Appleton Plug and Receptacle

Uploaded by

rezandriansyahAppleton Plug and Receptacle

Uploaded by

rezandriansyah- Powertite® Receptacles and Plugs: Details applications, features, and safety notes for Powertite® series receptacles and plugs.

- Technical Data: Grounding Styles, Wire Sizes, and Ratings: Presents technical data including grounding styles, wire sizes, and maximum horsepower ratings.

- 30 Amp Receptacles and Plugs: Lists specifications and catalog numbers for 30 Amp weatherproof or raintight receptacles and plugs.

- 60 Amp Receptacles and Plugs: Contains specifications and catalog numbers for 60 Amp receptacles and plugs designed for raintight conditions.

- 100 Amp Receptacles and Plugs: Provides details and specs for 100 Amp raintight weatherproof receptacles and plugs.

- Mounting Boxes for 30, 60, and 100 Amp Receptacles: Describes mounting boxes with catalog numbers for use with various amp levels.

- Replacement Parts for 30, 60, and 100 Amp: Details replacement parts available for several plug and cable connectors.

- Dimensions: Powertite® 30, 60, and 100 Amp: Illustrates dimensions and layouts for receptacles and mounting boxes in different configurations.

- 200 Amp Receptacles and Plugs: Lists catalog numbers, specifications for 200 Amp weatherproof plugs and receptacles.

- 400 Amp Receptacles and Plugs: Provides information and specs for high capacity 400 Amp receptacles and plugs.

- Mounting Boxes and Replacement Interiors for 200 and 400 Amp: Covers mounting options and interior replacements suitable for high capature receptacles.

- Dimensions: Powertite® 200 and 400 Amp: Details dimensions specific to 200 and 400 Amp installations and boxes.

- Plug Adapters for Conduit and Fittings: Explains adapter options and specs for connecting plugs and conduit fittings.

- Series Interchangeable Equivalents: Lists equivalent parts and catalog numbers across Crouse-Hinds and Appleton brands.

- IBR, IDSR, and WSRD Interlocked Switched Receptacles: Describes switched receptacles for enhancing safety, weatherproofing, and performance.

D-1

Master Index Cat. No. Index

D Index February 2004

Pin and Sleeve Receptacles,

Plugs, and Connectors: 30, 60, 100,

200 and 400 Amp.

30-, 60- and 100-Amp Powertite®

200-Amp Powertite®

400-Amp Powertite®

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-2

Cat. No. Index Master Index

February 2004 D Index

Pin and Sleeve Receptacles,

Plugs, and Connectors.

Page Description

5-31 Powertite® Receptacles and Plugs

3, 4 Features

5, 6 Technical Data

7, 8 30 Ampere

9, 10 60 Ampere

11, 12 100 Ampere

13 Mounting Boxes: 30, 60 & 100 Ampere

Powertite Series

®

14, 15 Replacement Interiors and parts: 30, 60 & 100 Ampere

16, 17 Dimensions: 30, 60 & 100 Ampere

18, 19 200 Ampere

20, 21 400 Ampere

PTA Powertite® Adapters

22, 23 Mounting Boxes, Interiors and parts: 200 & 400 Ampere

24 Dimensions: 200 Ampere

25 Dimensions: 400 Ampere

26-27 PTA Powertite® Adapters (30-200A)

28 - 31 Interchangeable Equivalents

33 IBR, IDSR and WSRD Interlocked Receptacles

34 Features

35 Catalogue ordering information

36 Dimensions

IBR/IDSR Series

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-

Master Index Cat. No. Index

D Index February 2004 3

Pin and Sleeve Receptacles, Plugs, and

Cable Connectors: Powertite® Series.

Applications

• Designed to supply power to portable

or fixed electrical equipment such as

motor generator units, welders, pumps,

compressors and similar apparatus.

• Ideal for use on shipping docks, ports,

and other “ship to shore” applications.

• Suitable for use in locations where a 1

weatherproof enclosure is required.

• Rough usage construction. 2

Features

• Available in 30-, 60-, 100-, 200-, and 3

400-ampere units.

• Available in two grounding styles: 4 30-, 60- and 100-Amp Powertite®

Style 1, shell grounding only; and Style

2, shell and extra pole grounding. 5

11

1

Grounding strap in Style 2 Receptacle

6

from extra pole to receptacle housing.

2

Screw locks receptacle housing and 7

interior into an assembly – also permits

easy field conversion to reverse service.

3

Receptacle interior retaining ring. 8 12

4

Raintight mounting box gasket.

5 Grounding detent springs in Style 1

9

and Style 2.

6

Longer ground terminal in Style 2

receptacle “makes first, breaks last”.

7

Floating-type plug terminal self-aligns 10

to receptacle contacts.

8

Screw locks plug housing and interior

60-Amp Style 2 Illustrated

into an assembly; also permits easy

field conversion to reverse service.

9 Grounding strap in Style 2 Plug from

extra pole to plug housing. 200-Amp Powertite®

10 Cable grip assembly.

11

Arc snuffing chamber.

12

Plug with clamping ring has neoprene

gasket. Ring threads onto screw cap

receptacle to provide raintight assembly

when properly tightened. Available in

30-, 60- and 100-ampere units.

• Neoprene bushing compressed by

cable collar prevents entrance of water.

Bushing is highly resistant to hydro-

carbon deterioration and is self-

extinguishing.

• Locking screw and slot prevents cable

collar from “backing off”.

• Brass contacts exert constant pres- 400-Amp Powertite®

sure along entire contact surface and

provide electrical continuity.

• 30- and 60-ampere contacts have

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-4

Cat. No. Index Master Index

February 2004 D Index

Pin and Sleeve Receptacles, Plugs, and

Cable Connectors: Powertite® Series.

phosphor bronze springs; 100-ampere tacle or connector. Prevents plug in- drawn, the gasketed Spring Door cover

contacts have two spring-loaded sertion in a receptacle or connector closes tightly against receptacle opening

borosilicate bearings; 200-ampere con- wired for a different voltage. automatically, providing weatherproof pro-

tacts are split-type; 400-ampere con- Suffix – P4: Looking at face of recep- tection. Spring Door has stainless steel

tacts have four spring-loaded borosilicate tacle, the receptacle interior or con- spring and shaft.

bearings. nector interior is rotated 22-1/2"

• Choice of receptacle types: weather- (relative to the polarization rib) clock-

proof spring door and raintight screw wise of standard and plug is polarized

cap (30-, 60- and 100-amp). Powertite to correspond.

200- and 400-ampere have raintight • Reverse Service: Add suffix – RS to

clamp cover receptacles. catalog number. Useful where a “hot ”

• Insulating blocks provide greatest plug feeds a dead receptacle.

dielectric and mechanical strength and 30-, 60- and 100-ampere – add suffix

lowest moisture absorption, lowest – RS to catalog number (or may be

“arc tracking”. easily performed in the field with only

• Positive polarization: only plugs a screwdriver).

Spring Door cover of the 60A and 100A

of same style, number of poles and 200- and 400-ampere – add suffix – RS

ampere rating can be used together. units may be located at any position in a

to catalog number. Available as a factory

360° circle by adjusting a setscrew. Setscrew

• “Circuit breaking”: in 30- through 200- assembled item only at extra cost.

also allows complete removal of cover.

amp units, any arcing created as line

Compliances

and load terminals disengage is safely

confined deep within terminal cavities. • CSA Specification C22.2 No. 42. NOTE: Spring Door cover in open position

Plugs may be withdrawn in an emer- • CSA Type 4x (up to 200 AMP). for illustration only.

gency under full rated loads without • UL Standard 498.

separate disconnect switches (400-amp • Appleton malleable iron products

plug for disconnecting use only–not for conform to ASTM A47-77, Grade 32510,

current rupturing). which has the following properties:

• 30-, 60- and 100-ampere Powertite® tensile strength, 50,000 psi; yield, 32,000

plugs also suitable for classified loca- psi; and elongation, 10%.

tions when used with Appleton EBR • Appleton aluminum products are pro-

explosion-proof interlocking circuit duced from a high strength copper-free

breaker receptacles (see Catalog Sec- (4/10 of 1% max.) alloy.

tion L).

ACP plugs are supplied with four bushings

Standard Materials to accommodate a wide variety of cable

• Plug, receptacle, connector and diameters. 30 Amp plug clamp used in first

mounting box housings: copper-free position with smallest I.D. bushing provides

aluminum. positive grip on cables as small as .390"

• Insulating blocks: fiber glass rein- such as are used in oil rig installations.

forced polyester.

• Contacts: brass; 30- and 60-ampere

have phosphor bronze springs and

100- and 400-ampere have borosilicate

bearings. 200-ampere has split-type

contacts. Product Cross Reference

Standard Finishes

• For classified location plugs, recep-

tacles, and connectors, see Catalog

• Aluminum plug, receptacle, connector Section L.

and mounting box housings: aluminum

polymer enamel. Illustrated Features

Both 60A and 100A Spring Door and Screw Reversible cable clamp (just loosen screws

• Insulating blocks and contacts: natu- Cap receptacles are threaded to accept and flip over) permits wide cable range.

ral finish. Each position accommodates one of two

clamping ring ACP plug. The ring threads

Options onto the receptacle to form a raintight bushings. Convenient in installations having

different cable sizes.

• Special Polarization: Add suffix – P4 assembly with plug in use – and also to

or – P5 to catalog number of recep- prevent plug fallout. When the plug is with-

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-5

Master Index Cat. No. Index

D Index February 2004

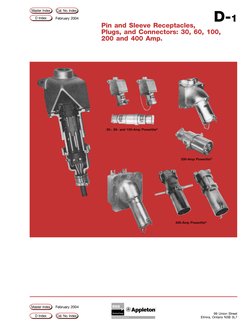

Powertite® Technical Data: Grounding

Styles, Maximum Wire Sizes, and

Horsepower Ratings.

Powertite Plugs and Receptacles Available in Two Grounding Styles. Range of wire sizes

accommodated in Powertite®

plug and receptacle terminals.

30, 60 and 100 Amp

Wire Recess Wire Size

Amps. Dia., Inches Range

30 .281 #10-#6

60 .312 #6-#2

100 .391 #4-#1/0

STYLE 1 STYLE 2

Shell Only Shell and Extra 200 Amp

Grounding Pole Grounding

Solder Conductor Max. Type

Recess Size Strand Conductor

0.562" 4/0 19 Gen’l wire

Dia. 3/0 259 Flex. cable

3/0 427 Extra flex.

400 Amp

0.84" 500MCM 37 Gen’l wire

Dia. 400MCM 259 Flex. cable

400MCM 427 Extra flex.

1.25" 1000MCM 61 Gen’l wire

Portable cord, Portable cord, Dia. 900MCM 427 Flex. cable

4-conductor 4-conductor RECEPTACLE 800MCM 703 Extra flex.

Grounded PLUG

thru Fourth

conduit (grounding)

system wire,

if desired

PLUG Powertite® Maximum

Factory Grounded

Equipment RECEPTACLE Equipment installed thru Horsepower Ratings

ground ground jumper conduit Not for normal starting and stopping, but

connected connected system plug may be withdrawn in an emergency

to plug shell to extra sleeve and if within these maximum H.P. ratings.

and plug shell extra pin

Motor Horsepower

Phase

Plug – Equipment grounding conduc- Plug – Equipment grounding conduc- Motor Amps 115V 230V 480V 600V

tor is wired directly to a solderless lug tor is not only connected to the solder-

which is connected to the plug housing less lug in the plug housing, but also 1-Phase 30 2 3 10 10

with a pressure connector. All terminals to an extra grounding pole. Grounding 2P, 2W 60 3 10 20 20

are “current carrying”. pole has copper alloy grounding jumper or 100 7-1/2 15 30 30

strap that connects to plug housing. 2P, 3W 200 15 30 40 40

Receptacle – Two detent spring

clips engage the grounded plug hous- Receptacle – Two detent spring clips 1-Phase 30 3 7-1/2 15 20

ing on plug insertion – grounded plug engage the grounded plug housing 3P, 3W; 60 7-1/2 15 30 30

shell makes contact with receptacle on plug insertion. Jumper from extra 3P, 4W; 100 10 20 40 40

ground spring before line and load grounding pole is electrically connected or 200 20 40 50 50

poles are engaged. Grounding path is to a screw on receptacle housing. 4P, 4W

maintained until after current-carrying Longer grounding pole “makes first

contacts disengage. All terminals are and breaks last”.

“current carrying”.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-6

Cat. No. Index Master Index

February 2004 D Index

Powertite® Technical Data:

Reverse Service, Polarization,

Pin and Sleeve Design.

Reverse Service Special Polarization

Useful where “Hot” Plug Feeds Dead Receptacle Standard Powertite receptacles, plugs

and connectors have positive polariza-

tion, which ensures that only plugs of

Standard Service Reverse Service the same style, number and ampere

“Hot” receptacle has recessed male Receptacle houses a dead plug inte- rating can be used together. In instal-

contacts to eliminate danger of rior. Plug houses a “hot” receptacle lations where there are different line

accidental touching.Plug has female interior, which has recessed male con- voltages, the SPECIAL POLARIZATION

contacts that are energized only upon tacts to eliminate danger of accidental option is desirable. This allows only

insertion in receptacle. touching. plugs and receptacles wired for the

same line voltage to be mated together.

Polarization Polarization Polarization Polarization The receptacle or connector interior

Rib Slot Rib Slot is positioned 22-1/2", relative to the

polarization rivet, to the left or right

(as specified) of standard, and plug is

polarized to correspond. This makes

it impossible to mate plugs and recep-

tacles of dissimilar voltages.

For ordering information see options,

page D-4.

Male Receptacle Female Plug Female Plug Male Receptacle

Interior Interior Interior Interior

Powertite® Pin and Sleeve Design

30 and 100 AMP

60 AMP

Pressure Wire Terminals. Solid Brass Pressure Wire Terminals. Solid Brass Contacts

Contacts with Phosphor Bronze Springs. with Two Spring-Loaded Borosilicate Bearings.

200 AMP

Solder Well Wire Terminals. Solid Brass Split-Type Contacts.

400 AMP

.84"

Solder

Recess

Solder Well Wire Terminals. Solid Brass Contacts with Four Spring-Loaded Borosilicate Bearings.

400 AMP

1.25"

Solder

Recess

Solder Well Wire Terminals. Solid Brass Contacts with Four Spring-Loaded Borosilicate Bearings.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

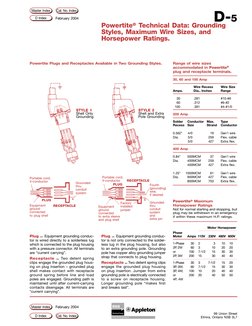

D-7

Master Index Cat. No. Index

D Index February 2004

NEMA 3, 3R, 4, 4X

Powertite® 30 Amp Pin and Sleeve

Receptacles and Plugs:

Weatherproof or Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .281". Wire Size Range: #10–#6.

Description Catalogue Number

Spring Door

and Screw Cap

Receptacles –

Weatherproof

Hub Receptacle Plug

Grounding Size with AEE Receptacle Cable Range, Clamping

Style Pole/Wire Inches Mounting Box* Only Inches Ring Plug**

Style 1 2P, 2W 1/2 ADRE3022-50 ADR3022 .390 to 1.375 ACP3022BC

3/4 ADRE3022-75 ADR3022 .390 to 1.375 ACP3022BC

3P, 3W 3/4 ADRE3033-75 ADR3033 .390 to 1.375 ACP3033BC

1 ADRE3033-100 ADR3033 .390 to 1.375 ACP3033BC

4P, 4W 3/4 ADRE3044-75 ADR3044 .390 to 1.375 ACP3044BC

1 ADRE3044-100 ADR3044 .390 to 1.375 ACP3044BC

Style 2 2P, 3W 3/4 ADRE3023-75 ADR3023 .390 to 1.375 ACP3023BC

1 ADRE3023-100 ADR3023 .390 to 1.375 ACP3023BC

3/4 ADRE3034-75 ADR3034 .390 to 1.375 ACP3034BC

3P, 4W 1 ADRE3034-100 ADR3034 .390 to 1.375 ACP3034BC

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-8

Cat. No. Index Master Index

February 2004 D Index

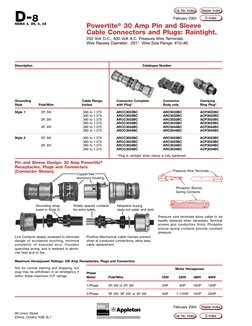

NEMA 3, 3R, 4, 4X

Powertite® 30 Amp Pin and Sleeve

Cable Connectors and Plugs: Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .281". Wire Size Range: #10–#6.

Description Catalogue Number

Grounding Cable Range, Connector Complete Connector Clamping

Style Pole/Wire Inches with Plug* Body only Ring Plug*

Style 1 2P, 2W .390 to 1.375 ARCC3022BC ARC3022BC ACP3022BC

.390 to 1.375 ARCC3022BC ARC3022BC ACP3022BC

3P, 3W .390 to 1.375 ARCC3033BC ARC3033BC ACP3033BC

.390 to 1.375 ARCC3033BC ARC3033BC ACP3033BC

4P, 4W .390 to 1.375 ARCC3044BC ARC3044BC ACP3044BC

.390 to 1.375 ARCC3044BC ARC3044BC ACP3044BC

Style 2 2P, 3W .390 to 1.375 ARCC3023BC ARC3023BC ACP3023BC

.390 to 1.375 ARCC3023BC ARC3023BC ACP3023BC

3P, 4W .390 to 1.375 ARCC3034BC ARC3034BC ACP3034BC

.390 to 1.375 ARCC3034BC ARC3034BC ACP3034BC

* Plug is raintight when clamp is fully tightened.

Pin and Sleeve Design: 30 Amp Powertite ®

Receptacles, Plugs and Connectors

(Connector Shown). Pressure Wire Terminals

Copper-free

aluminum housing.

Phosphor Bronze

Spring Contacts

Grounding strap Widely spaced contacts Neoprene busing

(used in Style 2). for extra safety. seals out water and dust.

Pressure wire terminals allow cable to be

readily replaced when necessary. Terminal

screws grip conductors firmly. Phosphor

bronze spring contacts provide constant

pressure.

Live Contacts deeply recessed to eliminate Positive Mechanical cable clamps prevent

danger of accidental touching, minimize strain at conductor connections, allow easy

possibility of exposed arcs. Insulator cable replacement.

quenches arcing, and is resistant to abnor-

mal heat and to fire.

Maximum Horsepower Ratings: 100 Amp Receptacles, Plugs and Connectors

Not for normal starting and stopping, but Motor Horsepower

plug may be withdrawn in an emergency if Phase

within these maximum H.P. ratings. Motor Pole/Wire 120V 240V 480V 600V

1-Phase 2P, 2W or 2P, 3W 2HP 3HP 10HP 10HP

3-Phase 3P, 3W; 3P, 4W; or 4P, 4W 3HP 7-1/2HP 15HP 20HP

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-9

Master Index Cat. No. Index

D Index February 2004

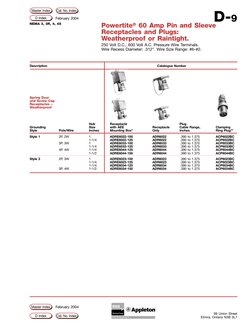

NEMA 3, 3R, 4, 4X

Powertite® 60 Amp Pin and Sleeve

Receptacles and Plugs:

Weatherproof or Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .312". Wire Size Range: #6–#2.

Description Catalogue Number

Spring Door Hinge

and Screw Cap rotates

Receptacles – 360°

Weatherproof

Hub Receptacle Plug

Grounding Size with AEE Receptacle Cable Range, Clamping

Style Pole/Wire Inches Mounting Box* Only Inches Ring Plug**

Style 1 2P, 2W 1 ADRE6022-100 ADR6022 .390 to 1.375 ACP6022BC

1-1/4 ADRE6022-125 ADR6022 .390 to 1.375 ACP6022BC

3P, 3W 1 ADRE6033-100 ADR6033 .390 to 1.375 ACP6033BC

1-1/4 ADRE6033-125 ADR6033 .390 to 1.375 ACP6033BC

4P, 4W 1-1/4 ADRE6044-125 ADR6044 .390 to 1.375 ACP6044BC

1-1/2 ADRE6044-150 ADR6044 .390 to 1.375 ACP6044BC

Style 2 2P, 3W 1 ADRE6023-100 ADR6023 .390 to 1.375 ACP6023BC

1-1/4 ADRE6023-125 ADR6023 .390 to 1.375 ACP6023BC

1-1/4 ADRE6034-125 ADR6034 .390 to 1.375 ACP6034BC

3P, 4W 1-1/2 ADRE6034-150 ADR6034 .390 to 1.375 ACP6034BC

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-10

Cat. No. Index Master Index

February 2004 D Index

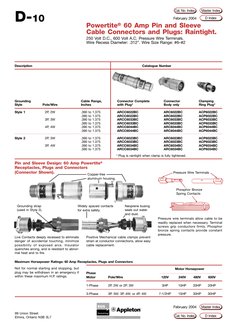

Powertite® 60 Amp Pin and Sleeve

Cable Connectors and Plugs: Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .312”. Wire Size Range: #6–#2

Description Catalogue Number

Grounding Cable Range, Connector Complete Connector Clamping

Style Pole/Wire Inches with Plug* Body only Ring Plug*

Style 1 2P, 2W .390 to 1.375 ARCC6022BC ARC6022BC ACP6022BC

.390 to 1.375 ARCC6022BC ARC6022BC ACP6022BC

3P, 3W .390 to 1.375 ARCC6033BC ARC6033BC ACP6033BC

.390 to 1.375 ARCC6033BC ARC6033BC ACP6033BC

4P, 4W .390 to 1.375 ARCC6044BC ARC6044BC ACP6044BC

.390 to 1.375 ARCC6044BC ARC6044BC ACP6044BC

Style 2 2P, 3W .390 to 1.375 ARCC6023BC ARC6023BC ACP6023BC

.390 to 1.375 ARCC6023BC ARC6023BC ACP6023BC

3P, 4W .390 to 1.375 ARCC6034BC ARC6034BC ACP6034BC

.390 to 1.375 ARCC6034BC ARC6034BC ACP6034BC

* Plug is raintight when clamp is fully tightened.

Pin and Sleeve Design: 60 Amp Powertite®

Receptacles, Plugs and Connectors

(Connector Shown). Copper-free

Pressure Wire Terminals

aluminum housing.

Phosphor Bronze

Spring Contacts

Grounding strap Widely spaced contacts Neoprene busing

(used in Style 2). for extra safety. seals out water

and dust.

Pressure wire terminals allow cable to be

readily replaced when necessary. Terminal

screws grip conductors firmly. Phosphor

bronze spring contacts provide constant

pressure.

Live Contacts deeply recessed to eliminate Positive Mechanical cable clamps prevent

danger of accidental touching, minimize strain at conductor connections, allow easy

possibility of exposed arcs. Insulator cable replacement.

quenches arcing, and is resistant to abnor-

mal heat and to fire.

Maximum Horsepower Ratings: 60 Amp Receptacles, Plugs and Connectors

Not for normal starting and stopping, but Motor Horsepower

plug may be withdrawn in an emergency if Phase

within these maximum H.P. ratings. Motor Pole/Wire 120V 240V 480V 600V

1-Phase 2P, 2W or 2P, 3W 3HP 10HP 20HP 20HP

3-Phase 3P, 3W; 3P, 4W; or 4P, 4W 7-1/2HP 15HP 30HP 30HP

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-11

Master Index Cat. No. Index

D Index February 2004

Powertite® 100 Amp Pin and Sleeve

Receptacles and Plugs:

Weatherproof or Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .391". Wire Size Range: #4–#1/0

Description Catalogue Number

Spring Door

and Screw Cap

Receptacles –

Weatherproof

Hub Receptacle Plug

Grounding Size with AJA Receptacle Cable Range, Clamping

Style Pole/Wire Inches Mounting Box* Only Inches Plug Plug**

Style 1 2P, 2W 1-1/4 ADJA1022-125 ADR1022 .875 to 1.906 ACP1022CD

1-1/2 ADJA1022-150 ADR1022 .875 to 1.906 ACP1022CD

3P, 3W 1-1/4 ADJA1033-125 ADR1033 .875 to 1.906 ACP1033CD

1-1/2 ADJA1033-150 ADR1033 .875 to 1.906 ACP1033CD

4P, 4W 1-1/2 ADJA1044-150 ADR1044 .875 to 1.906 ACP1044CD

2 ADJA1044-200 ADR1044 .875 to 1.906 ACP1044CD

Style 2 2P, 3W 1-1/4 ADJA1023-125 ADR1023 .875 to 1.906 ACP1023CD

1-1/2 ADJA1023-150 ADR1023 .875 to 2.500 ACP1023CD

1-1/2 ADJA1034-150 ADR1034 .875 to 1.906 ACP1034CD

3P, 4W 2 ADJA1034-200 ADR1034 .875 to 1.906 ACP1034CD

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-12

Cat. No. Index Master Index

February 2004 D Index

Powertite® 100 Amp Pin and Sleeve

Cable Connectors and Plugs: Raintight.

250 Volt D.C., 600 Volt A.C. Pressure Wire Terminals.

Wire Recess Diameter: .391". Wire Size Range: #4–#1/0

Description Catalogue Number

Grounding Cable Range, Connector Connector Clamping

Style Pole/Wire Inches Complete with Plug* Body only Ring Plug*

Style 1 2P, 2W .875 to 1.906 ARCC1022CD ARC1022CD ACP1022CD

.875 to 1.906 ARCC1022CD ARC1022CD ACP1022CD

3P, 3W .875 to 1.906 ARCC1033CD ARC1033CD ACP1033CD

.875 to 1.906 ARCC1033CD ARC1033CD ACP1033CD

4P, 4W .875 to 1.906 ARCC1044CD ARC1044CD ACP1044CD

.875 to 1.906 ARCC1044CD ARC1044CD ACP1044CD

Style 2 2P, 3W .875 to 1.906 ARCC1023CD ARC1023CD ACP1023CD

.875 to 1.906 ARCC1023CD ARC1023CD ACP1023CD

3P, 4W .875 to 1.906 ARCC1034CD ARC1034CD ACP1034CD

.875 to 1.906 ARCC1034CD ARC1034CD ACP1034CD

* Plug is raintight when clamp is fully tightened.

Pin and Sleeve Design: 100 Amp Powertite®

Receptacles, Plugs and Connectors (Connector Shown).

Copper-free

aluminum housing. Pressure Wire Terminals

Solid Brass Contacts with

Beryllium Copper Springs

Grounding strap Widely spaced contacts Neoprene busing Pressure wire terminals allow cable to be

(used in Style 2). for extra safety. seals out water readily replaced when necessary. Terminal

and dust. screws grip conductors firmly. Spring con-

tacts provide constant pressure.

Live contacts deeply recessed to eliminate Positive Mechanical cable clamps prevent

danger of accidental touching, minimize strain at conductor connections, allow easy

possibility of exposed arcs. Insulator cable replacement.

quenches arcing, and is resistant to abnor-

mal heat and to fire.

Maximum Horsepower Ratings: 100 Amp Receptacles, Plugs and Connectors

Not for normal starting and stopping, but

plug may be withdrawn in an emergency if Motor Horsepower

within these maximum H.P. ratings. Phase

Motor Pole/Wire 120V 240V 480V 600V

1-Phase 2P, 2W or 2P, 3W 7-1/2HP 15HP 30HP 30HP

3-Phase 3P, 3W; 3P, 4W; or 4P, 4W 10HP 20HP 40HP 40HP

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-13

Master Index Cat. No. Index

D Index February 2004

Powertite® Mounting Boxes for

30, 60 and 100 Amp Receptacles.

Description Catalogue Number

30 Ampere

Hub Size, Inches AEE AERH AERC AERA

1/2 AEE13 AERH13 AERC13 AERA13

3/4 AEE23 AERH23 AERC23 AERA23

1 AEE33 AERH33 AERC33 AERA33

60 Ampere

Hub Size, Inches AEE AERH AERC AERA

1 AEE36 AERH36 AERC36 AERA36

1-1/4 AEE46 AERH46 AERC46 AERA46

1-1/2 AEE56 AERH56 AERC56 AERA56

60, 100, 200

and 400

Ampere

Hub Size, Inches AJA (60, 100 Amp)* AJA (200 Amp) AJAC (200 Amp) AJAC (400 Amp)**

1 AJA310 – – –

1-1/4 AJA410 – – –

1-1/2 AJA510 AJA520 – –

2 AJA610 AJA620 – –

2-1/2 – AJA720 AJAC720 –

4 – – – AJAC400

Adaptors

for 60, 100

200 and 400

Ampere

For Panel

mounting

60, 100 Amp (15°) 60, 100 Amp (30°) 200 Amp (45°) 2400 Amp (45°)

1 AJA100 AR100 AJA200 AJA400

*Feed-Thru box furnished with one close-up plug in bottom recessed hub.

**Has feed-thru 4" tapped openings. Supplied with one 4" to 3" reducer and one 4" close-up plug.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-14

Cat. No. Index Master Index

February 2004 D Index

Replacement Interiors for Powertite®

Plugs and Receptacles: 30, 60,

and 100 Amp.

Description Catalogue Number

30 Amp Interiors

Style 1 Style 2

Interiors Interiors

Grounding Style Pole/Wire Receptacle Plug Receptacle Plug

Style 1 2P, 2W ARI-3022 API-3022 –––––––– ––––––––

3P, 3W ARI-3033 API-3033 –––––––– ––––––––

4P, 4W ARI-3044 API-3044 –––––––– ––––––––

Style 2 2P, 3W –––––––– ––––––––– ARI-3023 API-3023

3P, 4W –––––––– ––––––––– ARI-3034 API-3034

60 Amp Interiors

Style 1 Style 2

Interiors Interiors

Grounding Style Pole/Wire Receptacle Plug Receptacle Plug

Style 1 2P, 2W ARI-6022 API-6022 –––––––– ––––––––

3P, 3W ARI-6033 API-6033 –––––––– ––––––––

4P, 4W ARI-6044 API-6044 –––––––– ––––––––

Style 2 2P, 3W –––––––– ––––––––– ARI-6023 API-6023

3P, 4W –––––––– ––––––––– ARI-6034 API-6034

100 Amp Interiors

Style 1 Style 2

Interiors Interiors

Grounding Style Pole/Wire Receptacle Plug Receptacle Plug

Style 1 2P, 2W ARI-1022 API-1022 –––––––– ––––––––

3P, 3W ARI-1033 API-1033 –––––––– ––––––––

4P, 4W ARI-1044 API-1044 –––––––– ––––––––

Style 2 2P, 3W –––––––– ––––––––– ARI-1023 API-1023

3P, 4W –––––––– ––––––––– ARI-1034 API-1034

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-15

Master Index Cat. No. Index

D Index February 2004

Powertite® 30, 60 and 100 Amp

Replacement Parts.

Description Catalogue Number

ACP Plug Clamping Ring

(Includes Gasket)

30 Amp Plug - 2, 3 and 4-Wire CLMPR30

60 Amp Plug - 2 and 3-Wire CLMPR23W60

60 Amp Plug - 4-Wire CLMPR4W60

100 Amp Plug - 2 and 3-Wire CLMPR23W100

100 Amp Plug - 4-Wire CLMPR4W100

Receptacle Covers

Spring Cover

(Includes Gasket and Ring)

30 Amp - 2, 3 and 4-Wire PTSC30

60 Amp - 2 and 3-Wire PTSC60A

60 Amp - 4-Wire PTSC60B

100 Amp - 2 and 3-Wire PTSC100A

100 Amp - 4-Wire PTSC100B

Threaded Cover

(Includes Gasket and Chain)

30 Amp - 2, 3 and 4-Wire PTTC30

60 Amp - 2 and 3-Wire PTTC60A

60 Amp - 4-Wire PTTC60B

100 Amp - 2 and 3-Wire PTTC100A

100 Amp - 4-Wire PTTC100B

Bushing Bags for Plugs and Cable Connectors

30 Amp PTGB30

60 Amp PTGB60

100 Amp PTGBCD

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-16

Cat. No. Index Master Index

February 2004 D Index

Dimensions: Powertite® 30, 60 and

100 Amp Pin and Sleeve Receptacles,

Plugs and Connectors.

21/64" Dia. 3/8" Dia.

Spring Cover Front View Threaded Cap Spring Cover Back View Threaded Cap

Receptacle Mounted on AEE Box Receptacle mounted on AJA-AJAC Box

A B C D E F A B C D E F G

Dimensions in Inches Dimensions in Inches

30 Amp 6.88 3.75 4.25 7.13 3.88 5.00 60 Amp 10.94 8.00 8.81 12.00 4.88 6.88 7.81

60 Amp 9.75 5.25 5.50 10.00 4.25 6.38 100 Amp 12.75 9.00 9.19 13.13 4.88 6.88 7.81

Dimensions in Centimetres Dimensions in Centimetres

30 Amp 17.5 9.5 10.8 18.1 8.6 12.7 60 Amp 27.8 20.3 22.4 30.5 12.4 17.5 19.8

60 Amp 24.8 13.3 14.0 25.4 10.8 16.2 100 Amp 32.4 22.9 23.3 33.3 12.4 17.5 19.8

Connector A B A B

Dimensions in Inches Dimensions in Centimetres

30 Amp 10.50 3.13 26.7 7.9

60 Amp 13.25 3.81 33.7 9.7

ARCC Cable Connector 100 Amp 16.00 4.25 40.6 10.8

ADR Spring Cover ACR Threaded Cap ACP Plug

Receptacle Plug

No. Poles A B C D E No. Poles A B C D

Dimensions in Inches Dimensions in Inches

30 Amp 2,3,4 3.31 3.19 .3.8 2.72 2.06 30 Amp 2,3,4 6.00 4.75 3.13 1.86

60 Amp 2,3 4.88 4.63 4.50 3.50 2.31 60 Amp 2,3 7.81 4.94 3.50 2.23

60 Amp 4 4.88 4.63 4.50 3.50 2.44 60 Amp 4 7.81 4.94 3.81 2.55

100 Amp 2,3 5.81 5.50 4.50 3.50 2.44 100 Amp 2,3 10.50 6.63 4.00 2.47

100 Amp 4 5.81 5.50 4.25 3.50 2.56 100 Amp 4 10.50 6.63 4.25 2.72

Dimensions in Centimetres Dimensions in Centimetres

30 Amp 2,3,4 8.4 8.1 8.6 6.9 5.2 30 Amp 2,3,4 15.2 12.1 7.9 4.7

60 Amp 2,3 12.4 11.8 11.4 8.9 5.9 60 Amp 2,3 19.8 12.5 8.9 5.7

60 Amp 4 12.4 11.8 11.4 8.9 5.9 60 Amp 4 19.8 12.5 9.7 6.5

100 Amp 2,3 14.8 14.0 11.4 8.9 6.2 100 Amp 2,3 26.7 16.8 10.2 6.3

100 Amp 4 14.8 14.0 10.8 8.9 6.5 100 Amp 4 26.7 16.8 10.8 6.9

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-17

Master Index Cat. No. Index

D Index February 2004

Dimensions: Powertite® 30, 60,

and 100 Amp Mounting Boxes.

3/8" Dia.

AR100 4 Holes: 1/4 -20 Tap

2.75"

(10cm)

Adapter

2.94"

(7.5cm)

5.88"

3.69"

4.88" (14.9cm) (9.4cm)

(12.4cm)

3.50"

(8.9cm) 30°

6.88" 4.94"

(17.5cm) (12.5cm) 4.25"

21/64" (10.8cm)

7.81" Dia.

(19.8cm)

AJA Mounting Boxes♦♦ AERA* AERC** and AERH Mounting Boxes

Hub A B♦♦ C Hub A* B** C D E F G H J

Dimensions in Inches Dimensions in Inches

60 and 1 1.19 1.16 8.00 30 Amp 1/2 .69 5.31 3.38 3.38 2.50 2.63 4.56 2.72 .94

100 Amp 1-1/4 1.19 1.16 8.00 30 Amp 3/4 .75 5.31 3.38 3.38 2.50 2.63 4.56 2.72 .94

1-1/2 1.56 1.25 8.00 30 Amp 1 .81 5.31 3.38 3.38 2.50 2.63 4.56 2.72 .94

2 1.56 1.25 8.00

60 Amp 1/2 .81 6.50 4.25 4.25 3.13 3.50 5.88 3.50 1.38

Dimensions in Centimetres 60 Amp 3/4 .94 6.50 4.25 4.25 3.13 3.50 5.88 3.50 1.38

60 Amp 1 1.00 6.50 4.25 4.25 3.13 3.50 5.88 3.50 1.38

60 and 1 3.00 2.9 8.00

100 Amp 1-1/4 3.00 2.9 8.00 Dimensions in Centimetres

1-1/2 4.00 3.2 8.00

2 4.00 3.2 8.00 30 Amp 1/2 1.8 13.5 8.6 8.6 6.4 6.7 11.6 6.9 2.4

30 Amp 3/4 1.9 13.5 8.6 8.6 6.4 6.7 11.6 6.9 2.4

♦♦ AJA box has two hubs. 30 Amp 1 2.1 13.5 8.6 8.6 6.4 6.7 11.6 6.9 2.4

60 Amp 1/2 2.1 16.5 10.8 10.8 7.9 8.9 14.9 8.9 3.5

60 Amp 3/4 2.1 16.5 10.8 10.8 7.9 8.9 14.9 8.9 3.5

60 Amp 1 2.1 16.5 10.8 10.8 7.9 8.9 14.9 8.9 3.5

*Dimension “A” for AERA only. **Dimension “B” for AERC only

3/8" Dia. AJSC and AJS Mounting Boxes▲

Hub A B▲ C D

21/64" 5.88"

Dia. (14.9cm)

4.88"

(12.4cm) Dimensions in Inches

6.88" 60 Amp 1 1.19 1.16 3.88 .75

(17.5cm)

7.81"

1-1/4 1.19 1.16 3.88 .75

(19.8cm) 1-1/2 1.56 1.25 3.88 .75

2 1.56 1.25 3.88 .75

100 Amp 1 1.19 1.16 5.88 2.75

1-1/4 1.19 1.16 5.88 2.75

15° for 30 Amp; 18° for 60 Amp.

1-1/2 1.56 1.25 5.88 2.75

2 1.56 1.25 5.88 2.75

AEE Mounting Box (1/2", 3/4", and 1" Hub) Dimensions in Centimetres

A B C D E F G

60 Amp 1 3.0 2.9 3.88 1.9

Dimensions in Inches 1-1/4 3.0 2.9 3.88 1.9

1-1/2 4.0 3.2 3.88 1.9

30 Amp 4.13 5.00 3.63 4.50 3.38 1.44 .94 2 4.0 3.2 3.88 1.9

60 Amp 5.50 6.38 4.56 5.38 4.25 1.63 1.25

100 Amp 1 3.0 2.9 5.88 7.0

Dimensions in Centimetres 1-1/4 3.0 2.9 5.88 7.0

1-1/2 4.0 3.2 5.88 7.0

30 Amp 10.5 12.7 9.2 11.4 8.6 3.7 2.4 2 4.0 3.2 5.88 7.0

60 Amp 14.0 16.2 11.6 13.7 10.8 4.1 3.2 ▲ AJS box has one hub and AJSC has two hubs.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-18

Cat. No. Index Master Index

February 2004 D Index

**NEMA 3, 3R, 4, 4X

Powertite® 200 Amp Pin and Sleeve

Receptacles and Plugs.

250 Volt D.C., 600 Volt A.C., 50-400Hz Wire Recess Diameter: .687"

Wire Size Range: #4/0-#2/0. Pressure Wire Terminals.

Spring Door – Weatherproof Receptacles and Plugs

Description Catalogue Number

Hub Receptacle Plug

Grounding Size with AJA Receptacle Cable Range, Plug

Style Pole/Wire Inches* Mounting Box† Only** Inches Only

Style 1 3P, 3W 1-1/2 ADJA20033-150 ADR20033 .875 to 1.906 AP20033CD

2 ADJA20033-200 ADR20033 1.875 to 2.500 AP20033E

2-1/2 ADJA20033-250 ADR20033 1.875 to 2.500 AP20033E

4P, 4W 2 ADJA20044-200 ADR20044 .875 to 1.906 AP20044CD

2-1/2 ADJA20044-250 ADR20044 1.875 to 2.500 AP20044E

Style 2 3P, 2W 1-1/2 ADJA20023-150 ADR20023 .875 to 1.906 AP20023CD

2 ADJA20023-200 ADR20023 1.875 to 2.500 AP20023E

2-1/2 ADJA20023-250 ADR20023 1.975 to 2.500 AP20023E

4P, 3W 1-1/2 ADJA20034-150 ADR20034 .875-to 1.906 AP20034CD

2 ADJA20034-200 ADR20034 .875 to 1.906 AP20034E

2-1/2 ADJA20034-250 ADR20034 1.875 to 2.500 AP20034E

Maximum Conductor Size

Wire Recess Conductor Size Max. Strand Type Conductor

0.687" Dia. 4/0 19 General Wire

4/0 259 Flexible Cable

3/0 427 Extra Flexible Cable

2/0 259 Flexible Cable

2/0 259 Flexible Cable

Maximum Horsepower Ratings*

Motor Horsepower

Phase

Motor Pole/Wire 120V 240V 480V 600V

1-PHASE 2P, 3W 15HP 30HP 40HP 40HP

3-PHASE 3P, 3W; 3P, 4W; or 4P, 4W 20HP 40HP 50HP 50HP

*Not for normal starting and stopping, but plug may be withdrawn if necessary if within

these maximum H.P. ratings.

**Receptacle meets NEMA 3R with spring door closed and NEMA 3, 3R, 4, 4X with plug fully

inserted and wing nuts fully tightened or clamp cover installed with wing nuts fully tightened.

†Additional mounting boxes on page 22.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-19

Master Index Cat. No. Index

D Index February 2004

**NEMA 3, 3R, 4, 4X

Powertite® 200 Amp Pin and Sleeve

Receptacles, Plugs and Cable

Connectors.

250 Volt D.C., 600 Volt A.C., 50-400Hz Wire Recess Diameter: .687"

Wire Size Range: #4/0-#2/0. Pressure Wire Terminals.

Clamp Cover – NEMÅ 4X Receptacles and Plugs Clamp Cover – NEMA 4X Connectors and Plugs

Catalogue Numbers Catalogue Numbers

Receptacle

with AJA Receptacle** Plug Connector Complete Connector Plug

Mounting Box† Only Only with Plug* Body only Only

AJA20033-150 AR20033 AP20033CD ARCC20033CD ARC20033CD AP20033CD

AJA20033-200 AR20033 AP20033E ARCC20033E ARC20033E AP20033E

AJA20033-250 AR20033 AP20033E

AJA20044-200 AR20044 AP20044CD ARCC20044CD ARC20044CD AP20044CD

AJA20044-250 AR20044 AP20044E ARCC20044E ARC20044E AP20044E

AJA20023-150 AR20023 AP20023CD

AJA20023-200 AR20023 AP20023E ARCC20023CD ARC20023CD AP20023CD

AJA20023-250 AR20023 AP20023E ARCC20023E ARC20023E AP20023E

AJA20034-150 AR20034 AP20034CD

AJA20034-200 AR20034 AP20034E ARCC20034CD ARC20034CD AP20034CD

AJA20034-250 AR20034 AP20034E ARCC20034E ARC20034E AP20034E

Pin and Sleeve Design: 200 Amp Powertite Receptacles, Plugs and Connectors (Connector Shown).

Copper-free

aluminum housing.

Neoprene busing

seals out water

Widely spaced contacts and dust.

for extra safety.

Grounding strap Energized Contacts deeply recessed to Positive Mechanical cable clamps provide

(used in Style 2). eliminate danger of accidental touching, strain relief a conductor connections,

minimize possibility of exposed arcs. allow easy cable replacement.

Insulator quenches arcing, and is resis-

tant to abnormal heat and to fire.

*Plug and connector body combination is NEMA 4X rated when wing nuts are fully tightened on connector body.

**Receptacle meets NEMA 3R with spring door closed and NEMA 3, 3R, 4, 4X with plug fully inserted and wing nuts fully tightened or clamp

cover installed with wing nuts fully tightened. †Additional mounting boxes on page 22.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-20

Cat. No. Index Master Index

February 2004 D Index

Powertite® 400 Amp Pin and Sleeve

Receptacles and Plugs: Raintight.

250 Volt D.C., 600 Volt A.C. Solder Well Wire Terminals.

Wire Recess Diameter: .84" or 1.25".

Description Catalogue Number

Clamp Cover

Receptacle –

Raintight

Wire

Recess Tap Receptacle

Dia., Grounding Size with AJA Receptacle Cable Range, Plug

Inches Style Pole/Wire Inches* Mounting Box Only Inches Only**

.84 Style 1 3P, 3W 4 AJA40033-400 AR40033 1.875 to 2.500 AP40033E

4P, 4W 4 AJA40044-400 AR40044 1.875 to 2.500 AP40044E

Style 2 2P, 3W 4 AJA40023-400 AR40023 1.875 to 2.500 AP40023E

3P, 4W 4 AJA40034-400 AR40034 1.875 to 2.500 AP40034E

1.25 Style 1 3P, 3W 4 AJA40133-400 AR40133 2.500 to 3.000 AP40133F

AJA40133-400 AR40133 3.000 to 3.500 AP40133G

4P, 4W 4 AJA40144-400 AR40144 2.500 to 3.000 AP40144F

AJA40144-400 AR40144 3.000 to 3.500 AP40144G

Style 2 2P, 3W 4 AJA40123-400 AR40123 2.500 to 3.000 AP40123F

AJA40123-400 AR40123 3.000 to 3.500 AP40123G

4P, 4W 4 AJA40134-400 AR40134 2.500 to 3.000 AP40134F

AJA40134-400 AR40134 3.000 to 3.500 AP40134G

*Has feed-thru 4" tapped openings. Supplied with ** Plug is raintight when clamp is fully tightened on receptacle.

one 4" to 3" reducer and one 4" close-up plug.

.84" 400 Amp Receptacles, Plugs and Connectors

Solder

Recess Maximum Conductor Size

Solder Conductor Max. Type

Recess Size Strand Conductor

0.84" 500 MCM 37 General Wire

Dia. 400 MCM 259 Flexible Cable

400 MCM 427 Extra Flexible Cable

1.25" 1000 MCM 61 General Wire

Dia. 900 MCM 427 Flexible Cable

1.25"

Solder 400 MCM 703 Extra Flexible Cable

Recess

400 HP @ 600 volts a.c. and 350 HP @ 480 volts a.c.

This is for disconnect use only and not for current interruption.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-21

Master Index Cat. No. Index

D Index February 2004

Powertite® 400 Amp Pin and Sleeve

Cable Connectors and Plugs.

250 Volt D.C., 600 Volt A.C. Solder Well Wire Terminals.

Wire Recess Diameter: .84" or 1.25".

Description Catalogue Number

Cable Connectors

and Plugs

Wire

Recess Grounding Cable Range, Connector Plug

Dia.,Inches Style Pole/Wire Inches Body only Only

.84" Style 1 3P, 3W 1.875 to 2.500 ARC40033E AP40033E

4P, 4W 1.875 to 2.500 ARC40044E AP40044E

Style 2 2P, 3W 1.875 to 2.500 ARC40023E AP40023E

3P, 4W 1.875 to 2.500 ARC40034E AP40034E

1.25" Style 1 3P, 3W 2.500 to 3.000 –––– AP40133F

3.000 to 3.500 –––– AP40133G

4P, 4W 2.500 to 3.000 –––– AP40144F

3.000 to 3.500 –––– AP40144G

Style2 3P, 3W 2.500 to 3.000 –––– AP40123F

3.000 to 3.500 –––– AP40123G

3P, 4W 2.500 to 3.000 –––– AP40134F

3.000 to 3.500 –––– AP40134G

Pin and Sleeve Copper-free

Design: 400 Amp aluminum housing.

Powertite

Receptacles,

Plugs and

Connectors

(Connector

Shown).

Neoprene busing

Widely spaced contacts seals out water

for extra safety. and dust.

Live Contacts deeply recessed to eliminate Positive Mechanical cable clamps prevent

Grounding strap

danger of accidental touching, minimize strain at conductor connections, allow easy

(used in Style 2).

possibility of exposed arcs. Insulator cable replacement.

quenches arcing, and is resistant to abnor-

mal heat and to fire.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-22

Cat. No. Index Master Index

February 2004 D Index

200 and 400 Amp Mounting Boxes and

Replacement Interiors.

Description Catalogue Number

200 and 400 Amp

AJ Mounting

Boxes

Size,

Inches AJA (200 AMP) AJAC (200 AMP) AJAC (200 AMP)*

200 Amp Boxes 1-1/2 AJA520 ––––– –––––

2 AJA620 ––––– –––––

2-1/2 AJA620 AJAC720 –––––

400 Amp Boxes 4 –––––– ––––– AJAC400

200 Amp Interiors Style 1 Style 2

Interiors Interiors

Grounding Pole/Wire Receptacle Plug Receptacle Plug

Style

Style 1 2P, 2W ARI20022 API20022 ––––––– –––––––

3P, 3W ARI20033 API20033 ––––––– –––––––

4P, 4W ARI20044 API20044 ––––––– –––––––

Style 2 2P, 3W ––––––– ––––––– ARI20023 API20023

2P, 4W ––––––– ––––––– ARI20034 API20034

400 Amp Interiors Style 1 Style 2

Interiors Interiors

Wire

Recess

Dia., Grounding Pole/Wire Receptacle Plug Receptacle Plug

Inches Style

.84" Style 1 3P, 3W ARI40033 API40033 ––––––– –––––––

4P, 4W ARI40044 API40044 ––––––– –––––––

Style 2 2P, 3W ––––––– ––––––– ARI40023 API40023

2P, 4W ––––––– ––––––– ARI40034 API40034

1.25" Style 1 3P, 3W ARI40033 API40133 ––––––– –––––––

4P, 4W ARI40044 API40144 ––––––– –––––––

Style 2 3P, 4W ––––––– ––––––– ARI40123 API40123

3P, 4W ––––––– ––––––– ARI40134 API40134

*Has feed-thru tapped openings. Supplied with one 4" to 3" reducer and one 4" close-up plug.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-23

Master Index Cat. No. Index

D Index February 2004

Powertite® Series Replacement

Parts: 200 and 400 Amp.

Description Catalogue Number

Receptacle Covers

Spring Cover

(Includes Gasket and Ring)

100 Amp - 2 and 3-Wire PTSC200A

100 Amp - 4-Wire PTSC200B

Threaded Cover

(Includes Gasket and Chain)

200 Amp - 2 and 3-Wire PTBC200A

200 Amp - 4-Wire PTBC200B

400 Amp - 2 and 3-Wire PTBC400A

400 Amp - 4-Wire PTBC400B

Bushing Bags for Plugs and Cable Connectors

200 Amp - Suffix CD PTGBCD

200 Amp - Suffix E PTGB200E

400 Amp - Suffix E PTGB400E

400 Amp - Suffix F PTGB400F

400 Amp - Suffix G PTGB400G

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-24

Cat. No. Index Master Index

February 2004 D Index

Dimensions: Powertite® 200 Amp

Pin and Sleeve Receptacles, Plugs,

Connectors and Mounting Boxes.

For 3/8" Bolt

Front View Side View

Back View Side View

Receptacle Mounted on AJA and AJAC Boxes Connector Body

A B C D E F G H No. Poles A B C A B C

Dimensions in Inches Dimensions Dimensions

in Inches in Inches

8.00 10.75 6.75 9.50 14.00 15.25 3.75 1.88

2, 3 13.00 4.19 5.38 33.00 10.6 13.7

Dimensions in Centimetres 4 13.00 4.56 5.75 33.00 11.6 14.6

20.3 27.3 17.2 24.1 35.6 38.7 9.5 4.8

13/32" Dia. 3/8" – 16 Thread

Back View 4 Holes

Equally Spaced

Side View Back View Side View

Plug Receptacle

No. Poles A B C D E No. Poles A B C D E F

Dimensions in Inches Dimensions in Inches

2, 3 11.94 7.81 3.81 3.75 6.44 2, 3 6.56 8.13 4.19 5.63 6.63 3.50

Dimensions in Centimetres Dimensions in Centimetres

2, 3 30.3 19.8 9.7 9.5 16.4 3 16.7 20.6 10.6 14.3 16.8 8.9

Dimensions in Inches Dimensions in Inches

4 11.94 7.81 4.19 4.13 6.81 4 6.56 8.13 4.56 5.63 6.63 3.63

Dimensions in Centimetres Dimensions in Centimetres

4 30.3 19.8 10.6 10.5 17.3 4 16.7 20.6 11.6 14.3 16.8 9.2

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-25

Master Index Cat. No. Index

D Index February 2004

Dimensions: Powertite® 400 Amp

Pin and Sleeve Receptacles, Plugs,

Connectors and Mounting Boxes.

For 5/8" Bolt Box Wall Thickness: Top and

Bottom, .50" (1.3cm); Sides, .31" (7.9mm)

13/32" Dia.

6 holes equally spaced

3/8" – 16 Thread

Side View Side View Back View

Back View

Receptacle Mounted on AJAC Box Receptacle

Tap Size A B C D E F G H No. Poles A B C D E F

Dimensions in Inches Dimensions in Inches

4* 15.88 15.88 6.50 15.13 22.00 24.25 8.50 3.88 3 11.25 12.25 5.13 6.75 7.75 4.19

Dimensions in Centimetres Dimensions in Centimetres

3 28.6 31.1 13.0 17.2 19.7 10.6

4* 40.3 40.3 16.5 38.4 55.9 61.6 21.6 9.8

Dimensions in Inches

*AJAC Box has feed-thru 4" openings. Supplied with one 4" to 3"

reducer, and one 4" close-up plug. 4 11.25 12.25 5.63 6.75 7.75 4.69

1/2"-1/4" NPT Dimensions in Centimetres

Handle

4 28.6 31.1 14.3 17.2 19.7 11.9

Back View

Side View

Plug

No. Poles A B C D E F

Dimensions in Inches

Front View Side View

3 15.00 19.00 11.25 4.70 4.66 7.50

Dimensions in Centimetres

Connector Body

3 38.1 48.3 28.6 12.0 11.8 19.1

No. Poles A B C A B C

Dimensions in Inches

Dimensions Dimensions

4 15.5 19.00 11.25 5.19 5.16 8.00 in Inches in Inches

Dimensions in Centimetres 3 19.00 5.13 7.25 48.3 13.0 18.4

4 39.4 48.3 28.6 13.2 13.1 20.3 4 19.00 5.63 7.75 48.3 14.3 19.7

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-26

Cat. No. Index Master Index

February 2004 D Index

Powertite® Plug Adapters

for Conduit and Fittings.

Furnished complete with Setscrew.

Conduit

Description Size (inches) Catalogue Numbers

Powertite Adapter

NTP Standard Pipe Threads Accommodate Rigid Metal Conduit or Standard Con-

nectors for Flexible Conduit, Armoured Cable and Non-Metallic Cable.

For 30 Amp Plug 3/4 PTA-75

1 PTA-100

For 60 Amp Plug 3/4 PTA-75

1 PTA-100

For 100 Amp Plug 1-1/4 PTA-125

1-1/2 PTA-150

2 PTA-200

For 200 Amp Plug 1-1/4 PTA-125

1-1/2 PTA-150

2 PTA-200

Ordering Information EXAMPLE: 30 Amp Plug Cat. No. ST Liquidtight Connector separately from

To order Powertite Plug with Adapter, add ACP3022BC with Adapter tapped for 3/4" Cat. Sec. ST.

proper PTA suffix to plug catalog number, would be Cat. No. ACP3022-PTA-75. Order

omitting standard “BC” or “CD” suffix from

plug catalog number.

PTA Adapter for 30 and 60 Amp Powertite Plugs

PTA Adapter ST Liquidtight

Connector

Powertite Plug

Liquidtight Flexible

Metal Conduit

PTA Setscrew

PTA Adapter for 30 and 60 Amp Powertite Plugs

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-27

Master Index Cat. No. Index

D Index February 2004

Powertite® Plug Adapters

for Conduit and Fittings.

Furnished complete with Setscrew.

Applications and Features

• PTA adapter permits easy connection • Powertite Plug with Adapter serves • PTA Adapters are provided with

of liquidtight flexible metal conduit or as power source from main feeder line setscrew to positively lock ST Liquidtite

rigid metal conduit to Powertite Plugs. to power distribution equipment. Connector to Adapter.

The adapter replaces the cable grip • ST Liquidtite Connectors thread • Smooth, precision machined copper-

normally supplied with the plugs. directly into PTA Adapter, permitting free (4/10 of 1%) aluminum for more

• Ideal where flexible connections are use of liquidtite flexible metal conduit attractive appearance.

required, and in wet conditions. with Powertite Plugs.

Typical application includes Powertite Plug,

PTA Adapter and Liquidtight Connector. Use

of Liquidtight Flexible Metal Conduit ensures

equipment operation even in wet locations.

Dimensions of PTA Powertite Adapter

Conduit Dim. A Dim. C Dim. D

Catalogue Plug Size, Pipe Dim. B Dia., Length,

.25"

(6.3mm)

.63"

(15.8mm) Number Amp Inches Thread Thread Inches Inches

Setscrew (furnished) PTA-75 30 3/4– 2-1/8–

1/4 – 20 UNC – 2B Thru

and 60 3/4 14NPT 12UN 2B 2.50 2.15

PTA-100 30 1– 2-1/8–

and 60 1 11-1/2NPT 12UN 2B 2.50 2.15

PTA-125 100 1-1/4– 2-3/4–

and 200 1-1/4 11-1/2NPT 10UNS 2B 3.12 2.56

PTA-150 100 1-1/2– 22-3/4–

and 200 1-1/2 11-1/2NPT 10UNS 2B 3.12 2.56

PTA-200 100 2– 22-3/4–

and 200 2 11-1/2NPT 10UNS 2B 3.12 2.56

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-28

Cat. No. Index Master Index

February 2004 D Index

Powertite® Series Interchangeable

Equivalents.

Appleton Powertite® and Crouse Hinds Arktite Plugs, Receptacles,

Cord Connectors and Mounting Boxes listed here are Equivalent and

Completely Interchangeable.

Crouse-Hinds Appleton Crouse-Hinds Appleton Crouse-Hinds Appleton

Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No.

AJ37 AJA310 APC10255

APC10257 } ARCC1022CD APJ10255

AJ47 AJA410 APJ10257

} A CP1022CD

AJ47

AJ58

AJA510

AJA520

APC10355

APC10357 } ARCC1033CD APJ10275

APJ10277

AJ67 AJA610 APC10365

APC10367 } ARCC1023CD

AJ68 AJA620

APJ10355

APJ10357 } ACP1033CD

AJ69* { AJAC400*

RB300-200

APC10455

APC10457 } ARCC1044CD

APJ10365

APJ10367 } ACP1033CD

AJ78 AJA720 APC10465

} ARCC1034CD

APJ10375

} ACP1033CD

AJ79* { AJC400*

RB400-250

APC10467 APJ10377

AJ89* AJAC400*

APC20315

APC20317 } ARCC20033CD APJ10385

APJ10387 } ACP1023CD

AJC37

AJC47

AJAC310

AJAC410

APC20318 ARCC20033E APJ10455

APJ10457 } ACP1044CD

AJC57

AJC67

AJAC510

AJAC610

APC20325

APC20327 } ARCC20023CD APJ10465

APJ10467 } ACP1034CD

APC20328 ARCC20023E

AJC78 AJAC720

APC20415

APC20417 } ARCC2044CD APJ10475

} ACP1044CD

AP20355

} AP20033CD APJ10477

AP20357

AP20358 AP20033E

APC20418 ARCC20044E APJ20485

APJ20487 } ACP1034CD

AP20365

} AP20023CD

APC20425

APC20427 } ARCC20034CD

AP20367 APC20428 ARCC20034E APR3253

APR3255 } ARC3022BC

AP20368 AP20023E APC40318 { ARC40033E

AP40033E APR3353

} ARC3033BC

AP20455

} AP20044CD APR3355

AP20457

AP20458 AP20044E APC40328 { ARC40023E

AP40023E

APR3363

APR3365 } ARC3023BC

AP20465

} AP20034CD APC40418 { ARC4044E

AP20467 AP40044E APR3453

APR3455 } ARC3044BC

AP20468 AP20034E APC40428 { ARC4034E

AP40034E APR3463

} ARC3034BC

AP40358 AP40033E APR3465

AP40368 AP40023E APJ3273

APJ3275 } ACP3022BC

AP40458 AP40044E APR6253

} ARC6022BC

AP40468 AP40034E APJ3373

APJ3375 } ACP3033BC APR6255

AP403510 AP40133F APJ3383

} ACP3023BC

APR6353

APR6355 } ARC6033BC

APJ3385

AP403512

AP403610

AP40133G

AP40123F

APR6363

APR6365 } ARC6023BC

AP403612 AP40123G APJ3473

} ACP3044BC

AP404510 AP40144F APJ3475 APR6453

} ARC6044BC

APJ3483

} ACP3034BC APR6455

AP404512

AP404610

AP40144G

AP40134F

APJ3485 APR6463

APR6465 } ARC6034BC

AP404612 AP401144G APJ3383

APC3253

APC3255 } ARCC3022BC

APJ3385

APJ3273 } ACP6022BC APR10255

APR10257 } ARC1022CD

APJ3275 APR10355

} ARC1033CD

APC3353

} ARCC3033BC APJ6373

}

APR10357

APC3355

APJ6355

ACP6033BC APR10365

} ARC1023CD

APC3363

} ARCC3023BC

APR10367

APC3365 APJ6363

APJ6365 } ACP6023BC

APC3453

APC3455 } ARCC3044BC APJ6373

} ACP6033BC

APR10455

APR10457 } ARC1044CD

APJ6375 APR10465

} ARC1034CD

APC3463

APC3465 } ARCC3034BC APJ6383

} ACP6023BC

APR10467

APC6253

} ARCC6022BC

APJ6355 APR20315

} ARC20033CD

APC6255 APJ6453

APJ6455 } ACP6044BC APR20317

APC6353

} ARCC6033BC

APR20318

} ARC20033E

APC6355 APJ6463

APJ6465 } ACP6034BC APR20325 ARC20023CD

APR20327

}

APC6363

APC6365 } ARCC6033BC APJ6473

} ACP6044BC

APR20328 ARC20023E

APJ6475

APC6453

} ARCC6044BC

APR20415

} ARC20044CD

APC6455 APJ6483

APJ6485 } ACP6034BC APR20417

APC6463

APC6465 } ARCC6034BC

APR20418

APR20425 } ARC20044E

ARC20034CD

APR20427

APR20428 } ARC20044E

* Mounting Box only is not interchangeable – consult catalogue.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-29

Master Index Cat. No. Index

D Index February 2004

Powertite® Series Interchangeable

Equivalents.

Appleton Powertite® and Crouse Hinds Arktite Plugs, Receptacles,

Cord Connectors and Mounting Boxes listed here are Equivalent and

Completely Interchangeable.

Crouse-Hinds Appleton Crouse-Hinds Appleton Crouse-Hinds Appleton

Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No.

APR40318 ARC40033E AR40412 AR40144 ARE6454 ADRE6044-100-LC

APR40328 ARC40023E AR40422 AR40143 ARE6455 ADRE6044-125-LC

APR40418 ARC40044E ARE13 AEE13 ARE6464 ADRE6034-100-LC

APR40428 ARC40034E ARE23 AEE23 ARE6465 ADRE6034-125-LC

ARE33 AEE33 ARE6474 ACRE6044-100

AR321 ADR3022

AR325 ACR3022-LC ARE36 AEE36 ARE6475 ACRE6044-125

AR327 ACR3022 ARE46 AEE46 ARE6484 ACRE6034-100

AR331 ADR3033 ARE56 AEE56 ARE6485 ACRE6034-125

AR332 ADR3023 ARE3211

ARE3212

ADRE3022-50

ADRE3022-75

AREA6213 { ADR6022

AJA310

AR335 ACR3033-LC

AR336

AR337

ACR3022-LC

ACR3023

ARE3251

ARE3252

ACRE3022-50-LC

ACRE3022-75-LC AREA6214 { ADR6022

AJA410

AR338

AR341

ACR3033

ADR3044

ARE3271

ARE3272

ACRE3022-50

ACRE3022-75 AREA6253 { ADR6022-LC

AJA310

ARE3312 ADRE3033-75

AR342

AR345

ADR3034

ACR3044-LC ARE3313 ADRE3033-100 AREA6254 { ADR6022-LC

AJA410

AR346

AR347

ACR3034-LC

ACR3044

ARE3322

ARE3323

ADRE3023-75

ADRE3023-100 AREA6273 { ACR6022

AJA310

AR348 ACR3034 ARE3352

ARE3353

ACRE3033-75-LC

ACRE3033-100-LC AREA6274 { ACR6022

AJA410

AR621 ADR6022

AR625

AR627

ADR6022-LC

ACR6022

ARE3362

ARE3363

ACRE3023-75-LC

ACRE3023-100-LC AREA6313 { ADR6033

AJA310

AR631

AR632

ACR6033

ACR6023

ARE3372

ARE3373

ACRE3033-75

ACRE3033-100

AREA6314 { ADR6033

AJA410

ARE3382 ACRE3023-75

AR635

AR636

ADR6033-LC

ADR6023-LC ARE3383 ACRE3023-100

AREA6323 { ADR6023

AJA310

AR637

AR638

ACR6033

ACR6023

ARE3412

ARE3413

ADRE3044-75

ADRE3044-100 AREA6234 { ADR6023

AJA410

AR641 ADR6044 ARE3422

ARE3423

ADRE3034-75

ADRE3034-100 AREA6353 { ADR6033-LC

AJA310

AR642 ACR6034

AR645

AR646

ADR6044-LC

ADR6034-LC

ARE3452

ARE3453

ACRE3044-75-LC

ACRE3044-100-LC

AREA6345 { ADR6033-LC

AJA410

AR647

AR648

ACR6044

ACR6034

ARE3462

ARE3463

ACRE3034-75-LC

ACRE3034-100-LC

AREA6363 { ADR6023-LC

AJA310

ARE3472 ACRE3044-75

AR1021

AR1025

ACR1022

ADR1022-LC ARE3473 ACRE3044-100 AREA6364 { ADR6023-LC

AJA410

AR1027

AR1031

ACR1022

ADR1033

ARE3482

ARE3483

ACRE3044-75

ACRE3034-100 AREA6373 { ACR6033

AJA310

AR1032 ADR1023 ARE6213

ARE6214

ADRE6022-100

ADRE6022-125 AREA6374 { ACR6033

AJA410

AR1035 ADR1033-LC

AR1036

AR1037

ADR1023-LC

ACR1033

ARE6253

ARE6254

ADRE6022-100-LC

ADRE6022-125-LC AREA6383 { ACR6023

AJA310

AR1038

AR1041

ACR1023

ADR1044

ARE6273

ARE6274

ADRE6022-100

ADRE6022-125 AREA6384 { ACR6023

AJA410

ARE6313 ADRE6033-100

AR1042

AR1045

ADR1034

ADR1044-LC ARE6314 ADRE6033-125 AREA6414 { ADR6044

AJA410

AR1046

AR1047

ADR1034-LC

ACR1044

ARE6323

ARE6324

ADRE6023-100

ADRE6023-125 AREA6415 { ADR6044

AJA510

AR1048 ACR1034 ARE6353

ARE6354

ADRE6033-100-LC

ADRE6033-125-LC AREA6424 { ADR6034

AJA410

AR2031 AR20033

AR2032

AR2041

AR20023

AR20044

ARE6363

ARE6364

ADRE6023-100-LC

ADRE6023-125-LC

AREA6425 { ADR6034

AJA510

AR2042

AR4031

AR20034

AR40033

ARE6373

ARE6374

ACRE6033-100

ACRE6033-125

AREA6454 { ADR6044-LC

AJA510

ARE6383 ACRE6023-100

AR4032

AR4041

AR40023

AR40044 ARE6384 ACRE6023-125

AREA6455 { ADR6044-LC

AJA510

AR4042

AR40312

AR40034

AR40133

ARE6414

ARE6415

ADRE6044-100

ADRE6044-125

AREA6464 { ADR6034-LC

AJA410

AR40322 AR40123 ARE6424

ARE6425

ADRE6034-100

ADRE6034-125 AREA6465 { ADR6034-LC

AJA510

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-30

Cat. No. Index Master Index

February 2004 D Index

Powertite® Series Interchangeable

Equivalents.

Appleton Powertite® and Crouse Hinds Arktite Plugs, Receptacles,

Cord Connectors and Mounting Boxes listed here are Equivalent and

Completely Interchangeable.

Crouse-Hinds Appleton Crouse-Hinds Appleton Crouse-Hinds Appleton

Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No.

AREA6474 { ACR6044 AERX40418 AJA40044-400* ARRC3412 { ADR3044

AJA410

AERX40427 { AJA40034-400* AERC23

AREA6475 { ACR6044

AJA510 AERX40428

RB400-250

AJA40034-400*

ARRC3413 { ADR3044

AERC33

AERX403128 AJA40133-400*

ARRC3422 { ADR3034

AREA6484 { ACR6034 AERC23

AJA410

AERX403129 { AJA40133-400*

AREA6485 { ACR6034

AJA510 AERX403228

RB400-350

AJA40123-400* ARRC3423 { ADR3034

AERC33

AREA10214 ADJA1022-125

AERX403229 { AJA40123-400*

RB400-350 ARRC3452 { ACR3044-LC

AERC23

AREA10215 ADJA1022-150

AREA10254

AREA10255

ADJA1022-125-LC

ADJA1022-150-LC

AERX4031210

AERX4032210

AJA40133-400*

AJA40123-400* ARRC3453 { ADR3044-LC

AERC33

AREA10274

AREA10275

ACJA1022-125

ACJA1022-150

AERX4041210

AERX4041212

AJA40144-400*

AJA40144-400* ARRC3462 { ADR3034-LC

AERC23

AREA10314 ADJA1033-125 AERX4042210 AJA40144-400* ARRC3463 { ACR3034-LC

AERC33

AREA10315 ADJA1033-150 AERX4042212 AJA40144-400*

AREA10324

AREA10325

ADJA1023-125

ADJA1023-150

ARRC13

ARRC23

AERC13

AERC23 ARRC3472 { ACR3044

AERC23

AREA10354 ADJA1033-125-LC ARRC33 AERC33

ARRC3473 { ACR3044

AERC33

AREA10355 ADJA1033-150-LC ARRC36 AERC36

AREA10364

AREA10365

ADJA1023-125-LC

ADJA1023-150-LC

ARRC46

ARRC56

AERC46

AERC56 ARRC3482 { ACR3034

AERC23

AREA10374

AREA10375

ACJA1033-125

ACJA1033-150 ARRC3211 { ADR3022

AERC13 ARRC3482 { ACR3034

AERC33

AREA10384 ACJA1023-125

ARRC3212 { ADR3022

ARRC6213 { ADR6022

AERC36

AREA10385 ACJA1023-150 AERC23

AREA10415

AREA10416

ADJA1044-150

ADJA1044-200 ARRC3251 { ACR3022-LC

AERC13 ARRC6214 { ADR6022

AERC46

AREA10425 ADJA1034-150

ARRC6253 { ADR6022-LC

AREA10426 ADJA1034-200 ARRC3252 { ACR3022-LC

AERC23

AERC36

AREA10455

AREA10456

ADJA1044-150-LC

ADJA1044-200-LC ARRC3271 { ACR3022

AERC13 ARRC6254 { DR6022-LC

AERC46

AREA10465

AREA10466

ADJA1034-150-LC

ADJA1034-200-LC ARRC3272 { ACR3022

AERC23 ARRC6273 { ACR6022

AERC36

AREA10475 ACJA1044-150

ARRC3312

ADR3033 ARRC6274 { ACR6022

AERC46

AREA10476 ACJA1044-200 AERC23

AREA10485

AREA10486

ACJA1034-150

ACJA1034-200 ARRC3313

ADR3033

AERC33 ARRC6313 { ADR6033

AERC36

AREA20315 AJA20033-150

ARRC6314 { ADR6033

AREA20316 AJA20033-200 ARRC3322 { ADR3023

AERC23

AERC46

AREA20317

AREA20325

AJA20033-250

AJA20023-150 ARRC3323 { ADR3023

AERC33 ARRC6323 { ADR6023

AERC36

AREA20326

AREA20327

AJA20023-200

AJA20023-250 ARRC3352 { ACR3033-LC

AERC23 ARRC6324 { ADR6023

AERC46

ARRC6353 { ADR6033-LC

AREA20416

AREA20417

AJA20044-200

AJA20044-250 ARRC3353 { ACR3033-LC

AERC23

AERC36

AREA20425

AREA20426

AJA20034-150

AJA20034-200 ARRC3362 { ACR3023-LC

AERC23 ARRC6354 { ADR6033-LC

AERC46

AREA20427 AJA20034-250

ARRC6363 { ADR6023-LC

ARRC3363 { ACR3023-LC AERC36

AEXR20416 { AJA40033-400* AERC33

AEXR20417

RB400-250

AJA40033-400* ARRC3372 { ACR3033

AERC23 ARRC6364 { ADR6023-LC

AERC46

AERX20425 { AJA40023-400*

RB300-200 ARRC3373 { ACR3033

AERC33 ARRC6373 { ACR6033

AERC36

{ AJA40023-400*

ARRC6374 { ADR6033

AERX20426 RB400-250 ARRC3382 { ACR3023

AERC23

AERC46

AERX20427 AJA40033-400*

ARRC3383 { ACR3023 ARRC6383 { ACR6023

AERX20416 { AJA40044-400* AERC33 AERC36

RB400-250

ARRC6384 { ACR6023

AERC46

* Mounting Box only is not interchangeable

– consult catalogue.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-31

Master Index Cat. No. Index

D Index February 2004

Powertite® Series Interchangeable

Equivalents.

Appleton Powertite® and Crouse Hinds Arktite Plugs, Receptacles,

Cord Connectors and Mounting Boxes listed here are Equivalent and

Completely Interchangeable.

Crouse-Hinds Appleton Crouse-Hinds Appleton Crouse-Hinds Appleton

Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No. Catalogue No.

ARRC6414 { ADR6044

AERC46 ARRH3373 { ACR3033

AERH33 ARRH6374 { ACR6033

AERH46

ARRC6415 { ADR6044

AERC56 ARRH3382 { ACR3023

AERH23 ARRH6383 { ACR6023

AERH36

ARRC6424 { ADR6034

AERC46 ARRH3383 { ACR3023

AERH33 ARRH6384 { ACR3023

AERH46

ARRC6425 { ADR6034

AERC56 ARRH3412 { ADR3044

AERH23 ARRH6414 { ADR6044

AERH46

ARRC6454 { ADR6044-LC

AERC46 ARRH3413 { ADR3044

AERH33 ARRH6415 { ADR6044

AERH56

ARRC6455 { ADR6044-LC

AERC56 ARRH3422 { ADR3034

AERH23 ARRH6424 { ADR6034

AERH46

ARRC6464 { ADR6034-LC

AERC46 ARRH3423 { ADR3034

AERH33 ARRH6425 { ADR6034

AERH56

ARRC6465 { ADR6034-LC

AERC56 ARRH3452 { ACR3044-LC

AERH23 ARRH6454 { ACR6044-LC

AERH46

ARRC6474 { ACR6044

AERC46 ARRH3453 { ACR3044-LC

AERH33 ARRH6455 { ADR6044-LC

AERH56

ARRC6475 { ACR6044

AERC56 ARRH3462 { ACR3034-LC

AERH23 ARRH6464 { ADR6034-LC

AERH46

ARRC6484 { ACR6034

AERC46 ARRH3463 { ACR3034-LC

AERH33 ARRH6465 { ADR6034-LC

AERH56

ARRC6485 { ACR6034

AERC56 ARRH3472 { ACR3044

AERH23 ARRH6474 { ACR6044

AERH46

AARH13 AERH13

ARRH3473 { ACR3044

AERC33 ARRH6475 { ACR6044

AERH56

ARRH23

ARRH33

AERH23

AERH33 ARRH3482 { ACR3034

AERH23 ARRH6484 { ACR6034

AERH46

ARRH36

ARRH46

AERH36

AERH46 ARRH3483 { ACR3034

AERH33 ARRH6485 { ACR6034

AERH56

ARRH56 AERH56

ARRH6213 { ADR6022

ARRH3211 { ADR3022 AERH36

AERH13

ARRH6214 { ADR6022

ARRH3212 { ADR3022 AERH46

AERH23

ARRH6253 { ADR6022-LC

ARRH3251 { ACR3022-LC

AERH13

AERH36

ARRH6254 { ADR6022-LC

ARRH3252 { ACR3022-LC AERH46

AERH23

ARRH6273 { ACR6022

ARRH3271 { ACR3022

AERH13

AERH36

ARRH6274 { ACR6022

ARRH3272 { ACR3022 AERH46

AERH23

ARRH6313 { ADR6033

ARRH3312 { ADR3033 AERH36

AERH23

ARRH6314 { ADR6033

ARRH3313 { ADR3033

AERH33

AERH46

ARRH6323 { ADR6023

ARRH3322 { ADR3023 AERH36

AERH23

ARRH6324 { ADR6023

ARRH3323 { ADR3023

AERH33

AERH46

ARRH6353 { ADR6033-LC

ARRH3352 { ACR3033-LC AERH36

AERC23

ARRH6354 { ADR6033-LC

ARRH3353 { ACR3033-LC AERH46

AERC33

ARRH6363 { ADR6023-LC

ARRH3362 { ACR3023-LC

AERC23

AERH36

ARRH6364 { ADR6023-LC

ARRH3363 { ACR6023-LC AERH46

AERC46

ARRH6373 { ACR6033

ARRH3372 { ACR6033

AERC36

AERH36

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-32

Cat. No. Index Master Index

February 2004 D Index

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-33

Master Index Cat. No. Index

D Index February 2004

IBR, IDSR and WSRD

Interlocked Switched Receptacles

With Breaker or Disconnect Switch, Fusible or Non-fusible. Weather-Proof

or Watertight Receptacle for use with Powertite® ACP plugs.

IBR and IDSR Cast

Aluminum Enclosure

WSRD Stainless Steel Enclosure

Amperages: Voltages: Compliance Data:

30 600 Vac CSA Approved.

60 250 Vdc Cast Aluminum, Spring Door:

100 Enclosure 3 and 5.

Cast Aluminum, Screw Cap:

Enclosure 3, 4X and 5.

Stainless Steel: Enclosure 4X

Note: See catalogue page C-16 for disconnect

less interlocked receptacle.

For hazardous rated version of interlocked

receptacle see page K-22

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-34

Cat. No. Index Master Index

February 2004 D Index

IBR, IDSR and WSRD

Interlocked Switched Receptacles

With Breaker or Disconnect Switch, Fusible or Non-fusible. Weather-Proof

or Watertight Receptacle for use with Powertite® ACP plugs.

Applications

• Used to supply power to portable • Four models are available: IBR with

600V FB Circuit Breakers, WSRD and

and mobile electrical equipment in IDSR with both Fusible and Non-fusible

all indoor and outdoor non-hazardous disconnect switches.

locations.

• Used to provide short circuit • Provision is made for locking the op-

erating mechanism in the “OFF” position.

protection to portable equipment when

supplied with a circuit breaker or fused Standard Materials

disconnect. • IBR and IDSR Enclosure and

• Provides a convenient On-Off Receptacle: Cast copper-free aluminum

(Max. 4/10 of 1% copper content).

mechanism.

• Ideal for use in areas where dust, • WSRD-N4 Enclosure – Stainless

dirt or moisture is a problem. Steel.

• Suitable for use in chemical plants, Options: IBR and IDSR

process facilities, meat packing plants

and many manufacturing industries.

• LED Indicator Lights: one light indi-

cates power unit and other indicates

• Provides high amperage power to switch is in ON position add suffix –IL.

heavy equipment such as motor-gen-

erator sets, compressors, heating and

• Supplied with viewing window add

suffix –W.

cooling units, welders and conveyors.

• One normally opened, one normally

Features closed auxiliary switch, add suffix

• Receptacles are provided with a –AUX.

safety-interlock system. Plugs cannot

be inserted or removed unless the pow-

• Lockable cover latch add suffix –DL.

er switch is in the “OFF” position. Options: WSRD

• The Safety-Interlock is designed • Auxiliary Contacts– one set of NO,

NC: See table.

to free both hands for insertion and

removal of the plug. • Reverse service add suffix –RS.

• A cover interlock is provided to • Special polarization add suffix –P4.

prevent entry to the enclosure while the Standard Finish

operator is in the “ON” position.

• Corrosion resistant grey epoxy

• Uses standard Powertite ACP or paint.

CPH plugs for wide acceptability.

• WSRD - natural.

• Certified for use with Crouse-Hinds

Compliances

Arktite® plugs.

• IBR and IDSR receptacles are fur- • CSA Approved.

nished with rugged cast aluminum • Cast Aluminum, Spring Door:

housings. Enclosure 3 and 5.

• Flip cap standard and screw cap • Cast Aluminum, Screw Cap:

provided at no additional cost to meet Enclosure 3, 4X and 5.

TYPE 4X applications (screw cap not • Stainless Steel: Enclosure type 3, 3R,

available on 30 amp). 4, 4X, 12.

• Receptacles with 3 phase 4 wire

grounded receptacles are pre-wired to

the breaker or disconnect switch.

• Patented brass receptacle contacts

exert constant pressure for good elec-

trical continuity.

• Appleton’s insulating blocks provide

the greatest dielectric and mechanical

strength, and lowest moisture absorp-

tion available.

• Ergonomically designed yet rugged

cast aluminum handle for exceptional

durability and corrosion resistance.

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

D-35

Master Index Cat. No. Index

D Index February 2004

NEMA 3, 3R, 4, 4X, 5, 12

(30 Ampere receptacle is not available

IBR, IDSR and WSRD

as TYPE 4X.) Interlocked Switched Receptacles

With Breaker or Disconnect Switch, Fusible or Non-fusible. Weather-Proof

or Watertight Receptacle for use with Powertite® ACP plugs.

IBR/IDSR

B-Breaker *** HP at

Cat. No. F-Fusing* 600 VAC Aux. Contacts**

Cat. No. w/viewing window Amp. N-None 3-Phase Mating Plug 1 or 2 NO/NC

Cast Aluminum Enclosure & TYPE 3, 4X and 5*

IBR3034FB15 IBR3034FB15-W 15 B –– ACP3034BC WS30Aux 1 or 2

IBR3034FB20 IBR3034FB20-W 20 B –– ACP3034BC WS30Aux 1 or 2

IBR3034FB30 IBR3034FB30-W 30 B –– ACP3034BC WS30Aux 1 or 2

IBR6034FB35 IBR6034FB35-W 35 B –– ACP6034BC WS60Aux 1 or 2

IBR6034FB40 IBR6034FB40-W 40 B –– ACP6034BC WS60Aux 1 or 2

IBR6034FB50 IBR6034FB50-W 50 B –– ACP6034BC WS60Aux 1 or 2

IBR6034FB60 IBR6034FB60-W 60 B –– ACP6034BC WS60Aux 1 or 2

IBR1034FB60 IBR1034FB60-W 60 B –– ACP1034CD WS100Aux 1 or 2

IBR1034FB70 IBR1034FB70-W 70 B –– ACP1034CD WS100Aux 1 or 2

IBR1034FB90 IBR1034FB90-W 90 B –– ACP1034CD WS100Aux 1 or 2

IBR1034FB100 IBR1034FB100-W 100 B –– ACP1034CD WS100Aux 1 or 2

IDSR3034 IDSR3034-W 30 F 7.5/20 ACP3034BC WS30Aux 1 or 2

IDSR6034 IDSR6034-W 60 F 15/50 ACP6034BC WS60Aux 1 or 2

IDSR1034 IDSR1034-W 100 F* 30/70 ACP1034CD WS100Aux 1 or 2

IDSR3034-NF IDSR3034-NF-W 30 N 25 ACP3034BC WS30Aux 1 or 2

IDSR6034-NF IDSR6034-NF-W 60 N 60 ACP6034BC WS60Aux 1 or 2

IDSR1034-NF IDSR1034-NF-W 100 N 75 ACP1034CD WS100Aux 1 or 2

WSRD

Cat. No. HP at 600 Vac*** Aux. Contacts**

Cat. No. w/viewing window Amp Fusing* Std/Max 3-Phase Mating Plug 1 or 2 NO/NC

Stainless Steel Enclosure TYPE 3, 3R, 4, 4X, 12†

WSRD3352N4SQ WSRD3352N4WSQ 30 Fused 7.5/20 ACP3034BC WS30Aux1 or 2

WSRD33542N4SQ WSRD33542N4WSQ 30 Non-Fused -/20 ACP3034BC WS30Aux1 or 2

WSRD6352N4SQ WSRD6352N4WSQ 60 Fused 15/50 ACP6034BC WS60Aux1 or 2

WSRD63542N4SQ WSRD63542N4WSQ 60 Non-Fused -/50 ACP6034BC WS60Aux1 or 2

WSRD10352N4SQ WSRD10352N4WSQ 100 Fused 30/75 ACP1034CD WS100Aux1 or 2

WSRD103542N4SQ WSRD103542N4WSQ 100 Non-Fused -/75 ACP1034CD WS100Aux1 or 2

* Use only Type J fuses. Fuses not included in fused products. ** Auxiliary contacts ordered separately for field installation.

***STD/MAX ratings based on type of fuse used eg. For IDSR 3034 – rated at 7.5 HP with standard fuse or rated at 20 HP with time delay

fuse. † Square D E-Series Disconnect Switch.

Master Index February 2004

99 Union Street

D Index Cat. No. Index Elmira, Ontario N3B 3L7

D-36

Cat. No. Index Master Index

February 2004 D Index

Dimensions: IDR and IDSR

Interlocked Receptacle with

Enclosed Disconnect Switch

IDR or IDSR Interlocked Receptacle WSRD Interlocked Receptacle with Switch

with Enclosed Switch or Breaker TYPE 3, 3R, 4, 4X, 12

TYPE 3, 4X and 5

Device Rating A B C D E F G H

30 & 60 Amp 17.25" 16.63" 5.13" 8.13" 9.13" 22.25" 10.00" 6.13"

100 Amp 21.25" 20.63" 7.5" 10.38" 11.5" 26.25" 10.13" 6.50"

February 2004 Master Index

99 Union Street

Elmira, Ontario N3B 3L7 Cat. No. Index D Index

You might also like

- Eds Efs Explosionproof Pushbutton Pilotlight Selector Switch Control Stations Catalog PagesNo ratings yetEds Efs Explosionproof Pushbutton Pilotlight Selector Switch Control Stations Catalog Pages24 pages

- Network Load Sharing Vs Cross Current Compensation PDFNo ratings yetNetwork Load Sharing Vs Cross Current Compensation PDF4 pages