Professional Documents

Culture Documents

Aço Especial de Engrenagens 20CrMnTi

Uploaded by

Edson FelixOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aço Especial de Engrenagens 20CrMnTi

Uploaded by

Edson FelixCopyright:

Available Formats

OTAI SPECIAL STEEL is 20CrMnTi bearing/Gearing steel stockholders and

suppliers from china. more 16 years experience in GB 20CrMnTi steel

supply.

GB 20CrMnTi bearing/Gearing steel is GB standard Alloy Carburizing

Bearing/Gearing steel, GB 20CrMnTi properties is a chromium,

manganese, titanium alloy steel specification. 20CrMnTi is equivalent

with others standard bearing/Gearing steel, gearing steel. 20crmnti

steel properties as below:

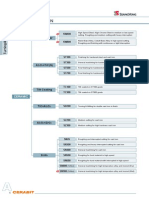

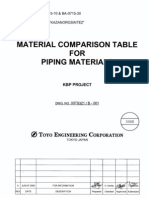

Related Specifications ASTM A29/A29M EN 10083/3 JIS G4053 GB/T GB/T 3077-

1988

Form of Supply

GB 20CrMnTi bearing/Gearing steel, we can supply the round bar, steel

flat bar, plate, hexagonal steel bar and steel square block. GB

20CrMnTi steel Round bar can be sawn to your required lengths as

one offs or multiple cut pieces. 20CrMnTi bearing/Gearing steel

Rectangular pieces can be sawn from flat bar or plate to your

specific sizes. Ground tool steel bar can be supplied, provide a

quality precision finished bar to tight tolerances.

Round sheet Square Plate

Chemical composition

0.95~ 0.25~

C(%) Si(%) 0.15~0.35 Mn(%) P(%) ≤0.025

1.05 0.45

S(%) ≤0.025 Cr(%) 1.40~1.65

Heat treatment Related

① Annealing of 20CrMnTi Alloy bearing/Gearing steel

Slowly heated to 790-810 ℃ and allow enough times, let the steel to

be thoroughly heated, Then cool slowly in the furnace. Different

annealing ways will get different hardness.The 20CrMnTi

bearing/Gearing steel will get Hardness MAX 248 HB (Brinell

hardness).

② Quenching and temperature of 20CrMnTi Alloy bearing/Gearing steel

Heated slowly to 788°C, Then put in salt-bath furnace keep 1191 ℃to

1204 ℃。quenching by oil get 60 to 66 HRc hardness. High

temperature tempering: 650-700℃,cool in air, get hardness 22 to

30HRC. Low temperature tempering: 150-200 ℃, Cool in ari, get 61-

66HRC hardness.

③ Hot work and cold work of 20CrMnTi Alloy bearing/Gearing steel

GB 20CrMnTi steel can hot worked at 205 to 538°C, 20CrMnTi

Bearing/Gearing steel can be cold worked using conventional

techniques in the annealed or normalized conditions.

Mechanical Properties

The mechanical properties of annealed GB 20CrMnTi bearing/Gearing

steel (typical for steel) are outlined in the table below:

Poisson Thermal

Bulk Shear

Tensile Yield ’s conductivit

modulus modulus

ratio y

MPa Mpa Gpa Gpa W/mK

0.27-

520 415 Min 140 80 46.6

0.30

Applications

GB 20CrMnTi steel is widely used for a variety of applications in the

used to the bearing/Gearings in rotating machinery. Typical

applications such as valve bodies, pumps and fittings, the high load

of wheel, bolts, double-headed bolts, gears, internal combustion

engine. Electric locomotives, machine tools, tractors, steel rolling

equipment, boring machine, railway vehicle, and mining machinery

transmission shaft on the steel ball, roller and shaft sleeve, etc.

Regular size and Tolerance

1) Hot Rolled round bar

Diameter Diameter Tolerance Diameter Diameter Tolerance

(mm) (mm) (mm) (mm)

≤12.70 -0.13 ~0.30 >50.80~63.5 -0.25~0.76

12.7~25.40 -0.13~0.41 >63.50~76.20 -0.25~1.02

>25.4~38.10 -0.15~0.51 >76.20~101.60 -0.30~+1.27

>101.60~

>38.1~50.80 -0.20~0.64 -0.38~3.81

203.20

2) Hot Rolled steel plate

Thickness Thickness Tolerance Thickness Thickness Tolerance

(mm) (mm) (mm) (mm)

≤25.4 -0.41~0.79 >127~152 -1.60~2.39

>25.4~76 -0.79~1.19 >178~254 -1.98~3.18

>76~127 -1.19~1.60 >254~305 -2.39~3.96

Others 20CrMnTi have not specified size, pls contact our experienced

sales team.

Processing

GB 20CrMnTi bearing/Gearing steel round bar and flat sections can be

cut to your required sizes. 20CrMnTi bearing/Gearing steel ground bar

can also be supplied, proviGBg a high quality tool steel precision

ground tool steel bar to your required tolerances. GB 20CrMnTi steel

is also available as Ground Flat Stock / Gauge Plate, in standard and

nonstandard sizes.

Contact our experienced sales team to help you with your 20CrMnTi

bearing/Gearing steel questions and enquiry by Email or

Telphone. The questions will be reply in 24 hours.

OTAI SPECIAL STEEL CO., LTD

Email: jack@otaisteel.com TEL: 0086-769-33232622 FAX: 0086-769-88705839

You might also like

- ASTM A29/A29M GB EN 10083/3 JIS G4053 GB: Round Sheet Square PlateDocument3 pagesASTM A29/A29M GB EN 10083/3 JIS G4053 GB: Round Sheet Square PlateximicayNo ratings yet

- 16MnCr5 SteelDocument3 pages16MnCr5 SteelaravindhNo ratings yet

- BS3100 A2Document11 pagesBS3100 A2AlexNo ratings yet

- 20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless SteelDocument2 pages20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless Steeltiele_barcelosNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- 60Si2Mn Spring Steel PDFDocument4 pages60Si2Mn Spring Steel PDFShubhamNo ratings yet

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Jis G3101 1995Document3 pagesJis G3101 1995Kholer BurgmanNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345No ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDocument5 pages20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanNo ratings yet

- Steel Plate For Boilers and Pressure Vessels: S.No. Steel Grade Executive StandardDocument7 pagesSteel Plate For Boilers and Pressure Vessels: S.No. Steel Grade Executive StandardHarish SivakumarNo ratings yet

- GB3077-1999 English VersionDocument20 pagesGB3077-1999 English VersionHermanto SupuNo ratings yet

- Tatin CelikDocument52 pagesTatin Celikgoran073No ratings yet

- REINFORCEMENTDocument3 pagesREINFORCEMENTanshdivyNo ratings yet

- Cu CR 1 ZRDocument38 pagesCu CR 1 ZRDaško MedenjaškoNo ratings yet

- S235JR / J0 / J2: Structural SteelDocument2 pagesS235JR / J0 / J2: Structural SteelAnonymous iHJPiQI7No ratings yet

- (Table Size: Larger Than 1500mm X 500mm) (Table Size: Larger Than 1500mm X 500mm)Document2 pages(Table Size: Larger Than 1500mm X 500mm) (Table Size: Larger Than 1500mm X 500mm)solehNo ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-04Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanNo ratings yet

- Tabla de Referencias de Aceros Inoxidables (ASTM A213)Document1 pageTabla de Referencias de Aceros Inoxidables (ASTM A213)Baltasar BuchiniNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Structural FabricationDocument46 pagesStructural FabricationmithileshNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- Thyssenkrupp s355jr Product Information Precision Steel en PDFDocument2 pagesThyssenkrupp s355jr Product Information Precision Steel en PDFjackcan501No ratings yet

- Carbon Steels: Hot-Rolled Steel StripDocument7 pagesCarbon Steels: Hot-Rolled Steel Stripwulfgang66No ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetMahammad ShehattaNo ratings yet

- Heavy Plates Catalogue-HD-mail Final 21082014 V2Document8 pagesHeavy Plates Catalogue-HD-mail Final 21082014 V2Hussain AliNo ratings yet

- Mild SteelDocument2 pagesMild SteelAnonymous qBXCI5gbNo ratings yet

- En-Gjs-400-15 - GGG40 PDFDocument2 pagesEn-Gjs-400-15 - GGG40 PDFDylkanWingsNo ratings yet

- S355JRDocument3 pagesS355JRYasmeen HaiderNo ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- BS 970 SteelsDocument8 pagesBS 970 SteelsTamal Guha100% (2)

- How To Get High Quality Boiler TubesDocument7 pagesHow To Get High Quality Boiler TubesYaneYangNo ratings yet

- GB5310 2008 Pipe SpecificationDocument5 pagesGB5310 2008 Pipe SpecificationRio EstikaNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 pagesG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- 03171344yzet PDFDocument30 pages03171344yzet PDFRobin LeeNo ratings yet

- LM29Document6 pagesLM29Thangapandian NNo ratings yet

- Kecepatan Potong Material Pahat HSS Pahat Carbida Halus Kasar Halus KasarDocument42 pagesKecepatan Potong Material Pahat HSS Pahat Carbida Halus Kasar Halus KasartrisnaNo ratings yet

- Tabel ParameterDocument42 pagesTabel ParametermasdayaniNo ratings yet

- Cutting Edge BrochureDocument2 pagesCutting Edge BrochureKen SmithNo ratings yet

- MDDocument17 pagesMDJay ShindeNo ratings yet

- 4.4.4 Gold PlatingDocument12 pages4.4.4 Gold PlatingSalem GarrabNo ratings yet

- PNS49Document14 pagesPNS49jbcast86No ratings yet

- GRADE 302: Element Content (%)Document3 pagesGRADE 302: Element Content (%)Shashank Saxena100% (1)

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Eutherme LH SPL PDFDocument1 pageEutherme LH SPL PDFAnonymous dxsNnL6S8hNo ratings yet

- X012 Designation Code For Power Cables PDFDocument1 pageX012 Designation Code For Power Cables PDFSunil SinghNo ratings yet

- Como Soldar 4140Document4 pagesComo Soldar 4140Luis Jose DuranNo ratings yet

- Datasheet-Sandvik-3r64-En-V2020-12-10 07 - 47 Version 1Document4 pagesDatasheet-Sandvik-3r64-En-V2020-12-10 07 - 47 Version 1Mada TetoNo ratings yet

- Parts of Vertical Roller MillDocument1 pageParts of Vertical Roller Millcostea002867% (3)

- Module 6 (Materials & Hardware) SubModule 6.1 (Aircraft MatDocument26 pagesModule 6 (Materials & Hardware) SubModule 6.1 (Aircraft MatInterogator5No ratings yet

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsJolettitoNo ratings yet

- Panorama FCW en v2 PDFDocument36 pagesPanorama FCW en v2 PDFFrancisco JesusNo ratings yet

- Comparison en 10277Document4 pagesComparison en 10277Ardeleana TisaNo ratings yet

- Chapter 13Document17 pagesChapter 13Oscar Espinosa BonillaNo ratings yet

- TAPPI TIP-0402-26 Welding of SS PipingDocument13 pagesTAPPI TIP-0402-26 Welding of SS Pipinga_parratNo ratings yet

- Warmanslurrypumps 160409025643 PDFDocument25 pagesWarmanslurrypumps 160409025643 PDFCleyton L. AlvesNo ratings yet

- ASTM A193-A193M-06aDocument13 pagesASTM A193-A193M-06aNadhiraNo ratings yet

- 4.1 Simple Magnetism and Magnetic FieldsDocument9 pages4.1 Simple Magnetism and Magnetic FieldsIshraque MahmudNo ratings yet

- Theory of Metal Machining: ProblemsDocument44 pagesTheory of Metal Machining: ProblemsAna Maria Trujillo100% (1)

- Continuous Casting: Continuous Casting, Also Called Strand Casting, Is The Process WherebyDocument8 pagesContinuous Casting: Continuous Casting, Also Called Strand Casting, Is The Process Wherebysurendra ratreNo ratings yet

- 3 Materila ScienceDocument34 pages3 Materila ScienceAlfred KuwodzaNo ratings yet

- Experiment No. 2 Rockwell Hardness Test IntroductionDocument3 pagesExperiment No. 2 Rockwell Hardness Test IntroductionAhmad Abd100% (1)

- Steel Bolts and Nuts and Similar Norm 2377: ObjectiveDocument9 pagesSteel Bolts and Nuts and Similar Norm 2377: ObjectiveanhthoNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- 4.0 Welding Filler Metal SpecificationsDocument1 page4.0 Welding Filler Metal SpecificationsAbdülHak ÖZkaraNo ratings yet

- An 910 An 911 An 914Document1 pageAn 910 An 911 An 914blackhawkNo ratings yet

- Iso 559 PDFDocument22 pagesIso 559 PDFsenthilNo ratings yet

- ManualDocument12 pagesManualGuilhermeNo ratings yet

- 0 Catalogo Completo Alfalaval IntercambiadoresDocument304 pages0 Catalogo Completo Alfalaval IntercambiadoresFrancisco RodríguezNo ratings yet

- Series: Masoneilan Cylinder ActuatorDocument20 pagesSeries: Masoneilan Cylinder ActuatorAfnan AliNo ratings yet

- Tutorial 3 - CIVE1179Tutorial - 3 - Inplane - Bending2016 PDFDocument2 pagesTutorial 3 - CIVE1179Tutorial - 3 - Inplane - Bending2016 PDFDilshan JayasuriyaNo ratings yet

- Analogi MaterialovDocument8 pagesAnalogi MaterialovrouquinNo ratings yet

- Astm A681 08 2022Document7 pagesAstm A681 08 2022sridevi72.puppalaNo ratings yet

- Copper Mining & Extraction Process Flow ChartDocument7 pagesCopper Mining & Extraction Process Flow Chartridwan septiawanNo ratings yet