Professional Documents

Culture Documents

Concrete Sand 211116 - 2758.1 With Petro

Concrete Sand 211116 - 2758.1 With Petro

Uploaded by

Alexandru Let0 ratings0% found this document useful (0 votes)

23 views10 pagesOriginal Title

Concrete Sand 211116 - 2758.1 with Petro

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views10 pagesConcrete Sand 211116 - 2758.1 With Petro

Concrete Sand 211116 - 2758.1 With Petro

Uploaded by

Alexandru LetCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Bulld something great™ [ey7aNH°

Report Template -Revsion 2 Jan 2020- Autores by K Al

Page iol

Boral Construction Materials

Materials Technical Services

Unit 4, 3-5 Gibbon load

Bauiknam Hils NSW 2153 Australia

PO Box 400, Winston Hills NSW 2163

TEST REPORT +81 (02) 9624 9900

F461 (02) 9624 9909

‘owboraLcom.au

CLIENT: ALLSANDS PTY LTD

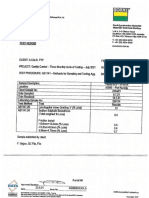

PROJECT: Quality Control Annual Testing of Sand ex Allsends Kurnell for Nov. 2021. FILE No: 819/24

TEST PROCEDURE: AS1141 — Methods for Sampling and Testing Aggregates REQUEST No: 97140

SPECIFICATION: AS2758.1- Concrete Aggregates - Date: 7 Nov. 2014, DATE TESTED: 2.12.21 to 17.12.21

[ Sample Description: Conerete Sand Stockpile

Location: Allsands Kumell

Date Sampled 16.11.21

Date Received: | 19.41.21

Laboratory Sample No: 260745

Test Method: Test i Spec. Results:

*ASTIALAT.A % Passing AS. Sieve

6.7mm 100"

475mm 90-100

236mm 60-100

1.18 mm 30-100 100

600 micron 15-100 98

425 micron - 84

300 micron 550 50

450 mioron 020 2

ASTIAT12 Material finer than 75 micron (%) 05 Nil

ASTIALA Uncompacted Bulk Density Um? Min. 12 1.32

Compacted Bulk Density 7 1.45

ASTIATS Paricle Density (Dry) Um? Min. 2.47 253

Paricle Density (SSD) vm? 255

Apparent Particle Density Um? 258

Water Absorption (7) 08

ASTI A Sodium Sulphate Soundness

Total weighted (% Loss) Max. 6 09

Fraction tested:

-600 jum +300 jum (% Loss) 09

ASTIAT.33 Silt Content (%) 2

ASTTAT.34 Organic impurities other than sugar Not darker Lighter than Std,

The colour assessment was made than std

visually using coloured reference glass

Note: Replacement for Report No: AGG97140.KA.1

*Sample washed over 7 micron sieve as per AS1141.11.1 Clause 6.5,

**As per Fine Aggregate ~ Recommended Gradings (Table 82), AS2758.1

Sample submitted by cient,

T. Schembri, Q.C File, File

De oral

ate Sil No, _ — NATA Accredited Laboratory

eed or camance il GONES 17085 -Tesrg

Teer al rol ero eer nha wou con fm Boi abrtry Number: 547

‘Toests rie Tec Sao ay foe aoe aed

Build something great™

Page 1 of 1

Report Template ~ Rev. (2) Apri 2017 — Authorised by M.A.

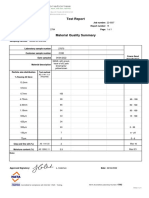

TEST REPORT

CLIENT: ALLSANDS Ply. Ltd.

PO Box 1630 North Sydney NSW 2059

BORAL

Boral Construction Materials

Materials Technical Services

Unit 4, 9-5 Gibbon Road

Baulkham Hils NSW 2153 Austria

PO Box 400, Winston Hils NSW 2183

“+61 (02) 9624 9900

F: +61 (02) 9624 9999

ww.boral.com.eu

FILE No.: 819 / 21

PROJECT: Quality Control Annual Testing of Sand from Allsands Kurnell for November 2021 REQUEST No.: 9714¢

to AS 2758.1 Specification. Concrete Aggregates, 7th November 2014.

TEST PROCEDURE:

AS 1012.20.1 — Determination of Chloride and Sulfate in Hardened Concrete and Aggregates — Nitric Acid Extraction

Method

AS 1141.31 — Determination of Light Particles

AS 1141.35 — Detection of Sugar

AS 1289.4.1.1 - Organic Matter content

AS 1289.4.3.1 — Determination of the pH value of a Soil

Laboratory Sample No.: 230745

Date Sampled: 16.11.21

Date Received: 19.11.24

Date Tested: 08.12.21

Sample Description Conerete Sand Stockpile

Field No. 1

TEST RESULTS:

Chloride as CI (%) 0.008

Sulfate as SO3 (%) 0.08

Light Particles (24) <1

Sugar Not Detected

Organic Matter (%) 04

pH 85

Sample submitted by the Client,

Tony Schembri, Q.C.File, Mat.File, File.

NATA /9"23Sarst00. OTILIA COSTACHE

ato 09.12.2021 guano) _ CHEMS7140.0C.1

TECHNICAL Tsp stot ered! astm a wma to pelt he Boe MTS Lely

“as esr Test Rar vty ote saree

NATA Accredited Laboratory

Number: 547

Bulld something great™ BORAL

NATA

WwW

TECHNICAL

Page 1 of 1

Reger Tompa— Re. (9). 2021 Autoried by MA

Boral Construction Materials

Materials Technical Services

Unit 4, 3-5 Gibbon Road

Bauikham Hils NSW 2169 Austria

PO Box 400, Winston Hills NSW 2183

+61 (02) 9624 9900

F: +81 (02) 9624 9809

\ww.boral.com.au

CLIENT: —Allsands Pty. Ltd, FILE No.: 819/21

PO Box 1630 North Sydney NSW 2059

TEST REPORT

PROJECT: Quality Control Annual Testing of Sand from Allsands Kurnell for REQUEST No.: 97140

November 2021 to AS 2758.1 Specification

‘TEST PROCEDURE:

‘AS 1141.12 - Material Finer than 75 micron *

AS 1141.13 — Material Finer than 2 micron

RMS T659 — Methylene Blue Adsorption Value of Road Construction Material

Laboratory Sample No.: 260745

Date Sampled: 16.11.21

Date Received: 19.14.21

Date Tested: From 6.12.21 to 7.12.21

‘Sample Description Concrete Sand Stockpile

Field No, 1

TEST RESULTS:

Material Finer than 75 micron (um) (%) * 1

Material Finer than 2 micron (tum) (%) Not Applicable

Methylene Blue Adsorption value (mg/g) 1

Methylene Blue Adsorption value for a Duplicate (mg/g) 1

Average Methylene Blue Adsorption value (mg/g) 1

1

OFI= MBV x Material Finer than 75jum (mg/g x %) *

‘Sample was provided by the Client.

* Note: This index calculation is not part of TINSW T659 or AS1141.12 and therefore not in the current scope of

NATA Accreditation for the Boral MTS Laboratory.

* The authorised signatory for AS 1141.12 is A. LIU.

Tony Schembri, , Q.C,File, Mat File, File,

Approved omnAle ALLIU S.DEBRINCAT

3 ~~ CHEM87140-SD-4-

date 43.4224 seraino

- ATA Accredited Laboratory

Arse cmp wn BYES 108 Teg

‘pet shleloc mrad eli ed Pe ron Bors MS ator rnber: $4

Test reits n this Test Report late cry tbe sare tested ial

6

Build something great™ ORAL

Peas ots Rew (@)isy2001———_Athosed by

Boral Construction Materials

Materials Technical Services

Unt 4 9-5 Gibbon Road

aula ls NSW 2189 Atala

PO Bo 400, Winston His NSW 2163

1: 461 (2) 9824 9900

F561 (2) 9624 9008

rest Repos wusntoralcoman

ALLSANDS PTY LTD File No: 81921

PO BOX 1630, NORTH SYDNEY, NSW 2059 Req, N 740

Date Received: — November 2021 Date Sampled: 16/11/2021

J Quality Control Annual Testing of Sand from Allsands Kurnell for November 2021,

Test Method: Accelerated Mortar Bar Test for AAR Assessment - RMS 7363

Lab Sample No ‘Sample Description Location

260745 Concrete Sand Stockpile Kumel

NA Boral GPISL Cement Berrima

Results:

Flow (): 18 WIC Rati: 0.52 Mixing Date; 07/12/2021

Expansion (%)

Aae (Dave) | avg. of I specimens

0.05

7 00s

10 0087

14 0088

17 0.108

21 0.134 4

0.000 4 & 4

os ws wos

Age(Days)

Mortar Bar Expansion (E) %

Duration of Specimens In Amol. NaOH at RMS T363 Aggregate Reactivity Classification

TO Days ZDays

>0.1" Reactive

*0.15% for naturally occurring fine aggregates

NATA

WwW

Sirens

Notes:

‘© Sample submitted by the Client

Tony Schembri, QC File, Mat. File, File

ei? Kaisar Humarhan

Approves Sonatoy [Lover __ Kear Huma

Date_0f.ef-2~ 2% sea no, CEMO7140.KH.1

ATA Accredited Laboratory

oaated compen wt ISONED 172 Testo

‘Titec eal rote ecrsusd ect hh he sero he ors MTS Labeaey Number: 547

‘osu nPe Test ert rat oe sage ees

GEOCHEMPET

SERVICES

ABN 25 065 630 506

PETROGRAPHIC, GEOLOGICAL & GEOCHEMICAL CONSULTANTS

28 Cameron Stet

(Conte, QLD 4019

‘Telephone: (07)3284 0020

Rnaitinbd@gexhompsioon

swwaugextenptoom

PETROGRAPHIC REPORT

ON A CONCRETE SAND STOCKPILE SAMPLE (260745)

FROM KURNELL

prepared for

BORAL RESOURCES (NSW) PTY LTD

MATERIAL TECHNICAL SERVICES

WINSTON HILLS, NSW.

Order Number: 6467368

Invoice Number: G2201505

Client Ref: Kamal Ali

Issued by A 797,

HLM. Spring BSc,

12 January 2022

January, 2022 Bo220102 Page | of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

GEOCHEMPET SERVICES, BRISBANE

260745 Date Sampled: 16/11/2021

21120059 Date Received: 06/12/2021

Kurnell Sample Type: Concrete Sand Stockpile

Allsands Pty Lid

Petrographic analysis in relation to use as concrete sand and in asphalt;

petrographic assessment of potential for alkali-silica reactivity

Methods Account taken of ASTM C295 Standard Guide for Petrographic

Assessment of Aggregates for Concrete, the AS2758.1 —2014 Aggregates

and rock for engineering purposes part 1; Concrete aggregates

(Appendix B), the AS1141 Standard Guide for the Method for sampling

and testing aggregates, of the content of the 2015 joint publication of the

Cement and Concrete Association of Australia and Standards Australia,

entitled (HB79-2015) Alkali Aggregate Reaction - Guidelines on

Minimising the Risk of Damage to Concrete Structures in Australia.

Identification Shelly, medium quartz sand

Description

The sample consisted of 500 grams of damp, clean greyish orange sand composed mainly of sub-

rounded to rounded, small quartz grains, but in detail speckled by small shell fragments,

Figure 1: Digital image of sub sample from supplied sand.

January, 2022 Bo220102 Page 2 of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

GEOCHEMPET SERVICES, BRISBANE

Ina crude test of a small dry subsample the following results were tabulated:

Sieve Size Wt % of sample

Coarse (>1.18mm) 0.3%

Medium (>0.3mm) 81.6%

Fine (20.075mm) 18.0%

Silt (<0.075mm) 0.1%

When a sub-sample was swirled in a beaker of water, the suspended fraction settled very

rapidly, leaving no turbidity or argillaceous scum, denoting the presence of very little silts and

clays.

The coarse fraction cons

lithic clasts

sted of predominately shell fragments and quartz. grains with minor

Figure 2: Digital image of sieve fractions.

January, 2022 Bo220102 Page 3 of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

GEOCHEMPET SERVICES, BRISBANE

Figure 3: Image of coarse sieve fraction dominated by shell fragments and quartz grains.

An approximate composition of the sand, expressed in volume percent of clast types and based

(on microscopic identification and brief counting of 100 points falling within sectioned fragments,

is:

36% quartz as unstrained to mildly strained free grains (29%) and simple

crystalline composite grains (7%)

22% quartz as moderately strained grains and crystalline composite grains

3% quartzite (2% moderately strained)

1% vein quartz (heavily strained)

<1% chert

4% _feldspars (4% K feldspar and <1% plagioclase)

<1% free mica

1% lithic clasts of intermediate volcanic rock

2% lithic clasts of acid tuff (<1% microcrystalline quartz)

4% lithic clasts of arenite (2% quartz)

2% lithic clasts of meta-pelite

25% carbonate shell fragments

‘The sand is dominated by quartz in the form of sub-rounded rounded grains (most commonly

around 0.2 to 0.6 mm in size) of unstrained to mildly strained free quartz grains (29%) and less

abundant rounded clasts of simple crystalline composites (7%) of two or more unstrained to

mildly strained quartz grains. Simple or polycrystalline grains of moderately strained quartz

amount to about 22%, Grains of quartzite amounted to 3% (25 moderately strained). About 1%

deleterious heavily strained vein quartz and <1% microcrystalline quartz as chert was noted.

January, 2022 Bo220102 Page 4 of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

GEOCHEMPET SERVICES, BRISBANE

Fresh to slightly weathered, and in some cases slightly altered feldspar, amount about 4%. Free

flakes of micas amounted to <1% of the supplied sand sample.

Minor other lithic clasts comprise 4% arenite (including 2% quartz) and 2 1% each of acid tuff

(mainly finely microcrystalline feldspars and quartz) , 1% intermediate volcanics (ferruginized in

parts), and 2% lithic clasts of meta-pelite

Carbonate shell fragments amount to 25%. The shells are wor broken fragments of various

types of shells, some coiled or chambered, some platy and curved and some porous. They may

include gastropods, bivalves, foraminifera and other organisms.

Comments and Interpretations

The supplied concrete sand sample (labelled 260745) from Allsands Pty Ltd, is considered to

consist of clean, shelly quartz sand which may be described broadly for engineering purposes as

‘medium quartz sand. It carries minor other mineral grains and minor durable lithic clasts.

The sand has a free silica content (or total quartz content) of about 64%, comprising 58%

quartz as free grains and crystalline composite grains, about 6% quartz locked within lithic clasts

of arenite, veined quartz and quartzite, and <1% finely microcrystalline quartz within lithic clasts

of chert and acid tuff.

The sand consists mainly of small, hard, strong, generally siliceous, rounded mineral and minor

Tock fragments, so it is interpreted to be physically suitable for use as concrete sand. Whilst the

carbonate shell fragments are not as hard as the dominant quartz and feldspar grains, they are

considered not to detract substantially from the quality of the sand for use in concrete but should

not be exposed to high temperatures.

The sand is considered adequate for use as a fine component in asphalt, given the high

carbonate and lower quartz, content.

in conerete. It carries <1% of cherty or finely microcrystalline quartz and 24%

moderately stained quartz and 1% heavily strained quartz.

Thus, sand of the type represented in the supplied sample is interpreted to be suitable for use in

conerete provided that appropriate precautions are taken in mix and engineering design to

take account of its perceived potential for mild or slow deleterious alkali-silica reactivity

Guidance on appropriate precautions can be obtained from the 2015 joint publication of the

Cement and Concrete Association of Australia and Standards Australia, entitled Alkali

Aggregate Reaction - Guidelines on Minimising the Risk of Damage to Concrete Structures in

Australia,

Free Content

The free silica content is about 64%,

January, 2022 Bo220102 Page 5 of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

GEOCHEMPET SERVICES, BRISBANE

Figure 4: Microscopic image taken at medium magnification with transmitted cross polarised

light. Image is dominated by rounded to sub-rounded quartz grains showing a range of

straining and abundant shell fragment can be scen as well as minor lithic clasts (note the vein

quartz fragment in the centre of the image).

January, 2022 Bo220102 Page 6 of 6

The material contained within this report may not be quoted other than in full. Extracts may be used only with

expressed prior written approval of Geochempet Services

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- As 3568-2020Document14 pagesAs 3568-2020Alexandru LetNo ratings yet

- Evaluating Physical Rheological and ChemDocument6 pagesEvaluating Physical Rheological and ChemAlexandru LetNo ratings yet

- Asphalt Binder "Skincare" AgiDocument18 pagesAsphalt Binder "Skincare" AgiAlexandru LetNo ratings yet

- High Modulus Asphalt Mixes With High Rate of RA - What Does It HappenDocument14 pagesHigh Modulus Asphalt Mixes With High Rate of RA - What Does It HappenAlexandru LetNo ratings yet

- Measyre PHBS 2586-1979Document18 pagesMeasyre PHBS 2586-1979Alexandru LetNo ratings yet

- C33B 6 Monthly COWDocument2 pagesC33B 6 Monthly COWAlexandru LetNo ratings yet

- A32 Sales APP v1Document1 pageA32 Sales APP v1Alexandru LetNo ratings yet

- 14 MM - SFS514 Jul 2021Document8 pages14 MM - SFS514 Jul 2021Alexandru LetNo ratings yet

- Methods of Testing Bitumen and Related Roadmaking Products: Method 30: Recovery of Residue From Bituminous EmulsionDocument12 pagesMethods of Testing Bitumen and Related Roadmaking Products: Method 30: Recovery of Residue From Bituminous EmulsionAlexandru LetNo ratings yet

- Rheological Characteristics of SyntheticDocument13 pagesRheological Characteristics of SyntheticAlexandru LetNo ratings yet

- R 39888 1 PDFDocument1 pageR 39888 1 PDFAlexandru LetNo ratings yet

- High Modulus Asphalt Specification (EME Class 2) Notes (NZTA M32 Notes - 2021)Document4 pagesHigh Modulus Asphalt Specification (EME Class 2) Notes (NZTA M32 Notes - 2021)Alexandru LetNo ratings yet

- C33B PSD COW (Ok)Document1 pageC33B PSD COW (Ok)Alexandru LetNo ratings yet

- As 1160-1996Document18 pagesAs 1160-1996Alexandru LetNo ratings yet

- Astm D244-09 (R 2017)Document9 pagesAstm D244-09 (R 2017)Alexandru LetNo ratings yet

- SIMS and ESCA Characterization of BitumeDocument8 pagesSIMS and ESCA Characterization of BitumeAlexandru LetNo ratings yet

- As 2008-2013Document12 pagesAs 2008-2013Alexandru LetNo ratings yet

- Bulk Density of Aggregate: Uncompacted Bulk Density (T/M ) 1.40 Compacted Bulk Density (T/M ) 1.2 1.55Document1 pageBulk Density of Aggregate: Uncompacted Bulk Density (T/M ) 1.40 Compacted Bulk Density (T/M ) 1.2 1.55Alexandru LetNo ratings yet

- C33B Annual Complete COWDocument19 pagesC33B Annual Complete COWAlexandru LetNo ratings yet

- Methods of Testing Bitumen and Related Roadmaking Products: Method 26: Determination of Sieve ResidueDocument12 pagesMethods of Testing Bitumen and Related Roadmaking Products: Method 26: Determination of Sieve ResidueAlexandru LetNo ratings yet

- Particle Size Distribution Report: Percent Passing (%) 100 100 99 94 76 11 2Document1 pageParticle Size Distribution Report: Percent Passing (%) 100 100 99 94 76 11 2Alexandru LetNo ratings yet

- Numbaa Yearly SweepDocument14 pagesNumbaa Yearly SweepAlexandru LetNo ratings yet

- Blue Dust Test ReportsDocument3 pagesBlue Dust Test ReportsAlexandru LetNo ratings yet

- 2ga 202109 0053 Att Item 6112Document2 pages2ga 202109 0053 Att Item 6112Alexandru LetNo ratings yet

- GALONG MU Report-LimilDocument3 pagesGALONG MU Report-LimilAlexandru LetNo ratings yet

- Crushed Glass SDSDocument7 pagesCrushed Glass SDSAlexandru LetNo ratings yet

- SNOW21W00390 - Compiled ReportsDocument21 pagesSNOW21W00390 - Compiled ReportsAlexandru LetNo ratings yet

- Particle Density & Water Absorption (Fine)Document1 pageParticle Density & Water Absorption (Fine)Alexandru LetNo ratings yet

- Stone Mastic Asphalt in The Uk: Sci Lecture Papers SeriesDocument10 pagesStone Mastic Asphalt in The Uk: Sci Lecture Papers SeriesAlexandru LetNo ratings yet

- Roadmap For Eliminating Use of Cutters - Revised AFPA v.2 - 21Document19 pagesRoadmap For Eliminating Use of Cutters - Revised AFPA v.2 - 21Alexandru LetNo ratings yet