Professional Documents

Culture Documents

Modern Portable Drum Grain Dryer For Farmers and Their Mathematical Model

Modern Portable Drum Grain Dryer For Farmers and Their Mathematical Model

Uploaded by

Academic JournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modern Portable Drum Grain Dryer For Farmers and Their Mathematical Model

Modern Portable Drum Grain Dryer For Farmers and Their Mathematical Model

Uploaded by

Academic JournalCopyright:

Available Formats

190 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

Modern Portable Drum Grain Dryer for Farmers and Their Mathematical

Model

Sobirov Xolxuja Abbozovich

Department of General Engineering, Andijan Institute of Mechanical Engineering

Xakimov Mirolimjon Murodiljonovich

Department of General Engineering, Andijan Institute of Mechanical Engineering

ABSTRACT

The article improves the method of increasing energy efficiency and the design of the dryer drum for

farmers by accelerating the process of drying the grain of the grain dryer and reducing the time spent

on drying the product.

KEYWORDS: portable dryer, dryer drum, grain, spiral fin, spring.

The proposed device belongs to the agricultural sector and can be used, in particular, for drying

grain products in farmers. A literary analysis of some existing devices was carried out [1, 2].

The main part of the drying process is carried out in a tumble dryer using hot air generated in a

heater. One of the disadvantages of this dryer is the complex design and high energy consumption, i.e.

the screw transport of the dryer, which operates regularly, is located outside the drum. As a result,

during the drying process, the grain passing through the auger is not spontaneously cooled, since the

temperature of the auger is much lower than the temperature inside the drum, and at the same time, the

consumption of electricity, the time spent on drying increases, and the process of uneven periodic

drying also negatively affects the quality grains and others.

The key task of the proposed device is to improve the process of moving and increase the

intensity of drying grain by volume and reduce the time spent on drying the product by improving the

design of the grain dryer drum and eliminating the screw transport.

In the proposed device, intensive mixing of the grain mass by volume is provided by a spiral-

shaped rib fixed (welded) to the drying drum from the inside along the entire length [3]. In this case,

the proposed direction of the spiral coincides with the direction of rotation of the drum. The proposed

drum provides grain movement not only down the slope due to gravity, but also partially up due to its

spiral rib. As a result, the volume and movement of the moved grain increases. The accumulation of

grain in the lower part of the drum is reduced, which improves the uniform drying process.

The main part of the grain drying process is drying with hot air generated in the heater. The hot

air generated in the heater accelerates the process of forced mixing of the dried grain mass with the

help of spiral fins. This ensures that the grain is of the same quality by volume and reduces the time

required to dry the product.

Middle European Scientific Bulletin, Volume 29 | Oct-2022

191 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

Fig. 1. Structural scheme of a portable grain dryer for farmers:

1 – loading bunker; 2-drying drum; 3 – automatic control valve; 4 and 5 product sorting

mechanisms; 6 - fixed section; 7 – heater; 8 – fan; 9 – electric motor; 10 and 12 front clutch and rear

clutch; 11 – gearbox; 13 – trailer; 14 - belt drive

The proposed device is illustrated by the following drawings and photocopies: Structural

diagram of a portable grain dryer in Fig.1, view of the drying drum (section A-A, section B-B) in Fig.2.

Fig.2. Type of dryer drum

A portable dryer consists of a receiving hopper 1, fixed to a drying drum 2, located at an angle

to the horizon (Fig. 2). At the same time, the dryer drum has a mechanism for pouring 3 grains with

automatic control. At the bottom of the automatically adjustable mechanism for pouring out the

product, there are mechanisms for sorting 4 and 5 of the finished product. A stationary section 6 is

coaxially installed at the top of the dryer drum, in which a heater 7 and a fan 8 are provided with belt

drive 14 and fan 15.

Middle European Scientific Bulletin, Volume 29 | Oct-2022

192 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

The principle of operation of the portable proposed dryer of the proposed grain products is as

follows: a certain amount of dried grain is fed through the hopper 1 to the dryer drum 2. After the grain

is poured into the dryer drum to a certain volume, the dryer drum starts to rotate and at the same time

the heater 7 supplies a stream of hot air to the drum. Drying of grain is gradually carried out by a

stream of hot air located in a drum. In the grain dryer, the working drum is located at a certain angle

relative to the horizon, most of the volume of the dried grain mass will begin to accumulate at the

bottom of the drum. A spiral-shaped rib installed inside the dryer drum (Fig. 2) pushes the accumulated

grain mass against the hot air flow created by the heater 7 located in the fixed section 6. the movement

of the flow of grain in the lower part of the drum. As a result, the volume of grain to be displaced per

revolution of the drum increases, and thus the drying of the grain is accelerated, which leads to a

reduction in the time spent on drying the product. The cover of the drum is opened and closed

automatically by the spring 20 [4].

The cycle (process) will continue until the grain moisture is reduced on demand level.

The proposed device differs from the closest analogue (prototype) by the following advantages:

1. In the proposed device, the rejection of screw transport and the simplification of the drying

device.

2. The process of mixing and drying of grain is accelerated by a spiral-shaped rib fixed inside

the drum. As a result, energy consumption is reduced.

To determine the main parameters that affect the regular opening and closing of lids, we will

build a dynamic model of a rotating drum and a complex movable lid (Fig. 3). In this case, we consider

this mechanical system as a two-mass mechanical system with respect to a stationary engine. We show

the vectors of forces acting in a mechanical system and the directions of their moments in a dynamic

model. Assume that the direction of the airing dryer is clockwise rotation.

Fig.3. Dynamic model of the mechanism

In the diagram: D - electric motor; 1- dryer drum with grain; 2- cover; 1 - angular

displacement of the drum, deg; 2 - angular displacement of the cover, deg; МД - engine torque, N.m.;

Мқ1 - torque relative to the axis of rotation of the sum of resistance forces (resistance forces and grain

friction forces) to the rotation of the drum, N.m.; МG2 - the moment of gravity on the drum (relative to

its axis of rotation, i.e. relative to the movable axis), N.m.; Мқ2 - the moment of grain pressure force

acting on the lid relative to the drum, N.m.; C1 - stiffness coefficient of the belt and other gears between

the electric motor and the dryer drum, Nm/rad; C2 - coefficient of stiffness of the spring that opens and

closes the lid, N/m.

We obtain the systems of equations of motion of the device mechanism [5]:

Ɛ1 = [ МД * iДБ - GД * rБ * sin γ - (G1 + G2 + GД ) * rВ *f -

- С1 * (1 - Д * /iДБ) ] / (JoБ + JoҚ)

Middle European Scientific Bulletin, Volume 29 | Oct-2022

193 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

Ɛ2 = [ 0,5 Ɩ2 (m2 *g sin(1 - 2) - S*pД sin1) - С2 * Ɩ2 *cos2] / JoҚ

We accept the initial conditions:

at t = 0; 01 = 02 = 0 ; ω1 = ωД ; Ɛ1 = Ɛ2 = 0

border conditions:

at t = Т ; Т1 = 1800 , those. this corresponds to half a revolution of the drum, which is

sufficient to analyze the process of opening and closing the lid during operation.

Using the obtained mathematical model, it is possible to construct the following dependency

diagrams, which are necessary for the synthesis of design parameters [6]:

2 = 1 (f) – dependence diagram of the angular displacements of the drum and cover;

2 = S2 (f) - diagram of the dependence of the angular displacement of the cover on the coefficient

of spring stiffness;

2 = pD (f) - diagram of the dependence of the angular displacement of the cover on the pressure

of the grain;

2 = GD (f) - diagram of the dependence of the angular displacement of the cover on the weight

of the grain;

2 = GQ (f) - diagram of dependence of the angular displacement of the lid on the weight of the

lid;

2 = ωБ (f) - diagram of dependence of the angular displacement of the lid on the angular velocity

of the drum;

2 = Ɩ2 (f) - diagram of angular displacement versus cover length.

Conclusions:

1. Thus, designed new device of the portable dryer for farmers and proposed new drum.

2. A system of equations has been obtained that takes into account almost all quantities that affect

the movement of a mechanical system, that is, a mathematical model of the first approximation of this

mechanical system.

3. Using a mathematical model, it is possible to construct the necessary diagrams not only of the

angular accelerations Ɛ1 and Ɛ2 of drums and covers, but also of their angular velocities ω1, ω2 and

angular displacements 1, 2. It is possible to carry out the synthesis of parameters based on the given

values of the coefficient of elasticity of the lid spring (С2) and the area of the window for unloading

dried rice (S), which is necessary for the proposed drying device.

References

1. Sarker, M.N. Ibrahim, N. Ab. Aziz, M.S. Punan. Application of simulation in determining

suitable operating parameters for industrial scale fluidized bed dryer during drying of high

impurity moist paddy. Journal of Stored Products Research. Volume 61, March 2015, Pages

76-84.

2. M. Yahya, Arfidian Rachman, R. Hasibuan. Performance analysis of solar-biomass hybrid

heat pump batch-type horizontal fluidized bed dryer using multi-stage heat exchanger for

Middle European Scientific Bulletin, Volume 29 | Oct-2022

194 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

paddy drying. Energy. Volume 254, Part B, 1 September 2022, 124294.

3. Bekkulov, B. R., Aliev, R., Sobirov, H. A., Nosirov, I. Z., Qayumov, B. A., & Rahmonkulov,

T. B. (2019). Ustrojstvo dlya sushki zernovyh produktov [Device for drying grain products].

Utility Model Patent of the Republic of Uzbekistan No FAP 01403. Bulletin, (7).

4. Собиров Х.А., Беккулов Б.Р., Хакимов М.М., Рахмонкулов Т.Б. Патент на полезную

модель АИС Республики Узбекистан. № FAP 01831. Устройство для сушки

продуктов зерновых культур. // Официальный вестник. – 2022. – №1.

5. APPLICATION OF LAGRANGE EQUATIONS OF THE 2nd KIND TO THE

MECHANISM OF THE DEVICE FOR DRYING RICE. RT Sobirov X., Bekkulov B.,

Khakimov M. POLISH JOURNAL OF SCIENCE №46 (2021) 1 (ISSN 3353-2389), 63-67.

6. Rahmonkulovich, B. B., Abdulhaevich, R. A., & Sadikovna, H. S. (2017). The energy-

efficient mobile device for grain drying. European science review, (11-12), 128-132.

Middle European Scientific Bulletin, Volume 29 | Oct-2022

You might also like

- Design Project Solar Clothes DryerDocument22 pagesDesign Project Solar Clothes DryerSaurav Kalita100% (1)

- Lab Report 3 (Me160p-2, Bellen)Document18 pagesLab Report 3 (Me160p-2, Bellen)Andre100% (1)

- Techspec QJ240 PDFDocument2 pagesTechspec QJ240 PDFNazeeh Abdulrhman AlbokaryNo ratings yet

- Sample EstimatesDocument159 pagesSample Estimatesadhinarayan1998No ratings yet

- Business Communication: ADVERTISING, Trade Shows, and Personal SellingDocument35 pagesBusiness Communication: ADVERTISING, Trade Shows, and Personal SellinggauravdgreatNo ratings yet

- Application of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural ConvectionDocument9 pagesApplication of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural Convectionhicham El FeroualiNo ratings yet

- Design of A Turgo Two-Phase Turbine Runner PDFDocument9 pagesDesign of A Turgo Two-Phase Turbine Runner PDFGabriel SimmerNo ratings yet

- Experimental Characterization and Modeling of Flash Bagasse DryerDocument25 pagesExperimental Characterization and Modeling of Flash Bagasse DryerMathusuthanan MariilayarajaNo ratings yet

- Design, Fabrication, and Testing of A Fluidized-Bed Paddy Dryer That Uses A Rice Hull-Fueled Furnace For Prototyping (Journal Article)Document14 pagesDesign, Fabrication, and Testing of A Fluidized-Bed Paddy Dryer That Uses A Rice Hull-Fueled Furnace For Prototyping (Journal Article)Caleb del MundoNo ratings yet

- Adsorptive Solar Powered Ice Maker Experiments PDFDocument15 pagesAdsorptive Solar Powered Ice Maker Experiments PDFali105No ratings yet

- Design and Analysis of A Solar Dryer ForDocument7 pagesDesign and Analysis of A Solar Dryer ForYousup AliNo ratings yet

- 6 DrummondDocument6 pages6 DrummondDarshak HaraniyaNo ratings yet

- Research On The Characteristics of A Novel Solar Drying System and Its ApplicationDocument6 pagesResearch On The Characteristics of A Novel Solar Drying System and Its ApplicationResearcherzNo ratings yet

- Lab Report 2 (Me160p-2, Bellen)Document14 pagesLab Report 2 (Me160p-2, Bellen)AndreNo ratings yet

- Ids 2022Document7 pagesIds 2022zhor El hallaouiNo ratings yet

- Cement Chapter 5Document18 pagesCement Chapter 5shani5573No ratings yet

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Document47 pagesLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueNo ratings yet

- Solar Steam GenerationDocument15 pagesSolar Steam GenerationSebastian MontecinoNo ratings yet

- Design, Construction and Performance Evaluation of Solar Maize DryerDocument8 pagesDesign, Construction and Performance Evaluation of Solar Maize DryerParth GuptaNo ratings yet

- Design, Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign, Construction and Evaluation of A Small Scale Solar DryerDinesh PoudelNo ratings yet

- Research Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatDocument9 pagesResearch Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatJuan PeraltaNo ratings yet

- On An Automated Headland Turn of Wide Width Air Seeders: Conference PaperDocument9 pagesOn An Automated Headland Turn of Wide Width Air Seeders: Conference PaperhenrengNo ratings yet

- Analysis of The Possibility of Using Solar Power Plants On The Basis of A Stirling Engine in KazakhstanDocument9 pagesAnalysis of The Possibility of Using Solar Power Plants On The Basis of A Stirling Engine in KazakhstanАсель ЖуматоваNo ratings yet

- Skills PresentDocument10 pagesSkills Presenteyad mohamadNo ratings yet

- Steam Gen DesignDocument8 pagesSteam Gen DesigndivjollyNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerzahreldinelaliNo ratings yet

- A Modified Model For Parabolic Trough Solar ReceiverDocument12 pagesA Modified Model For Parabolic Trough Solar ReceiverAJER JOURNALNo ratings yet

- Hydraulic System Design of Combined Harvester HeadDocument7 pagesHydraulic System Design of Combined Harvester HeadEmma OkurutNo ratings yet

- Mel 215 - Operation of Single Acting Cylinde-1Document8 pagesMel 215 - Operation of Single Acting Cylinde-1Aliyu omeiza YusufNo ratings yet

- RefrigerationDocument60 pagesRefrigerationMJ CREATIONSNo ratings yet

- Full TextDocument9 pagesFull Textjsk789No ratings yet

- Design, Construction and Performance Evaluation of A Mixed-Mode Solar DryerDocument9 pagesDesign, Construction and Performance Evaluation of A Mixed-Mode Solar DryerAdebiyi A FaruqNo ratings yet

- Design and Construction of A Solar Dryer For MangoDocument8 pagesDesign and Construction of A Solar Dryer For MangoIboyaima singhNo ratings yet

- Pneumatic System - 1Document12 pagesPneumatic System - 1Ikram NajihuddinNo ratings yet

- Ijaret: ©iaemeDocument8 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- Mathematical Modeling of The Temperature Regime of The "Livestock-Heliogreenhouse Complex" With Water Tank and Underground Heat AccumulatorDocument11 pagesMathematical Modeling of The Temperature Regime of The "Livestock-Heliogreenhouse Complex" With Water Tank and Underground Heat AccumulatorAcademic JournalNo ratings yet

- Paper Moisture Based Steam Usage Reduction in Paper PlantDocument5 pagesPaper Moisture Based Steam Usage Reduction in Paper PlantInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Entodrya: Proteinsect Engineering CompetitionDocument10 pagesEntodrya: Proteinsect Engineering CompetitionGonzalo BoninoNo ratings yet

- Lifter DesignDocument6 pagesLifter DesignMarcelo GuarachiNo ratings yet

- Nergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and DisseminationDocument16 pagesNergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and Disseminationshribavan2373No ratings yet

- 103 Ijmperdjun2019103Document12 pages103 Ijmperdjun2019103TJPRC PublicationsNo ratings yet

- Wankel CompressorDocument6 pagesWankel CompressorSenthil KumarNo ratings yet

- JishanDocument21 pagesJishanSapna KumariNo ratings yet

- Hydraulic PressDocument11 pagesHydraulic PressAlagu EswaranNo ratings yet

- Simulation Model of at Plate Solar Collector Performance: February 2011Document20 pagesSimulation Model of at Plate Solar Collector Performance: February 2011Meryem BenNo ratings yet

- Performance Analysis of A Solar DryerDocument11 pagesPerformance Analysis of A Solar DryerSerge KewouNo ratings yet

- Solar Heated GenerationDocument4 pagesSolar Heated GenerationAditya DarekarNo ratings yet

- Osintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Document5 pagesOsintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Pooja ChughNo ratings yet

- CryocoolerDocument22 pagesCryocooleralexNo ratings yet

- Solar Assisted Heat Pump DryerDocument6 pagesSolar Assisted Heat Pump DryerRajeshKolheNo ratings yet

- Ijaste 260-268Document9 pagesIjaste 260-268RoniPalebanganNo ratings yet

- Practical Work 3 Theme: Determining The Operation of Grain Washer and The Device For Cleaning Peel in Its Wet State (2 Hours) 1. Purpose of The WorkDocument4 pagesPractical Work 3 Theme: Determining The Operation of Grain Washer and The Device For Cleaning Peel in Its Wet State (2 Hours) 1. Purpose of The WorkNurberdiNo ratings yet

- 51Document9 pages51Dirajen Pullay MardayNo ratings yet

- Operation of Tube MillsDocument26 pagesOperation of Tube Millsssk3712100% (2)

- Furnace Presure ControllerDocument46 pagesFurnace Presure ControllerAnu Pillai0% (1)

- Current State of Automation Process of Convection Drying of Bulk MaterialsDocument6 pagesCurrent State of Automation Process of Convection Drying of Bulk MaterialsOpen Access JournalNo ratings yet

- Solar DryerDocument5 pagesSolar DryersamadonyNo ratings yet

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- Seminar On Heating and Cooling of AlternatorsDocument19 pagesSeminar On Heating and Cooling of AlternatorsSamir Kumar Jyotishi0% (1)

- Can Crusher MechanismDocument4 pagesCan Crusher MechanismaqmbaldiwalaNo ratings yet

- Development of A Water Air-Conditioner For The Semi-Arid Region of NigeriaDocument6 pagesDevelopment of A Water Air-Conditioner For The Semi-Arid Region of NigeriaOyeniyi Samuel KehindeNo ratings yet

- Applying CFD For Studying The Dynamic and ThermalDocument20 pagesApplying CFD For Studying The Dynamic and ThermalPUBG SORRYNo ratings yet

- Psychology Empirical Analysis of The Relationship Between Learning Motives and Attention Qualities Formed in StudentsDocument5 pagesPsychology Empirical Analysis of The Relationship Between Learning Motives and Attention Qualities Formed in StudentsAcademic JournalNo ratings yet

- The Usаge of Vаrious Interаctive Methods in TeаchingDocument6 pagesThe Usаge of Vаrious Interаctive Methods in TeаchingAcademic JournalNo ratings yet

- Pedagogical Skills of The Tennis Coach in Effective Organization of Tennis Sports and Health Promotion Activities To Strengthen Women's Social Activity and Health, Which Is Its BasisDocument4 pagesPedagogical Skills of The Tennis Coach in Effective Organization of Tennis Sports and Health Promotion Activities To Strengthen Women's Social Activity and Health, Which Is Its BasisAcademic JournalNo ratings yet

- Faoliyat Xavfsizligini Ta'minlash Vositalari XususidaDocument3 pagesFaoliyat Xavfsizligini Ta'minlash Vositalari XususidaAcademic JournalNo ratings yet

- Results of Quality of Life Indicators in Patients With OsteoarthritisDocument4 pagesResults of Quality of Life Indicators in Patients With OsteoarthritisAcademic JournalNo ratings yet

- Preliminary Information About Dragonflies Fauna Distributed in Kashkadarya RegionDocument6 pagesPreliminary Information About Dragonflies Fauna Distributed in Kashkadarya RegionAcademic JournalNo ratings yet

- Impact of Subsidy Removal On Supervision of Schools in NigeriaDocument6 pagesImpact of Subsidy Removal On Supervision of Schools in NigeriaAcademic JournalNo ratings yet

- Crisis and Disintegration of The Nogai HordeDocument3 pagesCrisis and Disintegration of The Nogai HordeAcademic JournalNo ratings yet

- Welfare Schemes For Tribes in West Bengal (2011-2020)Document6 pagesWelfare Schemes For Tribes in West Bengal (2011-2020)Academic JournalNo ratings yet

- Internal Affairs Bodies As Subjects of Tort Relations: Theoretical and Legal AnalysisDocument6 pagesInternal Affairs Bodies As Subjects of Tort Relations: Theoretical and Legal AnalysisAcademic JournalNo ratings yet

- Features of Teaching Probabilistic - Statistical ConseptsDocument5 pagesFeatures of Teaching Probabilistic - Statistical ConseptsAcademic JournalNo ratings yet

- Gender in The Education SystemDocument6 pagesGender in The Education SystemAcademic JournalNo ratings yet

- Linguistic and Specific MetaphorsDocument3 pagesLinguistic and Specific MetaphorsAcademic JournalNo ratings yet

- Social and Economic Importance of The Formation of Insurance RelationsDocument5 pagesSocial and Economic Importance of The Formation of Insurance RelationsAcademic JournalNo ratings yet

- To The Study of Studged Painted Ceramics of The Late Bronze and Early Iron Age in Central AsiaDocument5 pagesTo The Study of Studged Painted Ceramics of The Late Bronze and Early Iron Age in Central AsiaAcademic JournalNo ratings yet

- Acquiring German Language Via Making A DialogueDocument3 pagesAcquiring German Language Via Making A DialogueAcademic JournalNo ratings yet

- The Role of The Principles of International Environmental Law in The Implementation of Environmental Impact AssessmentDocument4 pagesThe Role of The Principles of International Environmental Law in The Implementation of Environmental Impact AssessmentAcademic JournalNo ratings yet

- A Contextual Analysis of Stylistic Convergences in J. Dryden's Drama "Aureng-Zebe"Document5 pagesA Contextual Analysis of Stylistic Convergences in J. Dryden's Drama "Aureng-Zebe"Academic JournalNo ratings yet

- Strengthening Access To Justice: Empowering Citizens and Businesses For Fairness and Effective Dispute ResolutionDocument10 pagesStrengthening Access To Justice: Empowering Citizens and Businesses For Fairness and Effective Dispute ResolutionAcademic JournalNo ratings yet

- Concept of Ibn Al-Arabi "Wahdat Ul-Wujud"Document5 pagesConcept of Ibn Al-Arabi "Wahdat Ul-Wujud"Academic JournalNo ratings yet

- MORPHOFUNCTIONAL CHANGES IN THE CORNEA AFTER LONG-TERM WEARING OF CONTACT LENSES, CONTRIBUTING TO THE DEVELOPMENT OF ARTIFICIAL (SECONDARY) DRY EYE SYNDROME (Literature Review)Document6 pagesMORPHOFUNCTIONAL CHANGES IN THE CORNEA AFTER LONG-TERM WEARING OF CONTACT LENSES, CONTRIBUTING TO THE DEVELOPMENT OF ARTIFICIAL (SECONDARY) DRY EYE SYNDROME (Literature Review)Academic JournalNo ratings yet

- Unsatisfactory Results After Tympanoplasty Surgery in Patients With Chronic Purulent Otitis MediaDocument4 pagesUnsatisfactory Results After Tympanoplasty Surgery in Patients With Chronic Purulent Otitis MediaAcademic JournalNo ratings yet

- Principles of Teaching Foreign LanguagesDocument4 pagesPrinciples of Teaching Foreign LanguagesAcademic JournalNo ratings yet

- Pleonasm As A Phenomenon of Speech RedundancyDocument4 pagesPleonasm As A Phenomenon of Speech RedundancyAcademic JournalNo ratings yet

- Expression of Some Phraseological Units of Zoonyms in The Uzbek and German LanguagesDocument6 pagesExpression of Some Phraseological Units of Zoonyms in The Uzbek and German LanguagesAcademic JournalNo ratings yet

- Development of Sports Infrastructure in Physical Education and SportsDocument7 pagesDevelopment of Sports Infrastructure in Physical Education and SportsAcademic JournalNo ratings yet

- Similarity and Originality of Works About The Travels of English Enlightener Writers and Uzbek Jadid WritersDocument7 pagesSimilarity and Originality of Works About The Travels of English Enlightener Writers and Uzbek Jadid WritersAcademic JournalNo ratings yet

- Modern Issues of Simultaneous Translation: Theory and PracticeDocument3 pagesModern Issues of Simultaneous Translation: Theory and PracticeAcademic JournalNo ratings yet

- Translation Strategies For Pun in William Shakespeare's "King Lear"Document5 pagesTranslation Strategies For Pun in William Shakespeare's "King Lear"Academic JournalNo ratings yet

- We Select A Variety For Our Republic From Non-Traditional Types of Cabbage To Obtain A High Yield When Planting Kohlrabi Cabbage in ReplantingDocument4 pagesWe Select A Variety For Our Republic From Non-Traditional Types of Cabbage To Obtain A High Yield When Planting Kohlrabi Cabbage in ReplantingAcademic JournalNo ratings yet

- Consumer Behaviour (Cma 206) Course Outline 2017Document4 pagesConsumer Behaviour (Cma 206) Course Outline 2017Faustino KufakunesuNo ratings yet

- Transport Layer - Computer Networks Questions & Answers - SanfoundryDocument4 pagesTransport Layer - Computer Networks Questions & Answers - SanfoundryMd Rakibul Islam100% (1)

- Development and Validation of HPLC Method For The Estimation of Nicergoline in Marketed FormulationsDocument5 pagesDevelopment and Validation of HPLC Method For The Estimation of Nicergoline in Marketed FormulationsRatnakaram Venkata NadhNo ratings yet

- PDS - OBM Viscosifier - LiquidDocument1 pagePDS - OBM Viscosifier - LiquidPranav DubeyNo ratings yet

- 436Document11 pages436Himanshu PanchalNo ratings yet

- Heart of SloveniaDocument51 pagesHeart of SloveniaVincenzo TorracaNo ratings yet

- 6 Thinking Hats Lesson PlanDocument9 pages6 Thinking Hats Lesson Planapi-409777377No ratings yet

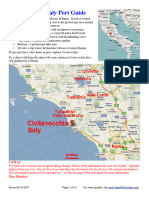

- Rome (Roma) Italy Port Guide - Toms Port GuidesDocument21 pagesRome (Roma) Italy Port Guide - Toms Port GuidessocialcornieNo ratings yet

- BYW29-50 THRU BYW29-200: Fast Efficient Plastic RectifierDocument2 pagesBYW29-50 THRU BYW29-200: Fast Efficient Plastic Rectifierdj_nickoNo ratings yet

- United States District Court Order To Show CauseDocument2 pagesUnited States District Court Order To Show CauseAndre Duke CoulterNo ratings yet

- DacMagic Plus Technical SpecificationsDocument2 pagesDacMagic Plus Technical SpecificationsDaniel TapiaNo ratings yet

- Discussion & Conclusion + Screenshot PDFDocument2 pagesDiscussion & Conclusion + Screenshot PDFRex LeopardNo ratings yet

- Relationship of Nifty-50 With Reliance Infrastructure LTDDocument3 pagesRelationship of Nifty-50 With Reliance Infrastructure LTDPrabhaNo ratings yet

- Immunity ProjectDocument9 pagesImmunity ProjectAditi ShresthaNo ratings yet

- Marjan Kiprijanovski, Slavko Georgievski, Nikola Saraginovski, Tosho ArsovDocument1 pageMarjan Kiprijanovski, Slavko Georgievski, Nikola Saraginovski, Tosho ArsovMirko PetrićNo ratings yet

- Vagelis Bebelis: Personal DataDocument3 pagesVagelis Bebelis: Personal DataCarlos TorresNo ratings yet

- New Hybrid Fuzzy Controller For Direct Torque Control Induction Motor DrivesDocument9 pagesNew Hybrid Fuzzy Controller For Direct Torque Control Induction Motor DrivesBook4AllNo ratings yet

- AutoCAD 1Document37 pagesAutoCAD 1first digosNo ratings yet

- ASTM A789 Stainless Steel TubingDocument6 pagesASTM A789 Stainless Steel TubingPlinio PazosNo ratings yet

- Big Cable GuideDocument54 pagesBig Cable Guided1sc0stuNo ratings yet

- Parental Leave Will CostDocument284 pagesParental Leave Will CostHòa HuỳnhNo ratings yet

- Micro SprinklerDocument32 pagesMicro Sprinklerprinceej100% (2)

- ExamDocument3 pagesExamSidraGhafoorNo ratings yet

- Icici PoDocument5 pagesIcici Potanujchopra1No ratings yet

- GEUC Invitation 2021Document1 pageGEUC Invitation 2021MIHAI SANDANo ratings yet

- Unit 2 Basic Test PDFDocument2 pagesUnit 2 Basic Test PDFAnna SolomennayaNo ratings yet

- Cleft Lip PalateDocument37 pagesCleft Lip PalateMuhammad Hamid Muktashim100% (1)