Professional Documents

Culture Documents

Soil Type

Soil Type

Uploaded by

Sohail Younis0 ratings0% found this document useful (0 votes)

7 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesSoil Type

Soil Type

Uploaded by

Sohail YounisCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

lopment -Coastal Village Ad" for Land Raising 4,

= All observed soft spots or loose zones should be compacted in place or excavated to

firm soil and replaced with properly compacted fil

= Receive fill areas should be proof rolled and inspected after clearing and grubbing, soft

spots or loose zones.

7.2.2. Subgrade Preparation and Compaction Criteria

‘The following are requirements of fil placement and compaction:

= Fill material shall be placed in lifts not exceeding 200mm in loose depth.

= Compacting shall begin only after the fil has been properly placed and material to be

compacted within 3%, plus or minus of the optimum moisture content as determined by

ASTM D-1557,

For asphalt pavement subgrade, fill shall be compacted to 85% relative density for

cohesionless solls or 95% of the maximum density as determined by ASTM D-1857 for

cohesive materials.

As per SAES-Q-006 where existing subgrade materials have a CBR of 5 or less, a sub

base with a minimum CBR of 15 shall be provided with a minimum thickness of 20cm. CBR

shall be determined by ASTM D 1883 at 95% compaction to ASTM D 1557 or AASHTO T

180, This sub base should not be considered as MOT sub base class A or B unless it

meets the requirement defined in Tables 4, 5 and 6 of SAES-Q-006.

7.3. Protection of found:

Sulfate altack to concrete is a welldocumented phenomenon and is caused by the

presence of high Sulfate content coming from either the ingress of the Sulfate of the

surrounding environment, such as, foundations soils or by the presence of Sulfate in the

concrete ingredients such as sand or aggregate, or both. The attack results in a

considerable internal expansion which may lead to cracking and disintegration of the

concrete,

It should be noted that practical experience has indicated that mixes having both minimum,

‘cement content and maximum free water to cement ratio may result in concrete of low level

of workability, such that full compaction to achieve dense concrete to resist chemical attack

cannot be easily achieved. It may be therefore, practical to increase the cement content

while maintaining the recommended water fo cement ratio in order to obtain the

appropriate workability to achieve full compaction of the concrete

Buried reinforced concrete is susceptible to deterioration by chemical attack if the

chemicals are in a solution form, and above a certain concentration. The two major types of

chemical attack are due to sulfate and chloride concentrations in the ground

as per SAES Q-001 and based on the results of chemical analysis conducted on the

subsurface form actions following are our recommendation for foundation;

Type of Cement: | + Pozzolan or slag

© Minimum Cement Content: 350 kgim3.

+ Maximum Water Cement Ratio: 0.4.

* Minimum Concrete Cover: 7.5 om.

* Minimum compressive strength of concrete fc = 32 MPa

+ Bitumen tanking membrane on the concrete surface.

'$19000221-Rev.0-Final Report Page 14 of 32

lopment -Coastal Village Ad" for Land Raising 4,

Cement below grade concrete should conform to Saudi ARAMCO Specification SAES-Q-

001. Concrete should be densified using vibrators. Minimum concrete cover for

reinforcement of foundations should be 75 mm (SAES Q-001). Concrete placed upon and

below grade shall be as follows:

= Plasticized sheet vapor barrier, minimum 0.25 mm (10 mils) in thickness, shall be

placed beneath slabs on grade. Outdoor sidewalks are exempted from this

Fequirement, Foundations shall have either a plasticized vapor barrier, minimum 0.25

mm in thickness or 50 mm sub-slab placed beneath the concrete.

= Plasticized sheet vapor barrier, minimum 0.25 mm (10 mils) in thickness or a 50 mm.

sub-siab (lean concrete) shall be placed beneath concrete foundations.

= Plasticized sheet vapor barrier shall be placed below and around the sides of concrete

that is placed directly into excavation without the use of formwork, where coal tar or

bitumen coating cannot be applied,

In addition, to provide a physical barrier to chloride migration and chloride attack of

reinforcing steel, consideration should be given to the use of concrete coatings such as

coal tar or bitumen that conforms to APCS-3 or APCS-10 of SAES-H-101. Epoxy coated

steel reinforcing may be considered for use but caution should be exercised since poor

handling and steel fixing can result in damage to the coating

7.4 Protection of Utilities

It is necessary that all the utility lines (water, sewage, oil pipelines and cables, etc.) be

protected against corrosion due to presence of deleterious salts in the soil materials used

for backfilling of utility trenches. Such protection can be provided by coating all the utility

lines with bitumen / epoxy paint. Waterproofing membrane or tanking shall be applied on all

underground concrete surfaces. It is recommended to conduct a drainage system for the

underground water by providing perforated pipes system at foundation level around the

buildings. For protection specifically required for certain underground utilities the

specifications of the manufacture of such utility should be followed.

7.5 Protection of Slopes

Soil particles are susceptible to being detached and carried away with concentrated runoff

streams, forming rills and gullies that grow with time, The slope integrity is diminished,

eroding the slope face and becoming a larger environmental and safely issue. Slopes

steeper than the natural angle of repose for the slope materials require additional

protection measures, as are slopes subject to more severe hydraulic stresses,

EnviroGrid effectively holds slope cover materials in place, thus reducing the potential for

erosion. Cell walls check the runoff streams associated with rainfall, keeping the overall

system intact. The infill material also rests within individual cells, allowing for much higher

angles of repose. EnviroGrid filled with soil promotes vegetation as both another source of

reinforcement and natural aesthetics. Overall effectiveness of the system is increased with

the plant roots integrated into the grid system

7.6 Pavements and Slabs-on-Grade

Subgrade suitability as per SAES-Q-006 section 4.3, where existing subgrade materials

have a CBR of 5 or less, a sub-base with a minimum CBR of 15 shall be provided with a

minimum Thickness of 20cm, CBR shall be determined by ASTM D 1883 at 95%

compaction to ASTM D 1557 or AASHTO T 180. This sub-base should not be considered

as MOT sub-base class A or B unless it meets the requirement defined in Tables 4, 5 and

6 of SAES.Q-006.

'$19000221-Rev.0-Final Report Page 15 of 32

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- R03 I24b01 Cce XX XX SDW Ic 10323Document1 pageR03 I24b01 Cce XX XX SDW Ic 10323Sohail YounisNo ratings yet

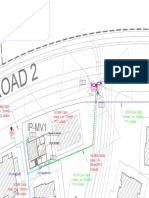

- Road 1 ProfileDocument1 pageRoad 1 ProfileSohail YounisNo ratings yet

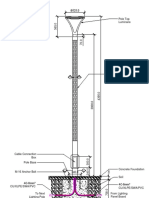

- Motion Detector Detail For Individual PoleDocument1 pageMotion Detector Detail For Individual PoleSohail YounisNo ratings yet

- Wallpapers 1Document102 pagesWallpapers 1Sohail YounisNo ratings yet

- Lighting Pole DetailDocument1 pageLighting Pole DetailSohail YounisNo ratings yet

- CamScanner 02-05-2023 09.59Document1 pageCamScanner 02-05-2023 09.59Sohail YounisNo ratings yet

- MV1 ModelDocument1 pageMV1 ModelSohail YounisNo ratings yet

- R03 I24b01 Cce XX XX Abd DR 10200 PDFDocument1 pageR03 I24b01 Cce XX XX Abd DR 10200 PDFSohail YounisNo ratings yet

- Irrigation 4&5 - Surge Analysis ReportDocument29 pagesIrrigation 4&5 - Surge Analysis ReportSohail YounisNo ratings yet

- Irrigation 1,2&3 - Surge Analysis ReportDocument29 pagesIrrigation 1,2&3 - Surge Analysis ReportSohail YounisNo ratings yet

- MV 2 ModelDocument1 pageMV 2 ModelSohail YounisNo ratings yet