Professional Documents

Culture Documents

Liebherr Rubber Tired Gantry Cranes RTG - Technical Description

Uploaded by

GogyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebherr Rubber Tired Gantry Cranes RTG - Technical Description

Uploaded by

GogyCopyright:

Available Formats

Technical Description

Liebherr Rubber Tyre Gantry Crane (RTG)

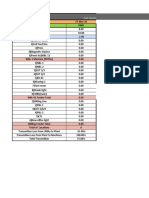

Dimensions

RTG Model Designation (example)

7 / 5 / 4 / WS

AC Drive

4 wheels per corner

1 over 5 high stacking

7 containers wide + truck lane

RTG Model Range*

A Typical Gantry Span 20.8m for 5 wide + truck lane

23.6m for 6 wide + truck lane

26.5m for 7 wide + truck lane

B Lifting Heights 12.3m for 1 over 3

15.2m for 1 over 4

18.1m for 1 over 5

21.0m for 1 over 6

C Travel Wheel Gauge 9.2m

D Equaliser Length 2.5m

E Length over travel guards 13.3m for 4 wheels per corner

13.7m for 2 wheels per corner

F Trolley travel Gantry span minus end approach

G Trolley end approach 2.40m

H Trolley end approach 2.25m

* other features and dimensions also available

Design Parameters

Classification according F.E.M. U7-Q2-A7 (Singlelift)

In service wind speed 72km/h

Out of service wind speed 150km/h

Maximum yard slope 1:100 in either direction

Self weight (model dependent) 116t - 138t

2 Rubber Tyre Gantry Crane

Liebherr Anti - Sway System

Eight Rope Reeving

Advantages by Design

Minimal spreader positioning times

Anti - Sway: Trolley & Travel direction

Anti - Skew

Trim and Skew spreader positioning

No Additional Ropes or Devices necessary

No head block - Reduced rope load and tare weight

Lower energy consumption

All Electrical Spreader - Less maintenance

Increase in Productivity of between 30 - 40% when compared to alternative designs.

Gantry Travel System

Features

Direct Driven, No Chain Drive

Gantry travel with load

Wheels hydraulically locked

Motors

4 motors on 16 wheeler

Reduced tyre wear with differential axles allowing

Wheels to rotate during 90° turn

2 motors on 8 wheeler

Rubber Tyre Gantry Crane 3

Liebherr Rubber Tyre Gantry Crane

Liebherr Reeving System: Sway Prevention, NOT Sway Correction

Electrical (Gantry Align) Steering and/or Active Hydraulic Steering

Rigid Robust Structure - Optimum for Automation

(Optional DGPS auto steering and container positioning)

Direct Gearbox Driven Travel Systems

Separate Drives for Hoist, Travel, Trolley (No Need for Side Shift on Spreader)

Allowing Superior Fine Positioning

Simultaneous Motion

Liebherr Drive Systems

Worldwide Liebherr Service Network

Extensive Training (In - House & On - Site Following Commissioning)

Purpose Built State-of-the-Art Design & Production Facilities Located in Ireland Since 1958

Highly Skilled & Experienced Employees (Expertise In House - For After Sales Service)

Responsibility with Liebherr (Eliminating Interface and Compatibility Problems)

(i.e. Structural, Mechanical and Electrical Design, Production, Commissioning and Service)

Lifting Capacity Generator Set

Single Lift 40.6t - 50t Power Rating 405kW

Twin Lift (optional) 50t - 65t Engine Type Scania / Cummins / Volvo

Alternator Type Marelli / Stamford

Diesel Fuel Tank Capacity 1000l – 1500l

Working Speeds * Operating voltage / frequency 480V / 60Hz

Generator Set Rating, Continuous 400kVA

Hoisting with No Load 56m/min

Hoisting with Rated Load 28m/min

Trolley Travel (with & without load) 70m/min Drive Power

Gantry Travel (without load) 130m/min

Gantry Travel (with rated load) 70m/min Hoist Unit (40.6t) 1 x 190kW AC

Stack Transfer (without load) 70m/min Trolley Unit 2 x 18kW AC

Gantry Travel Unit (8 Wheel) 2 x 70kW AC

* Alternative Speeds Also Available Gantry Travel Unit (16 Wheel) 4 x 35kW AC

Wheel Dimensions & Loading Drive System

Tyre Size (8 Wheel) 18.00 - 25 / 21.00 - 25 Switchgear / Control System designed and built by Liebherr using

Tyre Size (16Wheel) 14.00 - 24 / 16.00 - 25 well proven robust components and CMS system in accordance with

Avg./Max Wheel Load (Mod 7/5/2) 24.50t / 34.80t IEC 1131.

Avg./Max Wheel Load (Mod 7/5/4) 12.20t / 17.20t

RTG 04/2012 Subject to change without notice

Liebherr Container Cranes Ltd.

Fossa, Killarney, Co. Kerry, Ireland

Tel.: +353 64 6670200, Fax: +353 64 6631602

www.liebherr.com, E-Mail: sales.lcc@liebherr.com

You might also like

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- 8 Rope Reeving 3 PDFDocument4 pages8 Rope Reeving 3 PDFsanjay aNo ratings yet

- Technical Description of an RTG Rubber Tyre Gantry CraneDocument4 pagesTechnical Description of an RTG Rubber Tyre Gantry CraneZuhal ZaeemNo ratings yet

- TREEXDocument10 pagesTREEXahmed elsanabaryNo ratings yet

- GMK6300L Product Guide Imperial PDFDocument28 pagesGMK6300L Product Guide Imperial PDFAlexis Serrano AlavidNo ratings yet

- Technical Description Liebherr Rail Mounted Gantry Crane (RMG)Document4 pagesTechnical Description Liebherr Rail Mounted Gantry Crane (RMG)Haluk KayaNo ratings yet

- 2.BL Power TrainDocument52 pages2.BL Power TrainJorge Rojas100% (2)

- PDF Powerscreen Chieftain 2100X Bivitec 2 Deck Tech Spec Rev3 06-06-2011 ChieftainDocument11 pagesPDF Powerscreen Chieftain 2100X Bivitec 2 Deck Tech Spec Rev3 06-06-2011 ChieftainbogdanmichaelNo ratings yet

- GMK7550 Product Guide ImperialDocument60 pagesGMK7550 Product Guide ImperialLuis CuellarNo ratings yet

- GMK5275 Product Guide ImperialDocument24 pagesGMK5275 Product Guide Imperialosky1954trigoNo ratings yet

- DERUI DRWJ-0.75/DRWJ-1 Underground L.H.D SpecsDocument5 pagesDERUI DRWJ-0.75/DRWJ-1 Underground L.H.D SpecsHola NumerosisNo ratings yet

- GMK 5175Document21 pagesGMK 5175cornel_lupu100% (1)

- Powerscreen Chieftain 1400: 2 Deck Incline ScreenDocument13 pagesPowerscreen Chieftain 1400: 2 Deck Incline ScreenDulguunkherlen BudkhandNo ratings yet

- Powerscreen Chieftain 2100X: 3 Deck Incline ScreenDocument16 pagesPowerscreen Chieftain 2100X: 3 Deck Incline Screenfranco avilaNo ratings yet

- Cheftain 1400 CRIBA EspecificacionesDocument12 pagesCheftain 1400 CRIBA EspecificacionestonsupaNo ratings yet

- The SPMT Trailer1Document38 pagesThe SPMT Trailer1Anwar ShanNo ratings yet

- PDF Powerscreen Warrior 2400 2 Deck Tech Spec Rev4 06-06-2011 WarriorDocument18 pagesPDF Powerscreen Warrior 2400 2 Deck Tech Spec Rev4 06-06-2011 WarriorbogdanmichaelNo ratings yet

- Konecranes Brochure Rubber Tyred Gantry Crane English 201003Document2 pagesKonecranes Brochure Rubber Tyred Gantry Crane English 201003Eyad OsNo ratings yet

- BharatBenz 2523C 6x4 Technical SpecificationsDocument2 pagesBharatBenz 2523C 6x4 Technical Specificationsmanoj262400/2No ratings yet

- View thousands of Crane Specifications on FreeCraneSpecs.comDocument10 pagesView thousands of Crane Specifications on FreeCraneSpecs.comHennia AbdelkadirNo ratings yet

- ILC Crane Brochure - 300 T (GMK6300L)Document27 pagesILC Crane Brochure - 300 T (GMK6300L)Srikanth BoggaNo ratings yet

- XCT100 SpecifDocument37 pagesXCT100 SpecifErika Justiniano VargasNo ratings yet

- Kobelco BME800HD SpecDocument16 pagesKobelco BME800HD SpecKOKNo ratings yet

- GMK4115Document38 pagesGMK4115tincho_0026No ratings yet

- Cheiftain 1400 RinserDocument15 pagesCheiftain 1400 RinserbogdanmichaelNo ratings yet

- Chapter - 01 - EN - A600-1 - Edizione 10-2006Document6 pagesChapter - 01 - EN - A600-1 - Edizione 10-2006Razvan CristeaNo ratings yet

- Powerscreen Chieftain 1700 2 Deck Technical Specification Rev 9-01-01 2017Document16 pagesPowerscreen Chieftain 1700 2 Deck Technical Specification Rev 9-01-01 2017Mahmoud Abd El MonemNo ratings yet

- PDF Powerscreen Chieftain 2100X 3 Deck Tech Spec Rev5 06-06-2011 ChieftainDocument15 pagesPDF Powerscreen Chieftain 2100X 3 Deck Tech Spec Rev5 06-06-2011 ChieftainbogdanmichaelNo ratings yet

- PDF Powerscreen Commander 1400 2 Deck Tech Spec Rev4 06-06-2011 ComanderDocument10 pagesPDF Powerscreen Commander 1400 2 Deck Tech Spec Rev4 06-06-2011 ComanderbogdanmichaelNo ratings yet

- BTI Mine Runner PDFDocument8 pagesBTI Mine Runner PDFJesús Omar SolísNo ratings yet

- Erp VT Spec Sheet ViewDocument6 pagesErp VT Spec Sheet Viewkasparob25No ratings yet

- GMK5225 Product GuideDocument28 pagesGMK5225 Product GuideMary MarasiganNo ratings yet

- Grove Rt525e 25-TonDocument10 pagesGrove Rt525e 25-TonweldsaidiNo ratings yet

- XCMG Xca350uDocument57 pagesXCMG Xca350usdydcrane2017No ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderRidha AbbassiNo ratings yet

- RT PPM A400Document10 pagesRT PPM A400Jamal HabbasNo ratings yet

- Dando Geotec 6 (Dando Drilling Indonesia)Document2 pagesDando Geotec 6 (Dando Drilling Indonesia)Dando Drilling IndonesiaNo ratings yet

- Trituradora Eagle 1200 25 CCDocument2 pagesTrituradora Eagle 1200 25 CCRodrigo MartinezNo ratings yet

- Grove GMK6220L - Loading ChartDocument21 pagesGrove GMK6220L - Loading ChartVíctor José Guillermo Pardo gaeteNo ratings yet

- Grove 60 Ton PDFDocument24 pagesGrove 60 Ton PDFFabrizzio ZuñigaNo ratings yet

- Classic: Model HTA (3,000 LB To 6,000 LB) Drawbar Pull (13.3 KN To 26.7 KN)Document2 pagesClassic: Model HTA (3,000 LB To 6,000 LB) Drawbar Pull (13.3 KN To 26.7 KN)kilofome05No ratings yet

- Grove 880E PDFDocument20 pagesGrove 880E PDFulul khanNo ratings yet

- GMK5135Document20 pagesGMK5135Cesar Augusto Vera JaimesNo ratings yet

- Multitec-9000 (Dando Drilling Indonesia)Document2 pagesMultitec-9000 (Dando Drilling Indonesia)Dando Drilling IndonesiaNo ratings yet

- Terex Finlay 694 Screener Product SpecDocument6 pagesTerex Finlay 694 Screener Product SpeckamalNo ratings yet

- Kato 22 Load Chart 30058 PDFDocument17 pagesKato 22 Load Chart 30058 PDFLe Cong LyNo ratings yet

- Hitachi Sumitomo SCX1500A 3Document44 pagesHitachi Sumitomo SCX1500A 3Md Merajul Islam100% (1)

- Compact Track LoaderDocument2 pagesCompact Track LoaderagegnehutamiratNo ratings yet

- Grove RT700E: Product GuideDocument20 pagesGrove RT700E: Product GuideLuis Miguel Rivera SoplopucoNo ratings yet

- Geared Machine W140N for Elevator Suspension and RopingDocument4 pagesGeared Machine W140N for Elevator Suspension and Ropingjose100% (1)

- SANY SF558/808/818 Multi-Purpose Electro-Hydraulic Track Pile Driving RigDocument10 pagesSANY SF558/808/818 Multi-Purpose Electro-Hydraulic Track Pile Driving RigRakhmat RamdhaniNo ratings yet

- J-1175 Dual Power Jaw CrusherDocument8 pagesJ-1175 Dual Power Jaw CrusherAndrey L'vovNo ratings yet

- Specifications: G Andler ElehandlerDocument4 pagesSpecifications: G Andler ElehandlerDietz LaNo ratings yet

- Backhoe Loader: C3.6 Stage V Engine Excavator Style BoomDocument8 pagesBackhoe Loader: C3.6 Stage V Engine Excavator Style BoomInnocent katengulaNo ratings yet

- Ficha - Tecnica - Mixer - MK-A12m3Document4 pagesFicha - Tecnica - Mixer - MK-A12m3Ventasde VehiculosNo ratings yet

- Igo50 Self Erecting Tower Cranes Product Guide - Compass EquipmentDocument16 pagesIgo50 Self Erecting Tower Cranes Product Guide - Compass EquipmentCompass equipmentNo ratings yet

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Intelligent Skin and Occupancy in The Context of Increasing Energy Efficiency in BuildingsDocument8 pagesIntelligent Skin and Occupancy in The Context of Increasing Energy Efficiency in BuildingsGogyNo ratings yet

- 52 Structure New PDFDocument7 pages52 Structure New PDFVino EngineeringNo ratings yet

- Investigation On The Design of Double-Stage Scissor Lifts Based On Parametric Dimension TechniqueDocument19 pagesInvestigation On The Design of Double-Stage Scissor Lifts Based On Parametric Dimension TechniqueGogyNo ratings yet

- Exploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesDocument21 pagesExploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesGogyNo ratings yet

- Global Sensitivity Analysis For Bridge Crane System by Surrogate ModelingDocument8 pagesGlobal Sensitivity Analysis For Bridge Crane System by Surrogate ModelingGogyNo ratings yet

- Cat Hunting Optimization Algorithm: A Novel Optimization AlgorithmDocument23 pagesCat Hunting Optimization Algorithm: A Novel Optimization AlgorithmGogyNo ratings yet

- Productivity Analysis and Associated Risks in Steel StructuresDocument18 pagesProductivity Analysis and Associated Risks in Steel StructuresGogyNo ratings yet

- Optimization of The Multi Level Spring Restrainer For Bridges by Hybrid Particle Swarm and Gravitational Search AlgorithmDocument13 pagesOptimization of The Multi Level Spring Restrainer For Bridges by Hybrid Particle Swarm and Gravitational Search AlgorithmGogyNo ratings yet

- Shapes of Energy - Active Segments of Steel BuildingDocument14 pagesShapes of Energy - Active Segments of Steel BuildingGogyNo ratings yet

- Failure Modes of Pumps' Mechanical Parts and Coating Solutions For Wear ProblemsDocument101 pagesFailure Modes of Pumps' Mechanical Parts and Coating Solutions For Wear ProblemsGogyNo ratings yet

- Global Sensitivity Analysis For Bridge Crane System by Surrogate ModelingDocument17 pagesGlobal Sensitivity Analysis For Bridge Crane System by Surrogate ModelingGogyNo ratings yet

- Comparative Analysis of Hatch Cover Stocking Gantry Crane Hooks Manufactured From St37 and Weldox700 Steels Under Static Loading ConditionsDocument9 pagesComparative Analysis of Hatch Cover Stocking Gantry Crane Hooks Manufactured From St37 and Weldox700 Steels Under Static Loading ConditionsGogyNo ratings yet

- Mechanical Analysis of Forged Steel Ramshorn Hook-An Experimental StudyDocument6 pagesMechanical Analysis of Forged Steel Ramshorn Hook-An Experimental StudyGogyNo ratings yet

- Experimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersDocument19 pagesExperimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersGogyNo ratings yet

- Considering The Moment Effect On The Bolts' Circular Distribution in The End-Plate ConnectionDocument9 pagesConsidering The Moment Effect On The Bolts' Circular Distribution in The End-Plate ConnectionGogyNo ratings yet

- Design Optimization of Bullock Cart YokeDocument9 pagesDesign Optimization of Bullock Cart YokeGogyNo ratings yet

- Female Musicians and DancersDocument60 pagesFemale Musicians and DancersGogyNo ratings yet

- Assessment of Virtual Reality Based Safety Training Simulator For Electric Overhead Crane OperationsDocument13 pagesAssessment of Virtual Reality Based Safety Training Simulator For Electric Overhead Crane OperationsGogyNo ratings yet

- Curvilinear Mesh AdaptationDocument15 pagesCurvilinear Mesh AdaptationGogyNo ratings yet

- Kaiyuan CatalogDocument6 pagesKaiyuan CatalogGogyNo ratings yet

- Products CatalogDocument72 pagesProducts CatalogΑΝΑΣΤΑΣΙΟΣ ΣΑΦΡΙΔΗΣNo ratings yet

- Lifting BEAMSDocument90 pagesLifting BEAMSGogyNo ratings yet

- Training Simulator For Acquiring Operational Skill To Operate Overhead Traveling Crane While Suppressing Load SwayDocument13 pagesTraining Simulator For Acquiring Operational Skill To Operate Overhead Traveling Crane While Suppressing Load SwayGogyNo ratings yet

- Contemporary Meets Old in Rehabilitating Historic BuildingsDocument13 pagesContemporary Meets Old in Rehabilitating Historic BuildingsGogyNo ratings yet

- A Virtual Reality System For Training OperatorsDocument3 pagesA Virtual Reality System For Training OperatorsGogyNo ratings yet

- Study On Overturn Proof Monitoring System of Mobile CraneDocument10 pagesStudy On Overturn Proof Monitoring System of Mobile CraneGogyNo ratings yet

- Experimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersDocument19 pagesExperimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersGogyNo ratings yet

- Automatic Design Algorithms For Securing The Ground Contact Stability of Mobile CranesDocument13 pagesAutomatic Design Algorithms For Securing The Ground Contact Stability of Mobile CranesGogyNo ratings yet

- Heavy Lift Installation Study of Offshore Structure 2004Document203 pagesHeavy Lift Installation Study of Offshore Structure 2004Quang-derer75% (4)

- Gantry Girder DesignDocument45 pagesGantry Girder DesignmonaliNo ratings yet

- Technical Data Untuk Project PLN PDFDocument57 pagesTechnical Data Untuk Project PLN PDFAynul Andri AndokoNo ratings yet

- The Ideal Transformer: Load Impedance Apparent PowerDocument6 pagesThe Ideal Transformer: Load Impedance Apparent PowerRoshan EkkaNo ratings yet

- ECBC Implementation Experience - A Case Study on UPERC BuildingDocument21 pagesECBC Implementation Experience - A Case Study on UPERC BuildingAanchal MishraNo ratings yet

- Kwh Summary Report AnalysisDocument2 pagesKwh Summary Report AnalysisManoj TyagiNo ratings yet

- WEEK 9 - Chemical Reaction Equilibria Part 1Document34 pagesWEEK 9 - Chemical Reaction Equilibria Part 1Wan Nadatul NadwaNo ratings yet

- CAMP - Fabrication of Simple Piezoelectric Generators To Power LEDDocument3 pagesCAMP - Fabrication of Simple Piezoelectric Generators To Power LEDcgtnss4No ratings yet

- Ale75w Ale120wDocument26 pagesAle75w Ale120wThanh BarcaNo ratings yet

- Photoelectric Effect: Classical PredictionDocument7 pagesPhotoelectric Effect: Classical PredictionOliver58No ratings yet

- Bahria University Karachi Campus: Transmission Line Fault MonitoringDocument4 pagesBahria University Karachi Campus: Transmission Line Fault Monitoringsaud aliNo ratings yet

- (Sofia-Natalia Boemi, Olatz Irulegi, Mattheos SantDocument540 pages(Sofia-Natalia Boemi, Olatz Irulegi, Mattheos Santshawul gulilat100% (1)

- A Comparison of Computational and Experimental Results of Wells Turbine Performance For Wave Energy Conversion - Artigo - Taha PDFDocument8 pagesA Comparison of Computational and Experimental Results of Wells Turbine Performance For Wave Energy Conversion - Artigo - Taha PDFAdson Santos Silva Jr.No ratings yet

- Methanol SynthesisDocument6 pagesMethanol SynthesisGaurav BurdeNo ratings yet

- UPS Cyber PowerDocument42 pagesUPS Cyber PowerTrongtai PhamNo ratings yet

- B13 RRH SpecificationsDocument1 pageB13 RRH SpecificationsgarzuloNo ratings yet

- Gasification For Practical ApplicationsDocument352 pagesGasification For Practical ApplicationsOthmane DrissiNo ratings yet

- Q4 LESSON 3 (Fire Hazards)Document15 pagesQ4 LESSON 3 (Fire Hazards)WhySoSerious?No ratings yet

- Gate - 2006 PDFDocument13 pagesGate - 2006 PDFRBNo ratings yet

- Irfz24n PDFDocument9 pagesIrfz24n PDFSergio ReyesNo ratings yet

- Edwin Howard Armstrong - Radio's Premier InventorDocument49 pagesEdwin Howard Armstrong - Radio's Premier InventorAl KlaseNo ratings yet

- Esa 415 JDocument24 pagesEsa 415 JJaermirth MelladoNo ratings yet

- Solar Cell I-V Characteristic and The Solar Cell I-V CurveDocument5 pagesSolar Cell I-V Characteristic and The Solar Cell I-V CurveMuhammad BalyanNo ratings yet

- ANNEXURE 1 - Binding Proposal of CZD2x12XW-CBK030 - de Heus Can Tho 1 - 3834064Document12 pagesANNEXURE 1 - Binding Proposal of CZD2x12XW-CBK030 - de Heus Can Tho 1 - 3834064Thien Nguyenngoc100% (1)

- UN Climate Change Annual Report 2018Document62 pagesUN Climate Change Annual Report 2018Jose AlvarezNo ratings yet

- Stability in Air Cargo Handling ProcedureDocument14 pagesStability in Air Cargo Handling ProcedureMohamed Salah El DinNo ratings yet

- Commander SK Start Up Guide PDFDocument82 pagesCommander SK Start Up Guide PDFTazCelRauNo ratings yet

- BATCH PROCESS PlaybookDocument104 pagesBATCH PROCESS PlaybookKapil Dev SaggiNo ratings yet

- Lightning Flashovers On 77-kV Systems: Observed Voltage Bias Effects and AnalysisDocument6 pagesLightning Flashovers On 77-kV Systems: Observed Voltage Bias Effects and AnalysisJairo Curo MartínezNo ratings yet

- Underground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaDocument21 pagesUnderground Works: Projek Mass Rapid Transit Laluan 2: Sg. Buloh - Serdang - PutrajayaMohd FadliNo ratings yet

- Surface Grinding Machine: Chris-MarineDocument2 pagesSurface Grinding Machine: Chris-MarineRahila AlaviNo ratings yet

- Catalog EPCDocument68 pagesCatalog EPCJuan HincapieNo ratings yet