Professional Documents

Culture Documents

Tough Plastics Dunnage 2020

Uploaded by

Victor DharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tough Plastics Dunnage 2020

Uploaded by

Victor DharCopyright:

Available Formats

Tough Plastics

for Dunnage

When shipping your valuable, precision parts,

BASF has the solutions you need to protect them.

Elastocast® elastomers, Elastofoam® i-skins,

Elastollan® TPU and Elastocoat® elastomeric spray

systems provide rugged, durable high strength

protection for every possible configuration.

Benefits: Typical Applications:

• High chemical and moisture resistance • Reusable racks and containers

• Returnable packaging

• Superior tear and abrasion resistance

ISO‘s for Both Technologies:

• The most durable solution available

• Elastofoam 3120T

• Compatible with high and low pressure • Elastoflex® 3092T

dispensing equipment

• Robust processing properties Elastomer Products Polymer Type Hardness

• One ISO for solid and i-skin formulations

Elastocast 7247OR PPG 70A

I-skin System Density

Products (lb/ft3) Hardness Elastofoam 3731OR PPG 90A

Elastofoam 38751R 15 – 40 20 – 50 A Elastocast R4A90E PTMEG 90A

Elastofoam 3885OR 27 65A Elastocast R4A95E PTMEG 95A

Elastofoam 3865OR 27 70A Elastocast R4A972 PPG 97A

Elastofoam 38660 27 90A Elastocast R4D65 PTMEG 65D

About BASF’s Performance Materials division

BASF’s Performance Materials division encompasses the entire materials’ know-how of BASF

regarding innovative, customized plastics under one roof. Globally active in four major industry sectors

– transportation, construction, industrial applications and consumer goods – the division has a strong

portfolio of products and services combined with a deep understanding of application-oriented system

solutions. Key drivers of profitability and growth are our close collaboration with customers and a clear

focus on solutions. Strong capabilities in R&D provide the basis to develop innovative products and

applications. In 2018, the Performance Materials division achieved global sales of €7.65 bn. More

information online: www.plastics.basf.com.

THE DESCRIPTIONS, DESIGNS, DATA AND INFORMATION CONTAINED HEREIN ARE PRESENTED IN GOOD FAITH, AND ARE BASED For more information,

ON BASF’S CURRENT KNOWLEDGE AND EXPERIENCE. THEY ARE PROVIDED FOR GUIDANCE ONLY, AND DO NOT CONSTITUTE please contact:

THE AGREED CONTRACTUAL QUALITY OF THE PRODUCT OR A PART OF BASF’S TERMS AND CONDITIONS OF SALE. BECAUSE

MANY FACTORS MAY AFFECT PROCESSING OR APPLICATION/USE OF THE PRODUCT, BASF RECOMMENDS THAT THE READER

CARRY OUT ITS OWN INVESTIGATIONS AND TESTS TO DETERMINE THE SUITABILITY OF A PRODUCT FOR ITS PARTICULAR PUR-

Thomas McKay

POSE PRIOR TO USE. IT IS THE RESPONSIBILITY OF THE RECIPIENT OF PRODUCT TO ENSURE THAT ANY PROPRIETARY RIGHTS Market Segment Manager

AND EXISTING LAWS AND LEGISLATION ARE OBSERVED. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, Ph: +1-973-650-5654

INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE Email: thomas.mckay@basf.com

MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH HEREIN, OR THAT THE

PRODUCTS, DESCRIPTIONS, DESIGNS, DATA OR INFORMATION MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL

PROPERTY RIGHTS OF OTHERS. ANY DESCRIPTIONS, DESIGNS, DATA AND INFORMATION GIVEN IN THIS PUBLICATION MAY

CHANGE WITHOUT PRIOR INFORMATION. THE DESCRIPTIONS, DESIGNS, DATA, AND INFORMATION FURNISHED BY BASF HERE-

UNDER ARE GIVEN GRATIS AND BASF ASSUMES NO OBLIGATION OR LIABILITY FOR THE DESCRIPTIONS, DESIGNS, DATA OR

INFORMATION GIVEN OR RESULTS OBTAINED, ALL SUCH BEING GIVEN AND ACCEPTED AT THE READER’S RISK.

© 2020, BASF Corporation

® = registered trademark of BASF SE

You might also like

- BASIC GASKET GUIDE SELECTIONDocument10 pagesBASIC GASKET GUIDE SELECTIONTieu KakaNo ratings yet

- August Morning WorkDocument20 pagesAugust Morning Workapi-471325484No ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Basf PolyureaDocument10 pagesBasf PolyureaMohiuddin Muhin0% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- O Ring Guide SuperiorDocument32 pagesO Ring Guide SuperiorSuresh Kumar MittapalliNo ratings yet

- Gasket Catalog - James WalkerDocument52 pagesGasket Catalog - James WalkerJaime Lozano GonzálezNo ratings yet

- Gasket Jointing FullDocument48 pagesGasket Jointing FullManishBoyNo ratings yet

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityFrom EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityNo ratings yet

- Plastics For Orthotics and ProstheticsDocument4 pagesPlastics For Orthotics and ProstheticslarjcaNo ratings yet

- SABS Standards and Their Relevance to Conveyor SpecificationsDocument17 pagesSABS Standards and Their Relevance to Conveyor SpecificationsRobert Nicodemus Pelupessy0% (1)

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamNo ratings yet

- Joint SealantsDocument4 pagesJoint SealantsBudiawan BudtseNo ratings yet

- Deliver High Performance: Advanced MaterialsDocument6 pagesDeliver High Performance: Advanced Materialsmkamat007No ratings yet

- Baxchem Systems Brochure 20061 PDFDocument6 pagesBaxchem Systems Brochure 20061 PDFA MahmoodNo ratings yet

- Pebax Product Range BrochureDocument14 pagesPebax Product Range BrochureVictor CastrejonNo ratings yet

- EMPAQUES FLEXITALLICbroPackingsDocument11 pagesEMPAQUES FLEXITALLICbroPackingsSantiago SeveinNo ratings yet

- BUSAK SHAMBAN Industrial - Sealing.product - RangeDocument52 pagesBUSAK SHAMBAN Industrial - Sealing.product - RangeFrank NunesNo ratings yet

- Ifs Brochure 2009 PDFDocument12 pagesIfs Brochure 2009 PDFA MahmoodNo ratings yet

- Gasket BrochureDocument26 pagesGasket BrochureAreeb KhanNo ratings yet

- MegumThixonRobond PSGuideDocument4 pagesMegumThixonRobond PSGuideGermán Guerra FernándezNo ratings yet

- GASKETDocument47 pagesGASKETAMAN MALHOTRANo ratings yet

- Product Data: F149 Polyester MatrixDocument4 pagesProduct Data: F149 Polyester MatrixSaidiJalelNo ratings yet

- Euroguarco GasketDocument20 pagesEuroguarco Gasketwork.fransgintingNo ratings yet

- Packing BrochureDocument11 pagesPacking BrochureSasan AbbasiNo ratings yet

- MasterEmaco ADH 326 (Concresive Liq)Document4 pagesMasterEmaco ADH 326 (Concresive Liq)RodCorniNo ratings yet

- Masterflow 648Document2 pagesMasterflow 648api-283891975No ratings yet

- Basf Masterroc TSG 6 TdsDocument2 pagesBasf Masterroc TSG 6 TdsMalvika GargNo ratings yet

- 8508-8509-8510-Bulletin-REDocument4 pages8508-8509-8510-Bulletin-REChristian DeleonNo ratings yet

- MAC4082 TechProdSelectorDocument64 pagesMAC4082 TechProdSelectorhjcpintoNo ratings yet

- Ficha Tecnica - Lamina 8519 3m (1)Document2 pagesFicha Tecnica - Lamina 8519 3m (1)Juan Sebastian Martinez FloresNo ratings yet

- Ampacet Extends Clarifier and Antistat Ranges PDFDocument2 pagesAmpacet Extends Clarifier and Antistat Ranges PDFXuân Giang NguyễnNo ratings yet

- Systemplast Bearing UnitsDocument131 pagesSystemplast Bearing UnitsaNo ratings yet

- PressoDocument81 pagesPressoDiego Fernando AVENDA¥O RODRIGUEZNo ratings yet

- Kata Logs P Nauti KaDocument73 pagesKata Logs P Nauti KaSlobodan MaricicNo ratings yet

- Gazechim Brochure Nov 2012 PDFDocument13 pagesGazechim Brochure Nov 2012 PDFByron BrownNo ratings yet

- BASF 13XBF-Molecular-Sieve Datasheet Rev.08-2020Document2 pagesBASF 13XBF-Molecular-Sieve Datasheet Rev.08-2020mrsina.ab1997No ratings yet

- DSM Composite Resins Reintroduces Atlac Vinyl Ester Resins in South AfricaDocument8 pagesDSM Composite Resins Reintroduces Atlac Vinyl Ester Resins in South AfricaDeepshikha BehlNo ratings yet

- Co-Extruded Multi-Polymer Protective Tapes: 2A25 2A26 2A29 (Clear)Document3 pagesCo-Extruded Multi-Polymer Protective Tapes: 2A25 2A26 2A29 (Clear)Mario Daniel ConejoNo ratings yet

- Spec 3m 375Document2 pagesSpec 3m 375Thích Rong ChơiNo ratings yet

- Cadenas, Bandas y PiñonesDocument0 pagesCadenas, Bandas y PiñonesvegazelaNo ratings yet

- Mastertop DAF PDFDocument4 pagesMastertop DAF PDFFrancois-No ratings yet

- Plastic Material Selection GuideDocument7 pagesPlastic Material Selection Guide1000kyNo ratings yet

- 8548G, 8549L, 8550M Bulletin REDocument5 pages8548G, 8549L, 8550M Bulletin REChristian DeleonNo ratings yet

- 3M 8067 LeedDocument2 pages3M 8067 LeedStefano CamillucciNo ratings yet

- SC2050Document4 pagesSC2050A MahmoodNo ratings yet

- ACFInterconnect 6000575Document4 pagesACFInterconnect 6000575mazacotesNo ratings yet

- SD Certificate LevisDocument6 pagesSD Certificate LevisRezoanul HaqueNo ratings yet

- TDS - Masterpren TheDocument2 pagesTDS - Masterpren TheJaga NathNo ratings yet

- RTV Is800 SeriesDocument4 pagesRTV Is800 SeriesFaraan KhanNo ratings yet

- Intraplast: Expanding Grout AdmixtureDocument2 pagesIntraplast: Expanding Grout AdmixtureManoj ChhetriNo ratings yet

- Optitemp HT 2 EP: DescriptionDocument2 pagesOptitemp HT 2 EP: DescriptionWirawan Adi Setya RNo ratings yet

- 50A946 - ResinDocument3 pages50A946 - ResinFadzil Adly IshakNo ratings yet

- Mastertop DAP PDFDocument3 pagesMastertop DAP PDFFrancois-No ratings yet

- Ampacet Develops Process Aid Masterbatch For Outdoor Blown Film ApplicationsDocument1 pageAmpacet Develops Process Aid Masterbatch For Outdoor Blown Film ApplicationsXuân Giang NguyễnNo ratings yet

- Mastertop 100 Asean 0310Document2 pagesMastertop 100 Asean 0310BamsiamNo ratings yet

- 3M ScotchcastDocument4 pages3M ScotchcastPORT ENGINEER JAD LIFTBOATSNo ratings yet

- Mbrace Laminate LM, MM, HM TDSDocument3 pagesMbrace Laminate LM, MM, HM TDSDoug WeirNo ratings yet

- Polymer ST 77 0719 en Oi AsDocument2 pagesPolymer ST 77 0719 en Oi AsPranshu JainNo ratings yet

- 3MScotchcast 92NBADocument4 pages3MScotchcast 92NBAAnalia CanosaNo ratings yet

- 1431A Hygienic Connectors Brochure English WebDocument36 pages1431A Hygienic Connectors Brochure English Webkimba worthNo ratings yet

- multimediaDocument5 pagesmultimediarentalqatarNo ratings yet

- Science - SubstanceDocument9 pagesScience - SubstanceVictor DharNo ratings yet

- English L 14 A Lesson For AllDocument7 pagesEnglish L 14 A Lesson For AllVictor DharNo ratings yet

- 2018 Sustainability ReportDocument23 pages2018 Sustainability ReportVictor DharNo ratings yet

- Marathi GrammarDocument1 pageMarathi GrammarVictor DharNo ratings yet

- Supplier Guiding PrinciplesDocument20 pagesSupplier Guiding PrinciplesVictor DharNo ratings yet

- GO SNG 2017 en SmartDocument48 pagesGO SNG 2017 en SmartVictor DharNo ratings yet

- Sustainability Report 201516Document18 pagesSustainability Report 201516Victor DharNo ratings yet

- Role of IMC in Life Insurance PerformanceDocument60 pagesRole of IMC in Life Insurance PerformanceVictor DharNo ratings yet

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294No ratings yet

- SreejithDocument23 pagesSreejithAkn SNo ratings yet

- Perceptron: Tirtharaj DashDocument22 pagesPerceptron: Tirtharaj DashKishan Kumar GuptaNo ratings yet

- Sheet 5 SolvedDocument4 pagesSheet 5 Solvedshimaa eldakhakhnyNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet

- Module 4.Document16 pagesModule 4.Sania MaqsoodNo ratings yet

- Quadratic SDocument22 pagesQuadratic SShawn ShibuNo ratings yet

- Getting Started With Microsoft ExcelDocument12 pagesGetting Started With Microsoft ExcelRoshan AdhikariNo ratings yet

- Madd Powerpoint 1Document17 pagesMadd Powerpoint 1api-457366947No ratings yet

- Certificate of Incorporation Phlips India LimitedDocument1 pageCertificate of Incorporation Phlips India LimitedRam AgarwalNo ratings yet

- I - Refracted EnergyDocument6 pagesI - Refracted EnergyAmmad Ali QureshiNo ratings yet

- Six Sigma Statistical Methods Using Minitab 13 Manual4754Document95 pagesSix Sigma Statistical Methods Using Minitab 13 Manual4754vinaytoshchoudharyNo ratings yet

- Sophiajurgens Resume EdtDocument2 pagesSophiajurgens Resume Edtapi-506489381No ratings yet

- Jhamuna Tower Design DataDocument15 pagesJhamuna Tower Design DataArindam RoyNo ratings yet

- Overview of Common Communication Challenges and TipsDocument7 pagesOverview of Common Communication Challenges and TipsTinyEYE Therapy ServicesNo ratings yet

- Ett 531 Motion Visual AnalysisDocument4 pagesEtt 531 Motion Visual Analysisapi-266466498No ratings yet

- Proportional, Solenoid Actuated Flow Control Valves Type SE and SEHDocument16 pagesProportional, Solenoid Actuated Flow Control Valves Type SE and SEHwords2zhigang_612545No ratings yet

- Foundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureDocument1 pageFoundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureJosé CallisayaNo ratings yet

- Universiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603Document4 pagesUniversiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603000No ratings yet

- Bee Unit-IiDocument98 pagesBee Unit-IiHemant Ingale100% (1)

- PqdifsdkDocument2 pagesPqdifsdkrafaelcbscribdNo ratings yet

- Agricrop9 ModuleDocument22 pagesAgricrop9 ModuleMaria Daisy ReyesNo ratings yet

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDocument7 pagesCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNo ratings yet

- Lun Mapping DisksDocument11 pagesLun Mapping DisksKarn GusainNo ratings yet

- 3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Document3 pages3.4 Linearization of Nonlinear State Space Models: 1 F X Op 1 F X Op 2 F U Op 1 F U Op 2Ilija TomicNo ratings yet

- Dyno InstructionsDocument2 pagesDyno InstructionsAlicia CarrNo ratings yet

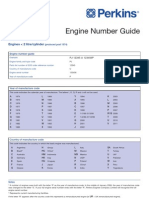

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)