Professional Documents

Culture Documents

Manual de Partes y Mantenimiento de Bomba CryoMach LOX

Manual de Partes y Mantenimiento de Bomba CryoMach LOX

0 ratings0% found this document useful (0 votes)

40 views28 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views28 pagesManual de Partes y Mantenimiento de Bomba CryoMach LOX

Manual de Partes y Mantenimiento de Bomba CryoMach LOX

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

<-

Prowl th

PHONE: (818) 765.6688

me goin rewire /

7306 GREENBUSH AVE. « NORTH HOLLYWOOD, CA 91605

FAX: (B18) 764-5749

E-mail: into@cqyomach.com

Wieb Site: wwaw.cryomach.cam

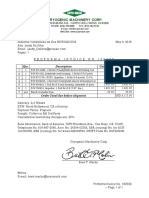

Bronze PRICED PARTS LIST WITH P/N’S NO. 721525-L3-B

Pump CRYOGENIC MACHINERY CORP.

Rev: 1/1/2002

TITLE: 15x2.5x10. MODEL: C-C-L 2T 200.059

ITEM] QTY] PARTNO. | DESCRIPTION PRICE FA., US$ [ NOTES,

T tf Motor with Special Shaft Call

3A |4_—_|HB816-13-1250_| Hex Head Bolt 4.00 Ib

3B 4 —_|HIB816-13-1500 | Hex Head Bolt 4.00 | With Pane!

4 [4 Jl waig-12s° | Lock Washer » 0.90 ng

3 |4 TEW816-063 Flat Washer 0.90 al

“6 [1 jor2-144 O-Rings 8.50

7a |i (960227 Intermediate Housing -2,689:00" | Bronze

eR [1 [960228 Intermediate Housing 4,294.00 |Bronze/SST

@ — {12 |ST816-13-2000 | Stud 7.50 | item 8 stud & nut 70

8 [12 |INS16-13 Hex Nut 0.90 fitem 8 stud & mat (0,4

9 |12 [Lwal6. Lock Washer , 0.90 iit

10/12 fFW816-063 | Flat Washer 0.90 ae

<1 fl [610-436 Gasket, Volute“ 2 + 38.00 a

12/1 |790612-7e70 impeller g 972.00 |+$120 trim/bal,

13° {1 {316-1400 Key 850

14 |i [sini06 Volute Housing 2,532.00

15 [1 [706210 Lock Washer, impeller 5.50

16 [1 [7007312 Impeller Screw 74.00

17 16 |HIB416-20-750 _| Hex Head Bolt - 2.50 S

18 16 |LW4i6-062 | Lock Washer, 075] 41S

19 1 930421 Labyrinth ~~ 2 674,00

20. {1 }706200 Shaft Shim 250

21a [1 [930419 Seal Housing, Labyrinth 2 1413.00 |3-port

tot gear +86} 2-por

22 |1_— [pat6.375 Pin 7.00

23 [1 [721029-7 Deflector 36.00

24 ft [s§8-32.312 Socket Hd. Set Screw 0.60

yo [4 ps-0-250 Drive Screw 0.75 OG ©

2d JL 4731003 Name Plate 49.00 Ja | GIE

DOSY

\

J

AS

“aN EO &

SY ESBSSS

a

> pies S

CRYOGEMIC MACHINERY CO.

NO. HOLLYWOOD, CA

CRYO-MACH 1.5x2.5x10.5,

MODEL: C-C-L

LABYRINTH SEAL PUMP

Prin be Pe gyes prnseo

CRYOGENIC: MACHINER’

7806 GREENBUSH AVE, * NORTH HOLLYWOOD, CA'91605,

PHONE: (618) 765-0688: FAX: (B18) 764-5749

E-mail info@eryomach.com

Web Site: ww eryornach.com

Bronze PRICED PARTS LIST WITH P/V’S _ |NO, 153105-L3-B

Puimp CRYOGENIC MACHINERY CORP.

Rae Rev: 1/1/2002

“TITLE: 1.5x3x10.5 MODEL: ~C-C-L 26 1 OO 29

1TEM nv] vant NO. [DESCRIPTION PRICE FA., US$ [NOTES

1 }G10-416 Gasket, Volute 38.00

2 |L Bstiasaz0 | Sate, 132600 ]+8120 trim/bal.

3 1. [g30902 Volute Housing Ass'y 4,140.00

4 1 $K416-1375 Key 9.00

5 1 |791219-3 Impeller Screw * 191.00

6 1 1791220 Lock Washer, impeller 9:00

7 1 1931123 Labyrinth 782.00

s 6 %. |SH10-24-500 Socket Hd. Cap Screw 2.50 [19

ae 6 |Lw10-047 Lock Washer 075 | 45

20 1 }P416-375 Pin 7,00

ib 1 (931120 Intermediate Housing 3,916.00

12 1 {800304 Insulator 44.00

13,1 [930728 Deflector 64.00

12 |B j8841620-250 | Socket a. Set Serew 0.80 | (1b

1A” |1 1122 ‘Seal Housing, Labyrinth ‘port

16 1 JOR2-151 O-Ring

7 L 1800215 ‘Shaft Shim

18 12. |ST816-13-2250 | Stad

19 [12° THINS16-13 Hex Nat

20. 16 |LW816-125 Lock Washer

21 16 fEw8i6-063_—| Flat Washer

22/4 {ERB816-13-1500

2B 41 |

39/1 |731018.

40 [4 |DS-0-250

Hex Head Bolt

‘Motor with Special Shaft

Name Plate

Drive Screw

Boupe do Oiguo de PO Cw

" veya Z2O1Y

CRYOGENIC MACHINERY CORP.

7906 GREENBUSH AVENUE * NORTH HOLLYWOOD, CA. 91605

PHONE: (816) 7656683 FAX: (818) 7648749

MAINTENANCE INSTRUCTIONS NO. 153105-L.

CRYO-MACH 15x 3x 10.5

MODEL: C-C-L PUMP

ELECTRIC MOTOR DRIVE

Praxair Venezuela

P.O. # 30539590 UP

Proj. # 16070B

SIN: 65026

<>

CRYOGENIC MACHINERY CORP,

7906 GREENBUSH AVENUE * NORTH HOLLYWOOD, CA. 91605

PHONE: (618) 7850888 FAX: (18) 7645749

MAINTENANCE INSTRUCTIONS NO. 153105-L

Bi .5 PUMPS

MODEL: C-C-L (Close Coupled)

‘These instructions must be followed every time pump is worked on. Read through these

instructions carefully and completely before working on pump. Prepare a clean area for

the disassembly of the pump. Cover the work bench with clean paper or a plastic sheet.

Be sure the tools are clean. For reference see drawing number 15310-L.

BEAI NT

Remove volute housing (3) by first removing nuts, lock washers, flat washers (19,20,21).

The volute gasket (1) is usually stuck on either the volute housing or on the intermediate

housing (11). Leave it there. Check bronze wear ring in volute housing for excessive

wear. Grooves in the wear ring are normal; however, they must not exceed .015 inch in

depth. Use judgment in estimating depth of the grooves. If the grooves should exceed the

maximum allowable of .015 inch, the wear ring should be replaced. Send the volute

housing to Cryogenic Machinery Corp. for wear ring replacement.

Using a dowel punch and hammer, bend the tab of the lock washer (6) out of the slot

provided in the impeller screw (5) with light tapping and remove impeller screw with an

Allen wrench. Discard lock washer. To prevent the shaft from rotating when removing

the impeller screw, hold the shaft by wrench flats.

Remove impeller (2) and key (4).

No. 153105-L * Rev. 9/18/00 * Page 1 of 5

Remove screws and lock washers (8,9) to remove seal housing (15). The labyrinth (7) is

likely to come out with seal housing. Remove “O” ring (16) and discard. Caution: the

labyrinth should be removed together with the seal housing. ‘The goal here is to prevent

the sheering off of the seal housing’s inner lining that has formed around the labyrinth

teeth, If needed, use a flat screwdriver behind the labyrinth to gently pry it loose from the

shat

Check bronze wear ring in intermediate housing for excessive wear in same manner as

\ear ring in volute housing. Replace wear ring if wear is excessive.

If the labyrinth did not come out with the seal housing remove it from the shaft now.

Remove shatt shim (17) and discard.

Use a center punch to mark the top of intermediate housing with respect to top of motor

(23). Remove bolts, lock washers and flat washers (20,21,22). Carefully remove

intermediate housing and insulator (12). Light tapping may be required to get

intermediate housing off the motor. Note any shim(s) behind intermediate housing and

their location on the motor “C”-face and write this down.

Loosen set screw (14), remove deflector (13) and pin (10).

Measure an axial dimension from the face of the motor to a shaft shoulder. Use a vernier

and a parallel bar to obtain this dimension, Record this dimension.

Itis recommended that the motor be sent to a reputable repair shop for check out and

bearing replacement. The following instructions must be given for the motor repair

@) When disassembling motor observe the possible use of shim(s) between the pump

end bearing and bearing cap. These shims must be put back in the same position at

reassembly,

b) Use only an arbor press when removing and installing beating from or onto the

shaft. NEVER APPLY ANY FORCE ON OR NEAR THE SHAFT SEAL

SHOULDER (shoulder at 1.15 inch diameter) or on the small end of the shaft. Use

the shaft shoulder at the wrench flats.

No. 153105-L * Rev. 9/18/00 + Page 2 of 5

Me

12.

13.

14.

15

<>

©) Bearings must be lubricated with a low temperature, and in some cases oxygen

compatible grease approved by customer. (Bearings can be ordered from CRYO-

MACH prelubricated with approved grease.)

d) Clean motor parts inside.

After bearing installation and assembly, check dimension measured in Paragraph No. 9.

Dimension must be the same #004 inch,

Check shaft runout per CRYO-MACH Handbook: "Pump Precision Checkout.”

Assemble pump by first installing pin (10) and deflector with set screw (13,14).

For 256 frame size or smaller motors, being extremely cautious, turn motor in an upright

position by setting the unit on back end. For frame sizes 284 and larger and blower cooled

(TEBC) units the motor should remain in the horizontal position due to its size, weight

and/or rear end bell/fan housing.

Install new shaft shim (17) onto shaft.

Use Molykote 321 Thread Lubricant (Dow Corning) or equivalent on all threads. This

lubricant is oxygen compatible and it is approved for oxygen service by the military

services,

Place intermediate housing (11) and insulator (12) onto motor “C” face. Install shim(s) if

used behind the intermediate housing and make sure to put them back in the same

location(s) from which they were removed. For 256 frame size or smaller motors loosely

install bolts, lock washers and flat washers (20,21,22). For frame sizes 284 and larger and

blower cooled (TEBC) motors dial in concentricity and perpendicularity per Maintenance

Instructions No. PPC-L “Pump Precision Checkout”

Install labyrinth (7) onto shaft, lining up slot with pin (10). If the labyrinth came out with

seal housing (15) in step 4, skip to step 17 now for careful installation together with seal

housing,

NOTE: Included with a new labyrinth is a honing tool. When a new Labyrinth is

received, check to see if it slips smoothly onto shaft. If it does not, then this tool

No. 153105-L * Rev, 9/18/00 + Page 3 of 5

17.

18.

19.

<>

must be used to polish the LD. of the Labyrinth to make a smooth slip fit onto

shaft. When using honing tool, submerge the labyrinth and honing tool into

solvent or light oil. Be sure not to use the honing tool excessively or the bore

will become oversized. This will scrap the Labyrinth. Be sure to thoroughly

clean the Labyrinth before attempting to install it.

Use a liberal amount of oxygen compatible (approved by your company) grease on “O”

ting (16). Place new “O" ring on back side of seal housing, pushing it all the way to the

flange. Carefully insert seal housing into intermediate housing and over labyrinth, slowly

moving intermediate housing from side to side while guiding seal housing if 256 frame

size or smaller motor. For frame sizes 284 and Jarger and blower cooled (TEBC) motors

slip the seal housing into the intermediate housing without re-dialing in. In some cases the

bolts, lock washers and flat washers (20,21,22) must be loosened to allow seal housing to

slip into intermediate housing and then re-tightened. The most important thing is to have

the seal housing centered (concentric) with the labyrinth. Therefore, the ultimate goal is to

dial in the intermediate housing so that the labyrinth seal turns the freest. Be sure that seal

housing is properly aligned to slots in intermediate housing (if applicable) to allow gas

Port accesses. CAUTION: Take extra care not to damage the lining in the LD. of the seal

housing with the labyrinth teeth, NEVER USE FORCE,

Install screws and lock washers (8,9) and torque to 108/120 In.-Lbs.

Torque bolts, lock washers and flat washers (20,21,22) holding intermediate housing to

motor “C”-face to 500/540 In.-Lbs. Spin shaft by hand to ensure smooth rotation with

minimal rubbing of labyrinth against seal housing. If excessive rubbing occurs, loosen

bolts holding intermediate housing, tap intermediate housing on the high indicator side to

reposition seal housing in such a way that only minimal or no rubbing occurs and re-

torque bolts. Repeat until there is minimal or no rubbing. Note: minimal rubbing is

considered to be when the intermediate housing is dialed in such that the labyrinth seal

turns the smoothest. Shaft can be turned by hand at the deflector

No. 153105-L * Rev. 9/18/00 + Page 4 of 5

20.

21

22,

23.

24,

25.

<=>

Install impeller (2) and key (4).

Slip a new lock washer (6) onto the impeller screw (5) and position the pre-bent tab into

the slot of the impeller screw. Do not reuse lock washers.

Install lock washer and impeller screw. When installing impeller screw make sure the bent

tab of the lock washer remains in the slot. Torque impeller screw to 210/240 In.-Lbs.

Position a tab of the lock washer over the slot provided in the impeller by further

tightening impeller screw if not already aligned. Using a dowel punch and a hammer,

bend this tab into the slot by light tapping. There must be a clearance of over .120 inch

between the back side of the impeller and the intermediate housing. A smaller clearance

of .050 to .080 inch between the back of the impeller and the bronze wear ring is

sufficient.

Install volute gasket (1) and volute housing (3) with bolts, lock washers and flat washers

(19,20,21). Torque nuts to 500/540 In.-Lbs.

Proceed to Start-up, Installation and Run-in for Pumps with Labyrinth Seal No. SI-1 Rev.

7/3100.

No. 153105-L + Rev. 9/18/00 + Page 5 of $

PARTS LIST

FOR 1.5x3x 10.5 PUMP

MODEL: C-C-L

SEE DRAWING NO. 15310-L

Item Description Quantity

1 Volute Gasket 1 |

2 Impeller i

3 Volute Housing Assembly 1

4 Key 1

5 Screw, impeller 1

8 Lock Washer, Impeller 1

7 Labyrinth 1

8 Socket Head Screw 6

9 Lock Washer 6

10 Pin 1

a Intermediate Housing Assembly 1

12 Insulator 1

13 Deflector 1

14 Set Screw, Socket Head i

15 Seal Housing 1

16 “O” Rin 1

17 Shim, Shaft Hl |

18 Stud 12

19 Nut 12 |

20 Lock Washer 16 |

21 Flat Washer 16 i

22 Bolt, Hex Head 4 |

23 Motor/Shaft 1 |

When ordering spares for this pump, please refer to:

CRYO-MACH 1.5 x 3x 10.5 Pump, Drawing Number 15310-L,

Pump Serial No. Call out Item No. and Description as above,

Order from: CRYOGENIC MACHINERY CORP.

7306 GREENBUSH AVE.

NORTH HOLLYWOOD, CA 91605

TELEPHONE: (818) 765-6688

FAX: (818) 764-5749

EMAIL: INFO@CRYOMACH.COM

No, 153105-L. |

€8159}20,20)

16)

(15)

13, (14

elsotesi# "wNd] 26-Se-s a7e

did I-9-9 }T3GON $°OTXEXG*T

AWOd~€ TWAS HINTYARYT

BNINVUG _NOLLVTIVISNI

VINYOATTY9 “GOOMATION “ON

"d¥09_AYANIHOWA_JINISOAYD,

ae

aa NOTLOIS

WW =NOTIORS

Ad 48/1

dod, “SSRI “TWAS

: =

AGN wb/T LGN wt/T

AYO. 289A, +} AuOd 'S¥9 Was

<>

CRYOGENIC MACHINERY CORP.

7306 GREENBUSH AVENUE * NORTH HOLLYWOOD, CA. 91605

PHONE: (810) 76558568 FAX: (818) 7049749

MAINTENANCE INSTRUCTIONS NO. PPC -L

PUMP _ PRECISION CHECKOUT

LABYRINTH SEAL PUMPS

‘SHAET_RUNOUT

‘The shaft runout should be measured at every bearing change. Shaft runout measurement

consists of two steps:

1. Check the runout of the portion of the shaft where the impeller is positioned (shown

below), by placing a dial indicator at the shaft diameter and rotating the shaft 360 degrees.

For pumps over 3600 RPM speed the maximum shaft diameter runout allowed is .0O1S

inch Total Indicator Reading (T.1.R.)

For pumps up to 3600 RPM speed the maximum shaft diameter runout allowed is .002

inch TLR.

Shaft Runout; Step 1

PPC-L- Page 1

<>

2. — Check the runout of the shaft shoulder against which the shaft shim is positioned (shown

below) by placing a dial indicator on the face of the shoulder and rotating the shaft 360

degrees. The maximum T.LR. allowed for pumps over 3600 RPM speed is .0005 inch.

For pumps up to. 3600 RPM speed allowable T.LR. is .001 inch.

Seal Shoulder Runout; Step 2

NOTE: If T.LR. is excessive for the above measurement the shaft must be reworked or

replaced.

SING 3S

Housing squareness should be measured whenever the intermediate housing is removed from the

motor. Mount:a dial indicator on the shaft and rotate the shaft, with the dial indicator, 360

degrees around the face of the intermediate housing as shown below. The maximum allowable

reading is 005 inch T.LR. on all pumps.

if there are shims in between the back

NOTE: In disassembling the intermediate housing, noti

face of the intermediate housing and the motor. The shims may be needed in the same

location when reassembling the intermediate housing.

PPC-L- Page 2

Housing Squareness Measurement

If the squareness of the intermediate housing is not within the allowable limits, shims must be

used. It is suggested that a package of shim assortments ranging from .001 inch to .010 inch be

obtained, preferably of brass material,

Always shim the intermediate housing at the mounting bolts as shown below.

Shimming of Intermediate Housing

PPC-L- Page 3

>

‘Take dial indicator readings close to the mounting holes. Set the dial indicator to zero where the

face is the highest. The other three readings at the three mounting holes will show what

thickness of shims should be used to correct the squareness of the intermediate housing

HOUSING CONCENTRICITY.

Measure housing concentricity when housing is removed from assembly as shown below.

Mount a dial indicator on the shaft and rotate it 360 degrees around the fitting diameter of the

housing. The maximum allowable total indicator reading is .005 inch for all pumps. If

Concentricity exceeds this limit, the following adjustments should be made.

With the use of a dial indicator, observe which way the intermediate housing should be shifted

for correcting concentricity. Set the dial indicator in that position. Loosen the mounting bolts

and with the use of a soft hammer, tap the intermediate housing to bring the runout within the

tolerance. You will have to determine how tight the mounting bolts should be installed in order

to permit the intermediate housing to be shifted with soft tapping.

Housing Concentricity Measurement

PPC-L- Page 4

<>

NOTE: Please bear in mind that the intermediate housing needs to be shifted by only half of the

total indicator reading to correct for eccentricity.

If the intermediate housing needs to be adjusted both ways (for squareness and concentricity),

always adjust for squareness first.

PPC-L- Page 5

CRYOGENIC MACHINERY CORP,

7306 GREENBUSH AVENUE

NORTH. HOLLYWOOD, CA 91605

Email: info@cryomach.com

Web Site: www.cryomach.com

° INSTALLATION

° SAFETY

© OPERATION

INSTRUCTIONS

CRYOGENIC CENTRIFUGAL PUMP

INSTALLATION

Storago

Handla the Pump carefully in moving it about prior to

Installation. f not installed Immogiatoly, store it In & dry

lecation and protect from of, dust, or molsture. Do not

remove the covers ffom the suction’and discharge flanges

‘ntl the piping i ready tobe Dotted to the Pup. Rotate the

Pump sha perodaly to keep tne moving parts coated wih

Location and Mounting

Paco the Pump es close as possibe tothe cryogenic uid

supply. Allow room for Inspection during operation. Loca

the Pump in a space which is wall ventlated. Pasian

‘ig, level foundation, using the largest possible bate.

volute assembly may be roteted to any postior

baltpat th

Instaliaton drawing,

Piping

‘Lay ou the pling n accordance to the Instlaton Diagram.

Giean the plping theroughy to remove foreign matter such

18 dif, scale, welding shot, groase, ol, wale, or pipe joint

wore

Rind ust

an are

65890 He axl

fang, 01000" Inch

rasa.

stool Ig 00 Drile at tow

xe metaltose sections adjacen! to fete

‘and discharge flanges of ihe Pump so as not lo exceed 80

pounds free or 60 feotpounds torque on the Pump casing

‘during Insiallation, cooldown, or pressurization. Fallure to

Include these expansion provisions will vold tho warranty

‘because t wil reeul in dstetion of tho casing and possi

rubbing damage to the impale. ts good practic to serure:

‘tho Pump to the foundation and thon fo connect ho piping to

tho Pump for algrment while the final ploing welds are being

made at a point removed from the Pump. In ts Way,

tmisalignment is teken up In the walds, not In distortion of the

Pump casing,

Use plpe at feast the same size as the Pump suction for

"a VENT VALVE ‘

THe OUTLET VALVE GATE

STRAINER

Rev. 4/26/02 ~ Page 1 of 2

<>

MAINTENANCE GUIDE (TROUBLESHOOTING)

Until the operating personnel become familiar with the pump, the following

are the most probable causes of operational difficulties.

Trouble Possible Cause [Correction

Pump will not prime [Wrong rotation Check direction of rotation

Insufficient NPSH Increase NPSH

Liquid not delivered [Pump not primed Increase NPSH

Vapor pocket in suction line

[Check for low points in suction line

Failure to deliver

rated capacity and

pressure

insufficient NPSH

increase NPSH

Wrong rotation

[Check direction of rotation

Loss of suction pressure

increase suction pressure

Impeller or Volute passages

clogged or inlet restricted

Disassemble, inspect and clean

Wear rings worn Replace

Impeller damaged Replace

Vapor in liquid Increase NPSH

\Vapor pocket in suction line

[Check piping for continuous slope. No

point should be lower than pump inlet.

Total head greater than head

Htor which pump was designed

Cut impeller dia. and re-balance

impeller for fixed speed pump. Redvice

speed for trailer/variable speed pump.

Pump overloads

river

Drive failure

Repair or replace driver

|Flow greater than rated flow

(Cut impeller dia. and re-balance

impeller for fixed speed pump. Reduce

[speed for trailer/variable speed pump.

Pump vibration

Insufficient NPSH

Increase NPSH

Vapor In liquid Inorease NPSH

Worn bearings: [Replace

Damaged rotating element Replace

Foundation not rigid Increase support

[Pump operating below Increase flow

minimum recommended flow

Impeller clogged

Disassembie, inspect and clean

Impeller rubbing

Impeller not tightened

securely on shaft

Tighten impeller screw

Bearing failure

Replace bearings, inspect/replace

impeller, seal and wear rings

[Excessive pipe loading

Ellminate pipe loading in warm and

(cold conditions

Leakage between —_|Volute gasket Replace

pump casings

Excessive seal [Sealing surface on seal or Replace seal assembly and rotating

leakage rotating ring damaged or worn _|seal ring

Impelier not tightened

securely on shaft

Tighten impeller sorew

<>

CRYOGENIC MACHINERY CORP.

7306 GREENBUSH AVENUE * NORTH HOLLYWOOD, CA. 91605

PHONE: (1a) 705-6808 FAX: (18) 7645749

START-UP, INSTALLATION AND_ RUN-IN

FOR PUMPS WITH LABYRINTH SEAL

For new pumps please proceed to the installation and start-up procedures below. For used

pumps where a seal was removed and reinstalled or where a new seal is being installed please

proceed to the labyrinth scal run-in procedure on page 4,

‘The installation of pumps with labyrinth seals is the same as its for pumps with mechanical

seals (see CRYO-MACH “Installation, Safety and Operation Instructions”). We cannot empha

size enough the importance of the “free rotational cheek”. ‘The pump was tested for free rota-

tion at the factory and at the time of its release no binding or metallic noise was observed.

‘The labyrinth seal housing has been supplied with 1/4” NPT taps for seal gases & vent and a 1/8”

NPT tap for pressure sensing and/or pressure gage,

Use only brass pipe nipples for connections to the labyrinth seal housing. Use extreme care

when installing the pipe nipples. Breaking or cross threading the pipe threads at the labyrinth

will be an expensive mistake. Never over-tighten pipe nipples into taps as this can cause the

seals to bind, requiring the seal to be run-in again.

3/8” bing should be used from the nipples (not at the labyrinth housing itself) to provide a

sufficient flow rate for the sealing gases and vent.

Connect 3/8” tubing from labyrinth seal control panel to labyrinth seal pipe nipples. See

labyrinth seal schematic (P&ID) and piping installation drawing,

Rev. 2, 9/14/00 -- LABYRINTH SEAL PUMP NO. SI-l -- Page I of S

<>

Ifthe sealing gas/gases come from high pressure vessels (high pressure is considered to be 50

PSI or more over the pump’s suction pressure) use two pressure reducers (regulators). First; to

reduce from high pressure to 40-50 PSI over the suction pressure, Second; to reduce this pressure

to the required sealing gas pressure.

‘One may wish to use a 4-10 foot long copper tubing coil to reduce icing on the vent line. If

‘condensation gets into the line and hence into the seal it can freeze the seal and cause damage.

START-UP

‘Single Gas Labyrinth

1, Make sure that motor is locked out if TEFC (totally enclosed fan cooled). Have an

electrician check lock out phase of motor. Remove fan cover from the end of motor. If the

motor type is TEBC (totally enclosed blower cooled) do not lock out motor or remove fan

cover. Turn the fan of TEFC motors by hand. For TEBC motors turn the pump shaft

either by hand around the deflector through the pump’s openings or if this area is

inaccessible by “bumping” the motor (starting and stopping the motor).

2. Check for free rotation, Rotation must be absolutely free. If free rotational check fails,

the piping is producing unacceptable stresses on the pump and must be corrected.

3. During cool-down of pump, slowly increase sealing gas pressure only until there is no

more liquid leckage.

4, When pump is cooled down, check for free rotation by turning motor fan at the end of

motor (or pump shaft as above). If rubbing occurs, turn motor fan until labyrinth turns

freely, Note: slight rubbing is acceptable. If motor fan cannot be tumed (do not use

excessive force), free rotational check has failed,

5. If free rotational check fails, start up procedures must stop. It indicates that cooling down

piping and pump introduces unacceptable stresses. Therefore, the piping must be checked

out and corrected.

Remember; the pump has been checked out for free rotation at the original installation and

at the start up in warm condition,

If the piping required correction, repeat all above steps.

7. If the pump rotates freely, reassemble motor fan cover,

Rev. 2, 9/14/00 -- LABYRINTH SEAL PUMP NO. SI-1 -- Page 2 of 5

After cool-down is completed make sure valves are set up to let the pumped liquid

advance either to its destination or to recirculate.

Start motor and observe if there is liquid leakage, Reset the sealing gas pressure if neces-

sary. In most cases 2-8 PSI sealing pressure higher than the gage pressure of the

labyrinth seal or the suction pressure will be sufficient.

Remember: the sealing gas pressure used should be the minimum required to prevent

liquid leakage.

Make sure that motor is locked out if TEFC (totally enclosed fan cooled), Have an

electrician check lock out phase of motor. Remove fan cover from the end of motor. If the

motor is TEBC (totally enclosed blower cooled) do not lock out motor or remove fan

cover. Turn the fan of TEFC motors by hand. For TEBC motors turn the pump shaft

either by hand around the deflector through the pump’s openings or if this area is

inaccessible by “bumping” the motor (starting and stopping the motor).

Check for free rotation, Rotation must be absolutely free. If free rotational check fails,

the piping is producing unacceptable stresses on the pump and must be corrected.

During cool-down of pump, make sure the vent gas line (the middle 1/4” NPT gas port) is

open/unrestricted. Leave the second port sealing gas (the aft 1/4” NPT gas port) closed.

Slowly increase the first port sealing gas pressure (the forward 1/4” NPT gas port) only

until there is no more liguid leakage.

When pump is cooled down, check for free rotation of pump by turning motor fan at

the end of motor (or pump shaft as above). If rubbing oceurs, turn motor fan until

labyrinth turns freely. Note: slight rubbing is acceptable. If motor fan cannot be tumed

(do not use excessive force), free rotational check has failed.

If free rotational check fails, start-up procedures must stop. It indicates that cooling down

piping and pump introduces unacceptable stresses. Therefore, the piping must be checked

out and corrected

Remember: the pump has been checked out for free rotation at the original installation and

at the start up in warm condition,

If the piping requited correction, repeat all above steps.

If the pump rotates freely, reassemble motor fan cover.

After cool-down is completed make sure valves are set up to let the pumped liquid

advance either to its destination or to reciroulate.

Rev. 2, 9/14/00 -- LABYRINTH SEAL PUMP NO. SI-I -- Page 3 of 5

9. Start motor and observe if there is liquid leakage. Reset the frst port sealing gas pressure

if necessary. In most cases 2-8 PSI sealing pressure higher than the gage pressure of the

labyrinth seal or the suction pressure will be sufficient.

Remember: the sealing gas pressure used should be the minimum required to prevent

liquid leakage.

10. Set the second port sealing gas to 10 PSI.

LABYRINTH SEAL RUN-IN PROCEDURE

Introdu

Because a new seal must be shipped in new condition, it is not yet broken-in. The only way to

break-in a seal is to install it into the pump in which it will be used, This is because of the

manufacturing tolerances that may yield small variations in axial distance from pump to pump

and/or different fits between the shaft and labyrinth LD. (a honing tool is supplied for proper fit

between the shaft and labyrinth LD, for this reason). Therefore, the seal cannot be broken-in at

the factory uniess the pump/motor that it will be installed in is sent to Cryogenic Machinery

Corp. In most cases a new seal will need to be broken-in at the site, Note: often when a used

seal is removed for a motor bearing change and then reinstalled some rubbing occurs. It is.

therefore good practice to run-in the seal again,

‘The break-in procedure for a new seal is as follows. Please read all instructions before

proceeding.

Set Up

1, Install seal per pump maintenance manual. Check free rotation.

.__A.small low pressure liquid nitrogen container (160 liter) will be needed near the pump.

3. Plug the 1/8" NPT reference pressure seal port, Leave all 1/4” NPT seal ports open. See

piping installation drawing,

4, Prepare a blank flange for the pump discharge with a through hole and fitting to connect

your 3/8” tubing. Install the LIN line from the container to pump discharge flange.

5. Prepare a blank flange for the pump suction with a 3/8" minimum through hole. Install to

pump suction flange. Stay clear of pump suction. Optional: you may wish to connect

Rev. 2, 9/14/00 -- LABYRINTH SEAL PUMP NO. SI-i -- Page 4 of 5

<>

tubing (3/8” minimum LD.) to the suction flange and direct it to a safe location away from

people.

Break-in Procedure

1, Start the pump for approx. 10 seconds and then stop it.

2. Open the nitrogen container valve to let liquid into the pump. Wearing protective gloves,

rotate pump shaft by hand until rubbing can be felt. Remove hand from pump shaft area

and close container valve.

3. Run the pump for approx. 10-20 seconds.

Check for free rotation. If you do not have free rotation repeat steps 3 and 4.

5. Ifyou have free rotation repeat steps 2 through 4. Repeat until pump has free rotation and

is completely frosted up (the same amount of frosting as you should see after a proper

cool-down during normal operation).

6. Be sure to remove all condensation from seal before pump installation,

7. The pump is now ready to install. Install pump per installation procedure starting on page

1 and follow start-up procedures starting on page 2 of this manual.

IMPORTANT: After installation remember to check for free rotation in a warm state and

again in @ fully cooled down state to ensure that there are no piping strains on pump.

Rev. 2, 9/14/00 -- LABYRINTH SEAL PUMP NO. SI-1_ ~~ Page 5 of 5

x] Saal solesio. |v s1oesgereo

33

dWNd 19-9 40

"GOW

809 ENV OREOOND || 99 ENG

cen ossees0e # 04]

‘yoreauon fog

SLNIW3YONI 406 ©

B3ONV1S3OBVHOSIO SIVIOS AV

(dN) LINANOD 3zIs WY.

"BONY $81 006.5" SIHOIWW YOIHL $7°0 3OURIO BONVHOSIA

NMOHS LON OnBIHS CIOS Ol 1vas WON ONIN :s310N|

HOS S¢ ‘3O¥Nd 3DaId SONVISIA

THOS/HAe/AOGE FIMOd YOLOM

HIDS S-£ "XW O'Sd ZI BDUNd SYD YOLOW

‘dH @'0 “SEV £°1 ‘S4AY 9°Z "THOP/THOS/HAL/NOEZ/ASL :83MOd YOLOW YIMOTR

“BSVIAO 8 TROW ‘NOLVOIVAM

“SH 0”977 8 9 9ZI "$048. IAO 8 AO FNGIHOS NOUWOREM GIGNSAWODSE

"NIG $8000" "F8IM 9 WANUY Id COOL :NOUOAIIG AVI1 13S 8 “Oe IC YOY Gla INBWIT TWA.

"OWS Oe Fav

‘981 006 HOM

‘SBFLI 0S 9 “SE 0 SONIOVOT SONYU TTEVMOTY KYW

S3HONI NI SNOISN3WIG

(08a) YOLOW AII009 ¥aMOTG G3SOTONS ATIVIOL

‘salon

1ert [002 [970 [OO

oo [eo | OB] ree [ary | vor [voweE] OF

w [wilets

1 tsyvots fa] v lawal on

Tals 10D.

A pveeaee (savan wsnors)

: 1 —_4 (SSN

‘MddIN eld OS"

“FEISNY S81 006-S'19\ dvI3ONs YOIOW)

SONVH 3OaViIOSI ZN LAN W/E

=

©

"s3008d LAN

"s$3904d LAN

SONVT NC

v

“GHNNOS al

(xvwol omy

EIVUNGNOD IAN P/E)

“GH'NNOD dial ‘O¥8 30

(xv ol omy

IQNOD LAN 7/€)

Ia va WS

{ONILUd NOISSI4dWO:

HIIM 3871 ¥add09 8/6)

08nd ZN Da “1510

u 17002056 a aul

SNIIYW TRG “KINO "#38 YO SSTOH Us

TAINO “wa/iss FOLXGexS | be

oe 3

SOEs] oxpre a) arom

“ASV CTBIHS GIOD Fea marr

ro a=55|

30916 VS COOMATION ISON | asncto rere

‘JOD ABSNHOWW SINBSOMO.

‘219s 60d POBH 199505 1x02-4/1

“OSH WRBINI ka

e/e|

e/a]

9}04 “BIUI/M 38ND 4

Jeuur PieUs PIED]

=] — Jeu fev] eu) =|] ev) ex/ st] co] ov 13

NOUdiIOS30

NOUV TIVISNI CIB’ ONIN SION XO8 TIOD

€ DSL

"BION

e

aAlegt |

IAL GELL

ed SEE

|} aarevar

QBLOINNOO VITZG HO BNA ‘SQVIT ¢ ‘AS ‘Hee

NMOHS S¥_qa¥3eNNN

3a ASW SQV) “WNOLLdO 3a¥ SHOTGD av;aT ‘Ss

‘AaWA AVI

SUINOMIO TSTIVS¥d IWNSGINI 40 YBN IWALOV “>

‘Oa1d103aS

NBHM G3QNO%d BBY SLVISONYZHL TWNOUGO '¢

“NOUWLON

BSYBARI OL SOVIT NM OML ANY JONVHOMSLNI 'Z

GBLOANNOO W113G YO G3L93NNOO

3AM YBHLG 39 AVN YOLOM GV37 338HL “1

‘S310N

ann

900009 7

oe cp0006

© 7 Sehizi0 war] zow 66/1¢/10 o3SKa8] Jr AE] OL AH

8 0) OlALOaTaA AOdIva SOTO) WNOUO ROWS OF SAIN Bs30 Aa

8

8 e20s9.106]

a0c09 seat

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Reporte 45006.1 Mantenimiento A Motor Electrico de Comp FEEDDocument13 pagesReporte 45006.1 Mantenimiento A Motor Electrico de Comp FEEDAsesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- Limpieza de Los IC Del Comp Feed Mayo. 2016Document10 pagesLimpieza de Los IC Del Comp Feed Mayo. 2016Asesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- Falla Motor Comp. Feed. Junio 2016Document6 pagesFalla Motor Comp. Feed. Junio 2016Asesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- PRO180509 Industria Venezolana de Gas INVEGASDocument1 pagePRO180509 Industria Venezolana de Gas INVEGASAsesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- Sullair 3225 John Crane Seal & AdapterDocument2 pagesSullair 3225 John Crane Seal & AdapterAsesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- Sulair Cabo 001-02Document4 pagesSulair Cabo 001-02Asesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet

- Brazil Sullair Rebuild ReportDocument2 pagesBrazil Sullair Rebuild ReportAsesoramiento y Servicios Múltiples S.A.R, C.A.No ratings yet