Professional Documents

Culture Documents

Design and Implementation of Engine Oil Pressure Switch Indicator

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Implementation of Engine Oil Pressure Switch Indicator

Copyright:

Available Formats

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

Design and Implementation of Engine Oil Pressure Switch Indicator

Gautham Prathap1* & Mr. Mohammad Sameer Baig2

1

Student, Level-5 Higher Diploma in Automobile Engineering, ASTI Academy, Dubai, UAE.

2

Academic Coordinator In-charge, ASTI Academy, Dubai, UAE.

Corresponding Author (Gautham Prathap) - a30620051@astiacademy.ac.ae*

DOI: https://doi.org/10.46431/MEJAST.2022.5404

Copyright © 2022 Gautham Prathap. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Article Received: 17 November 2022 Article Accepted: 12 December 2022 Article Published: 16 December 2022

ABSTRACT

An incorrect engine oil pressure gauge and an incorrect engine oil pressure sensor will provide false indications of low engine oil pressure or high

engine oil pressure. Standard oil pressure sensors work by displaying a warning signal when the oil pressure falls outside of the set range. Two

important components to the oil pressure sensor include the spring-loaded switch and a diaphragm. The spring-loaded switch is connected to the

diaphragm that is exposed to the oil pressure. Pressure switch indicator can be diagnosed using DMM and inspect visually on the engine block. Good

type of switch helps the ECU of Automobile engine to understand the oil pressure and actuate the moving parts or actuators accordingly.

Keywords: Oil pressure; Oil indicator; Dashboard warning light; Mechanical gauge.

░ 1. INTRODUCTION

In modern cars, trucks and buses, oil pressure sensors monitor the oil pressure in the motor oil and transmission oil

circuit. The measured pressures are recorded in real time in the control unit of the vehicle, evaluated and used to

optimise engine parameters. The result is fuel-saving, low emission and more efficient engine operation.

Figure 1. Diaphragm pressure switches with positive lead connector

The purpose of the internal combustion engine lubrication system is to provide optimal conditions for the oil film

formation in all friction couples, such as a piston-cylinder, piston rings-cylinder, main bearings, etc. The oil film is

designed to minimize the wear of the elements while ensuring the smallest possible friction losses. Lack of

continuity of the oil film, and thus boundary or mixed friction conditions, obviously have a negative effect on the

friction losses. However, the continuous oil film, depending on the conditions of its formation, may be

characterized by different values of friction losses. One of the factors that may affect the conditions of formation of

the oil film is the value of oil pressure in the lubrication system.

Oil pressure switches are typically used as an actuator which directly activates the oil warning light in driver

dashboard when the oil pressure in the engine will fall below the preset critical level or brings a signal to the ECU

(engine control unit), so to be warned about low pressure of engine oil and prevent damage to the engine.

Depending on the engine construction, the oil pressure switch usually can be found in one of the most common

ISSN: 2582-0974 [18]

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

locations: in the cylinder block of the engine or in the oil filter housing as well as at some engine types can be found

in the engine head.

The pressure switch is mounted onto the side of an engine block and wired to an oil gallery. As the force of the oil

pressure starts to build on the diaphragm, this force overcomes the switch spring pressure, which then pulls apart

the electrical contacts to turn on the warning light. If the oil pressure falls below the set limit, the diaphragm

releases pressure off the springs to close the switch contacts that would normally result in the display of a warning

sign to the driver

░ 2. WORKING PRINCIPLE

The switch is operated by a self-elastic diaphragm or movable diaphragm with fitted hairspring, whose position is

determined by the pressure applied to it. The required critical pressure for moving up the diaphragm and activating

(switching ON or switching OFF) the switch contacts is determined by the oil pressure of the engine. This critical

value of oil pressure is individual for every engine type and can vary. Usual value is between 0.25 and 0.75 bar (3.5

– 11 psi).

If the oil pressure falls below this critical value, the switch directly activates the oil warning light in driver

dashboard or in some engine management systems the switch returns a signal to the ECU, so to be warned about

low pressure of engine oil and prevent damage to the engine. The switch contacts can be either normally open or

normally closed.

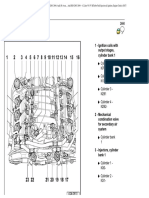

Figure 2. Cut-section view of pressure switch and its parts: 1. Washer for sealing, 2. Diaphragm, 3. Switch

housing, 4. Connector, 5. Switch contacts (A normally open, B normally closed), 6. Thread for tightness

The figure 2, under (A) shows illustrative drawing of one type of oil pressure switch with normally open contacts,

and under (B) one type of switch with normally closed contacts. The operation of these types of switches is

fundamentally similar in all instances, although the type, size and construction can vary upon the manufacturer

application or requirement of a used system.

At the switches with normally open contacts, when the engine oil pressure reaches the preset critical level, produces

movement of the diaphragm and activates the contacts of the switch, so the contacts are connected together, i.e. the

switch is closed (switched ON). The switches with normally closed contacts works opposite, when the engine oil

pressure reaches the preset critical level, deactivates the already connected contacts of the switch, so now the

contacts are disconnected, i.e. the switch is open (switched OFF).

ISSN: 2582-0974 [19]

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

2.1. Pressure Gauge Sensor

A low oil pressure warning light is one method used to alert the driver to fluctuations in the oil pressure levels. An

alternative system for this purpose is known as a mechanical type pressure gauge component. There is a Bourdon

tube inside a pressure gauge that tends to straighten out upon receiving pressure via a copper tubular component.

The Bourdon tube is attached to a needle on the gauge, which moves as the tube begins to take a different shape.

Movement of the needle across a scale on the gauge is used as a reference point to indicate changes in oil pressure

inside the engine to a vehicle.

Figure 3. Switch positive to indicator lamp and Negative grounded on engine body

░ 3. RESULTS

3.1. Diagnostics and Testing Procedures

3.1.1. Switch with Normally Open Contacts

(1) Check that there is an open circuit between the contacts when the engine is not running.

(2) Check that there is a short circuit (continuity) between the contacts when the engine is running.

(3) Check the continuity and condition of the pins, terminals and wires.

3.1.2. Switch with Normally Closed Contacts

(1) Check that there is a short circuit (continuity) between the contacts when the engine is not running.

(2) Check that there is an open circuit between the contacts when the engine is running.

(3) Check the continuity and condition of the pins, terminals and wires.

3.2. Testing Procedures with Multimeter

(1) Unplug the connector from oil pressure switch and check the connectivity between the contacts. If the switch is

with two pins, the check should be between the pins. In case when the switch is with only one pin, then the check

should be between the pin and mass (negative pole).

ISSN: 2582-0974 [20]

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

Figure 4. Multimeter probe connections for testing switch

(2) When the engine is not running, the read value of the electrical resistance from a multimeter in case of switch

with normally open contacts should be infinite (contacts are disconnected – switched OFF), and in case of switch

with normally closed contacts should be zero (contacts are connected – switched ON).

(3) When the engine is running, the read value of the electrical resistance from a multimeter in case of switch with

normally open contacts should be zero (contacts are connected – switched ON), and in case of switch with normally

closed contacts should be infinite (contacts are disconnected – switched OFF).

░ 4. CONCLUSION

In conclusion, an incorrect engine oil pressure gauge and an incorrect engine oil pressure sensor will provide false

indications of low engine oil pressure or high engine oil pressure which will breakdown the whole engine due to

poor lubrication in the moving parts. Standard oil pressure sensors work by displaying a warning signal when the

oil pressure falls outside of the set range. As mentioned in the results this can be diagnosed with proper automotive

tools and specific procedures. When the engine is not running, the read value of the electrical resistance from a

multimeter in case of switch with normally open contacts should be infinite (contacts are disconnected – switched

OFF), and in case of switch with normally closed contacts should be zero (contacts are connected – switched ON).

Similarly, when the engine is running, the read value of the electrical resistance from a multimeter in case of switch

with normally open contacts should be zero (contacts are connected – switched ON), and in case of switch with

normally closed contacts should be infinite (contacts are disconnected – switched OFF). Thus helps the ECU of

Automobile engine to understand the oil pressure and actuate the moving parts accordingly. In future modification

this oil pressure should also be controlled with engine speed with further enhancement of key programming of

ECU.

Declarations

Source of Funding

This research work did not receive any grant from funding agencies in the public or not-for-profit sectors.

ISSN: 2582-0974 [21]

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

Competing Interests Statement

The authors declare no competing financial, professional, or personal interests.

Consent for publication

The authors declare that they consented to the publication of this research work.

Authors’ Contributions

All authors equally contributed to research and paper drafting.

References

[1] Jim Halderman, (2022). Automotive Technology: Principles, Diagnosis, and Service, 6th edition Published by

Pearson (September 21st 2021).

[2] Roman Zinko, Oleh Polishchuk, (2021). Vehicle diagnostic system of the car engine MATEC Web of

Conferences 351, 01014 20th International Conference Diagnostics of Machines and Vehicles.

[3] Martin W Stockel, Martin T Stockel, James E Duffy, Chris Johanson, (2021). Auto Fundamentals,

Goodheart-Wilcox Publisher; 13th Twelfth Edition, Revised Workbook Ed.

[4] A Self-Diagnostic Method for Automobile Faults in Multiple Working Conditions Based on SOM-BPNN

Published online - 2021 Nov 3. DOI: 10.1155/2021/6801161.

[5] James Halderman, (2018). Automotive Engines : Theory and Servicing, Pearson Education (US), 19th ed ISBN:

13 9780134654003.

[6] Niu H. (2021). Fault diagnosis of automobile engine based on improved BP neural network. Modular Machine

Tool and Automatic Processing Technology.

[7] William B. Ribbens and Normassssn P. Mansour, (2003). Understanding automotive electronics and electrical

(6th ed.). Newnes. ISBN: 9780750675994.

[8] Hamrock, Bernard J. (2004). Fundamentals of fluid film lubrication. Steven R. Schmid, Bo O. Jacobson (2nd

ed.). New York: Marcel Dekker. ISBN: 0-8247-5120-5. OCLC 55739786.

[9] Bela G. Liptak (Ed), (2003). Instrument Engineers' Handbook, Fourth Edition CRC Press, ISBN: 1420064029,

Pages 790-793.

[10] Taskos Nikolaos, (2020). Pressure Sensing 101 – Absolute, Gauge, Differential & Sealed pressure. ES

Systems, Retrieved 2020-09-16.

[11] Stephen A. Dyer, (2004). Wiley Survey of Instrumentation and Measurement, John Wiley & Sons, ISBN:

0471221651.

[12] Safety requirements for electrical equipment for measurement, control and laboratory. General requirements.

1993. ISBN: 0-580-22433-3.

ISSN: 2582-0974 [22]

Middle East Journal of Applied Science & Technology

Vol.5, Iss.4, Pages 18-23, Oct-Dec 2022

[13] Ribbens, W.B., Mansour, N.P. (2003). Understanding Automotive Electronics. USA, Massachusetts: Elsevier

Science.

[14] Schwaller, A.E. (2005). Total Automotive Technology. USA, New York: Thomson and Delmar Learning.

[15] Hillier, V., Coombes, P. (2004). Fundamentals of Motor Vehicle Technology. UK, Cheltenham: Nelson

Thornes Ltd.

[16] Knowles, D., Erjavec, J. (2005). Tech One: Basic Automotive Service and Maintenance. USA, New York:

Thomson Delmar Learning.

[17] Inside a Car oil https://www.azosensors.com/article.aspx?ArticleID=44.

Appendix-A

Figure 5. Engine oil pressure switch design implementation wiring diagram using AutoCAD

ISSN: 2582-0974 [23]

You might also like

- Pressure JSDocument3 pagesPressure JSMarco OlivettoNo ratings yet

- Mercedes Axor Fuel System Repair ManualDocument20 pagesMercedes Axor Fuel System Repair ManualStephenson75% (4)

- SB03 3Document14 pagesSB03 3Clemente Rafael Marval Escalona100% (1)

- Basic Testing Pajero 1991Document12 pagesBasic Testing Pajero 1991nadaNo ratings yet

- Engine Oil Pressure Switch TestDocument2 pagesEngine Oil Pressure Switch TestRichard ChuaNo ratings yet

- LuDocument22 pagesLutomallor101No ratings yet

- DHDT CompressorDocument18 pagesDHDT CompressorGeorge J AlukkalNo ratings yet

- How to operate, maintain, inspect and overhaul a reciprocating aircraft engineDocument135 pagesHow to operate, maintain, inspect and overhaul a reciprocating aircraft engineshimi yayNo ratings yet

- General InformationDocument551 pagesGeneral Informationisaiahfrosh47No ratings yet

- Yza410202 (Manual) e PDFDocument12 pagesYza410202 (Manual) e PDFmarjukiNo ratings yet

- ICMaS Proceedings on Lubrication SystemsDocument4 pagesICMaS Proceedings on Lubrication SystemsFabrizzio_ValerNo ratings yet

- Seal Oil PresentationDocument10 pagesSeal Oil PresentationjeromejoeNo ratings yet

- The Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDocument11 pagesThe Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDewanjee AshrafNo ratings yet

- General Information: To IndexDocument9 pagesGeneral Information: To IndexRaymond FrostNo ratings yet

- Milenium Carlyle PDFDocument21 pagesMilenium Carlyle PDFvickers100% (1)

- 2 Engine With Mounting and Equipment PDFDocument99 pages2 Engine With Mounting and Equipment PDFMichael BochoridisNo ratings yet

- Mercedes-Benz Axor Fuel System Service ManualDocument20 pagesMercedes-Benz Axor Fuel System Service ManualErik SilvaNo ratings yet

- D AdjustmentsDocument11 pagesD Adjustmentsdguruge8No ratings yet

- Maintenance of Electrical Motors 1.5Document9 pagesMaintenance of Electrical Motors 1.5Sayed NagyNo ratings yet

- 1998 Mitsubishi Montero Instrument Panel GuideDocument51 pages1998 Mitsubishi Montero Instrument Panel GuideHernando MontenegroNo ratings yet

- A320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFDocument388 pagesA320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFKamalVirk100% (3)

- Easy Fast Smart Installation ManualDocument26 pagesEasy Fast Smart Installation Manualsagarisltd100% (3)

- 966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFDocument4 pages966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFOfftap's100% (2)

- Hanbell Service ManualDocument80 pagesHanbell Service ManualStephen Marcus100% (2)

- Engine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Document49 pagesEngine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Rafael Enrique Grijalva GarciaNo ratings yet

- Mercedes - 560 SL - Wiring Diagram - 1989 - 1989Document1,928 pagesMercedes - 560 SL - Wiring Diagram - 1989 - 1989OudayNo ratings yet

- Instrumentation ReportDocument5 pagesInstrumentation Reportrrajabu642No ratings yet

- Generator SetDocument30 pagesGenerator Setkash30No ratings yet

- Mercedes Sangyong Section+1A2++M161+Engine PDFDocument254 pagesMercedes Sangyong Section+1A2++M161+Engine PDFjonasNo ratings yet

- 164-11 Falla D6 DragaSurDocument11 pages164-11 Falla D6 DragaSurManuel ContrerasNo ratings yet

- ENGINE LUBRICATION OVERVIEWFDocument16 pagesENGINE LUBRICATION OVERVIEWFhoman83No ratings yet

- Pruebas y Adjustes - Troubleshooting 3512G PDFDocument32 pagesPruebas y Adjustes - Troubleshooting 3512G PDFPLANTAS ELECTRICAS H&BNo ratings yet

- 1 User Manual TYA-2000 ENGDocument8 pages1 User Manual TYA-2000 ENGUniversal calamba0% (1)

- SPN 164/fmi 2 - Epa07Document3 pagesSPN 164/fmi 2 - Epa07Hyo Won Lee60% (5)

- Section 6-1Document80 pagesSection 6-1Raidul WafiNo ratings yet

- Machine Maintenance.: General Workshop ProceduresDocument23 pagesMachine Maintenance.: General Workshop Proceduresvld7rpmNo ratings yet

- Cat C15 SDP Testing and Adjusting Manual 2 PDFDocument138 pagesCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (2)

- Cat C15 SDP Testing and Adjusting Manual 2 PDFDocument138 pagesCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (1)

- BOOST FUEL SYSTEM PERFORMANCEDocument38 pagesBOOST FUEL SYSTEM PERFORMANCEnahomNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- MAN B&W MC-C Engine DifferencesDocument67 pagesMAN B&W MC-C Engine DifferencesJack PotNo ratings yet

- 722 9Document6 pages722 9rebuilder67100% (7)

- 2013Document102 pages2013ctorres_505746100% (1)

- G32D DTCDocument59 pagesG32D DTCPower NguyenNo ratings yet

- Deutz TCD2012Document96 pagesDeutz TCD2012MinaSaeed93% (14)

- FugasDocument10 pagesFugasMario Núñez ObandoNo ratings yet

- P0093Document4 pagesP0093pankituna548780% (5)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Non-Unique Fixed Points of Self Mappings in Bi-Metric SpacesDocument12 pagesNon-Unique Fixed Points of Self Mappings in Bi-Metric SpacesMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Middle East Journal of Applied Science & Technology (MEJAST)Document22 pagesMiddle East Journal of Applied Science & Technology (MEJAST)Middle East Journal of Applied Science & TechnologyNo ratings yet

- Comparison of Glucose in Urine With Likening of Pigeons As PetsDocument3 pagesComparison of Glucose in Urine With Likening of Pigeons As PetsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Sensory Acceptability of Rabbit Longganisa in The Municipality of Isabel, LeyteDocument11 pagesSensory Acceptability of Rabbit Longganisa in The Municipality of Isabel, LeyteMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Middle East Journal of Applied Science & Technology (MEJAST)Document22 pagesMiddle East Journal of Applied Science & Technology (MEJAST)Middle East Journal of Applied Science & TechnologyNo ratings yet

- Review of Sentiment Analysis: An Hybrid ApproachDocument31 pagesReview of Sentiment Analysis: An Hybrid ApproachMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Non-Unique Fixed Points of Self Mappings in Bi-Metric SpacesDocument12 pagesNon-Unique Fixed Points of Self Mappings in Bi-Metric SpacesMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Study On Undamped Force Vibrations of A Spring Using Different MethodsDocument4 pagesStudy On Undamped Force Vibrations of A Spring Using Different MethodsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- A Systematic Review On Isolation, Identification, and Characterization of Agrobacterium Tumefaciens From Leguminous PlantsDocument5 pagesA Systematic Review On Isolation, Identification, and Characterization of Agrobacterium Tumefaciens From Leguminous PlantsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Comparison of Glucose in Urine With Likening of Pigeons As PetsDocument3 pagesComparison of Glucose in Urine With Likening of Pigeons As PetsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Evaluation of Anti-Microbial and Anti-Fungal Activities of Nano-TiO2 Assembled With Graphene CompositesDocument8 pagesEvaluation of Anti-Microbial and Anti-Fungal Activities of Nano-TiO2 Assembled With Graphene CompositesMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Study and Survey Analysis of Smart Blue Eyes Technology DeviceDocument4 pagesStudy and Survey Analysis of Smart Blue Eyes Technology DeviceMiddle East Journal of Applied Science & TechnologyNo ratings yet

- The Primary Source of Mercury in The Subsoil and Environmental ImpactsDocument4 pagesThe Primary Source of Mercury in The Subsoil and Environmental ImpactsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- How Breathing Rate Associate With Beauty Loving Behavior?Document3 pagesHow Breathing Rate Associate With Beauty Loving Behavior?Middle East Journal of Applied Science & TechnologyNo ratings yet

- Impact of Blood in Urine On Milk LikeningDocument3 pagesImpact of Blood in Urine On Milk LikeningMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Fractional Derivatives of Some Fractional Functions and Their ApplicationsDocument12 pagesFractional Derivatives of Some Fractional Functions and Their ApplicationsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- MAXFIBE SACHETS: The Natural Fiber Helps in Activation of Immune SystemDocument6 pagesMAXFIBE SACHETS: The Natural Fiber Helps in Activation of Immune SystemMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Design and Verification of New Generation Flexible Electronics and DisplayDocument5 pagesDesign and Verification of New Generation Flexible Electronics and DisplayMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Design and Analysis of Smart Haptic Technology DesignDocument5 pagesDesign and Analysis of Smart Haptic Technology DesignMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Design and Implementation of Innovative Mobile Phone DetectorDocument4 pagesDesign and Implementation of Innovative Mobile Phone DetectorMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Preservation of Milk and Dairy Products by Using BiopreservativesDocument8 pagesPreservation of Milk and Dairy Products by Using BiopreservativesMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Interconnection Between Moles On Face and Urine LeukocytesDocument3 pagesInterconnection Between Moles On Face and Urine LeukocytesMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Design and Performance Analysis of Line Following RobotDocument4 pagesDesign and Performance Analysis of Line Following RobotMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Site Investigation of Subsurface Lithology of Ignatius Ajuru University of Education, Port Harcourt, Nigeria, Using Electrical Resistivity MethodsDocument8 pagesSite Investigation of Subsurface Lithology of Ignatius Ajuru University of Education, Port Harcourt, Nigeria, Using Electrical Resistivity MethodsMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Is There Relativity of Chicken Likeness With Presence of Protein in Urine?Document3 pagesIs There Relativity of Chicken Likeness With Presence of Protein in Urine?Middle East Journal of Applied Science & TechnologyNo ratings yet

- Is There Any Connection Between Depression and Urine Glucose?Document3 pagesIs There Any Connection Between Depression and Urine Glucose?Middle East Journal of Applied Science & TechnologyNo ratings yet

- Motion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationDocument10 pagesMotion Control of Single Link Flexible Joint Robot Manipulator Using ANFIS MATLAB SimulationMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Microplastic Is An Emerging Problem For Marine LifeDocument10 pagesMicroplastic Is An Emerging Problem For Marine LifeMiddle East Journal of Applied Science & TechnologyNo ratings yet

- A Case Study On Factors Affecting Environmental Sustainability DevelopmentDocument8 pagesA Case Study On Factors Affecting Environmental Sustainability DevelopmentMiddle East Journal of Applied Science & TechnologyNo ratings yet

- Ford Engine Troubleshooter Reference ManualDocument42 pagesFord Engine Troubleshooter Reference Manualleeroyhill100% (4)

- CCP v2.1Document52 pagesCCP v2.1bhuwan_vijayNo ratings yet

- Fiat Ecuscan How To UseDocument11 pagesFiat Ecuscan How To Usedradubuh001No ratings yet

- Alfa 145 FusesDocument12 pagesAlfa 145 FusesDarcy Oliveira FilhoNo ratings yet

- A Brief Review of Technology Solutions On Fuel Injection System of Diesel Engine To Increase The Power and Reduce Environmental PollutionDocument10 pagesA Brief Review of Technology Solutions On Fuel Injection System of Diesel Engine To Increase The Power and Reduce Environmental PollutionkmesNo ratings yet

- Chevrolet Cruze WiringDocument264 pagesChevrolet Cruze WiringNeil CarolusNo ratings yet

- Service Manual: SR400 SR400EDocument342 pagesService Manual: SR400 SR400EAmonthep PongrattanasawatNo ratings yet

- Dokumen - Tips Ignition-ModuleDocument4 pagesDokumen - Tips Ignition-ModuleEdvandro Dennis Iturri ArteagaNo ratings yet

- Perkins 1204e E44ta 1204e E44tta 71206e E66ta Industrial Engine TroubleshootingDocument20 pagesPerkins 1204e E44ta 1204e E44tta 71206e E66ta Industrial Engine Troubleshootingallen100% (53)

- 10.1 Climate Control System OverviewDocument9 pages10.1 Climate Control System OverviewIgorIlnickijNo ratings yet

- RS6 FuelInjection ComponentLayoutDocument15 pagesRS6 FuelInjection ComponentLayoutgrushe100% (1)

- Reparacion ECMDocument6 pagesReparacion ECMarche70No ratings yet

- 1.8 5v Turbo DTC Obdii Fuel and IgnitionDocument20 pages1.8 5v Turbo DTC Obdii Fuel and IgnitionCristian CernaNo ratings yet

- List of Illustrations: Section 5 Auxiliary Power Unit (Apu)Document8 pagesList of Illustrations: Section 5 Auxiliary Power Unit (Apu)Emanøel AlvesNo ratings yet

- Control Engine 1kd FTV and 2kd FTDDocument41 pagesControl Engine 1kd FTV and 2kd FTDMuxumad Cabdulahi0% (1)

- Front Harness (Engine Part) - Schematic DiagramsDocument10 pagesFront Harness (Engine Part) - Schematic DiagramsVo Duy KhanhNo ratings yet

- VW Passat b5 Motronic Injection 1 8 LTR EngDocument160 pagesVW Passat b5 Motronic Injection 1 8 LTR EngChiulafli FediaNo ratings yet

- Plug Pin Symbol Input / OutputDocument5 pagesPlug Pin Symbol Input / OutputOsman GutierrezNo ratings yet

- NGD 0605 S enDocument154 pagesNGD 0605 S enJuan José Rodriguez100% (15)

- 797F Off-Highway Truck Operator'S Station: Global Manpower DevelopmentDocument26 pages797F Off-Highway Truck Operator'S Station: Global Manpower DevelopmentEdin Raul Yalle RafaelNo ratings yet

- MAN Diesel ME Training Course AbbreviationsDocument2 pagesMAN Diesel ME Training Course AbbreviationsioanNo ratings yet

- 851 TorcingDocument270 pages851 TorcingFrancisco Santiago Gallardo100% (1)

- Automotive: Describe EFI Engine Working ProcedureDocument19 pagesAutomotive: Describe EFI Engine Working ProcedureJ Naveen KumarNo ratings yet

- Machakos University: School of Engineering and TechnologyDocument7 pagesMachakos University: School of Engineering and TechnologyElectrical EngineeringNo ratings yet

- EMT3-C10186 Manual (Rev. 1) W E-Stop and Throttle Pot (71610)Document17 pagesEMT3-C10186 Manual (Rev. 1) W E-Stop and Throttle Pot (71610)Matias Contreras Köbrich100% (2)

- Justy Subaru Obd2Document64 pagesJusty Subaru Obd2JUANNo ratings yet

- AMALTHEA Project Leaflet Profile Oct 11Document2 pagesAMALTHEA Project Leaflet Profile Oct 11Knezevic BojanNo ratings yet

- Rexton Service ManualDocument1,991 pagesRexton Service Manualisforme93% (28)

- E - Theory/Operation - Efi: 1991 Mitsubishi MonteroDocument7 pagesE - Theory/Operation - Efi: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

- Схема Подключения Sequent 32 - OBDDocument1 pageСхема Подключения Sequent 32 - OBDYorman MuñozNo ratings yet