Professional Documents

Culture Documents

Ijett Shamsu PDF

Uploaded by

نیما مرادیOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijett Shamsu PDF

Uploaded by

نیما مرادیCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/275597447

Effect of Tempering Temperature on Mechanical Properties of Medium Carbon

Steel

Article in International Journal of Engineering Trends and Technology · March 2014

DOI: 10.14445/22315381/IJETT-V9P350

CITATIONS READS

33 11,505

5 authors, including:

Mustapha Mukhtar Usman Isyaku Muhammad

Northeastern University (Shenyang, China) Northeastern University (Shenyang, China)

11 PUBLICATIONS 63 CITATIONS 12 PUBLICATIONS 132 CITATIONS

SEE PROFILE SEE PROFILE

S. T. Auwal

Kano University of Science & Technology

20 PUBLICATIONS 237 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

A New life time distributions with applications to real data View project

Application of CAD/CAE/CAM tools in the production of Plastic injection Mould View project

All content following this page was uploaded by Mustapha Mukhtar Usman on 15 April 2021.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 15 - Mar 2014

Effect of Tempering Temperature on Mechanical

Properties of Medium Carbon Steel

S.A Tukur#,*1, M. M Usman*2, Isyaku Muhammad*3, N. A Sulaiman*4

#

Lecturer, Department of Mechanical Engineering, Kano University of Science and Technology, Wudil, Nigeria

*

PG Student, School of Mechanical Engineering and Automation, Liaoning University of Technology, Jinzhou 121001, China

Abstract— Untempered martensitic steels, while very hard are influencing factors in the choice of the quenching medium are

too brittle to be useful for most applications. Most applications the kind of heat treatment, composition of the steel, the sizes

require that quenched part be tempered, so as to impact some and shapes of the parts [7, 8].

toughness and further improve ductility. Current work reports In literature it is possible to find many works regarding the

and analyzes results of mechanical testing was performed on

quenching heat treatment with very encouraging results [9–11].

variously heat treated medium carbon steel samples, to arrive at

an optimum heat treatment strategy for judicious combination of Current processes leading to carbide spheroidisation rely on

hardness and tensile properties. Tensile and hardness test diffusion of carbon in a work piece heated to a temperature

specimens were fabricated using Lathe machine. These samples close to or slightly below Ac1 [12].

were subjected to various heat treatment sequences, consisting of The brittleness is caused by a predominance of martensite.

full annealing, hardening, oil quenching, and tempering at This brittleness is therefore removed by tempering [13].

different temperatures. Heat treated samples were then Therefore, medium carbon steel in its tempered state, it

mechanically tested for hardness (Rockwell) and tensile provides one of the best combinations of strength and

properties (yield strength, ultimate tensile strength, ductility). toughness obtainable in medium carbon steels. This makes

Mechanical testing of medium carbon steel samples revealed that

tempering of martensite one of the most important heat

with increasing temper temperatures: (a) hardness first increases

to a maximum and then gradually decreases; (b) yield strength treatments in modern steelmaking. Different combinations of

first decreases, then increases, and then decreases again; (c) time and temperature can give the desired mechanical

ultimate strength first increases to a maximum and then steadily properties during tempering, but, in general, temperature will

decreases; and (d) ductility (% elongation) increases, and then have the highest impact on tempering effect [14]. Previous

decreases before continue to increases rather sharply. The studies [15-17] have shown that with increasing the tempered

optimum heat treatment strategy was found to be at tempering temperature, the martensite transforms to the ferrite and

temperature of 250ºC for well balanced mechanical properties. carbides. However very limited information is available in

published literature about the optimum tempering temperature

Keywords— tempering temperature; medium carbon steel; for judicious combination of mechanical properties of medium

microstructure; mechanical property; martensite carbon steel. Results of this study can fill some of this gap.

The motivation for this research is based in an industrial

I. INTRODUCTION

interest in the tackling the trade-off between strength and

Steels represent the most important group of engineering

ductility so as to provide the designers and users in metal

materials as they have widest diversity of application than any

working industries with good guidelines to select proper

other engineering materials [1]. Furthermore, plain carbon

tempering temperature for heat treating medium carbon steel

steels are widely used for many industrial applications and

for optimum combination of mechanical properties.

manufacturing on account of their low cost and easy

fabrication [2]. They are classified on the basis of their carbon

II. EXPERIMENTAL WORK

content as their major alloying element is carbon. Steels with

Standard tensile and hardness test specimens were made from

carbon content varying from 0.25% to 0.65% are classified as

medium carbon steel in collaboration with a lathe machine.

medium carbon, while those with carbon content less than

Samples were subjected to different heat treatment sequences:

0.25% are termed low carbon. The carbon content of high

annealing, hardening, oil quenching, and tempering at four

carbon steels usually ranges within 0.65-1.5% [3]. Hardness

different temperatures: 250°C, 350°C, 450°C, 550°C. Heat

and other mechanical properties of plain carbon steels increase

treated specimens were mechanically tested for tensile

with the rise in concentration of carbon dissolved in austenite

properties, and hardness.

prior to quenching during hardening heat treatment [4], which

may be due to transformation of austenite into martensite [5].

A) Heat Treatment

The desirable properties of medium carbon steel can be

Ten of the twelve prepared tensile test and hardness test

achieved by adding suitable alloying elements and secondly

samples were heated to 900°C and soaked for 45 minutes

by various conventional heat treatment [6]. The mechanical

using a muffle furnace. The test samples were quickly taken

strength of medium carbon steels can also be improved by

out of the furnace and quenched in oil. Tempering treatment

quenching in appropriate medium. However, the major

was conducted immediately on eight hardened and quenched

ISSN: 2231-5381 http://www.ijettjournal.org Page 798

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 15 - Mar 2014

samples at different temperatures of 250°C, 350°C, 450°C, their austenites transformed to martensites. These are fine,

550°C with dwell time 30 minutes inside the furnace needle-like structures which are very strong and hard, but very

environment and allowed it to cooled in air to room brittle. This increase in hardness can be attributed to the

temperature. higher volume fraction of the harder martensite in the

developed steel; the transformation of austenite to martensite

B) Mechanical Testing by a diffusionless shear type transformation in quenching is

Mechanical tests were conducted on untreated, as-hardened also responsible for higher hardness obtained and this property

and hardened-tempered samples to evaluate their tensile and is attributed to the effectiveness of the interstitial carbon in

hardness properties. A HV-1000 Rockwell type digital hindering the dislocation motion [18]. After the hardened steel

microhardness testing machine was used to conduct the tempered the prevalent martensite is an unstable structure and

hardness test measurements. Hardness values were determined the carbon atoms diffuse from martensite to form a carbide

by taking the average of five HRC readings at different precipitate and the concurrent formation of ferrite and

positions on the test samples. Similarly, tensile test was cementite[3]. This allows microstructure modifications caused

conducted on untreated, as-hardened and hardened-tempered reduced in hardness level while increasing the ductility. The

samples at room temperature using a 600kN Avery-Denison re-heating of martensites during tempering would enable it to

universal testing Machine. The ends of the specimen were be transformed into sorbite or troostite. These are fine

gripped in the machine, and load was applied until failure dispersions of carbide in a ferrite matrix.

occurred. The initial gauge length and diameter were

measured before subjecting them to tension. The yield and

maximum loads were recorded directly from the resulted

graph, the broken ends of each of the specimens were fitted

and the final gauge length and also the smallest diameter of 60

the local neck were measured. The readings thus obtained

were used in the determination of the yield strength, ultimate 55

tensile strength, percentage elongation (ductility).

Hardness [HRC]

50

III. RESULTS AND DISCUSSION

Spectrometric analysis of the steel was carried out to

45

determine its chemical composition. The result is shown in

Table 1.

S/N Elemen Weight S/N Elemen Weight 40

ts % ts %

1 C 0.350 11 Co 0.015 35

2 Si 0.150 12 Nb 0.0050 Untreated Hardned at 900 Tempered at 250

Sample Condition

Tempered at 350 Tempered at 450 Tempered at 550

3 Mn 0.760 13 Ti 0.0037

4 P 0.033 14 V 0.0057 Fig.1: Variation of Hardness value of untreated, as-hardened and

5 S 0.034 15 W 0.010 hardened-tempered samples against temperatures

6 Cu 0.05 16 Pb 0.0050

B) Strength

7 Cr 0.071 17 Sn 0.026

8 Mo 0.0050 18 Zn 0.0076 Fig. 2 Compare the measured results of yield strength and

9 Ni 0.110 19 Fe 98.367 ultimate tensile strength of untreated, as-hardened and harden-

10 Al 0.025 tempered samples. Strength first increases to a maximum and

then keeps on decreasing as temper temperature increases.

Table 1 Composition of the steel sample investigated. The two curves are almost overlapping each other, indicating

that there is only a marginal effect due to the difference in the

A) Hardness heat treatment sequence. Maximum tensile strength of about

374MPa occurs at tempering of 250°C for the oil-quenched

Fig. 1 shows the micro hardness values of untreated, as- hardened-tempered samples. It should be noted that ultimate

hardened and hardened-tempered samples. As tempering strength variation has almost the same pattern as hardness

temperature increases, hardness first increases to a maximum variation. This confirms that there is an almost direct

and then gradually decreases. Sample hardened at 900°C give relationship between hardness and strength, just as for most of

the highest hardness value (24.2HRC) compared to as- the other steels. Similarly, the yield strength reached its

received and tempered counterpart. The steel material with maximum when hardened due to martensite formation as

approximate 0.35 carbon when heated to 900°C and soaked explained earlier and it then rapidly decreases after tempered

for 45mins, would have the carbon present dispersed to form at 250°C and continue to steadily decrease with increasing

austenite structures. The quenched specimens would have

ISSN: 2231-5381 http://www.ijettjournal.org Page 799

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 15 - Mar 2014

tempering temperature. The decreased in strength observed -tempered medium carbon steels was evaluated. The

was as a result of ferrite and cementite formed from the investigation reveals that the hardened samples give the

martensite. highest hardness and strength values while highest hardness

and strength values for the tempered samples was obtained at

temperature of 250°C for medium carbon steels. 250°C was

Tensile Strength

480

460 Yield Strength found to be an optimum temperature for well balanced

440 mechanical properties.

420

400

380 REFERENCES

Strength [MPa]

360 [1] M. S HTUN, S. T. KYAW and K.T LWIN, “Effect of Heat Treatment

340

320

on Microstructures and Mechanical Properties of Spring Steel, Journal

300 of Metals, Materials and Minerals, Vol. 18, (2) pp 191-192, 2008

280

[2] Smith, W.F.; and Hashemi, J. 2006. Foundations of Materials Science

260

240 and Engineering. 4th ed. McGraw-Hill, Ney York, NY, USA.

220 [3] Rajan, T.V.; Sharma, C.P.; and Sharma, A. 1988. Heat Treatment -

200

180

Principles and Techniques. Prentice-Hall of India Private Limited,

Untreated Hardned at 900 Tempered at 250 Tempered at 350 Tempered at 450 Tempered at 550

Sample Condition

New Delhi, India

[4] Thelning, K.-E. 1984. Steel and Its Heat Treatment. 2nd ed.

Butterworth, London, England, UK.

[5] Feng, C.; and Tahir, I.K. 2008. The effect of quenching medium on the

Fig.2: Variation of Strength of untreated, as-hardened and hardened- wear behaviour of a Ti-6Al-4V alloy. J. Mater. Sci. 43(2): 788-92.

tempered samples against temperatures

[6] Rassizadehghani, J.; Raygan, Sh.; and Askari, M. (2006). Comparison

of the quenching capacities of hot salt and oil baths. Metal Sci. Heat

C) Ductility Treat. 48(5-6): 193-8.

[7] Motagi B.S and Ramesh B. (2012): Effect of Heat Treatment on

Fig. 3 shows the results of measured ductility of tested Microstructure and Mechanical Properties of Medium Carbon Steel.

samples, against heat treated temperatures. The ductility of International Journal of Engineering Research and Development. Vol.

hardened sample was the least as compare to untreated sample, 2, Issue 1, Pp. 07-13.

but increases when tempered at 250°C, with slight decrease at [8] Jamiu K.O., Tajudeen K.A., Abdullarim B.R. (2012): Evaluation of

Mechanical Properties of Medium Carbon Steel Quenched in Water

350°C and 450°C and then increases sharply for the remaining

and Oil. AU J.T. 15(4): Pp. 218-224.

tempered sample. This could be as a result of ferrite and

[9] K.F. Wang,S. Chandrasekar,H.T.Y. Yang, Experimental and

cementite formed from the martensite. The highest value of computational study of the quenching of carbon steel,J. Manuf.Sci.

ductility of about 50.9% was obtained on the sample with Eng. 119 (1997) 257–265.

highest tempering temperature of 550°C. This is because [10] Y. Toshioka,Heat treatment deformation of steel products,Mater. Sci.

tempering treatment at elevated temperature is able to increase Technol. 1 (1985) 883–892.

the number of planes on treated sample for dislocation [11] J. Fuhrmann,D. Homberg,Numeric al simulation of the surface

movement to occur. hardening of steel,Int. J. Numer. Method Heat Fluid Flow 9 (6) (1999)

705–724,MCB University press.

[12] Nam W. J. & Bae C. M. (1999), Coarsening Behavior of Cementite

Particles at a Subcritical temperature in a medium Carbon Steel.

55

Scripta Materialia, Vol. 41, No. 3, pp. 313-318, ISSN 1359-6462

50

[13] Heat Treatment of Steel: Application and Heat Treatment of Society of

Automobile Engineer, Carbon and alloy Steels, Machinery’s Hand

45 Book, 1924

Ductility [% Elongation]

[14] J.H. Hollomon and L.D. Jaffe. Time-temperature Relations in

40

Tempering Steel. Metallurgical Transactions, 162:223–249, 1945.

35 [15] T. Senthilkumar and T. K. Ajiboye, Effect of Heat Treatment Processes

on the Mechanical Properties of Medium Carbon Steel, Journal of

30

Minerals & Materials Characterization & Engineering, Vol. 11, No.2

25

pp.143-152, 2012

[16] Defa Li, Feng Huang, Shisen Wang et al, Effect of tempering

20

Untreated Hardned at 900 Tempered at 250 Tempered at 350 Tempered at 450 Tempered at 550

temperature on microstructures and properties of niobium and titanium

Sample Condition microalloying low carbon bainite steel, 2nd International Conference

on Electronic & Mechanical Engineering and Information Technology

(EMEIT-2012)

Fig.3: Variation of Ductility of untreated, as-hardened and hardened-

tempered samples against temperatures [17] LI Hong-ying, HU Ji-dong, LI Jun et al, Effect of tempering

temperature on microstructure and mechanical properties of AISI 6150

IV. CONCLUSIONS steel, J. Cent. South Univ. (2013) 20: 866−870

[18] Callister Jr; W.O. (1987), Material Science and Engineering. An

The influence of heat treatment process and temperature on

introduction, John Willey, U.S.A pp 322-328

mechanical properties of untreated, as-hardened and hardened

ISSN: 2231-5381 http://www.ijettjournal.org Page 800

View publication stats

You might also like

- Effect of Tempering Temperature On MechaDocument3 pagesEffect of Tempering Temperature On Mechadhani bux jamaliNo ratings yet

- Ijirt155149 PaperDocument8 pagesIjirt155149 PaperMohamed HassanNo ratings yet

- 10 Effect ofDocument6 pages10 Effect ofMada PerwiraNo ratings yet

- Effect of Tempering Behavior On Heat Treated Medium Carbon (C 35 MN 75) SteelDocument6 pagesEffect of Tempering Behavior On Heat Treated Medium Carbon (C 35 MN 75) SteelMuhanad MamooriNo ratings yet

- Surface Hardness Behaviour of Heat Treated Ni-Cr-Mo Alloys: V.K.MuruganDocument6 pagesSurface Hardness Behaviour of Heat Treated Ni-Cr-Mo Alloys: V.K.MuruganJai Prakash ReddyNo ratings yet

- Matecconf Rimes2017 02008Document10 pagesMatecconf Rimes2017 02008P I GuddimathNo ratings yet

- Influence of heat treatment on impact toughness of carbon steelsDocument5 pagesInfluence of heat treatment on impact toughness of carbon steelsbuseNo ratings yet

- Obiukwu Osita, Udeani Henry, Ubani ProgressDocument12 pagesObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarNo ratings yet

- Mechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationDocument8 pagesMechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationTeddy MokhoNo ratings yet

- Analysis of Mechanical Properties of Mild Steel Applying Various Heat TreatmentDocument6 pagesAnalysis of Mechanical Properties of Mild Steel Applying Various Heat TreatmentUmesh LahorkarNo ratings yet

- IJMMSE - Effect of Annealing On Low Carbon Steel Grade 1008Document6 pagesIJMMSE - Effect of Annealing On Low Carbon Steel Grade 1008TJPRC PublicationsNo ratings yet

- A Case Study of Heat Treatment On AISI 1020 SteelDocument6 pagesA Case Study of Heat Treatment On AISI 1020 SteelEdna Odette Melo UscangaNo ratings yet

- Effectof Carburization Timeand Temperatureonthe Mechanical Propertiesof MildDocument6 pagesEffectof Carburization Timeand Temperatureonthe Mechanical Propertiesof MildGond AbhishekNo ratings yet

- Effects of Carburizing Process Variables On MechanDocument7 pagesEffects of Carburizing Process Variables On Mechanashav patelNo ratings yet

- Heat Treatment and Mechanical Characterization of En8 Steel: AIP Conference Proceedings March 2019Document13 pagesHeat Treatment and Mechanical Characterization of En8 Steel: AIP Conference Proceedings March 2019adam kurniawanNo ratings yet

- Mechanical Properties of Medium Carbon Steel After Heat TreatmentDocument9 pagesMechanical Properties of Medium Carbon Steel After Heat TreatmentKavin PrakashNo ratings yet

- Kay Ali 2015Document6 pagesKay Ali 2015João Paulo Moreira Santos BarbosaNo ratings yet

- Effect of Annealing Temperature On The Microstructure, Microhardness, Mechanical Behavior and Impact Toughness of Low Carbon Steel Grade 45Document4 pagesEffect of Annealing Temperature On The Microstructure, Microhardness, Mechanical Behavior and Impact Toughness of Low Carbon Steel Grade 45hpsingh0078No ratings yet

- Reference 10Document4 pagesReference 10Adnan SaadiNo ratings yet

- 2014 MechanicalPropertiesCharacterizationofaModifiedHP TypeHeat ResistantAlloyDocument6 pages2014 MechanicalPropertiesCharacterizationofaModifiedHP TypeHeat ResistantAlloyAlexeyNo ratings yet

- The Effect of Heat Treatment On The Hardness and Impact Properties of Medium Carbon SteelDocument10 pagesThe Effect of Heat Treatment On The Hardness and Impact Properties of Medium Carbon SteelSoumyadipNo ratings yet

- The Effect of Heat Treatment On The Hardness and IDocument10 pagesThe Effect of Heat Treatment On The Hardness and IJitendra KumarNo ratings yet

- Biswas 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012065Document7 pagesBiswas 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012065Ersan GönülNo ratings yet

- Microstructure SteelDocument7 pagesMicrostructure SteelL.A MangaNo ratings yet

- Analysis of Mechanical Properties of Mild Steel Applying Various Heat TreatmentDocument4 pagesAnalysis of Mechanical Properties of Mild Steel Applying Various Heat Treatmentফিনাইলআইসোসায়ানাইডNo ratings yet

- Mechanical Characterization of Heat Treated EN 9 Steel: March 2017Document8 pagesMechanical Characterization of Heat Treated EN 9 Steel: March 2017Arthanari VaidyanathanNo ratings yet

- The Heat Treatment Analysis of E110 Case HardeningDocument10 pagesThe Heat Treatment Analysis of E110 Case HardeningGuussttNo ratings yet

- XIII. Effects - of - Carburization - Time - and - Temperature - On - TDocument7 pagesXIII. Effects - of - Carburization - Time - and - Temperature - On - THà ThắngNo ratings yet

- 4-Ph.D Paper 1,2023Document11 pages4-Ph.D Paper 1,2023Mahmoud Essam ElsaifyNo ratings yet

- Effect of Heat Treatment On The Performance of 30MnB4 Steel For Being Used As Grade 10.9 BoltDocument6 pagesEffect of Heat Treatment On The Performance of 30MnB4 Steel For Being Used As Grade 10.9 Boltkim983124No ratings yet

- Review Jurnal Praktikum Material WakidDocument2 pagesReview Jurnal Praktikum Material WakidBERKAH JAYANo ratings yet

- Effect of Heat Treatment On The Fracture Toughness of AISI 4140 SteelDocument6 pagesEffect of Heat Treatment On The Fracture Toughness of AISI 4140 Steelou82muchNo ratings yet

- The Influence of Heat Treatment and Resulting MicrDocument11 pagesThe Influence of Heat Treatment and Resulting MicrAB UkaniNo ratings yet

- Ismail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Document10 pagesIsmail 2016 IOP Conf. Ser. Mater. Sci. Eng. 114 012108Paviter SinghNo ratings yet

- Steel Microstructure Effect on Mechanical Properties and Corrosion BehaviorDocument15 pagesSteel Microstructure Effect on Mechanical Properties and Corrosion BehaviorGanesh RakateNo ratings yet

- Effect of Cooling Medium and Tempering On Microstructures and Hardness of SK3 High Carbon SteelDocument12 pagesEffect of Cooling Medium and Tempering On Microstructures and Hardness of SK3 High Carbon Steelabdul azhimNo ratings yet

- Metals 11 01121Document18 pagesMetals 11 01121Izod GetterNo ratings yet

- Study The Effect of Cooling Medium On The Torsion Resistance and Hardness of Medium Carbon SteelDocument10 pagesStudy The Effect of Cooling Medium On The Torsion Resistance and Hardness of Medium Carbon Steelمسعود بوزويرNo ratings yet

- Materials Chemistry and Physics: Maryam Soleimani, Hamed Mirzadeh, Changiz DehghanianDocument7 pagesMaterials Chemistry and Physics: Maryam Soleimani, Hamed Mirzadeh, Changiz Dehghanianahmed ezwaiNo ratings yet

- Munawar 2018 J Phys3A Conf Ser 962 012063Document8 pagesMunawar 2018 J Phys3A Conf Ser 962 012063Bagas AlfaridzieNo ratings yet

- Heat Treatment Lab ReportDocument7 pagesHeat Treatment Lab Reportmuvhulawa bologo100% (1)

- Effect of Various Heat Treatment Process On Tensile Strength and Elongation of Stainless SteelDocument5 pagesEffect of Various Heat Treatment Process On Tensile Strength and Elongation of Stainless SteelehsanNo ratings yet

- Semi-Hot Stamping As An Improved Process of Hot StampingDocument8 pagesSemi-Hot Stamping As An Improved Process of Hot StampingAndress SsalomonnNo ratings yet

- Sae 1025Document6 pagesSae 1025Mada PerwiraNo ratings yet

- Effect of Heat TreatmentDocument5 pagesEffect of Heat TreatmentsupNo ratings yet

- 20 Parthipan Scopus PaperDocument6 pages20 Parthipan Scopus PaperkamalbrittoNo ratings yet

- Enhancement of Mechanical Properties On Aluminum Alloys - A ReviewDocument3 pagesEnhancement of Mechanical Properties On Aluminum Alloys - A ReviewhsemargNo ratings yet

- Ijmerr v3n2 30Document6 pagesIjmerr v3n2 30remo senNo ratings yet

- 1515 3804 1 PBDocument11 pages1515 3804 1 PBkeviensyafiNo ratings yet

- Las JurnalDocument8 pagesLas JurnalEby Nugroho MeinsideNo ratings yet

- Sliding Wear Properties of A Composite of Aluminum 2024 Powder Reinforced With Heat Treatment and Silicon CarbideDocument12 pagesSliding Wear Properties of A Composite of Aluminum 2024 Powder Reinforced With Heat Treatment and Silicon Carbideabdullah 3mar abou reashaNo ratings yet

- Heat Treatment and Alloying of Spherulitic Graphite Cast Iron For Intensification of PropertiesDocument8 pagesHeat Treatment and Alloying of Spherulitic Graphite Cast Iron For Intensification of PropertiesEditor IJTSRDNo ratings yet

- The Heat Treatment of Austenisation Analysis of Me PDFDocument8 pagesThe Heat Treatment of Austenisation Analysis of Me PDFGuussttNo ratings yet

- Materials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaDocument15 pagesMaterials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaJimmy the ReverendNo ratings yet

- A Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase SteelsDocument9 pagesA Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase Steelsahmed ezwaiNo ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelMuhammad Rizki Ash-ShidiqNo ratings yet

- Project 11111Document6 pagesProject 11111Nasreen ClothNo ratings yet

- 1 Ijmmsedec20171Document12 pages1 Ijmmsedec20171TJPRC PublicationsNo ratings yet

- Analisa Pengaruh Variasi Temperatur Tempering Terhadap Sifat Mekanis Baja Aisi 9254 Aplikasi Pegas Ulir/Spiral Daihatsu Zebra 1.3Document8 pagesAnalisa Pengaruh Variasi Temperatur Tempering Terhadap Sifat Mekanis Baja Aisi 9254 Aplikasi Pegas Ulir/Spiral Daihatsu Zebra 1.3eka fitria rahmanNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Odusotenewpaper PDFDocument11 pagesOdusotenewpaper PDFنیما مرادیNo ratings yet

- Odusotenewpaper PDFDocument11 pagesOdusotenewpaper PDFنیما مرادیNo ratings yet

- Numerical Analysis of The 45 MM Reinforcement Bar Rolling ProcessDocument5 pagesNumerical Analysis of The 45 MM Reinforcement Bar Rolling Processنیما مرادیNo ratings yet

- Mechanical Behaviour and MicrostructuralDocument11 pagesMechanical Behaviour and Microstructuralنیما مرادیNo ratings yet

- ASTM D5528 - 2013 Fracture Toughness Mode IDocument13 pagesASTM D5528 - 2013 Fracture Toughness Mode IPablo OrtegaNo ratings yet

- Stressing Calculation GunutiaDocument112 pagesStressing Calculation GunutiaArindam GhoshNo ratings yet

- Structural Control Systems for Earthquake and Wind ResistanceDocument38 pagesStructural Control Systems for Earthquake and Wind Resistanceutsav_koshtiNo ratings yet

- The Terrible Beauty of ThermodynamicsDocument9 pagesThe Terrible Beauty of Thermodynamicsels243No ratings yet

- MEMS-Based Gravimetric Sensors For Explosives Detection: Abstract-A Compact, Rapid System For Trace Detection ofDocument4 pagesMEMS-Based Gravimetric Sensors For Explosives Detection: Abstract-A Compact, Rapid System For Trace Detection ofShereen SelvarajNo ratings yet

- The Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral BucklingDocument13 pagesThe Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral Bucklingmaz234No ratings yet

- OPzV2 350Document2 pagesOPzV2 350suryadiNo ratings yet

- Hollow Section Acc. To 10219Document3 pagesHollow Section Acc. To 10219Abdul HadhiNo ratings yet

- Sonic Velocity Mach Number PDFDocument2 pagesSonic Velocity Mach Number PDFShreyasGadkariNo ratings yet

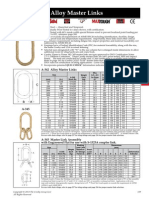

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- Electrical Machine 1 Solved MCQs (Set-5)Document6 pagesElectrical Machine 1 Solved MCQs (Set-5)Ultra Legend gamingNo ratings yet

- Sustarinc ds2012Document2 pagesSustarinc ds2012Berno Muishond KohlmeyerNo ratings yet

- Tutorial No. 1 Free VibrationDocument3 pagesTutorial No. 1 Free VibrationNjuguna WaweruNo ratings yet

- Quiz - Thermal Radiation - With AnsDocument3 pagesQuiz - Thermal Radiation - With AnsaukitNo ratings yet

- Parallel CircuitDocument14 pagesParallel CircuitJOSHUANo ratings yet

- Some Liquid Holdup Experimental Data in Trickle-BedDocument6 pagesSome Liquid Holdup Experimental Data in Trickle-BedKrittini IntoramasNo ratings yet

- DIACDocument12 pagesDIACnishantmadhukar50No ratings yet

- Pengenalan Karakterisasi MaterialDocument23 pagesPengenalan Karakterisasi Materialfikri wahyu pratamaNo ratings yet

- Bernoulli's Theorem DemonstrationDocument21 pagesBernoulli's Theorem DemonstrationDafiMabo100% (2)

- Thermal Bridges in Building Construction — 2D Composite StructureDocument10 pagesThermal Bridges in Building Construction — 2D Composite Structureashraf-84No ratings yet

- Shape Memory Alloys in Fibre-Reinforced Polymer Composites PDFDocument16 pagesShape Memory Alloys in Fibre-Reinforced Polymer Composites PDFvasudevan mcNo ratings yet

- 1 - Introduction To UPV - Dave CorbettDocument42 pages1 - Introduction To UPV - Dave Corbettdimitrios25100% (3)

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaNo ratings yet

- Mapegrid G 220Document2 pagesMapegrid G 220draganugNo ratings yet

- 2016Document896 pages2016Someshwar KoreNo ratings yet

- Lifting The Lid On The PotentiostatDocument18 pagesLifting The Lid On The PotentiostatSantiago EdingerNo ratings yet

- Heat TreatmentDocument33 pagesHeat TreatmentColeNo ratings yet

- Particulate Pollutants Emission Control TechnologiesDocument72 pagesParticulate Pollutants Emission Control TechnologiesalyaNo ratings yet

- Materials and Design: Tolga Dursun, Costas SoutisDocument10 pagesMaterials and Design: Tolga Dursun, Costas SoutisCláudia TurraNo ratings yet

- Engg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Document24 pagesEngg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Manuel MirandaNo ratings yet