Professional Documents

Culture Documents

27 Pattern of Holes

27 Pattern of Holes

Uploaded by

Ramiro Acosta Cepeda0 ratings0% found this document useful (0 votes)

18 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views10 pages27 Pattern of Holes

27 Pattern of Holes

Uploaded by

Ramiro Acosta CepedaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

ENC Programming Handbook 3 Elion

27

PATTERN OF HOLES

In point-to-point machining operations, those consisting,

of dalling, reaming, tapping, boring, etc., we are often r=

{quired to machine either a single hole or a series of holes

with the same tool, usually followed by other tools. In pra

tice, several holes are much more common than a single

hole, Machining several holes with the same tool means

machining a patiern of holes ora hole paitern. An English

dictionary defines the word 'pattem' as a ‘characteristic or

consistent arrangement or design’. Translated to hole ma-

chining terms, any two or move holes machined with the

same tool establish a pattern, The desired hole pattern is

laid out in the part drawing either randomly (characterisuic

‘arrangement or design) or ina certain order (consistent ar-

‘rangement or design). Dimensioning ofa hole pattern fol-

lows standard dimensioning practice.

‘This chapter describes some typical hole pattems laid out

fon a flat part and the various methods of their program-

ming. To make matters simple, all programming examples

related to hole pattems will assume a center drilling opera-

tion, using a #2 conter drill, with chamfer diameter 0.150,

1 the depth of 0.163 (programmed as Z-0.163 - see page

202), Program zero (program reference point 20) isthe top

face of part and the tool is assumed to be already in the

spindle. For the purposes of clarity, no hole diameters or

material size and thickness are specified in the examples,

From the dictionary definition above, we have to est-

lish what makes a hole pattem characteristic or consistent.

Simply, any series of holes that are machined with the same

tool, one hole after another, usualy inthe ender of conven:

snce. That means all holes within a single pattem have the

same nominal diameter. It also means that all machining

rust stat atthe same R-level and end at the same Z-| poser

H$esooooee 4+

+

a6

al tsa

Figure 27-2

‘Stalght row bale pato - program example 02702

Programming approach takes advantage of a fixed cycle

repetition feature, using the K or Laddress. It would by

iient to program each hole individually. As always, the tool

will be positioned atthe frst hole in G90 mode, then the ey=

cle will machine this hole in block NS.

For the remaining holes, G90 mode must be changed to

xeremental mode GOL, which instructs the control to ma

chine the remaining nine holes incrementally, along the

X-axis only. The same logie would also apply fora vertical

paticm along the Y-axis, In that case, the pitch increment

‘would be programmed along the Y-axis only. Note that the

repetition count is always equal to the number of spaces,

not the number of holes. The reason? ‘The first hole has al

ready been machined in the eyele eal block.

G43 21.0 HOI Mos

G99 Gai RO.1 2-0.163 3.0

0.95 19

09

20 mos

x0 YO

‘Two features of program 02702 should be emphasized

Inblock N6, the dimensioning mode was changed from ab-

solute G90 fo incremental G91 mode, to take advantage of

the equal pitch distance. When all ten holes have been ma-

‘chined, the program hs to include return to machine 2er0

position motion, inthe example, along all three axes. How=

fever, without a calculation, we do not know the absolute

position atthe tenth hole forthe X-axis (the Y-axis remains

unchanged atthe position of 0.60 inches ~ Y0.6). To solve

this ‘problem, cancel the cycle with G80, leave G91 mode

in effect and move to machine 2er0 position in the Z-axis,

first (for safety reasons). Then - stil in the incremental

mode G91 ~ return both X and Y axes to machine zero si:

multancously.

Normally, this first tool of the example would be fol-

lowed by other tools wo complete the hole machining. To

protect the program and machining from possible prob-

Jems, make sure that the G90 absolute command is rein-

stated for every tool that follows,

ANGULAR ROW HOLE PATTERN

Patter of holes in a row at an angle is variation of a

straight line pattem. ‘The difference between them is that

the incremental pitch applies to both X and Y axes. A hole

patter of this type will be established on the part drawing

as one of two possible dimensioning methods:

‘= X and ¥ coordinates are given forthe ist and last hole

{In this method, the pattem angular position is not speci-

fied and no pitch between holes is given,

‘=X and ¥ coordinates are given forthe first hole only

In this method, pattem angular position is specified and

the piteh between holes is given.

In cither ease, all necessary X and ¥ dimensions are

available to write the program. However, the programming

approach will be different for cach method of drawing

dimensioning.

+ Pattern Defined by Coordinates,

This method of programming is similar to the

row patie Since the pitch between holes is not given, the

increment between holes along each of the two axes must

be calculated, This axial distance is commonly known as

the delia distance (delta X is measured along the X-axis,

delta ¥ is measured along the Y-axis) Such calculation can

bbe done in two equally accurate ways.

‘The first calculation method can use a trigonometric

‘method, but itis much easier to use the ratio of sides in-

stead. In Figure 27-3, the pattern length along X-axis is

10.82 and along Y-axis it is2.0: (2.625 -0.625 = 20)

ENC Programming Handbook 3 Elion

PATTERN OF HOLES

227

N6 G91 X2.164 ¥O.4 KS (L5)

1.0. 10.82:

Figure 27-3

‘Angi ole pate with 0 sets of coonates- rogram 02703

Patter of this kind has all holes spaced by oqual dis-

tances along X and Y axes. As all holes are equally spaced,

the ratio of sides for individual hols i identical tothe ratio

of whole pattern, When expressed mathematically, the in-

cerement between holes along the X-axis is equal to the

overall distance of 10.82 divided by the number of X-axis

spaces; the increment along the Y-axis is equal to the over-

all distance of 2.0 divided by the number of Y-axis spaces.

Number of spaces for a six hole pattem is five, so the

X-axis inerement (delta X) is:

10.82 / 5 = 2.1640

and the Y-axis increment (delta Y) is:

2.0/5=0.48

Te other calculation method uses trigonomettic func-

tions, which may also be used as a confirmation of the frst

method, and vice versa. Both results must be identical, oF

there is a mistake somewhere in the calculation. First, =

tablish some temporary values:

A= tan™(2.0 / 10.82) = 10.47251349°

c

0 / sina = 11.00329063

a

c/s

20065813

Now, the actual increment along the two axes ean be cal

culated, using C1 dimension as the distance between holes:

X increment = Cl x cosh

Y sneremant = Cl = sink

2.1610

‘4000

Both calculated increments match, calculation is correct,

‘and can now be used to write the program (02703) - block

N6 contains the values

3 G90 G54 GOO x1.0 ¥0.625 $900 03

Na GA 21.0 #01 MOR

N5 G99 G8i RO.1 2-0.163 3.0

7 G80 HOB

9 G28 20 m5

9 G28 x0 x0

io 180

‘

Note thatthe program structure is identical to the exam-

ple ofthe straight row pattem, except the incremental move

with KS (LS) address is along two axes instead of one.

‘© Pattern Defined by Angle

An angular line patter ean also be defined in the draw-

ing by the X and ¥ coordinates ofthe first hole, number of

‘equally spaced holes, distance between holes and the angle

of pattern rotation - Figure 27-4

aor?

= Se am

{ mil ‘

20

7+

20

gure 27-4

‘Angular hole patiom wi coontes, ard angle 2704

In order to calculate the X and Y coordinate values, use

trigonometric functions in this case:

x

¥

4.0. cosis

4.0 x eins

3.063703305,

1-03527618

Program can be written after you round of the calculated

values - program 02704:

17 Go cao

G90 G54 GOO x2.0 ¥2.0 900 M03

43 21.0 01 MOS

G99 G8i_RO.1 2-0.163 F3.0

G91 94.8637 ¥1.0353 Ke (L6)

cao OS

28 20 05

28 x0 YO

10

SESRGEGRA

mo

2

Since the calculated increments ae rounded valuos, a cata

‘accumulative errs inevitable In most cases, any eor will

be well conainad within the requited drawing tolerances.

However, for projects requiing the highest precision, ths error

‘may be important and must be takon into consid

ENC Programming Handbook 3 Elion

228

Chapter 27

To make sure all ealeulations are correct, simple check-

ing method can be used to compare all calculated values:

© Stop 1

Fin the absolute coordinates XY ofthe fast hole:

2.0 + 4.0 x 6 x cosis

= 25.18221963 = x25. 1622

© Step 2

Compare these new XY coordinates with the previously

calculated increments as they relate to the last hole of the

pattem (using rounded values):

x

x

3.8637 x 6

1lo3sa x 6

25.1822

@.2u18

Note that both X and ¥ valuesare accurate, When round

ing, particularly when a large number of holes is involved,

‘the accumulative crror may cause the hole pattem out of |

tolerance. In that ease, the only correet way to handle pro-

gramming isto calculate the coordinates ofeach hole as ab-

solute dimensions (that means from a common point rather

than a previous point), Programming process will take a lit-

tle longer, but it will be much more accurate.

CORNER PATTERN

Patter of holes can be arranged as a comer - which is

nothing more than a pattem combining the straight andlor

angular hole patterns - Figure 27-5

corner hole will be machined hwice. Visualize the complete

process - the /ast hole of one row pattem is also the first

hole of the next pattern, duplicated, Creating a special cus-

tom macro is worth the time for many comer pattems, The

‘normal solution isto move the tool 0 its frst position, call

the required cycle and remain within that cycle:

3 G90 GS4 GOO x2.2 v1.9 $900 03

Na GA 21.0 #01 MOR

5 G99 Gai RO.1 2-0.163 3.0

N6 GOL M15 ¥i.8 K2 (12)

7 21.8 6 (16)

NB ¥-i.8 K2 (12)

No Gao’ mog

Lo G22 20 Mos

NLL G28 x0 YO

BZ 180

‘

‘This program offers no special challenges. In block N6,

the angular row of holes is machined, starting from the

lower let hol, in N7 itis the horizontal row of holes, and

in NS the vertical vow of holes is machined, for continuous

order. Just like in the earlier examples, keep in mind that

the repetition count K ot L is for the number of moves

(spaces), not the number of holes.

GRID PATTERN

Basic straight grid pattem can also be defined as a set of

equally spaced vertical and horizontal holes, each row hav-

ing equally spaced holes. fspacing ofall vertical holes isthe

same as spacing of all horizontal rows, the final grid pattern

will be a square. If spacing of all vertical holes is not the

‘same as spacing ofall horizontal rows, the resulting grid pat-

{em isa rectangle, A grid pattem is sometimes called a rect-

angular hole pattern - Figure 27-6,

te ey

0000 a or

‘ T 000

19 e000) 24

7@ o000

wel 2 LL 00000

00000

Figure 27-5 00000

‘Corner pattem of holes - program example 02705 HPooog

All rules mentioned for the straight and angular hole pat- 24

tems apply fora comer patem al, Tees npr la

diferene the comer whichis conmmon to tworows

corner patier can be programmed by calling a fixed ey-

cle for each row. Soon, it will become apparent that each

Figue 276

Rectangular gid hale ptt program example 02706

ENC Programming Handbook 3 Elion

PATTERN OF HOLES

229

A grid patter is very similar to a series of comer pattems,

using similar programming methods. One major consid-

cration for a grid pattern programming is in its efficiency.

Each row can be programmed as a single row pattem, start-

ing, for example, from the left side of each row. Techni-

cally that is correct, althouzh not very efficient duc to loss

‘of time, when the tool has to travel fromthe last hole of one

row, t0 the first hole ofthe next row,

More efficient method will look like a zigeae motion. To

program a zigzag motion, program the first row or column,

starting at any comer hole, Complete that row (column),

then jump to the nearest hole of the next row (column) and

repeat the process until ll rows and columns are done. The

‘wasted time of the rapid motion is kept to the minimum.

ma

ma

’

‘Two features of the program are worth noting - one isthe

jump from one row ofthe pattern to another ~ it has no rep-

‘tition address K or L, which is the same as KI (L1), be-

‘cause only one hole is being machined at that location. The

second feature may not be so obvious tight away. To make

the program a bit shorter, start along the axis that contains

the larger number of holes (Y-axis in the program example

(02706). This example isa variation on the previous exam-

piles and also adheres to all the rules established so far, A

special subprogram made for a grid pattem is also a com-

‘mon programming approach and can be used as well

‘® Angular Grid Pattern

Straight grid pattem is the most common pattern for

square and rectangular hole arrangement. A grid pattern

may also be in the shape of a parallelogram (hexagon, for

example), called an angular grid pattern ~ Figure 27-7.

Again, programming approach remains the same as for

previous rectangular grid patter, the only extra wotk re

(quired is the calculation of angular inerements, similar to

methods shown:

00000

oo0000e+4

o00000

ooo

gue 2-7

‘Angular gri ol pate - rogram example 2707

Unknown increment in the drawing isthe distance mea-

sured along the X-axis, froma hole in one horizontal row to

the next hole in the following horizontal row:

X = 4.6 x tanlé = 1.319028774 (0.319)

Program can be written ina similar way a forthe straight

row grid, except the extra jump’ between rows will take

place along both axes;

02707 GaGotAR GRID)

mao

2 G17 G40 G0

13 G90 G54 G00 x4.0 ¥3.5 $900 M03

G43 21.0 HO MOS

G99 Gai RO.1 2-0.163 3.0

BRRSSSRRE

Many experienced programmers will consider even more

efficient way of approaching the programs for grid patterns

by using subprograms or even User Macros. Subprogram

are expecially useful for grid pattems consisting ofa large

rhumber of rows oF a lage numberof eotums, as well as

several tools. The subject of subprograms, including a

practical example of a really large grid pattem, starts on

jpage 383. The subject of user macros is not covered inthis

hhandbook, but Hanue CNC Custom Macros book is avail

able from industrial Pres, Ine (www industriapress.com).

ENC Programming Handbook 3 Elion

230

Chapter 27

ARC HOLE PATTERN

Another quite common hole pattem is a set of equally

spaced holes arranged along an are (not circle). Such an

equally spaced set of holes along any portion of acirete cit

cumference ereates an are hole pattern.

Basic approach to programming an are hole pattern

should be the same as if programming any other pattern

Select the first hole that is most convenient. Is it the first

hole or the last hole on the are that is easier to find the coor-

dinates for? Perhaps starting at 0° (3 o'clock or East post

tion) would be a better choice? Mustration in Figure 27-8

shows a typical layout of an are hole pattern

a

R25 .

8 a0 Tye

10

! | 4 EQSP HOLES

15

Figure 2-8

‘Arc hole pate - rogram 02708

In the pattern, are center locations are known, sos the are

radius, angular spacing between holes and the number of

equally spaced (EQSP) holes along the circumference.

A number of ealeulations is needed to find the X and Y

coordinates for each hole center location within the bolt

hole patter. Procedure is similar to that of an angular line

ina grid pattem, but with several more calculations. These

calculations use trigonometric functions applied to cach

hole separately - all necessary data and other information

are listed in the drawing.

For any number of holes, exactly the double number of |

calculations will be required to get the coordinates for both

axes. Inthe example, there are four holes, therefore eight

calculations will be necessary. Initially, it may seem asa lot

of work. In terms of calculations, itis a lot of work, but

keop in mind that only two trigonometric Formulas are in-

volved for any number of holes, so all caleulations will bo

come a lot more manageable. Incidentally, this observation

can be applied to just about any other similar programming

application,

The best way to illustrate arc pattern programming, isto

use the drawing example above. Firs, the programming

task will be split into four individual steps:

© STEP

Start with calculation of hole that is nearest to 0° loea-

tion @ o'clock position or East direction), then continue for

‘other holes inthe counterclockwise direction of the ar,

© STEP2

Use trigonometric functions to calculate X and Y coordi-

inates of the first hole:

Hole #1 - at 20 degrees

x

x

‘© STEP3

Use the same trigonometric formulas asin Step 2 and cal-

cculate XY coordinates for the 3 remaining holes. For each

hhole in the pattern, increase the included angle by 20°, so

the second hole angle wll be 40", the third 60°, and soon:

Hole #2 at 40 degrees

X= 1.5 + 2.5 x costo = 3.415111108 (03.4151)

Y= 110 + 2.5 x indo = 2.606969024 (¥2.607)

Hole #3 - at 60 degrees

X= 1.5 + 2.5 x coe6o = 2.750000000 (X2.75)

x

Hole #4 - at 60 degrees.

110 + 2.5 x #in6o = 3.165063509 (x3.1651)

X= 1.5 + 2.5 x coeB0 = 1.934120804 (1.9341)

Y= 1.0 + 2.5» sino = 3.462019383 (x3.462)

© stera

Ifthe XY coordinates are calculated in the same order as

they will appear in the CNC program, the listing of all hole

locations can be used in that order (CCW shown):

x3.8492

xa.4151

32.7500

x1 9341

v1.g551

26070

¥311651

¥314620

Now, program for the hole are pattem ean be written, us-

wg the XY coordinates for each hole location from the es-

tablished calculations. program 02708:

(6 X3.4151 ¥2.607

7 32.75 ¥3.1651,

3 x119341 ¥3.462

ENC Programming Handbook 3 Elion

PATTERN OF HOLES

231

x9 G30 mos

io G22 20.1 0s

NLL G28 x1.9341 ¥3.462

m2 160

.

‘There are two other methods (pethaps more efficient) to

program an arc hole patter. The fist method will take an

advantage ofthe local coordinate system ((i32), described

‘on page 399. The second method will use polar coordinate

system (optional on most controls), described later in this

chapter - in program 02710 (page 233),

BOLT HOLE CIRCLE PATTERN

A patton of equally spaced holes along the cireumfer-

cence of a circle is called a holt circle pattern ora bolt hole

‘pattern. Since the circle diameter is actually pitch diameter

Of the pattem, another name for a bolt circle pattern of

holes is a pitch circle pariem. Programming approach is

very similar to any other patter, particulaely to the are hole

ppaticm and mainly depends on the way the bolt circle pat-

tem is oriented and how the drawing is dimensioned.

A typical bolt circle in a drawing is defined by XY coor-

dinates ofthe circle center, its radius or diameter, the num-

ber of equally spaced holes along the circumference, and

angular orientation of holes, usually in relation to the

X-axis (that is to the zero degrees).

A bolt circle can be made up of any number of equally

spaced holes, although some numbers are much more com-

‘mon than other, for example: 4,5, 6,8, 10,12, 16, 18,20, 24

In later examples, the 6-hole and the 8-hole patterns (and

their multiples) have two standard angular relationship to

the X-axis at 2ero degrees

Figure 27-9 is atypical bolt circle drawing, Programming

approach fora bol cirleis similar to that of arc pattem.

210.0

Figue 27-9

Bal cle ole pate - program 02708

First, select the machining location to stat from, usually

atprogram zero. Then find the absolute XY coordinates for

the center of given circle. In the illustration, bolt pattern

center coordinates ate X7-5Y6,0, There will be no machin-

{ng at this location, but the cirele center will be the starting

point for calculations of all holes on the bolt circle. When

the circle center coordinates are known, vite them down.

Each hole coordinate located on the circumference must be

adjusted by one of these values. When al calculations for

the first hole are done (based on cirele center), continue to

calculate the X and Y coordinates forall other holes on the

cirele circumference, in an orderly manner.

{In example 02709 are 6 equally spaced holes on the bolt

cirele diameter of 10.0 inches. That means there a 60" in-

crement between holes (360/660). The most common

starting position for machining is atthe boundary between

‘quadrants, That means the most likely start will beat a po-

sition that corresponds to the 3, 12, 9 or 6 o’clock on the

face of an analog watch. In his example, start will beat the

3 o'clock position. There is no hole atthe selected location,

thenearest one will bat 30” in the counterclockwise direc

tion. A good idea isto identify this hole as a hole number |

Other holes may be identified in a similar way, preferably

in the order of machining, relative to the first hoe.

Note that cach calculation uses the same format. Other

‘mathematical approach can be used as well, but watch the

consistency of all calculations - only the anele changes:

Hole #1 -at 30 degrees

X= 7.5 + 5.0» cos30 = 11,830127 («12.8301)

¥=6.0+ 5.0» sin30 = 9.500000 (v9.5)

Hole #2 -at 90 degrees

X= 7.5 + 5.0 « e090 = 7.500000 (X7.5)

¥ = 6.0 + 5.0» sin90 = 110000000 (x11.0)

Hole #3 -at 150 dogroes

16987298. (x3.1699)

‘50000000 (v8.5)

5 +5.

10+ 5.

4 at 210 degrees

7.5 + 5.0 x eoa210

6.0 + 5.0 x sinzi0

116987298 (x3.1699)

‘50000000 (3.5)

Hole #5 - at 270 degrees

7.5 + 5.0 « coa270

6.0 + 5.0 x ainz70

50000000 (7.5)

‘00000000 (1-0)

Hole #6 - at 330 degrees

12.830127 (911.8301)

3.500000 (¥3.5)

ENC Programming Handbook 3 Elion

232

Chapter 27

Once all coordinates ae calculated, program is written in

the same way as for other pattems, shown alread

It would be more logical to select the bolt circle center as,

program zero, rather than the part lower left comet. This

‘method would climinate moifications of bolt circle center

position for cach coordinate value and perhaps reduce a

possibility of an error. At the same time, it would make it

more difficult to set work offset (G54) on the machine. The

best solution is to use G2 local coordinate offset method

This method is especially useful for those jobs that require

translation ofthe bolt cirele patter (or any other pattern) 10

other locations of the same part setup. For details on local

coordinate offset and the G52 command, see page 399.

* Bolt Circle Formula

In the previous calculations, there are many repetitious

data, Basie methods are the same, only the angle changes.

This type of calculation offers an excellent opportunity for

creating a common formula that can be used, for example,

as the basis of a computer program, calculator data input,

tte. Figure 27-10shows the basic data for such a formula.

Using following explanations and formulas, coordinates

for any hole in any bolt circle patter can be calculated

casily. The formula is similar for both axes - study itwell:

= cos ((n-1) xB+A) xR +X,

Y= sin((n-1) x B+ A)xR+Y,

s

Hole X coordinate

Hote ¥ coordinate

Hole number counter - CCW from O°

Number of equally spaced holes

Angle between holes = 360/4

First hole angi - from 0°

Bot circle radius or bol circle giameter/2

Bol circle conte rom the X orign

Bolt ctce cantar ram the ¥ rgin

© Pattern Orientation

Bolt cirele pattem orientation is specified by the angle of

the first hole from 0° of the bolt circle.

In daily applications, bolt cele pattems will have not

only different number of holes, but different orientations as

‘well, Bolt circles most commonly affected are those whose

‘number of equally spaced holes is based on the multiples of

six (6,12, 18,24, ..) and multiples of eight (4,8, 16,24, 32,

). This relationship is important of

the first hole wll influence the postion of all other holes in

the bolt ciecle pattern,

Figure 27-11 shows relationship of te frst hole position

to the 0” location of abolt circle 0° location is equivalent to

the3 o'clock position or the East direction.

Figure 27-10

Basi data fora frmul ocala bt le pate cordate

Figure 27-411

Typealenentztens of i and eight hale at clas

ENC Programming Handbook 3 Elion

PATTERN OF HOLES

233

POLAR COORDINATE SYSTEM

So fi, all mathematical calculations relating to the ae or

bolt cirele patter of holes have been using lengthy tigo-

nometrc formulas to calculate each coordinate. This seems

to bea slow practice fora modern CNC system with a very

advanced computer, Indeed, there is a special program-

‘ming method available (usually as a control option) that

takes away all tedious calculations from an arc or bolt cir-

cle patter - it is called the polar coordinate system. There

fare 1Wo polar coordinate functions available, always ree

‘ommended to be written asa separate block:

Adie

cent <4 J!

G15 | Polarcoondinate system cancel OFF

G16 | Polar coordinate system ‘on

Program input values for bolt hole or are patterns may be

programmed with the polar coordinate system commands

‘Cheek first options of the control before using this method,

Programming format is similar to that of programming,

fixed cycles. In fact, the forma is identical -for example:

We G9. 8. KL LR BF.

‘Two fictors distinguish a standard fixed cyele from the

‘same cycle used in polar coordinate mode,

‘The first factor isthe initial command G that procedes the

cycle - no special G-code is required for a standard cycle.

For any cyele programmed in polar coordinate system

mode, the preparatory command G16 must be issued toa

tivate polar mode (ON mode). When polar coordinate

mode is completed and no longer required in the program,

‘command GIS must be used to terminate it (OFF mode).

Both commands must be in a scparate block:

ce (POLAR COORDINATES oN)

092.68... KK Re Be Bee

(DCHINING HOLES)

as (POLAR COORDINATES OFF)

BARZEs

"The sevond factor is meaning ofthe X and Y words. In a

standard fixed eyele, XY words detine the hole position in

rectangular coordinates, typically as an absolute location.

In polar mode and G7 in effect (XY plane), both words

take on a totally different meaning -specifying aradius and

an angle:

1 Xsword becomes rads ofthe bolt circle

"= Y.word becomes angle ofthe hole, measured trom 0°

Figure 27-12 illustrates all three basic input requirements

for a polar coordinate system,

Figure 27-12

Tree basi characteristics of polar corns

Inadltion to the X and Y data, polar coordinates also re-

guire the center of rotation (pivot point). This is the last

point programmed hejore G16 command. Karlier, data in

program O2708 and Figure 27-8 were calculated using

‘wigonometre functions. With the polar coordinates control

‘option, final program can be much simplified - 02710:

(6 G99 GAL X2.5 ¥20.0 RO.1 Z-0.163 F3.0

7 32.5 v40.0

8 2215 ¥60.0

9 92.5 80.0

wo Gis (POLAR COOROINATES OFF)

Ii G80 moo

In the next program 02711, holes are equally spaced on

bolt citcle circumference. Dimensions in Figure 27-13 are

applied to the polar coordinate programming method.

fe

e

Figure 27-19

Polar coordina Syston applied fo bl hla eke program 02711

ENC Programming Handbook 3 Elion

Chapter 27

234

02711 (G15-G16 FOLAR EXAMPLE)

mm G20

2 G17 G40 G80

3 G90 G54 G00 xO xO $900 03. (PIVOT For)

14 G43 21.0 HOL MOB

4S G16 (POLAR COORDINATES o8)

6 G99 GBl Xx6.8 YO RO.1 2-0.163 F3.0

7 X6.8 ¥60.0

a X6.8 ¥120.0

19 X6.8 ¥180.0

m0 X6.8 ¥240.0

mi x6.8 ¥300.0

m2 ais, (POLAR CooRDINATES OFF)

m3 G80 09

Note thatthe center of polar coordinates (also called pivot

point) is defined in block N3- itis the fast and ¥ location

programmed before the polar command G16 is called. In

the program example 02711, the center is at XOY0 loca-

tion (block N3) - compare it with program 02710.

Both, the radius and angle values, may be programmed in,

citer absolute mode G9 or incremental mode G91.

{fa particular job requires many arc or bolt hole pattems,

polar coordinate system option will be worthy of purchase,

even atthe cost of adding it later. Ifthe Fanuc User Macro

‘option is installed, macro programs ean be ereated without

having polar coordinates on the control and offer even

‘more programming flexibility,

# Plane Selection

Subject of planes is briefly deseribed on page 247, and in

detail as.a separate chapter, staring on page 279.

There are three mathematical planes, used for variety of |

ations, such as polar coordinates.

G17 | XV plane selection

G18 | ZX plane selection

G19 | YZ plane selection

Selection of a correct plane is exiremely critical to the

proper use of polar coordinates. Always make ita habit to

program the necessary plane,

ven the default G17 plane.

G17 plane is known as the XY plane. If working in another

plane, make double sure to adhere to the following rules:

The ist axis of selected pane

is programmed wit the are radias value

The socond axis af selected plane

is programmed asthe angular position of the hole

In a table format, all three plane possibilities are shown,

Note, that ino plane is selocted in the program, the control

system defaults to G17 - the XY plane.

Geode | Selected plane | Firstaxis | Second axis

a7 x X= radius | Y= angle

aa a Z=radus | X= ange

a9 % Y=radus | = onole

Most polar coordinate applications take place in the de-

fault XY plane, programmed with G17 command.

© Order of Mac!

ing

‘The onder in which holes are machined can be controlled

by changing the sign of the angular value, while the polar

‘coordinate command is in effect. If the angular value is

programmed as a positive number, the order of machining.

will be counterclockwise, based on 0° position. By chang

ing the value toa negative number, the order of machining,

‘will be clockwise (reversed),

This feature is quite significant for efficient program-

ming approach, particularly foe a large number of various

bolt hole pater. For example, a center drilling or spot

rill operation can be programmed very efficiently with

postive angular values (counterclockwise order). Start wil

be at the first hole and, after the tol change, drilling can

continue in reverse order, starting with the lst hole. Allan-

‘gular values will now be negative, forthe clockwise order

cof a subscquent tool. This approach requires a fot mor

‘work in standard programming, when polar coordinates are

not used, The polar coordinate application using G16 com

‘mand eliminates all unnecessary rapid motions, therefore

shortening the overall cycle time.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GD and T Project-1Document9 pagesGD and T Project-1Ramiro Acosta CepedaNo ratings yet

- ProjectDocument1 pageProjectRamiro Acosta CepedaNo ratings yet

- PROJECT1Document6 pagesPROJECT1Ramiro Acosta CepedaNo ratings yet

- Top FlangeDocument1 pageTop FlangeRamiro Acosta CepedaNo ratings yet

- Unit 4 Locating DevicesDocument18 pagesUnit 4 Locating DevicesRamiro Acosta CepedaNo ratings yet

- GD and T Project-1Document9 pagesGD and T Project-1Ramiro Acosta CepedaNo ratings yet

- Unit 8 Jigs & Fixture ConstructionDocument30 pagesUnit 8 Jigs & Fixture ConstructionRamiro Acosta CepedaNo ratings yet

- Unit 1 Introduction To WorkholdingDocument31 pagesUnit 1 Introduction To WorkholdingRamiro Acosta CepedaNo ratings yet

- CNC Final Project-Ramiro AcostaDocument7 pagesCNC Final Project-Ramiro AcostaRamiro Acosta CepedaNo ratings yet

- Unit 9 General-Purpose WorkholdersDocument12 pagesUnit 9 General-Purpose WorkholdersRamiro Acosta CepedaNo ratings yet

- Unit 3 Locating and Clamping PrinciplesDocument39 pagesUnit 3 Locating and Clamping PrinciplesRamiro Acosta CepedaNo ratings yet

- Unit 7 Drill BushingsDocument24 pagesUnit 7 Drill BushingsRamiro Acosta CepedaNo ratings yet

- Unit 5 Clamping DevicesDocument19 pagesUnit 5 Clamping DevicesRamiro Acosta CepedaNo ratings yet

- Ajustes Agujero Único Eje ÚnicoDocument32 pagesAjustes Agujero Único Eje ÚnicoRamiro Acosta CepedaNo ratings yet

- Guia de Aprendizaje Ingles-Tecnologia Docente HineldaDocument8 pagesGuia de Aprendizaje Ingles-Tecnologia Docente HineldaRamiro Acosta CepedaNo ratings yet

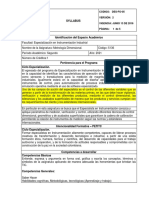

- 2.des-Fo-05 Syllabus MetrologíaDocument4 pages2.des-Fo-05 Syllabus MetrologíaRamiro Acosta CepedaNo ratings yet

- Bops Stack 11 5M GRS 158wrotating NG HeadDocument2 pagesBops Stack 11 5M GRS 158wrotating NG HeadRamiro Acosta Cepeda100% (1)

- Packers Ecuador - SertecpetDocument129 pagesPackers Ecuador - SertecpetRamiro Acosta CepedaNo ratings yet

- Encuentro Final de MetrologíaDocument2 pagesEncuentro Final de MetrologíaRamiro Acosta CepedaNo ratings yet