Professional Documents

Culture Documents

Gesab 96093 INJECTION MIXING UNIT DN900 L3170 2020-07-09

Uploaded by

ilkay tomlayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gesab 96093 INJECTION MIXING UNIT DN900 L3170 2020-07-09

Uploaded by

ilkay tomlayCopyright:

Available Formats

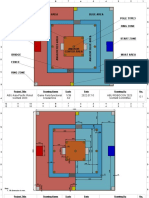

8 7 6 5 4 3 2 1

SIDE VIEW FRONT VIEW

NOTE: MINIMUM SERVICE SPACE BEND OK

F FROM INJECTION BOSS FLANGE F

900

170

1

650

E 4 E

Exhaust Gas

Flow DIRECTION

914 x 4

BEND NOK BEND NOK

D D

3170

3 3

BEND OK

C C

NOTES:

B 1. Tolerance according to DS/EN ISO 13920-B, DS/EN22768-1-m TABLE B

ITEM Q-ty DESCRIPTION MATERIAL

2. Material: all components exposed to urea in stainless steel (AISI316) 1 1 INJECTION PIPE 914x4, L=3160 mm AISI316

2 1 INJECTOR BOSS 114x205x3 mm AISI316

3. Weight approx: 470 kg. 3 1 FLANGE, DN900/DIN86044/ PN2.5 S235JRG2

4. Thermal insulation not included 4 1 NAME PLATE HOLDER: 190x150x140 THICKNESS: 4 mm S235JRG2

5. Please note rotation of Injection unit in respect to possible pipe bend at the inlet side. DRAWING STATUS: SCALE:

ISO 1:10

The design of this injection/mixing unit is based on the following MCR data DESIGNER: CREATED: CHECKED BY: CHECKED: SHEET:

MSL 01-Jul-20 OS 01-Jul-20 1/1

Min. exhaust gas temp. G teborgs Energy Systems AB

Max. exhaust gas Urea Max. urea flow Min. injection air flow (Nlit/min, HULL NUMBER: TITLE:

( C, at max. exhaust

flow ( kg/h) concentration (%) ( lit/h) at max. urea flow) Exportgatan 81A

A gas flow) SE-42246 Hisings Backa

Sweden

INECTION MIXING UNIT DN900, L3170 A

Phone: +46-31 7441950

40 Fax: +46-31 7797841

E-mail: gesab@gesab.net

www.gesab.net

PROJECT: DRAWING NUMBER: REVISION:

96093 A

8 7 6 5 4 3 2 1

You might also like

- Ranjit SinghDocument8 pagesRanjit SinghRANJIT100% (1)

- Afloat 2Document256 pagesAfloat 2Matthaios SkantrzourakisNo ratings yet

- Full Download Test Bank For Chemistry Principles and Reactions 8th Edition by Masterton PDF Full ChapterDocument34 pagesFull Download Test Bank For Chemistry Principles and Reactions 8th Edition by Masterton PDF Full Chapteryen.resiege.ffrq100% (15)

- Philips Panorama Open MRI - DrawingsDocument17 pagesPhilips Panorama Open MRI - DrawingsStanTofeNo ratings yet

- Pe Unit Plan TemplateDocument3 pagesPe Unit Plan Templateapi-239320998No ratings yet

- Batemans BayDocument1 pageBatemans BayAnonymous riBDrDGiNo ratings yet

- General Notes and Specifications: ElevationDocument12 pagesGeneral Notes and Specifications: Elevationcsa csaNo ratings yet

- Ag Group: Unless Otherwise Specified: JSL 03-10-04Document1 pageAg Group: Unless Otherwise Specified: JSL 03-10-04Anonymous IQD4PqB876No ratings yet

- PIPE RACK PIP-Rev.1Document1 pagePIPE RACK PIP-Rev.1ardiansyah.tegalNo ratings yet

- Ramp IsuzuDocument1 pageRamp IsuzuBeli OnlineNo ratings yet

- 19.ball Valve 9 and 3 PDFDocument4 pages19.ball Valve 9 and 3 PDFShabirNo ratings yet

- 27° A A C 120° .090 .005 Cast .015 DBC: Revisions Zone Rev. Description Date Approved 0 New Sketch 7/17/17 PRB 1Document1 page27° A A C 120° .090 .005 Cast .015 DBC: Revisions Zone Rev. Description Date Approved 0 New Sketch 7/17/17 PRB 1nidhal kotorsiNo ratings yet

- GA FilterDocument1 pageGA FilterPruthviraj JuniNo ratings yet

- Game Field ABU Robocon 2023Document9 pagesGame Field ABU Robocon 2023Rasyid YahyaNo ratings yet

- 119456-2-0-Configuration 5K0 973 323 + Cap UniDocument2 pages119456-2-0-Configuration 5K0 973 323 + Cap Unimirelusha_lovely3829No ratings yet

- B Top Standard JointsDocument4 pagesB Top Standard Jointsd!egoNo ratings yet

- Mixer Top CoverDocument2 pagesMixer Top CoverSHAILESH PATELNo ratings yet

- Fig FM276 Strainers CraneFS DS 1702 P208Document1 pageFig FM276 Strainers CraneFS DS 1702 P208ธนาธิป 002No ratings yet

- Decanting PostDocument2 pagesDecanting PostIsrael López LagosNo ratings yet

- Shot Sleeve 21668Document3 pagesShot Sleeve 21668Michael Naím Dévora QuintanarNo ratings yet

- Acople 5R10Document1 pageAcople 5R10Jose Emilio Carrero AngaritaNo ratings yet

- Catalogue Pressure GaugeDocument2 pagesCatalogue Pressure GaugeSupriyaRongNo ratings yet

- Gate Valve DrawingDocument2 pagesGate Valve Drawingpriyanka GNo ratings yet

- ShopDocument1 pageShopRaul VerberNo ratings yet

- Pile Cap DesignDocument1 pagePile Cap DesignMaitrayee AdityaNo ratings yet

- NAS1713Document2 pagesNAS1713Bogdan RusuNo ratings yet

- Jkrta 50205 001Document1 pageJkrta 50205 001M Febi TrihandokoNo ratings yet

- CDJ 900 AssemberlyDocument6 pagesCDJ 900 AssemberlyAndrew GaffneyNo ratings yet

- 220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIIDocument1 page220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIINambi RajaNo ratings yet

- HBX-9016DS-VTM: 84147 Third Angle ProjectionDocument2 pagesHBX-9016DS-VTM: 84147 Third Angle ProjectiongugttfhhyNo ratings yet

- Large New 4 CCP-rev. DDocument2 pagesLarge New 4 CCP-rev. DElma TabakNo ratings yet

- Gasket: Isometric View Top ViewDocument1 pageGasket: Isometric View Top ViewNeocent DesignsNo ratings yet

- Nas1715 (MS9350, MS9351, MS9352)Document2 pagesNas1715 (MS9350, MS9351, MS9352)Bogdan RusuNo ratings yet

- SICPM-P-0500 A02 v02 Filter CartridgeDocument2 pagesSICPM-P-0500 A02 v02 Filter CartridgeCrisnuel RamirezNo ratings yet

- Fastenings: Do Not Scale Drawing RevisionDocument1 pageFastenings: Do Not Scale Drawing RevisionAladin Al AyubiNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- 089245-2-0-Configuration 4H0 973 323 + Cap UniDocument2 pages089245-2-0-Configuration 4H0 973 323 + Cap Unimirelusha_lovely3829No ratings yet

- Mixer MachineDocument14 pagesMixer MachineFebrian DjokamNo ratings yet

- DPWH (Phase 4)Document4 pagesDPWH (Phase 4)Dennis LugoNo ratings yet

- QCS - SS Bottom Plates - DetailedDocument11 pagesQCS - SS Bottom Plates - DetailedMohamed JazathNo ratings yet

- Restriction Orifice Plates PDFDocument1 pageRestriction Orifice Plates PDFjbadgujarNo ratings yet

- Pf20xxx XXXX SF 10 InstDocument1 pagePf20xxx XXXX SF 10 InstFelipe SalvatierraNo ratings yet

- Annexure 2 PDFDocument1 pageAnnexure 2 PDFHaitNo ratings yet

- G Head DimensionalDocument1 pageG Head DimensionalSergio Andres Ramos CarmonaNo ratings yet

- Cabinet ADocument1 pageCabinet AAbram Gil BondocNo ratings yet

- HBXX-6516DS-VTM Line Drawing - AspxDocument3 pagesHBXX-6516DS-VTM Line Drawing - AspxAndhi WidayantoNo ratings yet

- GS96 0208Document1 pageGS96 0208mihaiNo ratings yet

- PozarneStepenice V1Document2 pagesPozarneStepenice V1Vladimir MNo ratings yet

- Cabinet BDocument1 pageCabinet BAbram Gil BondocNo ratings yet

- CATDrawing1 ModelDocument1 pageCATDrawing1 Modelawarade276No ratings yet

- Lifting Specification RexDocument1 pageLifting Specification Rexsamir.ahmed7577No ratings yet

- SHIBATA Donut Rubber FenderDocument1 pageSHIBATA Donut Rubber FenderJose LugardoNo ratings yet

- OXF - Duplex Brochure Updated 2023Document2 pagesOXF - Duplex Brochure Updated 2023j8164322No ratings yet

- Assy Nozzle - R02Document1 pageAssy Nozzle - R02DwisantosoNo ratings yet

- YjhhhjjDocument1 pageYjhhhjjmusang berjanggutNo ratings yet

- SQUARE 45 ARRANGE - Sheet1Document1 pageSQUARE 45 ARRANGE - Sheet1Hiren PatelNo ratings yet

- E12004180 - Light Weight Lub Lower AssyDocument1 pageE12004180 - Light Weight Lub Lower Assysachin kadamNo ratings yet

- All Dimensions Metric: FAA24270APDocument6 pagesAll Dimensions Metric: FAA24270APЕкатерина АндрееваNo ratings yet

- 1 - Beam - Yj - B002: Grid LocationDocument1 page1 - Beam - Yj - B002: Grid Locationisback944No ratings yet

- Cipld 1036 WW Flyover 313+850 ST DWG 301 PDFDocument3 pagesCipld 1036 WW Flyover 313+850 ST DWG 301 PDFAnkush SharmaNo ratings yet

- High MastDocument1 pageHigh MastHeidi MontalvanNo ratings yet

- Plan View Isometric View: RPK-SE-942Document1 pagePlan View Isometric View: RPK-SE-942ajNo ratings yet

- Gesab 95131 SCR Chamber 2020-07-09Document1 pageGesab 95131 SCR Chamber 2020-07-09ilkay tomlayNo ratings yet

- GE-MA-041 MANUAL SCR SYSTEM Working FileDocument62 pagesGE-MA-041 MANUAL SCR SYSTEM Working Fileilkay tomlayNo ratings yet

- l27 38 - Propulsion Manpm 00 0156 PreviewDocument2 pagesl27 38 - Propulsion Manpm 00 0156 Previewilkay tomlayNo ratings yet

- Man Ec91Document4 pagesMan Ec91ilkay tomlayNo ratings yet

- EPR in Waste ManagementDocument11 pagesEPR in Waste Managementdorexp17No ratings yet

- ReadingDocument3 pagesReadingMuhamad IbrohimNo ratings yet

- 060610at617pm Mayday Re Are We Under Terrorist Attack YesDocument12 pages060610at617pm Mayday Re Are We Under Terrorist Attack YesRalph Charles Whitley, Sr.No ratings yet

- University of Calicut: Examination ResultsDocument1 pageUniversity of Calicut: Examination ResultsArun Saji Josz RbzNo ratings yet

- Z370 AORUS Gaming 3: User's ManualDocument48 pagesZ370 AORUS Gaming 3: User's ManualAtrocitus RedNo ratings yet

- C C C !" # # $C% & #'C%Document12 pagesC C C !" # # $C% & #'C%Sneha ShahNo ratings yet

- Intro To Threads PDFDocument4 pagesIntro To Threads PDFNANDINI BNo ratings yet

- Youth Protection WaiverDocument1 pageYouth Protection WaiverKatie McCarthyNo ratings yet

- Geography Chapter 2 - Land, Soil, Water, Natural Vegetation & Wildlife ResourcesDocument3 pagesGeography Chapter 2 - Land, Soil, Water, Natural Vegetation & Wildlife ResourcesGarvit BilewalNo ratings yet

- LKPD Bahasa Inggris Kelas VII - Descriptive TextDocument1 pageLKPD Bahasa Inggris Kelas VII - Descriptive TextAhmad Farel HusainNo ratings yet

- Asgkit Coding STDDocument10 pagesAsgkit Coding STDDavid ZamudioNo ratings yet

- The Story of MacroeconomicsDocument32 pagesThe Story of MacroeconomicsMohammadTabbalNo ratings yet

- Xtraction User GuideDocument63 pagesXtraction User Guidegunalprasadg100% (1)

- Research Paper On Employee BenefitsDocument7 pagesResearch Paper On Employee Benefitskrqovxbnd100% (1)

- Atma Rama Anandha Ramana - Scenes PDFDocument2 pagesAtma Rama Anandha Ramana - Scenes PDFKoushik KattaNo ratings yet

- Expectation-Maximization AlgorithmDocument13 pagesExpectation-Maximization AlgorithmSaviourNo ratings yet

- Aima (Ncym) Circular 13Document3 pagesAima (Ncym) Circular 13kxalxo7637No ratings yet

- Cap Bora BrochureDocument8 pagesCap Bora BrochureMotasim SelićNo ratings yet

- Amazing Race Math QuestionsDocument2 pagesAmazing Race Math QuestionsROSALEN M. CUNANANNo ratings yet

- DX11 Effects in Metro 2033Document47 pagesDX11 Effects in Metro 2033test23No ratings yet

- Negative Effects of Social Media AddictionDocument2 pagesNegative Effects of Social Media AddictionTubagus Fikih AriansyahNo ratings yet

- Abaqus Example Using Beam ElementsDocument18 pagesAbaqus Example Using Beam ElementsŞener KılıçNo ratings yet

- Grounding-101 IEEE IAS PDFDocument81 pagesGrounding-101 IEEE IAS PDFRoySnk100% (2)

- 2012 Nike Football Clinic 4Document2 pages2012 Nike Football Clinic 4Bruno ChuNo ratings yet

- Affiliate Marketing Step by StepDocument27 pagesAffiliate Marketing Step by StepJulia FawcettNo ratings yet

- Trigon 4to3 SecDocument11 pagesTrigon 4to3 SecmalcommmNo ratings yet