Professional Documents

Culture Documents

Used Oil Refinery Plant

Used Oil Refinery Plant

Uploaded by

multilinkaddis0 ratings0% found this document useful (0 votes)

9 views2 pagesOriginal Title

used-oil-refinery-plant

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesUsed Oil Refinery Plant

Used Oil Refinery Plant

Uploaded by

multilinkaddisCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

22 Re-Refining Plants in 5 Different Continents

> Used Oil Refinery Plant (Group - |, I, III)

> Regenerative Media Based Polishing Systems

» Transformer Oil Recycling Plant

» Automatic Blending Plants

> Grease Manufacturing Plant

» Water Naphtha Separator

Six Stages of the Process:

Our Plant processes used lube oil, using high vacuum molecular distillation

technology in the following six stages:

Stage 1 : De-hydration and De-gas oil Skid |

Stage 2 : Distillation Skid-II & III*(Depends on plant capacity) Lube oil SN 150 - 500

Stage 3 : Pollution Skid -IV Scrubber and Thermal Oxidizer

Stage 4 : Regenerative Media Based Polishing Systems for Group-| or Hydrogenation Group - I!

Stage 5 : Effluent Water Treatment

Stage 6 : Packaging or Bulk dispatch

This process technology re-refines used lube oil to its maximum output by means of

environmentally friendly PLC controlled fully automatic, continuous process.

The plant processes used lube oil and industrial oils, using high vacuum molecular distillation

technology.

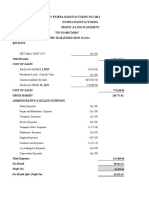

The Processed Output

* 77% of Base Oil ( SN 80,150, 300, 400-500)

4% Diesel, Naphtha & Light Oil

14% of residue (Asphalt)

5 % water

By-Products

The Plant will also produce the by-products with the typical characteristics as follows.

The actual characteristics will be depending on the feedstock.

1. Light Fuel

Specific gravity 0.760 - 0.770

Flash point, °C 20

2. Gasoil 4. 180 CST Fuel Oil

Specific gravity 0.840 - 0.860

Viscosity, cSt at 40°C 3-6 Fumace oil is a dark

aan pai a oe viscous residual product

} mg KOMar 7 used as a fuel

3. Asphaltic Residue in different types of

Specific gravity 0.900 - 1.050 combustion equipment.

Viscosity, cSt @100°C 300 kinematic viscosity range of

Ash content, wi% 5-10 125 to 180 CSt at 50°C

Sulfur, wt% 1-2

Softening point,°C_ 10 - 15

LHY, keallkg 8,500

Metals, wt% 2-4

lon )

www.thermopac.in

eed

ea

@ Wilcrest, 2500 Wilcrest, Suite 300, Houston Texas 77042, USA.

=} ¢ +1 (832) 8889260 2 houston@thermopac.in

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- JZC Waste Oil Recycling Machine 2021Document15 pagesJZC Waste Oil Recycling Machine 2021multilinkaddisNo ratings yet

- 7th Eastern ProceedingsDocument68 pages7th Eastern ProceedingsmultilinkaddisNo ratings yet

- 2014 Tot Enjra StatDocument54 pages2014 Tot Enjra StatmultilinkaddisNo ratings yet

- Export GuideDocument29 pagesExport GuidemultilinkaddisNo ratings yet

- Project 6936 OverviewDocument9 pagesProject 6936 OverviewmultilinkaddisNo ratings yet