 22) 120 | 199

1.750% 1748 2") 007 | 1.727 | oes | 1326 '28) 106 | 212

vers “1.873 1 ove | — | — |rs77 “2 126 | 140

1975 '% 4.73 || o06 | 1.853 ~% | 026 | 1.489 721 120 | 193

1e7s 2) 1.973 81 07 | 1.852% | 020 [1451 2) 166 | 212

cee o ooo}

@ 2000S) r990 es] ons | — | [702 el ze | a9

2.000 22|1,908 “| o06 | 1.978 °° | 026 | 1.614 °%| 127 | 193

2000 1 1.906 73 | oo7 | 1977 “2 | oz | 1576 722) 166 | 212

[22s 7] 2123 *1 oe | —— | — |1.807 *9%) 126 | 149

2.125 /%l 2129 1 06 | 2103 72% | 026 | 1.739 °%| 127 | 193

2125 2129 | oo7 | 2102 1% | 029 | 1.701 ~%! 166 | 212

2.250 '%| 224 | "oe | — | — | 1.952 °%| 126 | 149

2.250 *%! 2.248 | 096 | 2.208 °° | 026 | 1.064 7%] 127 | 193

r 00 era ove

2.250 *%'| 224 | oor |22e7 °° | oso |1.826 1%) -66 | 212

2975 '@ 273 | oo | —— | — |2or7 *%| -26 | 149

2a7s (| 2473 | 006 | 2353 8 | oz | 1.989 | 89 -a7 | 198

00 | 000 | og | +

2.375 °°! 2.373 owe 007 | 2.352 029 | 1951 ~% 166 | 212

9 ‘ee oes coe

[2500 =$5[ 2406 68 | os | — | — | 2200 i) sas | ao

2.500 ieee 2498 °°! 006 (2.478 | 026 2114 288) soz 193

oo cee | vee ons

00a) 000, | 000]

2500 *| 2408 “| oo7 |2a7r “| 029 | 2076 | 106 | 212

“Replace X's appearing in Giyd Ring Piston Assombly No. colurnns with proper later code as indicated. Eg,

28G00500A46 is @ 286 Series Giyd Ring With Turel® A Elastomer anc Turcite® 46 seal ring.

“Consult Catalog 1'C206 for Siyaring install dimensions.

it

"Radial Conpneketi Piston Rings.

Dimensional Data

T

A PISTON DIAMETER B G

croove |

c Cy cnooe |"

cvunoes | wirHourstvonne ww suyonn om | va | kL

Soneow. | ‘horoN SEAANGS ston BEANNeS 2 |

Dac Da.cr |

im. To. | im tot_Eman | Om _To._Emam_| im To |

faces ° | 2623 *2| 00s | — 2s27 1 126 | 149

2625 | 2628 “| oce | 2603 [cas |2200 oH 107 | 198

= pee

2425 7% 2623 7 | 007 [2602 2% | oz | 2201 °2| 166 | 212

2750 *%la748 ~™) oo6 | —— | — |2as2 “| 126 | 149

| 2-750 00) one |

2750 “2748 || os [2728 | 026 |2aea ° | 127 | 198

2750 | 2748 °%%| oo7 | 2.727 ~2 | 029 | 2.926 °%| 166 | 212

[ears -)2e7s °°] cos | — 2677 | 126 | 149

2ars -2/2073 °°) 006 [20s °&2 | c26 | 2.4ae ' | 127 | 199

[2075 | 2673 | 007 |2sse °° |.o2e joss 1% 106 | 212

as Zaheer

Fa000 - [2008 °2| 006 | —— | — |aroe :%| 126 | 49

2.000 ~9¢| 2008 ° | 0s [2070 2% | 026 [zor “S| 127 | 199

3.000 -%\ 2908 | oor [2977 :%% | cz | 2576 128) 166 | 212

cca oe aa | sos

| 3.125 “Sl 3123 2) 006 3.103 2% | 026 | 2.739 ~ | 127 | .199

‘aa a “2 tea

3.125 23123 °%| oor [ato 8 | 029 2.701 6] 166 | 212

‘200 - oo | ‘00|

325 3123 8) 098 [ator -%% | oe | 2.02 | 247 | 908

i a a 1 ‘ | ec

3.250 *%\a2ag °° 006 3.228 (0 026 | 2.864 * S| 127 | 193

ti

3250 | 3248 | oor | aze7 % | ove | 2.020 | 8% 166 | 212

(3250 ' 0m 9248 ‘fp | 008 9.226 “So | 032 | 2634 “| 247 | 08

ca] cao eco 1

a7 °%/3.373 °°) 00s | 3.953 "| 026 | 2989 “th! 127 | .193

jaa7s 3973 | 007 ease 2° | 02 | 20st 2) 66 | 212

3975 -%/ 9370 | 008 [3051 0% | ove 2750 Wl a7 | 308

ove a ce 1 z

3500 -2| o498 2] 006 [47a “9% |.oz6 | ars ‘20! 127 | 105

12

“Replace X's appearing in Giya Ring Piston Assembly No. columns with proper letter code as indicated. Eg.

28G00500A46 is a 28G Series Glyd Ring With Turel® A Elastomer and Turcite® 46 seal ring.

“Consult Catalog VC206 for Siycing install dimensions.

EE

Compression

Piston Rings

PISTON DIAMETER B |G

] “cpoove

c | Cy Strom

cnoove

Sontn | “RetOweewincs: | ASTONBERRINES 2 oi

im to | om oe | om theme | Om |

coo | +.000 000)

3500 ‘1 5498 °°] 007 |aa77 88 | 029 |ao7e || 166

500 0, Ee |

3500 ‘3408 ~2"| 08 [3476 2 | os [2.064 ' 9) 247

| 3.625 ~$| 3.623 |) 006 | 3.603 ° 32 |.026 | 3.209 'O8) 127

3625 [3623 °°] oor |ae0e °° | 029 |az01 2°) 106

3625 “3! 3623 | 008 | 3601 || 032 | 3.009 ° 9) 247

3790 '%1 3748 °%) 006 [3.728 *82 | 026 | aace 8°) 127

3760 *2| 3748 *8| oor |a7er ‘% | 029 |a.s26 *%| 166

3750 | 3748 | os [3726 °2 | oe | 3198 - 2°] 297

3e7s ‘13873 | 006 [3053 2? | 026 | aaa 2°) 127

eo] a =o | 9 oon

307s ‘13873 | oo7 |aese 2 | 029 | 34st ' 8°) 166

aa7s |) 3873 | os |aest | ose | azs9 Me) 247

~ 2 + eno 0 oon

4000 “22) se8 72) 006 [sere |e [sor °2°) 27

.oaa} +900 000 +.

4000 '2213.998 °%2) 007 |so77 *22 | 029 |asve ~%%) 106

4.000 *%\ 3.998 ‘22! oo8 [3076 °% |.oa2 | 3.ae4 *%| oar

4125 2) 4.129 8) 006 |a103 72 | ces |a7s0 2) 127

| 9001 9 ae

4.125 729) 4.123 70) gor |a.to2 72% | 029 | 3.701 *2%) 166

4125 72/4129 1%) oo [ator *2 | ose | aso9 98] 247

4250 '%) 4240 | 006 |a228 °® | 02 |ascs ~2%| 127

ese lnel : va

4250 *%/ 4248 °%| oo7 |aze7 “| 029 [3.826 “| 166

4250 '2%) 4248 | oe [4226 7% | oa |aeas 9 247

4975 '0% 4373 | 06 [45s °°" | 025 | s980 °°] 127

aa7s *%/ 4973 | oo7 [aase °° | 029 | 3951 ~%%] 166

“Replace Xs appearing in Giyd Ring Piston Assembly No. columns with proper leer code as indicated. Eg,

‘28G00500A46 is a 28G Series Giyd Ring With Turel® A Elastomer and Turcite® 46 seal ring.

"Consult Catalog 1/206 for Siydring install dimensions.

15

| A | PISTON DIAMETER B G

| . Gy ongoe |e

seen eee eat eee

Om | bm oh Eman | Om ToL Eman | Om, Th '

4075 =) 4a7a “| ooo | a5: “ |.ooe |a7s9 °2| 247

4.500 = #21 905 | aa7e | 026 [aria 2) tar :

4.500 | 907 [4.477% | 029 | 4076 °%| 168

| 4500 | S| oe | sare “98 | ase [3008 S| 247

4.628 “aT 006 | 4603 2% | 028 [aes 2) 127

4.025 =| 907 | 4.602 ~° |.oe9 | 4e01 22 166

4.625 | 908 [4601 2 | oa2 | 4.009 28) 247

| 4.750 ce! 906 | 4.728 9" |026 | 464 '22| 127

4750 8) oor | 4.727 2 | o09 |4se6 ° 29) 168

4.750 =e! 90s [4.726 8 | ose | 4.108 22) 27

4875 182 | 006 | 4.953 72" | 026 | 4.489 2°) 127

4875 wT 07 [4.062% | 029 [sat © 29) 168

4975 4e73 “| 08 | 4.861 2 | cae | acs 22) 247

5.000 “4008 S| 006 [4978 2% | oes |acis 22) 127

5000 ~22) 4900 ~ (| 007 | aa77 “2 [029 |asre °22| 68

5.000 ° | 4.998 °° | oo | 976 2" | 032 | 4.088 °°] 247 :

[ares “2/5123 °°] 006 |5103 ° | 028 [ara <2] 127

5125 5123 | 07 |st02 “2° | 029 [4701 ° 29) 105

5125 8 5.1232) 008 |s.101 °2% | ose | asoa “21 247

[s2s0 “Mel 5240 $8] 06 [5220 “28 | 026 [aase *92| 27

[250 22) 5248-22] oor [5227 °22 | 020 [ass '92| 68

5.250 4 5248 °%| 008 | 5.226 "2 | 032 | acaa | 2a7

“Replace Xs appearing in Gly Rng Psion Assembly No, clunne with proper leter code as indicated. Eg

fa BOGODSOOAA oa 206 Sees Gh Ang Wi Tur A Elastomer and ute” 46 Sea rg |

"Consult Catalog 1/6206 for Slycring install dimensions.

Dimensional Data

; a

A risTow Mere B G

c Cy come (vom

cyuwoen | wmour styonns sw sevonns me | soos | OL

Sono | ‘nsvoeesmmes | piston Beanies “88

oad Da.

om. ta. | om. ta Pras | om. tou ema | Om

5375 S| 5.973 "22 | 006 | 5.353 2% | 026 |4gea |) 127 | 193

5975 S@|sara | oor [sae 2% | ove [aos 2% 6s | 2x2

5375 ~S) sara) ona [sas 2% | cae |azso “2! ar | 08

sa7s Sl sa73 |) oog | 5.349 1% |.o36 | 4.545 7) 320 | 415

5500 8} 5408 °%| 006 eave 2 |.006 [sax 222] 27 | 190

5500 S| 5493 S| o07 [5477 2% | 020 | 5076 209 168 | 212

~ 00 +000 000, 0

8500 '@l 5.493 °°] oo8 |s.a7e 2% | oe | 4084 °) 247 | 308

5500 '%*/ 5498 °%| 009 |s.ara *2° | 096 | 4670 *%| 320 | ats

5.625 °%) 5.623 °°) oo7 |s.co1 *% | og0 | 5109 7%) 157 | 258

cou] = gpg 00 = aro oo

5.625 ‘Tl 5.623 °°) ope | 6.601 “| 092 | 5.009 °°) 247 | 908

5625 [5623 | on 5509-2 | 008 |47es 2%) 300 | 415

5760 “&!|5740 +2] 07 |57a6 2% | 050 |sa5e 2) 57 | 58

5760 -%| 5700 | 00 [5726 °° | coe [sae *2°) 247 | 200

5750 S574 | 009 [5724 2% [aoe [4920 | 220 | ais

5875“) 5a79 | oo7 [sas 2% | cao [aso a7 | ase

ove] 010 ; 5

se75 Sl sara 2°| oo [ses % | ose [e250 “CR a7 | ono

3075 “| 5a7 °° | 009 [sea | 036 [aoa *2°| azo | ais

6.000 °%8) 5.098 *%°| 007 |s.976 *2% | 030 | 5.404 *%| 157 | 258

oo 7 a0 7000 000

6.000 fu] 5908 “9m | 008 |so76 “2 | ose |s.aa4 °9%) 247 | 08

e000 225008 22] 009 [sor 2 | 096 |sa70 “2 aa0 | ais

+ xs + cn + 000 et

6.125%! 5.123 *%) 007 [e101 *% | 090 | 5.609 *%%) 157 |] 258

ond 7 a0 - 000 + an

6.125 74/6123 7 | 008 |e.101 °° | 032 [5.509 ~%| 2a7 | 208

“Replace X's appearing in Giyd Ring Piston Assembly No. columns with proper letter code as indicated. Ea,

28G00500A46 is a 28G Series Giyd Ring With Turel® A Elastomer and Turcite® 46 seal ring

“Consult Catalog 1/C206 for Slydring install dimensions.

15

Dimensional Data

‘Turcite Giyd ing’

Radial Compression Piston Ri

A PISTON DIAMETER B G

cc Cw GROOVE ner

seme | wmgneweme | aman | OP [cmt

=a tea

[Regt] seg oa [ead | Pe

6.125 “6123 | 009 [6.099 °° |.o6 | 5.205 *22| 220 | 415

6250 § 8/628 °%| co7 |o.2c6 2% | oc |s7o4 1%] 157 | 250

6250 (4/6248 | 008 | 6.226 | oy |.o92 | 5.634 “fp) 247 | 908

6250 % 6.248 '%| 009 | 6.224 ~2% | one |s.4z0 | a20 | ats

fes7s 6573 2) oo7 feast 2 |.o30 | sec “22 as7 | 258

6375 (6373 | 008 [6951 2 | ose [5.750 °%| 247 | 908

fears ear | 009 [eas °° |.os [sss 19%] 20 | ais

6500 -% [6.40 | 007 [eae <2 | 000 |s.oee M6] 157 | 250

[e500 “6498 2] oe [ea7e ~2 | ose [sees 29) 247 | 200

‘6500 “| 6408 “| 009 [e474 °% | 096 | 5.670 “| 320 | a15

6.750 1 oip| 6.748 “fey | 007 | 6.726 ‘oy |.090 | 6.284 | oo) 167 | 258

[e7s0 ‘fal ere 25 | 008 [eras ‘52 | ose eos ‘| 247 | 200

|6750 ‘56.748 °%| oo9 | 6.724 “| 036 |5.920 °S2) s20 | a1

7.000 °%8 6998 °° | 007 | 6.976 ~% | 030 | 6.484 * fe] .157 | 258

7.000 *%! 6008 | 008 | e.e7e .2 | ose [ease “S| 247 | 08

“7000 “26.008 | oe [eave “8 | 006 [6.170 <1 20 | at

7.250 -2%| 7.208 °%] oor |7226 °& | 030 |e7ae 82] 157 | 250

7250 ©] 7.248 ~%%| oa 7.228 °% |.o92 |6eaa "| 2a7 | 208

7250 *%| 7.208 °%| o09 [7.224 “S| 096 [6420 °%%| 920 | ats

7500 | 7.408 °%| co7 [7.476 ~8 |.090 |eeea “(| 157 | 250

7.500 “24 7.408 °%8| cos [7.476 9 | ose |6eea "| 2a7 | 200

[700 ~22] 7408 *3| 009 [za7a SS |.oa5 | 6.670 *f%| 320 | ais

“Replace X's appearing in Giyd Ring Piston Assombiy No. colurnns with proper letter code as indicated. Eg.

28G00500A46 is a 28G Series Giyd Ring With Turel® A Elastomer and Turcite® 46 seal ring.

“Consult Catalog 16206 for Siydring install dimensi

16

| A PrstoN oiaMeTER B G

| 4

enoove

c Cy oo

| enoove

cumoes | wrnourstvonns vr styoRIN a | vo | OL

soneom | ‘novo eeanmes eToN BEANS 8

Da oo

es ee ee

ca ‘00 | 000 ‘000

| 7.750 in| 7.748 15% | 007 | 7.726 °° | 030 | 7.230 °%%) 187 | 258

7750 °°) 778 2) oo | 7726 "S| ose | 7304 ~%) 2ar | oe

on "000 co ~ oe

7.750 ° | 7.748 '%) 00a | 7-724 °° | 036 | 6920 °%| 320 | 415

8,000 | 5] 7.998 ‘Sm | 009 | 7.975 Ct" | 033 | 7.484%) 157 | 258

if + | +000, ‘00 oa]

8.000 5) 7.998 "33 010 | 7974 MO |.cge | 784°) ar | 308

| 000°) 7908 2) or | 7973S |.one | 7470 | azo | as

8.250 “‘fa| 8.248 °°! 009 | 8.225 °° | 033 | 7.734 7%) 157 | 258

@ (8250 25] e240 S| 010 | e204 "8 |.0a6 | 7.634 8) a7 | 308

ia a & | 030

a2s0 "| gave -%| 011 | 0220 | oe | 7420 | azo | ais

2600 "21 e498 S| 009 | 047s '%% | 009 | 7980 182] 57 | 258

2500 2%) e498 2%) o10 | e474 “% | one | 7aca | 2a7 | 00

2500 “| e408 28] o1t | e473 2 | ogo | 7.670 °°] 20 | ais

9.000 * too] 8998 “O55 | 009 | 8.975 °° | 033 | 8.484 “2% 457 | 258

9.000 *%5| seas 2] ovo | aor" | 036 | oes °°] 247 | 00

2.000 "21 seas "| or | 070% | ge | 0170 °22| 20 | ais

2500 12] e498 | 009 | 0475 2 | oss | oes °°) 67 | 250

. 9500 "| ess “S| oro | ear 0 | 0x6 | ee *™| a7 | aoe

2500-1 9.408 ST ort | aa7a °o% | 0x9 | 670 | a0 | ais

10.000 °°) 9.998 °°! oo9 | 9.974 * 034 9.484 °° 457 258

10.000 *°) g998 ~°°! o10 9.973 °°" | 937 9.384 °°! 247 | 308

ae aa 2 a=

© ro.000 8) e298 =] o11 | 970 2 | ov | erro 20) a0 | aie

I 004 +000 +.000 ++.909|

10.500 20.498 °°) cop [1a4ra = | og | oooe 28) 57 | 250

“Replace X's appearing in Giyd Ring Piston Assembly No. columns with proper leer code as indicated. Eg.

28G00500A46 is a 28G Series Glya Ring With Turel® A Elastomer and Turcite? 46 seal ring, 7

Consult Catalog 1/0206 for Stydring install dimensions.

Dimensional Data

aN ‘ Turcite Glyd Ring

Standard Sizes -

Radial Compression Pi ;

A PrsTON DIAMETER B G

cnoove

c Cy wor

cyunoer | wrHour strona wert svoRnG pa | soo | kL

Soatom ‘neToN Beans psroweeannes | Too

Dacr Dac

im tou | im Toh __Eass | Om. To. emax_| Om To

10.500 *%5|10.498 *%| o10 |10.473 °° | 097 | 904 °°) 247 | 308

008 00 900 co

10.500 “510.498 “$8 | 011 |10.470 “fy, | .042 | 9.670 | 5] 920 | 415

|r1.000 ©°°%/10.098 2°] 08 |10.974 °% [004 [10.404 | 157 | 258

11.000 ' 10.996 -%| .o10 [10.970 28 | 097 10.084 ' 2] 27 | 308

11.000 “%)10.998 8] 011 [10.970 6% |.o42 [10.170 | 320 | ais

11.500 “8]11.498 2°] 009 [11.474 <2 | oa4 [10.984 °%] 157 | 268

11.500 7 %8l11,498 - $80) o10 |14.473 "$2 | 037 10.884 fy| 247 | 308

11.500 %]11.408 -2%| 011 [11.470 18° | 042 |10.670 '%%| 320 | a5

ond 090 xo = 000

12,000 *%l11,998 '%| 009 [11.973 "M2 | 035 11.484 7) 157 | 258

+005 00 000 | 00

12,000 *l11,998 ° 2} o10 |11.973 “6 | 37 11.984 "| 247 | 308

12.000 °2*\11.998 8] ort [17.968 8 | o4a |t.a70 2] 320 | a5

oo 000 | cca ona

12.500 °%%|12.408 "| 011 [12.468 "0 | .o44 11.670 ”{%5) 320 | 415

I | 000 co ‘ee

13.000 “2%}12.998 "20 011 |12.968 “fie | 044 12.170 “ffy| 920 | 415

13500 °|13.498 =| ort [13.467 “8 | 46 [12.670 '%%| 20 | 415,

067 “20 900 ~ eo

14.000 *7l13,998 *2%| o12 [13.967 “2 | o46 |13.170 72%) 900 | 415

14,500 "°7l14.4o8 “9? | o12 |14.467 “tie | 046 |19.670 * S55) -320 | 415

or 00 co 00

15.000 °%7|14.098 79% | o12 |14.967 ‘ty | 048 [14.170 ' 05) 920 | 415

a7 =000 ca ooo

15,500 “715.498 °°] 012 |15.467 °° | 046 |14.670 28) 920 | 415

~ 7 “000 "08 "00

16.000 *"|15.998 °%| o12 |15.967 “| 046 |15.170 12%) 920 | .415

“Replace X's appearing in Glyd Ring Piston Assembly No. columns with proper letter code as indicated. Eg. 8

‘28G00500A46 is 2 28G Series Glyd Ring With Turel? A Elastomer and Turcite® 46 seal rin,

“Consult Catalog 1/206 for Slydring install dimensions.

18

Installation Data

Turcite Glyd Ring’ Piston Seals

INSTALLATION TOOLS

1 iy

00,

NOTE: Nylon or Dati” material's recommended for instalation tools,

*SHAMBAN wil design and fabricate a custom installation tool upon request.

STEP 1 ican andiubricate all gland hardware, Shamban seal components and installation tools.

STEP 2 Piacorubver (elastomer into gland assembly as shown in FIGURE A.

STEP 3 Piaceicading mandrel onto piston as shown in FIGURE A.

STEP 4 Place shamban Glyd Ring cap on loading mandrel as shown in FIGURE A

GLYO RING ELASTOMER GLYD RING CAP

’

=

PUSHER TOOL

& FIGURE A

Piston Seal (0.D.) ee

Turcite Glyd Ring’ Piston Seals

STEP 5

Push Shamban Glyd Ring cap up the loading mandrel and into the gland using the pusher

tool as shown.

GLYD RING CAP

tM

Ss

SN

LoaoiNG N

PUSHER TOOL

|

STEP 6

Remove loading mandrel and pusher tool from piston.

STEP 7

Push while twisting sizing tool onto Shamban seal assembly as shown.

PISTON: Le —sizine rine

STEP 8

Push while twisting piston into bore for completion of seal installation.

For More

Information Contact:

sSHAMBAN

Indust Sealing Syste rp

2531 Bemer Drive PO. Box 176

fort Wayne, IN £6801

Phone (219) 749

80. FAX (219) 7.

180016 728 ‘Pagid dena AS. Sona Conga

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Revista Tutorial 3d 2a EdicaoDocument80 pagesRevista Tutorial 3d 2a EdicaoFrank NunesNo ratings yet

- Relação Premiados - Salão de Humor e Artes 2014 - FinalDocument2 pagesRelação Premiados - Salão de Humor e Artes 2014 - FinalFrank NunesNo ratings yet

- Porca Din 439 BDocument7 pagesPorca Din 439 BFrank NunesNo ratings yet

- Tabela Parafusos Agosto 2003Document88 pagesTabela Parafusos Agosto 2003Frank NunesNo ratings yet

- BUSAK SHAMBAN Industrial - Sealing.product - RangeDocument52 pagesBUSAK SHAMBAN Industrial - Sealing.product - RangeFrank NunesNo ratings yet

- Flexitol GBDocument18 pagesFlexitol GBFrank NunesNo ratings yet

- Bombas VickersDocument1 pageBombas VickersFrank NunesNo ratings yet

- BOLLHOFF Nuestra Gama SPDocument8 pagesBOLLHOFF Nuestra Gama SPFrank NunesNo ratings yet

- Bomba F 02Document10 pagesBomba F 02Frank NunesNo ratings yet

- Catálogo de VedaçõesDocument17 pagesCatálogo de VedaçõesFrank NunesNo ratings yet

- Bomba F 01Document9 pagesBomba F 01Frank NunesNo ratings yet

- Atributos Formais DixonDocument6 pagesAtributos Formais DixonFrank NunesNo ratings yet

- Palavras CognatasDocument10 pagesPalavras CognatasFrank NunesNo ratings yet