Professional Documents

Culture Documents

4.11 HDP1100-D2 (1406)

Uploaded by

jarek0 ratings0% found this document useful (0 votes)

227 views12 pagesMAN ME-C main engine - hydr.pump

Original Title

4.11_HDP1100-D2(1406)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMAN ME-C main engine - hydr.pump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

227 views12 pages4.11 HDP1100-D2 (1406)

Uploaded by

jarekMAN ME-C main engine - hydr.pump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

(lel 100-D2 | (AUER

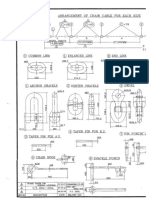

FUEL VALVE TEST PUMP UNIT | INSTRUCTIONS FOR USE

oN Th Bb EG AR ALA BRA

CHANGZHOU LU SHI MARINE MACHINERY CO.,LTD.

Bai FC 88 8

DESCRIPTION AND OPERATION INSTRUCTION

FOR TEST PUMP UNIT (HDP1100-D2)FOR

MARINE DIESEL ENGINE FUEL VALVE

1,FUNCTION

This instruction has been to facilitate the understanding of the working principle of the pump unit

‘The various control instruments and manoeuvring handles are fitted with a number. THESE NUMBERS ARE

MENTIONED IN THIS INSTRUCTION AND ARE ALSO REFERRING TO THE NUMBER FOUND ON THE

DRAWING SHOWING THE COMPLETE PUMP UNIT. furthermore these numbers are found on the control

panel of the pump unit

Please read this instruction carefully before using the pump unit, and follow the instruction given very carefully

2.MAIN TECHNICAL DATA.

(1) Oll pressure output: Max.80Mpa at 0.7Mpa air input

(2) Air consumption: 12 Litres / cycle at 0.7Mpa of no back pressure.

(3) Max.oil flow at zero pressure: 40 ML / cycle at an air input of 0.4Mpa.

(4) Pump speed: 20 cycles / min at 0.4Mpa air input and no back pressure.

(5) Tank capacity: 8 Litres

(6) Dimensions: 760480 1250mm

(7) Net Weight: 90 kg

3.CONTROL PANEL DESCRIPTION

(1) FULL STROKE PUSH BUTTON.

(2) Oil Pressure relief valve

(3) Regulating valve for air pressure.

(4) Fiter

(5) Switch (OPENING PRESSURE / VENTING PRESSURE / RESET)

(6) Manometer for primary air pressure

(7) Digital instrument: WORK PRESSURE

(8) Digital instrument: VENTING+OPENING PRESSURE

(9) HP oll output

(10) Air inlet quick connector.

(11) Oil inlet

(12) Pump

(13) Electro-magnetic vaive.

4.PREPARATION BEFORE CONNECTING THE PUMP UNIT

(1) The tank is filled with hydraulic oil (viscosity 7-10 cst at 50°C) through oil inlet. The tank will hold 8 litres.

Open the pressure relief valve (2) by turning anti-clockwise. The air regulating valve (3) is closed by tuning anti-

clockwise.

(2) Compress air is led through a. flexible hose to the air inlet (10) on the right side of the cabinet. To avoid

‘contamination of the pump. Itis essential that an effective and water separator is inserted in the airline.

The air regulating valve (3) is open by turning the handle clockwise slowly. Until the manometer indicates

approx 0.4Mpa,

Pumping of fuel oil through the whole system is now done for about one minute to make sure that no

entrapped airs found in the unit.

(8) Connection of the fue! valve to the test unit.

‘The fuel valve is mounted on the seat found on the left side of the cabinet. The fuel valve may be con-

nected by means of a flexible high pressure hose, one end to fuel valve, one end (G1/4") to HP oil oulet (8). The

test pump unit is. now ready for use.

5. HOW TO USE HDP1100-D2

(I)Test A : VENTING FUNCTION

Switch knob (5) to RESET position

«Adjust air regulating valve (3) until air pressure gauge (6) is 0.2Mpa.

Maintain the pressure for about 1 minute, then tum the regulating valve (3) anti-clockwise. air pressure

gauge (8) shows 0 Mpa,

LUSHI MARINE MACHINERY

2% Close pressure relief valve (2).

¥Agjust air regulating valve (3) until WORKING PRESSURE (8) is 15 Mpa

% Switch knob (5) to VENTING PRESSURE.

%Pull out the quick release handle (1), when internal venting opens, the WORKING PRESSURE (8)

decreased slowly, venting pressure is shown on display (7),

¥éRelease the quick release handle (1)

% Close air regulating valve (3) — turn it anti-clockwise

Open pressure relief valve (2) — turn it anti-clockwise.

(2)Test B : OPENING PRESSURE

2% Switch knob (5) to RESET position,

Adjust air regulating valve (3) until air pressure gauge (6) is 0.2Mpa,

2Maintain the pressure for about 1 minute then close relief valve (2),

»Switch knob (5) to OPENING PRESSURE position

Adjust air regulating vaive (3) until display (7) shows the fuel valve opening pressure stable. The electro-

magnetic valve (13) closed, and high pressure pump (12) stopped automatically.

%Close regulating valve (3) — tur it anti-clockwise.

%Open pressure relief valve (2) — tur it anti-clockwise.

¥Repeat upper procedures and get two “same” opening pressures(+/- 1 Mpa).

(3)Test C : LEAKAGE TESK

Switch knob (5) to RESET position

%Close pressure relief valve (2)

%Adjust regulating valve (3) until displayed WORKING PRESSURE (8) is 1-2 Mpa. lower than OPENING

PRESSURE MEASURED in TEST B. Check if there is any oll leakage.

% Close regulating valve (3) — turn it anti-clockwise.

%

You might also like

- Galley Proving CabinetDocument40 pagesGalley Proving CabinetjarekNo ratings yet

- Double Bottom ConstructionDocument5 pagesDouble Bottom ConstructionjarekNo ratings yet

- Galley Backing OvenDocument50 pagesGalley Backing OvenjarekNo ratings yet

- Galley Cooking Plate Futura - rp4Document43 pagesGalley Cooking Plate Futura - rp4jarek100% (1)

- Anchor Chain CableDocument2 pagesAnchor Chain CablejarekNo ratings yet

- Shell ExpansionDocument1 pageShell ExpansionjarekNo ratings yet

- H-01 1A000H001 Midship SectionDocument21 pagesH-01 1A000H001 Midship SectionjarekNo ratings yet

- 4.18 - Operation - PMI Auto-Tuning (1312)Document48 pages4.18 - Operation - PMI Auto-Tuning (1312)jarekNo ratings yet

- Stern Frame and Rhorn ConstructionDocument17 pagesStern Frame and Rhorn ConstructionjarekNo ratings yet

- Construction Profile &deck PlanDocument4 pagesConstruction Profile &deck PlanjarekNo ratings yet

- Aft End ConstructionDocument2 pagesAft End ConstructionjarekNo ratings yet

- 4.22 - Vicous Damper Installation & Operation (1312)Document6 pages4.22 - Vicous Damper Installation & Operation (1312)jarekNo ratings yet

- 4.12 - LC Avm 01 (1007)Document24 pages4.12 - LC Avm 01 (1007)jarekNo ratings yet

- 4.10 HPM-1800 (1007)Document8 pages4.10 HPM-1800 (1007)jarekNo ratings yet

- 4.8 - MD-SX Instruction (1309)Document56 pages4.8 - MD-SX Instruction (1309)jarekNo ratings yet

- ZEN-EEA-1005 - 0 CC SYDNEY Electrical MTODocument3 pagesZEN-EEA-1005 - 0 CC SYDNEY Electrical MTOjarekNo ratings yet

- ZEN-MAC-1010 - 0 CC SYDNEY IMO Sampling PointDocument2 pagesZEN-MAC-1010 - 0 CC SYDNEY IMO Sampling PointjarekNo ratings yet

- ZEN-BAS-1005 - 0 CC SYDNEY Modified Lightship Weight Estimation ReportDocument9 pagesZEN-BAS-1005 - 0 CC SYDNEY Modified Lightship Weight Estimation ReportjarekNo ratings yet

- Alfa Laval BWTS - PMSDocument2 pagesAlfa Laval BWTS - PMSjarek100% (1)

- ZEN-EEA-1003 - 0 CC SYDNEY BWTS Single Line DiagramDocument5 pagesZEN-EEA-1003 - 0 CC SYDNEY BWTS Single Line DiagramjarekNo ratings yet

- Selfjector Operation Manual 1,2Document101 pagesSelfjector Operation Manual 1,2jarekNo ratings yet

- Fitting & Acc.Document595 pagesFitting & Acc.jarekNo ratings yet

- 4400hm-Bwts-9315953-Zen-Bas-1003 - 1 - BV CC Sydney BWMP - Comment SheetDocument3 pages4400hm-Bwts-9315953-Zen-Bas-1003 - 1 - BV CC Sydney BWMP - Comment SheetjarekNo ratings yet

- 4400hm-Bwts-9315953-Zen-Bas-1003 - 1 - BV CC Sydney BWMPDocument167 pages4400hm-Bwts-9315953-Zen-Bas-1003 - 1 - BV CC Sydney BWMPjarekNo ratings yet

- BSB2 - FX - 05 Spare Parts Catalog - ENDocument46 pagesBSB2 - FX - 05 Spare Parts Catalog - ENjarekNo ratings yet

- PAS WP121L-WP151L Marine WAs - en - GB - 1804Document39 pagesPAS WP121L-WP151L Marine WAs - en - GB - 1804jarekNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)