Professional Documents

Culture Documents

Astm C1875 - 18

Uploaded by

Ryan SaputraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm C1875 - 18

Uploaded by

Ryan SaputraCopyright:

Available Formats

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles

for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

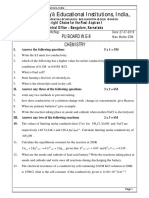

Designation: C1875 − 18

Standard Practice for

Determination of Major and Minor Elements in Aqueous

Pore Solutions of Cementitious Pastes by Inductively

Coupled Plasma Optical Emission Spectroscopy (ICP-OES)1

This standard is issued under the fixed designation C1875; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Middle Distillate Fuels by Inductively Coupled Plasma

1.1 This practice describes a procedure for collection, Atomic Emission Spectrometry (ICP-AES)

sample preparation and analysis of aqueous pore solutions E1479 Practice for Describing and Specifying Inductively

obtained from cementitious materials at different hydration Coupled Plasma Atomic Emission Spectrometers

times when analyzed by ICP-OES for the six most common

readily soluble elements aluminum, calcium, potassium, 3. Terminology

silicon, sodium and sulfur. 3.1 Definitions:

1.2 The values stated in SI units are to be regarded as 3.1.1 Unless otherwise specified, for definitions of terms

standard. No other units of measurement are included in this used in this practice refer to Terminology C1738/C1738M.

standard.

1.3 This standard does not purport to address all of the 4. Summary of Practice

safety concerns, if any, associated with its use. It is the 4.1 This document describes practice for determining the

responsibility of the user of this standard to establish appro- concentration of multiple dissolved components in the pore

priate safety, health, and environmental practices and deter- solution of cementitious pastes as a function of time using

mine the applicability of regulatory limitations prior to use. inductively coupled plasma optical emission spectroscopy

1.4 This international standard was developed in accor- (ICP-OES). A cementitious material is mixed with water at a

dance with internationally recognized principles on standard- desired water to solid ratio using a Practice D1129 certified

ization established in the Decision on Principles for the constant mixer. Aliquots of the mix are divided into centrifuge

Development of International Standards, Guides and Recom- tubes and stored in a water bath or environmental chamber at

mendations issued by the World Trade Organization Technical constant temperature. The samples centrifuged at different

Barriers to Trade (TBT) Committee. times. The extracted pore solution is filtered and diluted with a

5 % nitric acid solvent. The prepared test solutions flow into

2. Referenced Documents the plasma torch of the ICP instrument where it is vaporized

2.1 ASTM Standards: and ionized, producing characteristic atomic wavelength emis-

--`,`,````,``,,,,`,,`,`,``,,,,,`-`-`,,`,,`,`,,`---

C25 Test Methods for Chemical Analysis of Limestone, sion spectra. The spectra are dispersed by a high resolution

Quicklime, and Hydrated Lime grating and the intensities of the individual wavelengths are

C114 Test Methods for Chemical Analysis of Hydraulic measured. Elemental concentrations are determined by relating

Cement the emission intensities at specific wavelengths for an unknown

C1738/C1738M Practice for High-Shear Mixing of Hydrau- sample to analytical curves made from reference standards of

lic Cement Pastes known composition. The concentration of the elements in the

D1129 Terminology Relating to Water solutions can then be calculated. Internal standards compensate

D1193 Specification for Reagent Water for variations in test sample flow rates in the instrument.

D5673 Test Method for Elements in Water by Inductively

Coupled Plasma—Mass Spectrometry 5. Significance and Use

D7111 Test Method for Determination of Trace Elements in 5.1 The chemical composition of the liquid in cementitious

pastes is an important indicator of the solid component

1

reactivity at early times, being influenced by the content and

This test method is under the jurisdiction of ASTM Committee C01 on Cement

rate of reaction of readily soluble alkali components, lime, and

and is the direct responsibility of Subcommittee C01.23 on Compositional Analysis.

Current edition approved July 1, 2018. Published August 2018. DOI: 10.1520/ other soluble phases. Monitoring the solution composition with

C1875-18 time can provide valuable diagnostic information about cement

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by S&P Global under license with ASTM

1Licensee=PT Pertamina (Persero)/5987886001, User=Rullyanti, Novie

No reproduction or networking permitted without license from S&P Global Not for Resale, 02/07/2023 01:07:12 MST

C1875 − 18

quality and reactivity to supplement other sources of charac- 7.6 Calibration Blank Solution—5 % (v/v) HNO3.

terization data. This practice is intended to aid in the interpre-

7.7 Nitric Acid—5 % (v ⁄v).

tation of the concentrations of readily soluble components in

cement paste solutions, which may include portland cement, 7.8 Check Standards—Quality control certified NIST trace-

limestone, fly ash, ground granulated blast furnace slag, or able samples that are stable and representative of the samples

other components. It provides guidance for measuring the time of interest. These check standard samples represent ground

dependence of the concentrations of one or more components, truth samples and are used to check that the measurement

on an elemental basis, including, but not limited to, aluminum, process is in control.

calcium, potassium, silicon, sodium, and sulfur. 7.9 Internal Standards—Internal standards are used to cor-

6. Apparatus rect for instrument drift and physical interferences. Refer to

instrument operating manual for suggested internal standards.

6.1 Spectrometer—Spectrometer-An inductively coupled Add internal standards to blanks, samples, and standards in a

plasma emission spectrometer of the simultaneous or sequen- like manner.

tial type including RF generator, torch, nebulizer, connector

tube, spray chamber, recommended peristaltic pump and host 7.10 Membrane Filter—Nylon 25 mm diameter, 0.2 µm.

computer. Sample uptake is done by self-aspiration, or with a 7.11 Syringe and Needle—Capacity of at least 2 mL.

peristaltic pump.

7.12 Centrifuge Tubes—Clean plastic centrifuge tubes the

6.2 Mass Flow Controllers—A mass-flow controller to regu- appropriate size for centrifuge.

late the nebulizer gas may be used as recommended by the

instrument manufacturer. 7.13 Glassware—Volumetric flasks complying with the re-

quirements of ISO 1042, made of borosilicate glass complying

6.3 Balance—Top loading or analytical, with automatic tare, with the requirements of ISO 3585. Glassware should be

with capacity of at least 500 g and a sensitivity of at least 0.1 cleaned before each use by soaking in nitric acid and then

g to weigh paste mix components. rinsing thoroughly with deionized water.

6.4 Centrifuge—Use a centrifuge capable of accommodat-

7.14 Pipette—Calibrated volumetric pipettes and pipette

ing two or more 50 mL centrifuge tubes at rotational speeds up

tips, for dispensing.

to 5000 min-1.

6.5 Timer—Calibrated timer for use of tracking blending 8. Hazards

and reaction times.

8.1 The toxicity or carcinogenicity of each reagent used in

7. Reagents and Materials this practice has not been precisely defined; however, each

7.1 Ordinary laboratory apparatus are not listed, but are chemical should be treated as a potential health hazard.

assumed to be present. Adequate precautions should be taken to minimize exposure of

personnel to chemicals used in this practice.

7.2 Purity of Reagents—At a minimum, reagent grade or

better chemicals shall be used in all tests. 8.2 Gases under high pressure are used in this practice. Use

only apparatus rated for handling the high gas pressures that

7.3 Purity of Water—References to water shall be under- occur in this practice.

stood to mean deionized water. Tap water may be used only to

prepare cement paste mixes if desired. If tap water is used for 9.1 Powder Homogenization—A uniform distribution of

mixing the composition of the water itself must be separately powder components is essential to ensure representative sam-

--`,`,````,``,,,,`,,`,`,``,,,,,`-`-`,,`,,`,`,,`---

measured as a test sample as described in Section 11. pling during the mixing process, especially for blended powder

components such as portland cement and fly ash. Powders

7.4 Argon—High purity grade (99.99 %).

should therefore be homogenized for 30 minutes with a

7.5 Calibration Standards—Single-element or multi- planetary mixer or similar device.

element calibration reference solutions that combine appropri-

ate volumes of the stock solutions or weighed reagent-grade 10. Sample Preparation and Collection

chemicals in acid-rinsed volumetric flasks. Dilute to the

volume of the flask using a 5 % (v/v) nitric acid solution. Prior 10.1 High Shear Mixing:

to preparing the multi-element solutions, analyze each stock 10.1.1 Blend the solid and liquid components to make a

solution separately to check for strong spectral interference and paste according the standard practice described in Practice

the presence of impurities. Take care when preparing the D1129.

multi-element solutions to verify that the components are 10.1.2 Set a timer to mark the end of mixing. The time on

compatible and stable (i.e., that they do not interact to cause this timer will serve as the total reaction time for the remainder

precipitation) and that none of the elements present will of the procedure.

contribute to mutual spectral interference. Calibration refer- 10.1.3 Stir the paste with the spatula for no more than 15 s

ence solutions must be verified initially using a quality control ensure homogeneity.

sample and monitored periodically for stability. Mixed calibra- 10.1.4 Transfer (25 6 1) g of the paste into each of twelve

tion standards will vary, depending on the number of elements centrifuge tubes with secured lids in the minimum amount of

being determined. time possible, preferably less than 2 min.

Copyright ASTM International

Provided by S&P Global under license with ASTM

2Licensee=PT Pertamina (Persero)/5987886001, User=Rullyanti, Novie

No reproduction or networking permitted without license from S&P Global Not for Resale, 02/07/2023 01:07:12 MST

C1875 − 18

10.1.5 Place the twelve centrifuge sample tubes upright in 12. Interfaces

sample holders and place them in the temperature control 12.1 Refer to ICP-OES operating manual for instructions on

device (water bath or environmental chamber). minimizing and checking for interferences.

10.2 Liquid Solution Extraction:

10.2.1 Refer to manufacturerâs manual for instructions 13. Preparation of ICP-OES Apparatus

on safe and optimal operation of centrifuge. 13.1 Prepare and operate the spectrometer in accordance

10.2.2 Set centrifuge parameters to 5000 rpm for approxi- with the manufacturerâs instructions. The present practice

mately 1 min, and load one centrifuge tube filled with (25 6 1) assumes that good operating procedures are followed. Design

g of solid to serve as a counterweight. differences between spectrometers make it impractical to

10.2.3 Within the first 10 min on the timer, select one of the specify the required steps in detail.

samples and place it into the centrifuge opposite the preloaded 13.2 Peristaltic Pump—If a peristaltic pump is used, inspect

counterweight. Begin centrifuging. Record the time indicated the pump tubing and replace it, if necessary, before starting

on the timer when the centrifuge started. each day. Verify the solution uptake rate and adjust it to the

10.2.4 Immediately after the centrifuge comes to a complete desired rate.

stop, remove sample centrifuge tube. 13.3 ICP Excitation Source—Initiate the plasma source at

10.2.5 Using a needle tip syringe, extract pore solution from least 30 min before performing an analysis. During this warm

sample without disturbing solid material in tube. up period, nebulize either water or a dilute (5 %) acid solution.

10.2.6 Invert syringe and cautiously remove needle tip and NOTE 3—Some instrument manufacturers recommend even longer

add a 0.20 µm nylon membrane filter at the syringe opening. warm-up periods to minimize changes in the slopes of calibration curves.

--`,`,````,``,,,,`,,`,`,``,,,,,`-`-`,,`,,`,`,,`---

10.2.7 Transfer pore solution from syringe through filter 13.4 Wavelength Profiling—Perform any wavelength profil-

into a clean empty plastic sample container. Label and note ing that is specified in the normal operation of the instrument.

centrifugation time recorded in 10.2.3. 13.5 Operating Parameters—Assign the appropriate oper-

10.2.8 Repeat 10.2.2 through 10.2.7 at different desired ating parameters to the instrument task file so that the desired

times, based on the running time being kept on the timer set in elements can be determined. Parameters to be included are

10.1.2. element, wavelength(s), background correction points

NOTE 1—Many cement pastes will begin to harden after three hours, or (optional), inter-element correction factors, and integration

perhaps even sooner, making extraction of the liquid by a centrifuge time. Multiple integrations (typically three) are required for

difficult or impossible. each measurement. A typical measurement time is 10 s.

11. Preparation of Test Solutions and Standards 14. Calibration and Standardization

11.1 Preparation of Test Sample: 14.1 Allow the ICP-OES instrument to warm up for at least

11.1.1 Transfer appropriate amount of a filtered sample into 30 min. Operate the spectrometer according to the operation

a volumetric flask then dilute to volume with 5 % HNO3. manual for the instrument.

Repeat for each filtered pore solution from 10.2. 14.2 Calibrate the instrument for the elements chosen over a

suitable concentration range by atomizing the calibration blank

NOTE 2—Appropriately dilute samples to within the calibration range of

each chosen element. and mixed calibration standard solutions, including any inter-

nal standards, and recording their concentrations and signal

11.2 Preparation of Calibration Standard: intensities. A minimum of six standards and a blank should be

11.2.1 Blank—Prepare a blank solution by adding same used for calibration with one of the standards. The computer

concentration of diluted acids as used in the sample dissolution software will establish the slope, intercept and correlation

(usually 5 % nitric acid). coefficients for each element. Use manufacture suggested

11.2.2 Calibration Standards—repare known concentrations wavelengths each element. The calibration correlation coeffi-

of single-element or multi- element calibration reference solu- cient shall be equal to or greater than 0.990. It is recommended

tions by combining appropriate volumes of the stock solutions that the calibration blank and standards be matrix matched with

in acid-rinsed volumetric flasks. Add sufficient 5 % nitric acid the same acid concentration contained in the samples. Analyze

to dilute to volume. Take care when preparing the multi- appropriate reference solutions to validate the calibration of the

element solutions to verify that the components are compatible instrument before proceeding to the sample analysis.

and stable (they do not interact to cause precipitation) and that 14.3 Alternatively, calibrate according to the manufacturer’s

none of the elements present exhibit mutual spectral interfer- instructions if equivalent results are achieved.

ence. Calibration reference solutions must be verified initially

using a quality control sample and monitored periodically for 15. Analysis by Inductively Coupled Plasma Optical

stability. Emission Spectroscopy

11.3 Preparation of Check Standard: 15.1 Aspirate the prepared samples into the calibrated

11.3.1 Prepare the same way as the calibration standards instrument using the same conditions established for the

11.2.2 specifically using NIST traceable certified reference calibration procedure. Rinse sufficiently to prevent carryover

solutions. between samples.

Copyright ASTM International

Provided by S&P Global under license with ASTM

3Licensee=PT Pertamina (Persero)/5987886001, User=Rullyanti, Novie

No reproduction or networking permitted without license from S&P Global Not for Resale, 02/07/2023 01:07:12 MST

C1875 − 18

15.2 Run a blank and a check standard (certified NIST 16.3.2 The result obtained for the LCS shall fall within the

traceable solution) every few samples or as established to be limit of 610 % of the expected value, or meets the desired

necessary for the instrument. Analyze a blank and check limits. If the result is not within these limits, reporting of

standard at the end of each run. The concentration shall be results should be halted until the problem causing the deviation

within 610 % of the expected value and the internal standard is identified and resolved. An indication of the occurrence

should fall within established limits of deviation. If the should accompany the reported results.

concentration is out of range, correct the problem, recalibrate

the instrument and rerun the samples in question. 17. Calculations

15.3 Perform the corrections and calculations, including 17.1 To calculate the concentration of each element in the

dilution factors, using the instrument host computer. original undiluted solution, multiply the measured concentra-

tion of that element by the dilution factor.

16. Quality Control

--`,`,````,``,,,,`,,`,`,``,,,,,`-`-`,,`,,`,`,,`---

16.1 Confirm the performance of the instrument and cali- 18. Report

bration curve by analyzing a quality control sample. 18.1 Data to report shall include the following:

16.2 Internal Standard: 18.1.1 All sample and standard information including

16.2.1 Select the appropriate internal standard element(s) source details;

for the capabilities (mass availability, sensitivity) of the ICP- 18.1.2 Sample analysis results;

OES instrument available. Yttrium is often used as an internal 18.1.3 Quality assurance and quality control data;

standard for this purpose. The element(s) chosen for the 18.1.4 Identity of laboratory analysts;

internal standard should not be a component of the test 18.1.5 Information on instrumentation operation and equip-

specimen or calibration standard. Add internal standards to ment used;

blanks, samples, and standards in a like manner. 18.1.6 Any other information that may help identify the

specimen preparation conditions or measurement conditions.

16.3 Laboratory Check Standard (LCS):

16.3.1 To ensure that the test method is in control, analyze 19. Precision and Bias

a certified NIST traceable standard solution every few samples

or as established to be necessary for the instrument. The 19.1 This practice is provided for users to develop their own

standard added to 5 % HNO3 (v/v) should be appropriate for precision and bias statements when using this method.

the type of samples analyzed and should produce results of

sufficient precision to ensure meaningful assessment of accu- 20. Keywords

racy. The LCS must be taken through all the steps of the 20.1 atomic emission; cementitious; chemical analysis; hy-

analytical method including sample preservation and pretreat- dration; ICP; inductively coupled plasma; optical emission;

ment. pore solution; spectroscopy

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

Copyright ASTM International

Provided by S&P Global under license with ASTM

4Licensee=PT Pertamina (Persero)/5987886001, User=Rullyanti, Novie

No reproduction or networking permitted without license from S&P Global Not for Resale, 02/07/2023 01:07:12 MST

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stream of NectarDocument4 pagesStream of NectarderekmendozaNo ratings yet

- Why Are Black Women Rated Less Physically Attractive Than Other Women, But Black Men Are Rated Better Looking Than Other Men?Document6 pagesWhy Are Black Women Rated Less Physically Attractive Than Other Women, But Black Men Are Rated Better Looking Than Other Men?koa_x100% (2)

- 2004, Vol.22, Issues 2, The Clinical Use of Botulinum ToxinDocument90 pages2004, Vol.22, Issues 2, The Clinical Use of Botulinum ToxinRizweta Destin100% (1)

- Gastropod Saudi ArabiaDocument9 pagesGastropod Saudi Arabiajadoonreal1979No ratings yet

- Episode 1Document8 pagesEpisode 1iisuperraghaviiNo ratings yet

- L0810348 PDFDocument98 pagesL0810348 PDFhughstimsonNo ratings yet

- Multiple Myeloma Case Studies (Tandem 2017) (Final)Document52 pagesMultiple Myeloma Case Studies (Tandem 2017) (Final)Syed Ali Akbar100% (2)

- 00 EAN Abstract 2016 BookDocument956 pages00 EAN Abstract 2016 BookAlexandra MardareNo ratings yet

- 27-07-19 SR - Icon, Neon & Medicon (Reg) Board W.e-Viii Chemistry (Pu) Q.paperDocument2 pages27-07-19 SR - Icon, Neon & Medicon (Reg) Board W.e-Viii Chemistry (Pu) Q.paperudaya bhasakrNo ratings yet

- Exercise-7-ProtozoanDocument3 pagesExercise-7-Protozoanyzabelgodwyn.villeguezNo ratings yet

- Play Therapy With AdultsDocument26 pagesPlay Therapy With AdultsMateus MoraisNo ratings yet

- MD Tanjil 22Document1 pageMD Tanjil 22wasi Wasikhan890yahoo.comNo ratings yet

- Den ROCIP4 Safety ManualDocument111 pagesDen ROCIP4 Safety ManualMuhammad ImranNo ratings yet

- Brosur Geister Esu X-400htDocument4 pagesBrosur Geister Esu X-400htUlqiorra Blackwood100% (1)

- Account Statement From 1 Jan 2021 To 31 Jan 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 1 Jan 2021 To 31 Jan 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancevenkNo ratings yet

- Surgery: FacultyDocument9 pagesSurgery: FacultyShivam Dutta0% (1)

- SuperFlo High Performance Pump Owners Manual EnglishDocument16 pagesSuperFlo High Performance Pump Owners Manual EnglishAldiNo ratings yet

- Q4 Performance Task 1 Charles KMT Law and Boyles LawDocument2 pagesQ4 Performance Task 1 Charles KMT Law and Boyles LawAndrie SegueraNo ratings yet

- Lenormand Meanings - ProphetDocument2 pagesLenormand Meanings - Prophetlottimagi100% (1)

- NEW Normal Tissue Tolerance Master 11-2014Document11 pagesNEW Normal Tissue Tolerance Master 11-2014damodara kumaranNo ratings yet

- Food Processing - PPTDocument20 pagesFood Processing - PPTAngelie Rescallar100% (2)

- STRATAFIX Portfolio For Robotic Surgery BrochureDocument12 pagesSTRATAFIX Portfolio For Robotic Surgery BrochureRodrigo AlencarNo ratings yet

- Design and Implementation of An Infant Monitoring and Control SystemDocument58 pagesDesign and Implementation of An Infant Monitoring and Control SystemKOFI BROWNNo ratings yet

- Unit 1Document14 pagesUnit 1Mohammed HussainNo ratings yet

- Trucks DesigDocument116 pagesTrucks DesigEdgar Rojas EspejoNo ratings yet

- Radioactivity 6 QPDocument6 pagesRadioactivity 6 QPshookookie 101No ratings yet

- Physical Effects Employed For Signal TransductionDocument24 pagesPhysical Effects Employed For Signal TransductionrimalisaacNo ratings yet

- A Study On Sale and Distribution Management of Hindustan Unilever LimitedDocument35 pagesA Study On Sale and Distribution Management of Hindustan Unilever LimitedJakir HussainNo ratings yet

- Safety Data Sheet: Valvoline Valplex EP GreaseDocument7 pagesSafety Data Sheet: Valvoline Valplex EP Greasediah ayuNo ratings yet

- Daikin Itouch ManagerDocument16 pagesDaikin Itouch ManagerSurya LiemNo ratings yet