Professional Documents

Culture Documents

Hydro en Aw 6082

Uploaded by

Velissarios DemetriouOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro en Aw 6082

Uploaded by

Velissarios DemetriouCopyright:

Available Formats

Technical

datasheet ‐ Extruded products

Alloy EN AW‐6082 [AlSi1MgMn]

Medium strength alloy with higher strength than 6005A. Due to elements like manganese, added to increase toughness,

it is less suitable for decorative anodising.

Commonly used for structural applications in engineering and transportation due to good toughness and high yield‐ and ultimate

tensile strength. Examples of applications include seat‐rails, bumper beams, scaffolding, train‐floors, and valve‐blocks.

Typical Applications

Structural beams Bumper rails Scaffolding Train floors

Chemical Composition 1

Si Fe Cu Mn Mg Cr Zn Ti Pb Bi Sn Others

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Max Max Each Tot

0.70 1.30 0.50 0.10 0.40 1.00 0.60 1.20 0.25 0.20 0.10 0.05 0.15

1 Chemical composition in weight-% according to EN-573-3:2013; Hydro internal limits are tighter – different variants to fulfill T6 and T66

properties.

Mechanical Properties 2,3

Wall HBW b Vickers b

Rp0,2 Rm A A50mm

Temper thickness t TYPICAL TYPICAL

[MPa] [MPa] [%] [%]

[mm] VALUE VALUE

T4a t≤25 110 205 14 12 70 80

Open Profile T5 t≤5 230 270 8 6 90 95

t≤5 250 290 8 6 95 100

Open Profile T6a

5<t≤25 260 310 10 8 95 100

Hollow Profile T5 t≤5 230 270 8 6 90 95

t≤5 250 290 8 6 95 100

Hollow Profile T6a

5<t≤15 260 310 10 8 95 100

Hydro Special variants - Contact your local Hydro supplier

Hydro T64c Hollow all 250 325 15 - 105 110

Hydro T66 all 320 340 8 6 110 115

2 Properties according to EN 755-2:2016 for extruded profile, minimum values unless else specified

3 If a profile cross section comprises different thickness which fall in more than one set of specified mechanical property values, the lowest

specified value shall be considered as valid for the whole profile section

a Properties may be obtained by press quenching

b Brinell hardness values for information only. Vickers converted from Brinell value and should be considered approximate

c aged for high elongation

Temper Designations 4

T4 Solution heat treated and naturally aged

T5 Cooled from an elevated temperature shaping process and then artificially aged

T6 Solution heat treated and then artificially aged

T64 Solution heat treated and then artificially aged in underageing conditions (between T6 and T61) to improve formability

Solution heat treated and then artificially aged – mechanical property level higher than T6 achieved through special control

T66 of the process

4 Temper designations according to EN 515:1993

Hydro Innovation & Technology, Finspång, Sweden 1/3 Hydro 6082_Rev.2 – 01/2019

Technical datasheet ‐ Extruded products

Alloy EN AW‐6082 [AlSi1MgMn]

Physical Properties 5

Modulus Coefficient of

Modulus of Thermal Specific Heat Electrical

of Melting Range Density linear

Temper Rigidity Conductivity Capacity Resistivity

Elasticity [°C] [g/cm ]

3 expansion

[GPa] [W/mK] [J/kgK] [nΩm]

[GPa] [10-6K-1]

70 26 575 - 650 2.71 897 23.1

T4 150 41

T6 172 39

5 Reference: MNC Handbok nr 12, version 2, SIS, 1989. Typical properties at room temperature 20°C

Comparative Characteristics of Related Alloys 6

Property 6060 6063 6005 6005A 6082

Tensile strength 1 2 3 3 4

Impact strength 2 2 1 3 4

Surface finish 5 4 3 3 2

Suitability for decorative anodizing 5 5 4 3 2

Corrosion resistance 5 5 4 4 4

Machinability 2 3 4 4 5

Coldforming 5 5 4 4 3

Weldability 5 5 5 5 4

6 Relative grading, 5 = top grade

Fatigue Properties

Example of fatigue properties for 6082 in temper T6.

90

Transverse direction

Provided for informational purposes only, not to be Extrusion direction

considered as guaranteed properties. Results are valid

80

for the investigated specimens taken from a specific

Stress amplitude (MPa)

sample.

70

Tests performed at 20 ± 2 °C on 6 mm thick flat

specimens by Hydro Innovation & Technology,

60

Finspång, Sweden.

Axial testing, constant amplitude, sine wave loading at

50

around 100 Hz test frequency.

Load ratio (min. stress / max. stress) R = 0.5.

40

5 6 7 8

Runouts are indicated by the arrows. 10 10 10 10

Cycles to failure

Hydro Innovation & Technology, Finspång, Sweden 2/3 Hydro 6082 _Rev.2 – 01/2019

Technical datasheet ‐ Extruded products

Alloy EN AW‐6082 [AlSi1MgMn]

Heat Treatment Response 7

Example of heat treatment response for alloy 6082.

6082 - Rp0,2

330

310

290

Strength [MPa]

270 Temperature

250 165 °C

230 175 °C

210 185 °C

190 195 °C

170

150

0.1 1 10 100

Ageing Time [h]

6082 - Rm

340

330

320

Temperature

Strength [MPa]

310

300 165 °C

290 175 °C

280 185 °C

270 195 °C

260

250

0.1 1 10 100

Ageing Time [h]

6082 - A50mm

22

20

18

Temperature

Elongation [%]

16

165 °C

14

175 °C

12 185 °C

10 195 °C

6

0.1 1 10 100

Ageing Time [h]

7 Solid profile, 200 x 3 mm, water quenched after extrusion, 24 h natural ageing prior to artificial ageing, properties in extrusion direction

Hydro Innovation & Technology, Finspång, Sweden 3/3 Hydro 6082 _Rev.2 – 01/2019

You might also like

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- Nedal Alloy Datasheet en AW 6005ADocument1 pageNedal Alloy Datasheet en AW 6005Aankur panwarNo ratings yet

- Nedal Alloy Datasheet en AW 6060Document1 pageNedal Alloy Datasheet en AW 6060ankur panwarNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Document1 pageAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Hydro en Aw 1050aDocument1 pageHydro en Aw 1050aManoranjan MohapatraNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- ALUMERO - Alloys EN AW 6082 AlMgSi1 - WebDocument1 pageALUMERO - Alloys EN AW 6082 AlMgSi1 - WebemilasanovskiNo ratings yet

- ASTM A53 Data SheetDocument3 pagesASTM A53 Data Sheetmarcelomaster88No ratings yet

- ASTM A53 Data Sheet PDFDocument3 pagesASTM A53 Data Sheet PDFmarcelomaster88No ratings yet

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Document1 pageAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- 51 CR V4Document4 pages51 CR V4armin_kunosic9871No ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- ASTM A106 Data SheetDocument4 pagesASTM A106 Data Sheetmarcelomaster88No ratings yet

- 41 CR 4Document2 pages41 CR 4Dewi Lanjarsari Purnama SastriNo ratings yet

- Info EN755 9Document19 pagesInfo EN755 9Don JonesNo ratings yet

- SINOXX 4006 Steel: Designation by StandardsDocument3 pagesSINOXX 4006 Steel: Designation by StandardsKiranNo ratings yet

- 6005A Alloy SHTDocument2 pages6005A Alloy SHTgaju_scribdNo ratings yet

- 41 CR 4Document3 pages41 CR 4AHMED FATHINo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Sheet Coil & Plate Alloy 6061: Technical DataDocument2 pagesSheet Coil & Plate Alloy 6061: Technical DataSarat SrinivasNo ratings yet

- EN - AW - 6061 (WL 3.3214) Specs ENDocument2 pagesEN - AW - 6061 (WL 3.3214) Specs ENBogdan RusuNo ratings yet

- Cosmos Alminium-Technical - Specifications PDFDocument2 pagesCosmos Alminium-Technical - Specifications PDFmindsopenNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- 20201002114953-DIWETEN 355+M 08 2020 E-AktuellDocument6 pages20201002114953-DIWETEN 355+M 08 2020 E-AktuellHAINo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- Product Catalog AluminiuDocument32 pagesProduct Catalog AluminiusnoofsnoofNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Sae J 403-Aisi 1042 1045 - ForminDocument2 pagesSae J 403-Aisi 1042 1045 - ForminKenvi AlarconNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

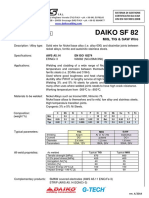

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocument1 pageMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Aluminium Alloy 6082 - T6 T651 PlateDocument2 pagesAluminium Alloy 6082 - T6 T651 Plateyokartik100% (1)

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Vdi 2230 FDocument10 pagesVdi 2230 FDaniel Nauzet Salazar JorgeNo ratings yet

- Etd 2mark With AnswerDocument16 pagesEtd 2mark With AnswertagoreboopathyNo ratings yet

- Efficient P-N Junction-Based ThermoelectricDocument9 pagesEfficient P-N Junction-Based ThermoelectricKeshav DabralNo ratings yet

- Wire Splices and Soldering JointsDocument17 pagesWire Splices and Soldering JointsKieth Casper MendelebarNo ratings yet

- KP WPS PQR GTAW FCAWDocument1 pageKP WPS PQR GTAW FCAWwahyuNo ratings yet

- Blackbody Radiation SpectrumDocument3 pagesBlackbody Radiation SpectrumernaNo ratings yet

- Evaluation of Seismic Response Modification Factors For RCC Frames by Non Linear AnalysisDocument6 pagesEvaluation of Seismic Response Modification Factors For RCC Frames by Non Linear AnalysisPrashant SunagarNo ratings yet

- Internal ForcesDocument17 pagesInternal ForcesJaya KarthigaaNo ratings yet

- Soil Mechanics & Foundation Equations Sheet: Ce340 Geotechnical Engineering Equations Sheet by Jiliang LiDocument7 pagesSoil Mechanics & Foundation Equations Sheet: Ce340 Geotechnical Engineering Equations Sheet by Jiliang LiPaulo ParenasNo ratings yet

- Aircraft Structure PDFDocument51 pagesAircraft Structure PDFسید مسعود ابطحیNo ratings yet

- Product Data Sheet of Resin DM 470-300 PDFDocument4 pagesProduct Data Sheet of Resin DM 470-300 PDFPrashant ShindeNo ratings yet

- E0018 - 08 - 21 HRCDocument36 pagesE0018 - 08 - 21 HRCServando LozanoNo ratings yet

- Written Work 3 - Attempt Review Chem122Document9 pagesWritten Work 3 - Attempt Review Chem122Lymenson Boongaling100% (1)

- Problem 1: Analytical Fracture Mechanics (MAE256F) Prof. Vijay GuptaDocument3 pagesProblem 1: Analytical Fracture Mechanics (MAE256F) Prof. Vijay GuptaClaireNo ratings yet

- Influence of PH, High Salinity and Particle Concentration On Stability and Rheological Properties of Aqueous Suspensions of Fumed SilicaDocument12 pagesInfluence of PH, High Salinity and Particle Concentration On Stability and Rheological Properties of Aqueous Suspensions of Fumed SilicaChan NovNo ratings yet

- Application of Polymer For Energy GenerationDocument18 pagesApplication of Polymer For Energy GenerationIzzatiHazwaniNo ratings yet

- Biosensors: Carbon Nanotube (CNT) - Based BiosensorsDocument33 pagesBiosensors: Carbon Nanotube (CNT) - Based BiosensorsOussama ZeggaiNo ratings yet

- Material Product Data Sheet Tungsten Carbide - 12 % Cobalt PowdersDocument4 pagesMaterial Product Data Sheet Tungsten Carbide - 12 % Cobalt PowdersAli El AliNo ratings yet

- Lecture 14 ElectroceramicsDocument29 pagesLecture 14 Electroceramicsdebayan sethNo ratings yet

- 49.bolt Transverse Double Shear CalculationDocument7 pages49.bolt Transverse Double Shear CalculationvenkateswaranNo ratings yet

- Medical Device Solutions: Links Science To LifeDocument8 pagesMedical Device Solutions: Links Science To Lifeabhijit_gothoskar6039No ratings yet

- Abaqus User ManualDocument1,103 pagesAbaqus User ManualsrgsuccessNo ratings yet

- Technique For Strengthening of Masonry Wall Panels Using Steel StripsDocument18 pagesTechnique For Strengthening of Masonry Wall Panels Using Steel StripsMiss NatalieNo ratings yet

- Ch03 Complete SetDocument18 pagesCh03 Complete SetMuhammad Uzair ArshadNo ratings yet

- Tribo Behav PTFE Sliding Against Steel Sea Water PDFDocument8 pagesTribo Behav PTFE Sliding Against Steel Sea Water PDFarmin_kunosic9871No ratings yet

- Yang 2013Document4 pagesYang 2013Dwi suparwatiNo ratings yet

- Porus Si SnO2Document9 pagesPorus Si SnO2kishnitNo ratings yet

- Relaxation of Steel in Prestressed Concrete: Jose TrevinoDocument13 pagesRelaxation of Steel in Prestressed Concrete: Jose TrevinoAmano GhzayelNo ratings yet

- Shear Force and Bending MomentssDocument32 pagesShear Force and Bending Momentssمحمد شمسNo ratings yet

- Electrical Systems 2Document3 pagesElectrical Systems 2Nathanael CHEONGNo ratings yet