Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

José Faria0 ratings0% found this document useful (0 votes)

15 views618 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views618 pagesUntitled

Untitled

Uploaded by

José FariaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 618

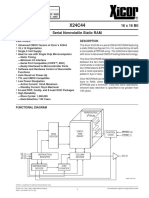

PENTRA 120

Technical manual

Part number : RAA 007 B Ind. A

ABX DIAGNOSTICS

BP. 7290

Rue du Caducée

o«4 Parc Euromédecine

(34184 MONTPELLIER x OF

Code’

Tel.: (33) 4 67 14 15 16

Diaanostics FAX : (33) 4 67 14 15 17

a

REVISIONS

SECTIO-

VISION REVISION al DATE

Creation 15.03.95

Update all sections All 20.02.96

RAH 313 AN] Update section 8 Computer connection 8 12.07.96

RAH 382 A late all sections, creation section 7 all 02.04.97

RAH 496 A ¢ all sections all 26.01.98.

ction 4 and: RAS 102 A, RAS 104 A,

RAH 521 A, section 9} all 28.04.98

RaH615 a | Replacement & the instrument appellation. a Aeoiae

Manual updated tq major index B.

$

+b

This manual is a guide for the maintenance and repair ofj

ithe PENTRA 120 Automated Hematology Analyzer.

Data in this manual has been verified and validated and is believed to be adequgfe for the

intended maintenance and repair of the hematology analyzer. If the hematologyAnalyzer or

the procedures are used for the purpose beyond the capabilities specified ipfhis manual,

confirmation of their validity and suitability should be obtained from ABYDiagnostics;

otherwise ABX Diagnostics does not guarantee results and assumesfho obligation or

liability. This publication is not a license to operate under nor a recommgndation to infringe

upon any product or process patents.

POTENTIAL HAZARDS:

The hematology analyzer includes several safety featuygs to guard the operator from injury,

the instrument from damage and the test results frofi inaccuracies. To alert the service

engineer of potentially hazardous conditions, one ofthe bold captioned headings which are

described below is provided wherever necessaryShroughout this text

y

re

Flags a procedurd that if not followed properly, can prove to be extremely

hazardous to ejther the operator or the environnement or both.

izes operating procedures that must be followed to avoid possi-

Emphasizes operating procedures that must be followed to avoid

erroneous results.

Note _ | Emphasizes the important information especially helpful to the operator

before, during or after a specific operational function,

1 - Introduction

1.1, PENNQA 120 DOCUMENTATION

1.2.6, Software .

1.2.7. Computer connectio!

1.2.8, Maintenance

1.2.9. Troubleshooting

1.3. ASSISTANCE MENU OVERVIEW

1.3.1. Calibration records

1.3.2. Intervention records

1.3.8. Reagent records «rn

1.3.4. Control blood records...

1.3.5. Adjustments

1.3.6. Settings

1.3.7. Connection ..

1.3.8. Shell .

1.3.9. ApPIiCATION «sno

1.3.10. Assistance menu overview synoptic

oNnnn

BARR ARROOO

NNN Nooaaaa

2- Installation and startup

2.1, PACKAGING

2.2, SITE PREPARATION

2.2.1. Power Supply Requirements

2.2.2. Uninterruptable Power Supplies

2.2.3, Waste Disposal Requirements...

2.2.4. Host Computer

2.2.5, Space and accessibility...

2.3. IN SITE TRANSFER

2.4, UNPACKING...

2.4.1, Instrument

2.4.2. Ejection tray

2.4.3, Printer

2.4.4, Accessories

2.4.5, Reagents...

2.5. CONNECTIONS...

2.5.1. Ejection tray to instrument...

2.8.2. Printer to instrument

2.5.3. Reagents to instrument...

2.5.4. Waste to instrument

2.5.5. Laboratory computer to instrumer

2.6. STARTUP.

2.6.1. Printer startup

2.6.2. Instrument startup and iniylization

2.6.3. Primary checks

3 - Mechanic principles and description

3.1.GENMAL PRINCIPLES.

1. Generalities

3.N Cycle descriptions ..

3.2. STEPPER NQTORS PRINCIPLES.

3.3. MECHANIC DESCRIPTION

3.3.1. Racks

3.3.2. Rack loader.

3.3.3. Rack rotation tray

3.3.4. Rack sampler

3.35. Ejection tray i

©eo0ovoan

enn

4 - Electrical description

4.1. POWER SUPPLY MODULE

4.1.1. Description

4.1.2. Main supply socket

4.1.3. Main supply filter...

4.1.4, Toric transformer

4.1.5. Power supply board

4.1.6. Cooling fan ...

4.1.7, Vacuum/pressure board

4.2. BOARD LOCATIONS

4.2.1. Mother board area ... :

4.2.2. Pneumatical door area (backside)

4.2.3, Instrument backside area...

4.3, INPUTSIOUTPUTS

4.4, FLAT CABLES AND WIRINGS

4.8. PENTRA 120 INTERCONNECTION DIAGRAM.....

54.

5.3. INPUTS/OUTPUTS...

5 - Electronic principles

SURE AND SIGNAL PROCESSING.

‘1.1. HGB measurement

E resistive count

OD measure

5.2.9. Blood aspiration detectio

5.2.10. Chamber photocell manaement

5.2.11. Pressure and vacuum contro}.

¢

5.3.1. Liquid cristal display

5.3.2. Matticial keyboard...

5.3.3. IBM PC keyboard

5.3.4, Barcode reader 7

5.3.5. Graphic printer output...

5.3.6. Open tube cycle switch

5.3.7. External barcode reader.

5.3.8. Data output ......

5.3.9. Modem output

5.3.10. SCSI cap.

6 - Electronic description

6.1. INTRODUCTION ...

6.2. ALARM BOARD

6.3. INTERFACE ##1 BOARD ...

6.4. INTERFACE #2 BOARD

6.5. LCD BOARD

6.6. LED BOARD

6.7. JM 340 MICROPROCESSOR BOARD ...

6.8. OD PREAMPLIFIER BOARD.

69. OD SIGNAL BOARD

6.10. PHOTOCELL BOARD......

6.11. POWER SUPPLY BOARD

6.12. PRESSURE VACUUM BOARD

6.13, PREAMPLIFIER #1 BOARD.

6.14, PREAMPLIFIER #2 BOARD.

6.15. PULSE #1 BOARD...

6.16. PULSE #2 BOARD...

6.17. PUMP MOTOR DRIVER BOARD

6.18. PUMP MOTOR FILTER BOARD .......

6.19. WBC/RBC/PLT/HGB SIGNAL BOARD ..

6.20. RESISTIVE BASO SIGNAL BOARD

6.21. RS232/FIFO PRINTER BOARD ..

6.22, SCSI ADAPTOR BOARD

6.23. STEPPER MOTOR POWER BOARD

6.24. STEPPER MOTOR COMMAND BOARD

6.25. TEMPERATURE CONTROL BOARD...

6.26. DISTRIBUTION BOARD

6.27. VACUUM PRESSURE BOARD

6.28. MATRICIAL KEYBOARD BOARD

6.29. G96 MOTHER BOARD...

6.30. SCSI HARD DISK wssssnereennnilrn

6.31. FLOPPY DISK

6.32, FLUOLOGIC BOARD...

6.33. LASER BENCH BOARD

7 - Software description

7.3. 0S9 COMMANDS. seen

7.3.1. File management

7.3.2. Command interpret shel ....

7.3.3. Error message file

7.3.4, Examples of different comands to be used on the PENTRA 120

7.4, PENTRA 120 SOFTWARE GENERM STRUCTURE ........ sennseense 19

7.4.1. Introduction

7.4.2. Application module purpose .

7.4.3. Communication between tasks

7.4.4, PENTRA 120 application startup

7.4.8. application module structure

7.4.6. Module description...

7.4.7. Ramdisk

7.48. Errorfile

7.5. PENTRA 120 INSTALLATION PROGRAM

7.5.1. Introduction

7.5.2. Startup

7.5.2. Installation of an application release

7.5.3. Complete installation -

7.6. GLOSSARY

8 - Computer connection

8.1. COMPUTER CONNECTION PRINCIPLES

8.1.1. XON - XOFF

8.1.2. Uniditectionnal mode description

8.1.3. Bidirectional mode description.

8.2. ARGOS FORMAT PRINCIPLES

8.2.1. Introduction...

8.2.2. Results characteristics.

8.2.3. Patient file characteristics.

8.2.4, End of communication

8.3, ABX FORMAT PRINCIPLES

8.3.1. Message structure

8.3.2. Details about the structure...

8.3.3. Identifier list and their formats

8.3.4, Pathology...

8.35. Histograms and matrix...

8.3.6, Patient result identification ....

8.3.7. Packet type.

8.3.8. Other identifiers

8.4. CONNECTION SETUP

8.4.1. RS 232 cable installation

8.4.2, Instrument setup

8.4.3. Output format setup...

8.5. ASSISTANCE

8.6. GLOSSARY ..

9 - Maintenance

9.1. PENQRA 120 MAINTENANCE PROCEDURES ..

Introduction...

9.2. SERVICE TENUINICIAN MAINTENANCE & ADJUSTMENTS

MNce frequency chart table

20 maintenance kit.

1.1, PENTRA 120 DOCUMENTATION ....

1.2, SERVICE MANUAL CONTENT

1.3, ASSISTANCE MENU OVERVIEW ..

14. INTRODUCTION

CONTENT

1.1.1. Operation manual

1.1.2, Reference manual

4.1.3. Customer service manual

1.1.4. Technical manual .

1.1.5. Exploded views manual

BoNNNN

1.2.1. Instrument installation

1.2.2, Mechanical description

1.2.3. Electrical description ..

1.2.4. Electronic principles ....

1.2.8. Electronic description...

1.2.6. Software

1.2.7. Computer connection

1.2.8. Maintenance

4.2.9, Troubleshooting

DRARRRRROOD

1.3.1. Calibration records

1.3.2. User intervention records «8

1133. Technician Intervention records.

1.3.4. Reagent records

1.3.5. Blank cycle records...

1.3.6. Information window

4.3.7. Adjustments

1.3.8. Connection ...

1.3.9. Parameter sategug/.

1.3.10. Restoring parayféters..

13.11. SHELL .

1.3.12. Application

BURY KoCooouan

RAA007 6 ind.A Page 1/1 7807195,

1. INTRODUCTION

1. Operation mani

jeference manual

1.1.3. Customer service manual

ITRA 120 DOCUMENTATION

This manual is a TECHNICAL MANUAL for the PENTRA 120 instrument. It has a specific part

1umber RAA 007 B which index is updated according to the technical changes from the manufac-

er. This manual is one part of the PENTRA 120 documentation which includes the following

RAC 030 A (French language)

RAB 022 A (English language)

RAB 029A (Spanish language)

RAB 031 A (German language)

RAB 033 A (Italian language)

- Reference matNal RAC 031 A (French language)

RAB 023A English language)

RAB 030 A (Spanish language)

RAB 032 A (German language)

RAB 034 A (Italian language)

Customer service manual \ RAC 032A (French language)

FAB 024 A (English language)

Technical manual Fg 007 B (English tanguage)

+ Exploded views manual: RAP bey B (English language) PENTRA 120 STANDARD

RAP 0098 (English language) PENTRA 120 CE & VEGA RETIC

%

%.

7 %,

‘The operation manualis delivered with the instrumént. It belongs to the installation kit. The operation

manual contains all basic informations in order to bg able to run the PENTRA 120 instrument in

the normal mode, thats to say manual or automatic ercing mode, barcode identification for the

‘sampling tube and bidirectionnal connection. it describys as well the emergency analysis mode

and the calibration operations.

The reference manual is delivered with the instrument. It belon

reference manual contains all informations about the instrument s

configuration. It describes all possible operation modes and as well

Quality control, statistics, results management, etc...

to the installation kit. The

p and the user's specific

ther functions such as

This customer service manual is delivered during the PENTRA 120 customer tra)

This manual contains all informations concerning the instrument operation principles

ment and reagent specifications, the instrument pneumatic and hydraulic principles,

‘some basic maintenance and troubleshooting procedures.

RAAQO?BIndA Paget a8

1.1.5, Exploded views manual

1.2. SERVICE MANUAL CONTENT

1. INTRODUCTION

-al manual

‘This technical manual is delivered during the PENTRA 120 field service engineer trainni

it contains all required informations in order to install, maintain and repair the PI

instrument.

{tincludes as well the technical details forthe instrument connection to a main labogftory computer.

‘This exploded views manual is delivered during the PENTRA 120 field gfrvice engineer trainning

course. It contains all required informations about part numbers (gf the PENTRA 120 spare

paris. describes as well the instrument assemblies and sub-asserpfes, it shows the assembling

and dismantling orders.

The PENTRA 120 technical informations have begA spit up in diferent manuals (Customer

service and exploded views manuals) in order to k@@p a light document in the field

Instrument description, specifications, operatiopprinciples, pneumatic and hydraulic principles

are described in the customer service manuai*

é

Sections contained inthis manual are as iow

go

Instrument installation

=Mechanical description. +

Electrical description,

= Electronic description.

Software

= Computer connect

-Maintenance.

Troubleshooting

The last section of

120 instrument mi

‘ment according

‘document is dedicated to the Technical notes concerning the PENTRA

f changes. These notes will be integrated to the different parts of the docu-

the manual updated versions,

PENTR4A20 instrument installation has to be achieved by qualified service engineer only. This

sectionfescribes the required precautions to take before, during and after the instrument instal

PENTRA 120 instrument has an easy mechanical operation. 4 stepper motors are involved to

allow the rack transfer from the loading tray to the ejection tray. Mechanical checks and

‘adjustments are made much easier using the motor specific software programs (ASSISTANCE

menus}.

RAA007B Ind. A Page 1/3 180199

1. INTRODUCTION

ical description

is section describes the PENTRA 120 electrical principles, including the power supply module.

feconnection diagram, flat cables and wiring schematics belong to this section.

:nd servo-contrals,

1.2.5. Electronic description

This section describes the PENTHA,120 electronic boards. Each board file includes :

~ Aboard description

- Aboard synoptic diagram 6

Aboard view component side diagraéy,

Y

‘This section describes the PENTRA 120 operating,

stem and application program. It gives as

well the main shell commands required for the instrum

i troubleshooting.

1.2.7. Computer connection

This section describes the PENTRA 120 specifications ret

red for an external computer

connection. This connection has to be achieved by the laboral

computer specialist.

Maintenance

This section gives the maintenance operation time table. All maintenaN\e and service kits are

described as well as the specific tools and products required.

This section is divided into «procedures» describing all necessary maintenaNge operation. Each

Procedure gives the intervention time, the required tools and products, the Wpecifc kit, Each

procedure has its own part number and are updated with an index when requir,

1.2.9. Troubleshooting

This section gives the main lines for the PENTRA 120 troubleshooting. This sectiot

updated according to the return of informations from the field,

RAA007 Bind.A ~ Page 174 18/07/99

1. INTRODUCTION

1.3. ASSISTANCE MENU OVERVIEW

‘The general synoptic of the ASSISTANCE functions is given on the last page of Yyf section.

From the MAIN MENU displayed when the MENU key is pressed, 4 functiog® are available

(Diag.1)

THnes

s-gtavistics »

2User oe

Machine ob

NCTA

5

an i

a-hesgent records

fiankeycte recy

e-lator nation

sustnenes

Connect ian.

3

Diag.

‘The ASSISTANCE menu contains numerougdunctions to help the operator and the technician

to check, adjust, or repair the instrument, >

Move the cursor to the function <4> ASSISTANCE and press ENTER. The ASSISTANCE

menu is displayed (Diag.1) e

The different funcffons of the ASSISTANCE menu allow the user and the

ow the correct operation of the instrument. Some of

to be used by trained technicians only for diagnos-

jooting purposes. These functions are protected with

fA function is described in the PENTRA 120 user's manual, section 4 "ASSISTANCE & OTHER

‘CLES’.

RAAOOTBInd.A Page 115 TSOT88

1. INTRODUCTION

1.3 Technician Intervention records

This function allows the technician to resume

directly on the instrument its intervention

aa Duration, purposes, spare parts used and various

os comments can be entered in this function. The

Content of this record can be reviewed by the

user, but the entry of the data is protected by

the technician password. From the ASSIS-

TANCE menu, move the cursor to the function

<3> and validate. The technician intervention

record menu is displayed (Diag.2). From the

Diag.2 function <1> Record review, validate, the

technician record window is displayed (Diag.3).

ae

CE

7

Diag.3

‘The technician intervention record can be printed out uS¥g the key. The PRINTOUT

menu is displayed (Diag.4)

i

EE

IGT

[ETE

Diag.4

RAA007Bind.A Page 116

Diag.5

Diag.6

1. INTRODUCTION

Press <1> to print all data, or when data have been selected using the bar of

keyboard from the previous menu (Diag.3), press <2> (Diag 5)

AES

GER

IE

Daye

Data entries can be deleted ugjng the key. Press to validate (Diag.6)

(SEI

CIEE

aed

CGE

Peineoue oF thr AseTS wemas——

RAA007 Bind.A-

Page 1/7 ~ 18/01/99

1. INTRODUCTION

When a new entry is required, from the

a Technician intervention record menu,

EET ET move the cursor to the function <2>

(Diag.7) and validate. The message

Tequesting the technician password is

displayed (Diag.8). Enter the password and

validate. The data entry window is

displayed (Diag 9).

Diag.7

Sec-up functioWytities For authorised starr only

Pease enter tnd access code # 7

rameter safeguard

Restoring paranecers 7

Boipptication

Diag.8

(PAROS

MRD

Jefgeaedacevteu

Connection

Poraneter "safeguard

Restoring paranevers

shel

Application

MIT

Technietan

Description:

burst ton

Diag.

RAA007B Ind.A ~~ Page 18 = Te0T93

1. INTRODUCTION

Reagent records

‘This function is described in the PENTRA 120 user's manual, section 4 “ASSISTANCE &

CYCLES"

HER:

1.3.5, Blank cycle records

“This function is described in the PENTRA 120 user's manual, section 4 "ASSISJANCE & OTHER

CYCLES"

1.3.6. Information window

‘This function is described in the PENTRA 120 user's manual, secti

CYCLES",

4" ASSISTANCE & OTHER,

1.3.7. Adjustments

Move the cursor to the function <7>

‘ADJUSTMENT (Diag. 10) and press ENTER.

The PASSWORD window is displayed

(Diag. 11). Using the alphanumeric keyboard,

enter the password “tech” and press ENTER.

The ADJUSTMENT menu is displayed

(Diag. 12).

EES

L-catipration records

JS hdes Tatervent von recoras,

1 3-Hechnician intervention records

a Reagent records. ?

Tank cycle records

&-Intornation uindou g

#lonneceon . .

-Paraneter sareguar:

Gckestoring paranccers

icshett

Bppt tcacion

Diag.10

Dialogue

ponnece to

-araneter safeguard

RAROO7B Ind. A Page 18 7601189

1. INTRODUCTION

Diag.12

RAAOO7B ind.

Janene.

e-laene

‘The ADJUSTMENT m&gu allows the following adjustments

1 - Correction coefM¥ent for the calibration

2 - Correction coetticN\gt for the human blood

3 - Correction coefficieN for the control blood

4 - Correction coefficient fgg the calibrator

5 - Special optical alignmerttgycie

6 - Instrument alarm adjust

\Vacuum/pressure alarm adjustment

Blood detection cell adjustfgent

Drain chamber cell adjust

Reagent detection cell adjust

7 Motor mechanical adjustments“

8 - Piercing block mechanical adjustment

9 Instrument special operation modes

40 - 5PO1 board threshold adjustment

11 - HGB caloulation adjustments

12 - Double matrix scatter plot

43 - Standard amplification of the LMNE matrix

14 - WBC balance adjustment

1.3.7.1. Calibration correction

‘The calibration on one or several parameters can be adjusted as Wescribed in the technical

procedure : RAS XXX A

43.

Human blood correction

‘The human blood correction during the calibration on one or several parameters:

be adjusted

as described in the technical procedure : RAS 159A,

1.3.7.3. Control blood correction

The calibration on one or several parameters can be adjusted as described in the tech)

procedure : RAS XXX A,

Page 1/10 —FBOT799

1. INTRODUCTION

1.3.7.4, Calibrator correction

‘The calibration on one or several parameters can be adjusted as described in the tegfinical

procedure : RAS XXX A.

4.3.7.5. Alignment cycle

‘The alignment cycle is used during the optical flowcell alignment procedure agflescribed in the

technical procedure : RAS 098 A.

1.3.7.6. Alarm adjustments

1 The vacuum pressure alarm adjustment is describes

RAS 112A,

the technical procedure

2. The blood detection cell alarm adjustment is de,

RAS 111 A.

fibed in the technical procedure

3- The drain chamber cel alarm adjust meny

RAS XXX A.

‘described in the technical procedure

4. The reagent detection alarm adjust

RAS XXX A. >

ma

é

al adjyatments

The stepper motor mechanical adjustryght procedure is described in the technical procedure :

RAS 102 A. :

@

1.3.7.8, Piercing block mechaniéal adjustments

‘ent is described in the technical procedure

1.3.7.7. Stepper motor mecha

The piercing block mechanic:

RAS 104 A

jiustment procedure is described in the technical procedure :

1.3.7.9. Instrument sgecial operation modes

fal mode : Use during normal instrument operation.

ransfer mode : See the procedure RAS 099 A.

= DIFTEX mode : See the procedure RAS 098 A

4 - Raw counts : See the procedure RAS XXX A

(7.10. 5P01 board threshold adjustment

he 5P01 board thresholds can be adjusted as described in the technical procedure : RAS

XXKA.

RAA0O7Bind.A Page 111 180799

1. INTRODUCTION

.7.11. Haemoglobin calculation values.

1- Proportion

2- HGB blank reject

3- Minimum blank ref.

Double matrix scatter plot

The doubWmatrix scatter plot can be used as described in the technical procedure : RAS XXX

A

1.3.7.13. Standar\amplification of the LMNE matrix

.3.8. Connection

This function is used during the instrurfignt connection setup as described in section 8 of this

manual ae

%

Parameter safeguard y

This function is described in the PENTRA 120 user

CYCLES",

‘anual, section 4 "ASSISTANCE & OTHER

Restoring parameters

This function is described in the PENTRA 120 user's manual, Syction 4 "ASSISTANCE & OTHER

CYCLES",

1.3.11. SHELL

‘This function is described in the section 7 of this manual.

1.3.12. Applica

This function is described in the section 7 of this manual.

RAA0O7BInd A ~

Page 1/12 1810193

2.1, PACKAGING

2.2, SITE PREPARATION .. :

2.2.1. Power Supply Requirements.

2.2.2. Uninterruptable Power Supplies

2.2.3. Waste Disposal Requirements.......

2.2.4. Host Computer .

2.2.5. Space and accessibilty

2.3. INSITE TRANSFER

2.4, UNPACKING

2.4.1. Instrument

2.4.2. Ejection tray

2.4.3. Printer

2.4.4, Accessories...

2.4.5. Reagents

2.8. CONNECTIONS.

2.5.1. Ejection tray to instrument...

2.5.2. Printer to instrument.

2.5.3. Connection of the laser supply

2.5.4. Reagents to instrument

2.55. Waste to instrument

2.56, Laboraory computer fo frument ..

2.6. STARTUP

2.6.1. Printer startup

2.6.2. Laser power supply lartup (VER)

2.6.3. Instrument startup/And initialization

2.6.4. Primary checks

2. INSTALLATION & STARTUP

CONTENT

RAA007 B Ind. A

Page 2/1 18/01/99

2. INSTALLATION & STARTUP

2.ANRACKAGING

Instrument and required accessories arrive in 3 wooden boxes. The larger one which is loaded

on a pallet contains the instrument, the middle size one contains the ejection and reagent tray

and the instrument accessories, the smaller one contains the printer. Reagents and

onsummables are delivered on a separate pallet

Diag.

- Carefully inspect the 3 packages. If you ae signs of mishandling or damage, file a claim with

the carrer immediately, Ifthe shippement wa separately insured, fle a ciaim withthe insurance

company. %,

“

2.2. SITE PREPARATION

2.2.1. Power Supply Requirements

See Technical Specifications (Customer service manual) foNgrecise details of the power supply

requirements for the PENTRA 120.

Before switching on the instrument it should be cilycked that the operating

voltage pre-set on the PENTRA 120 is the same main voltage.

For protection against shock hazards, the equipment should be connected approved power

sources, such as 3-wire grounded receptacle for the 100 -125 V or 200 - 244 V line voltage

ranges.

‘Where an ungrounded receptacle is encountered, have a qualified electrician rep

properly grounded receptacle in accordance with the official Electrical Code.

ice it with a

Do not, under any circumstances, remove the grounding prong from the power plug

= Do not use extension cords.

RAA007BInd.A Page 2/2 18/01/99

Waste Disposal Requirements

2.2.4. Host Computer ¢

‘Space and accessi

2. INSTALLATION & STARTUP

terruptable Power Supplies

Anvuninterruptable power supply is not a mandatory requirement for the PENTRA 120. Nev

the heart of the system is a computer and it is known that such devices can ul

unfavourably affected by power failures or unexpected powerline conditions that f

normal specifications. For this reason and also to avoid inconvenience to cli

preferred to install an Uninterruptable Power Supply (UPS).

if circumstances at a site are such that power supply failures are expe

unacceptable nuisance then an uninterruptable power supply may be inst

the customer.

Selection and installation of an UPS should be carried out in

circumstances and the power requirements of the PENTRA 120,

sideration of the local

No facilities exist for indication to the PENTRA 120 to auto

FBHONA 1

‘Oring 2,4x1,9 rit = FAA 025 A. 1

Microsampling needle 2 GBD 200 A 1

Reagent straw 360mm 3 GAB 067 A 1

Sampling needle joint + GALO74A 1

Rotation tay spring 2 GBD 015 A 1

Dispenser membrane mi” GBD 107 A 1

Dispenser membrane 1mi gf 0.5m GBD 108 A 1

2.4.5. Reagents

RAA0O7 Bind. A Page 2/9 18/0199

2. INSTALLATION & STARTUP

&5. CONNECTIONS

Unscrews the 3 instrument cover screws

and open the instrument cover (Diag.8).

Release the reagent tubes from the

compressor locking pin and remove the

tyraps from the pin.

- Remove the transport locking pin from the

‘compressor and install into the holes the

rubber stoppers contained in the plastic bag

attached to the pin (see Diag.9 & 10)

Connect the reagent detection plug between the instMgrent and the reagent/ejection tray

(See Diag. 10). Unscrew and remove the fixation screws of INe reagenvejection tray located on

the front, right handside of the instrument frame (Diag. 10).

RAA007 Bind.A

Page 2/10

18/01/99

2. INSTALLATION & STARTUP

install the pins ofthe reagent /ejection tray inside the holes located at the back, right handsidg

frame of the instrument and fixe the assembly from the front right handside of the instrumg

frame with the previous screws. Push the piercer inside the instrument to get access tg

inside of the instrument, connect the Tygon tubes to their respective connectors (Diag.

— ArwospHene

Diag.14

‘Check that the piercer does not touch the reagent tubgyvhen moving frontward and backward

inside the instrument.

ffic plug at the rear of the instrument.

= Connect the external barcode reader to the spe

é

<

z

<4 < 4d

reouence

pene

‘owen

[Ran

EXTERNAL BARCODE READER PLUG

RAA0O7 B Ind.A Page 2/11 18/01/99

2. INSTALLATION & STARTUP

Using the printerZinstrument cable included in the printer package, connect the printer input 2

(ee Diag,14) to the instrument output as shown on the instrument rear panel (Diag. 13).

Tighten the connector using the 2 metal springs located on each side of the connector (Diag. 13)

‘Check that the voltage indicatiof\shown at the rear side of the printer

corresponds to the laboratory voltige (Diag.14)

NEC PRINTER

Diag. 14

Using the printer power cable included in the printer package, connect the printer input 1 to the

laboratory main supply.

RAA0O7 Bind. A Page 2/12 18/0799,

2. INSTALLATION & STARTUP

2.5.3. Connection of the laser supply

Laser supplies are available under the following part numbers

XBA 367 AS : Laser supply 220V

XBA 368 AS : Laser supply 240V

XBA 269 AS : Laser supply 120V

XBA 370 AS : Laser supply 100V

XBA 373 AS : Laser supply 230V

a Nail

www) BAS) ponds J the main laboratory voltage

ere bers)

Diag. 15

1 = Grounding collar connection

= Unscrew the 2 nuts of the grounding

collar <1> and <2> of the supply cable

and controle cable (Diag.16) using a key

size 7 and an hexagonal key size 3.

= Connect the 2 cables on their respec-

tive connectors on the laser supply and

screw the 2 CHC 4x8 screws of the

grounding collars <1> and <2> on the

supply side plate (Diag.17).

The nuts are no more used.

Beware of pushing properly the protec:

tion sleeve next to the collar.

RAA007 B Ind. A Page 2/13 18/01/99

2. INSTALLATION & STARTUP

the cover on the side plate (Diag. 18)

Diag.18

2- Changing the supply\oltages

- The operation vdkgge setup (from 100V to 240V) is done using the primary terminal (white

wire) on one of the Xavailable positions (TAB 202 and TAB 203) located at the bottom of the

supply module on the Nagulator board and 3 banks of jumpers located on the power board fixed

vertically (Diag.19)

The different combinations Netween the primary terminal and the jumpers are resumed into

the table below.

7

6

‘OPERATION VOLTAGE Ea

Firor! | TAR20¥ commun a

back we, Paso : x % x a x * 7

inte wee | ——raseo9 tay x x x x

Table 1

2 examples are given on next page for a better understanding,

After having switched off the laser supply,

vention to allow a capacitor discharge.

RAA007 B ind.A

wait at least 1/2 hour before int]

Page 2/14

2. INSTALLATION & STARTUP

250-6 Top View

‘rap203

AB 202

0

oa

mans TAI

Diag.19

To

~ Replace top cover.

Example 1 : Setup to 240 Vac operation :

- Turn supply off and unplug from AC line. Un:

and remove top cover.

Locate the terminals TAB201, TAB202

placed on the bottom of the laser si

regulator board.

- Place the white wire on termi

- On the Power PCB placed

Bank #3

- place the 2 jumpegfon pair #3 together and pin

pair #4 together.

To trim the

and #2 on thy

fut Line Voltage, locate Banks #1

ower PCB.

= Jumpeyfne pin pairs according to the table. To

trim tg 240 Vac, jumper pin pair #4 together on both

Bank@it and Bank #2.

Gkample 2 : Setup to 100Vac operation.

Is

- Turn supply off and unplug from AC line.

- Unscrew and remove top cover.

= Locate the terminals called TAB201, TAB 202 and

TAB 203 on the regulator board.

= Place the white wire to the terminal TAB202.

- On the Power PCB, locate Jumper Bank #3

2 jumpers on the pin pair #1 together and pin pair #2 together.

the Input Line Voltage, locate Banks #1 and #2 on the Power PCB.

-JA trim to 100Vac, jumper pin pair #1 together on both Bank #1 and Bank #2.

RAAQO7 Bind. A

Page 215 16/01/89

2. INSTALLATION & STARTUP

3.4. Reagents to

A- AX DILUENT

The diluent container must be placed below the instrument level (under the bench).

lean the top of the diluent container before opening it. Remove the container

per and install the reagent straw equipped with the level detection and the

A

A

A

A

A

AN

AN

A

g upset? og Rar

Be aE i ut i

to of ene Se H ea

el Hunn d BEE

ome ys (NESE GH

| menue sume 0 0 6 6] i

| ae Hd QQ)

| ane et Sm rs oe ~

Rese Beet gue, SG soe

Diag.20 7

- Connect the level detection plug to the correspondigg connector of the rear panel (Diag. 19).

B- ABX Basolyse

- Clean the top of the ABX Basolyse container and open it

install the reagent detection straw with its rubber stopper. The

be placed at the same level than the instrument.

{emove the container stopper an

X Basolyse container has to

= Connect the other end of the Tygon tube to the ABX Basolyse coNgection of the instrument,

rear panel, and the ABX Basolyse level detection plug to the correspoWging connector.

C- Plugged-in reagents

‘ABX Basolyse, ABX CLEANER, ABX Eosinofix, ABX Retix : identify the bot

they are equipped with the rubber stopper. Return the bottle and firmly inset

corresponding position in the ejection tray (Diag.21).

make sure

= Check the reagent connections between the PENTRA 120 and the reception tray that

no reagent leaks,

RAAOO7 Bind.A Page 2/16

2. INSTALLATION & STARTUP

‘The waste container must be placéd below the instrument level (under the bench). Remove the

waste container stopper and ingfall the waste container straw (the shorter one) equipped with the

If the instrument has to be connected on a main laboratory computer, follow the procedure

described section 8 COMPUTER CONNECTION, contact the laboratory computer specialist to

achieved the connection.

RAA07 Bind. A Page 2/17 18/01/99

2. INSTALLATION & STARTUP

«6. STARTUP

X11. Printer startup

NEC PRINTER

EPSON PRINTER

Diag.22

After having checked

laboratory main voltage,

(Diag.22). Check that the

2.6.2. Laser power supply startup (VER)

Diag.23

at the voltage shown on the rear of the printer corresponds to the

Instrument startup and initializatior

Diag.24

MARCHE/ABRET

ONorF

SecTEUR,

ac IN

+

Ness the ON/OFF switch of the printer located below the front panel

AQWER and SELECT indicators are ON.

Check that the laser protection cover of

the laser optical bench is ON.

- After having checked that the voltage

shown on the rear of the laser power supply

responds to the laboratory main voltage,

s the ON/OFF switch and check that

foltage lamp is ON. Turn the key of

jer power supply located above the

‘switch to the position 1 (Diag.23).

After having checked that the

on the rear of the PENTRA’

Ponds to the laboratory main vol

the ON/OFF switch located on th

of the instrument (Diag.24),

RAA007Bind.A

Page 2/18

18/01/99

INSTALLATION & STARTUP

The LCD lights on and thinstrument

initialization starts (Diag.2§

Diag.25

2.6.4. Primary checks

o£

Jo

= When the initialization is completed, the

following screen is displayed (Diag.26).

- Carry out in the correct order the following

ae steps:

2 .

Diag.26

1 - Press the AIENU> key and move the cursor to the "MACHINE" function. Press

land move jhe cursor to the "ALARMS" function. Unvalidate all the chamber drain alarms.

[ESC> key to return to the main menu.

2 RKa manual blank cycle in order to check the possible leaks of pressure and vacuum.

3frress the key and run an "AUTOCONTROLE" cycle in order to check

1@ mechanical operations.

4.- Run reagent priming cycles, diluent first to prime the hydraulic lines. Check the correct

drainage of the chambers.

5 - Run several manual blank cycles and check that the reagent lines are correctly primed,

without air bubbles.

FAA0O7 Bind. A Page 2119 18101188

2. INSTALLATION & STARTUP

6- Run a general cleaning cycle and check that the results are within the specifications given in

the user's manual

7 - Return to the "ALARMS" function and revalidate the drainage alarms.

8 - For the PENTRA 120 instruments delivered with an EPSON laser printer, go to the function

> “LASER PRINTER INITIALIZATION of the "MACHINE" menu and validate.

in. a STARTUP cycle.

10 - RuNgeveral fresh blood samples, check that all parameters appear normally

ssh and normal blood sample 10 times and check that the repetabiliy is correct.

12 - Perform a Yelibration procedure as described in the user's manual.

RAA0O7 BInd.A Page 2/20

18/01/99

3. MECHANIC PRINCIPLES & DESCRIPTION

Content

3.1.GENERAL PRINCIPLES

3.1.1. Generalities

3.1.2. Cycle descriptions

3.2. STEPPER MOTORS PRINCIPLES .....

3.2.1. Generalities :

3.2.2. Absolute and relative homes

3.2.3. Home recovering

3.2.4, Programmable motion

3.2.5. Enter step number

8.2.6. Motors power off

3.2.7. Error acknowledge ...

© 000002

3.3. MECHANIC DESCRIPTION

3.3.1. Racks

3.3.2. Rack 10ader eon

A Rack loading tray ..

B - Rack shutters

CG - Rack retainers,

D - Stepper motor

E - Rack detection ..,

3.3.3, Rack rotation tray

3.3.4. Rack sampler J...

description ..

jotor

3.3.5, Ejection, = =

A Meghanical description

foper motor

Page 31 “18701799

3. MECHANIC PRINCIPLES & DESCRIPTION

Diag.

mechanical principles are used in the PENTRA 120 to provide the mechanical movements of

instrument parts

Stepper motors : Loading of the cassette into the rotation tray.

Rotation of the cassette into the rotation system

Movement of the piercer in front of the cassette

Ejection of the cassette into the ejection tray

Extraction of the sample tube from the cassette

Piercing of the tube stopper

Cleaning of the manual sampling needle

Activation of the commutation valve

Activation of the sampling valve

= DC motor

‘The movements of the cassett®into the instrument are a combinaison of the different principles:

1 -Loading cassettes : stepper motor

2- Rotation of the cassette to the sampling position : stepper motor

3- Movement of the piercer in front of tfie sample tube : stepper motor

4 Tube grabbing and extraction : air cylinders.

5 - Piercing of the sample tube stopper : alieylinder

6 - Re-insertion of the tube into the cassette air cylinder

7 - Rotation of the cassette to the ejection posifign : stepper motor

8- Ejection of the cassette : stepper motor”

TOADING

ROTATION

l EXTRACTION,

fl

PIERCING]

indB ~ Page a2

3. MECHANIC PRINCIPLES & DESCRIPTION

ycle descriptions

Pneumatical and mechanical cycles are controlled by 2 different processes

= R2D2 process controls the pneumatical cycle.

CYSPEO process controls the mechanical cycle.

‘The CYSPEO process can be considered as the "master" process, R2D:

‘These 2 processes are directly linked for the correct instrument op:

“attached” together as a pneumatical phase can occur during diffe

the "slave" process.

tions but they are not

it mechanical phasis,

Each process has different phases as follow

Pneumatical cycle

Phase A : Starting phase without priming

Phase A_XXX : Starting phase with specific priming

Phase B1_XXX : Sampling phase without measure

Phase B2_XXX : Sampling phase with measure.

Phase B3_XXX : Measure phase. >

Phase B4_XXX : Neutral phase without action

Phase C1_XXX : End phase specific to the,ahalysis type.

Phase C : End phase. 2

$

XXX : can be CBC, DIF or RET. Aa

ding to the analysis type.

The pneumatical cycle unfolds as f Bliow

fsSSETTE PNEUMATICAL CYCLE

A B2_20KB3_OKBA_YOXKCI_ OK _C

Diag.2

Each phasgias a duration of 30 seconds. The B_XXX phase corresponds to the analyses of

the tubegfn the cassette, the B1_XXX represents the sampling of the first tube, the B3_XXX

represofts the measure of the last tube of the cassette,

‘yh mechanical cycle includes the 2 cassettes A and B which can be loaded into the rotation

fystem. The cassette A is always loaded in the position 0 of the rotation tray (position which is

‘acing the loader after an home command of the rotation system, see Diag. 3), the cassette B

is loaded into the position 1 of the rotation tray.

‘The position 0 and 1 are identified on the rotation tray by 2 barcode labels, the barcode label 0

is facing the barcode reader when the cassette A is in the sampling position (see Diag.3).

WAAOOTAING.B Page 33 FeO

3. MECHANIC PRINCIPLES & DESCRIPTION

\

BAR CODE \

LABEL 1

NN

|

|

i] $

[+-CASSETTE 8

Diag.3

‘The mechanical cycle includes 4+1 phases as folow

- Loading cassette.

Cassette identification.

- Mixing cassette.

- Cassette ejection.

+ sampling phase (of the previous cassette) which may occur any moment of the 4 phases.

Each phase has a duration of 30 seconds. The mechanical cycles

fsssere AOA 08 ween wore eal aad] exces ta

baawree sone ele | adel a itl _

| HA

k }

ib g

iB

Diag.4

RAAOO7AIndB SSS Page

3. MECHANIC PRINCIPLES & DESCRIPTION

“The cassette identification includes a reading of the cassette barcode label as.

as a tube presence detection

NOTE

The mechanical phases sequence can be modified according to some special ever

aresampling request, or consecutive analyses of 2 different cassettes (CBC, DIFF,

which requires a specific priming cycle, etc

Pneumatical and mechanical cycles are combined as follow

fel

Diag.5

é

‘The diferent movements ofthe casspffe during the mechanical eycle phases are checked by

specific switches and End Of Run getectors (switches or optical detectors). Morover, different

cchecks occur during the oycle phases =

- Loading

‘Amechanical cycle can onj/tart if a cassette is detected into the loader.

‘An empty place should bgfavaitable into the rotation tray (0 or 1).

- Identification :

The reading of the

analysis type, the,

Tube presence

any probler

rcode label of the cassette should validate the cassette number, the

imber of positions of the cassette (10 or 15 tubes).

fs to be confirm by the tube detector.

‘curs during the cassette identification, the cassette is automatically rejected,

‘sampling

fing phase includes the following steps : reading of the tube barcode label, reading of

fe label of the rotation tray position (0 or 1), grabbing of the tube by the grabber, 1

fxing, reading of the barcode label of the rotation tray position (should be the same than

frst reading 0 or 1), re-positionning of the tube into the cassette.

problem occurs during the reading of the position barcode label, an emergency stop is

formed,

Pages TSOT9S

3. MECHANIC PRINCIPLES & DESCRIPTION

per motors are controlled by the stepper motor command board which is able to command

ferent movements. These movements are driven by 4 specific stepper motors under the

of different opto-detectors and micro-switches.

Run 2 (EOR2) giving the end of motion position.

stepper motor includes also a position encoder.

Sst

Diag.6

-S: Speed = X : Total number of steps t&pe reached

+ Sst : Starting speed SI: Speed level

- St: Final speed - Ra : Acceleration rate

+ Rd : Deceleration rate - Tol : Tolerance

RAA007Aind.B Page a6

3. MECHANIC PRINCIPLES & DESCRIPTION

‘The tolerance parameter acts as a security when an EOR sensor has to be reached. A generg

order of (X+Tol) steps is effectively executed and the stop at the EOR has to be ingfided

between the steps (X+Tol) and (X-Tol). This procedure is called Control by general

counting,

‘Several test programs are available to check the motor oper

applications are dedicated for maintenance purposes only

on these applications will be executed. None of the sect

be activated in these menus.

Each of the 4 axis (sampler, rotation, ejection, loading) is command

program accessible through the successive menus «MEN!

«ADJUSTMENTS»

ith a special «MOTORS»

», ASSISTANCE», then

Assistance’

I-statistics >

2-Recalculation

>

1-Calibration recordsy

2-Inter vention recongs

eagent. records

‘ontrol_ blood refonss

eLc ings:

2-Connection (°

A-Calibration

2-Open/closed tube

3-Hunan ‘blood

4-Control blood

5-Calibrator

6

gs

9

a

elles > | |) SR

Diag.7

‘Several commands are,

types are available :

failable to get different movements and various tests. 2 main program

sein

res y |

(Taree

= A program «MOTOR

MOVEMENTS: displaying on the

same screen the usual commands of

the 4 axis,

J-Internal barcode reading

2-Initiating internal barcode

3-Sensor reading

4-Hotor adjustment

5-Piercing needle movenents

8-Rotating system movements

?-E jectar novenents

B_Laading novenents

G-Grabber noverents,

A-Special cycles

ve

Diag.8

RAAQOTAIndB ~*~ TST Te0T95

Diag.9

Diag.10

3. MECHANIC PRINCIPLES & DESCRIPTION

PEP oe

3-Manual Sampling position

4-Cassette barcode position

S-Cassette position data capture

6-Tube present (cassette 19 tubes)

q ?-Tube

8-Hone

9-Turn clockwise thro 90 deg-

@-Turn clockwise thro 180 deg.

A-Turn clockwise thro 270 deg.

Ejector -

jection complete

Loading flaps

oe

~ 4 specific programs (1 for each axis) disblaying on the same screen for 1 axis the usual

commands as well as some special commands,

(ARTI

TORE

rae

TIM

WARNING : Before selecting an axN

ensure that this is mechanically

9,

osing

4-Opening / Closing

S-Hovenent. paraneterable normal dirs

B-Movenent. paraneterable opposite dir+

7-No. of steps data capture

8-Hone recovery adjustment

9-Disconnect motors

Q-Maintain ‘notor on full power

A-Acknouledge error

RAAOO7AindB

Page a8 —FBOT78

3.2.2. Absolute and relative homes

3.2.3. Home recovering

Programmable motion

3. MECHANIC PRINCIPLES & DESCRIPTION

2 different figures can be described

The motor has always the same motion from the starting point up to the EOR,

ponds to the maximum amplitude. In such a case, the final speed is always the

exact number of steps can be easely calculated. The motor home can

home. This is the case of the loading motor, rotation motor and ejection

- The motor has different motions according to the previous starting poi to reach the EOR. In

such a case, speeds and phasis durations are calculated automatically afcording to the requested

motion. As a matter of fact, when a home detection is requestedflhe final speed when the

home is reached, can be different according to the motion durgfon. This can lead to some

slight differences in the final stop position. In order to avoid fis problem during automatic

cycles, the home reading is done according to the previous rybtion. Final speeds to the home

are then constant and this is call relative home detection/This is the case of the sampling

motor.

‘Only the first home detection at the instrument startup jf an absolute home detection.

During the return to home phasis, the stepper Jnotor turns until the sensor change its status.

“The motor stops at his moment. However, a stg in such a position very ctical can be dangerous

as the sensor may easely change its statusibrations for exemple). In order to make sure that

this problem will not arise, the motor is ABt stopping at the sensor detection, but few motor

steps further. o

This fixed number of steps is named “home recovering». It is adjustable through a mainte-

nance program. A minimum valug 1S mandatory. Moreover, in order to cancell the sensor

mechanical agjustments (index, a etc..., the «zero» position is corrected when adjusting

this recovering value.

This movement activatey/a motor «step by step» with a repeated pressure on the «ENTER»

ints are possible corresponding to the rotation direction of the motors.

foorresponding to 1 pressure on the «ENTER» key is programmable

foommand when validated, stops the electrical supply of the 4 motors. This command

Wws the manual motion of the 4 axis during mechanical adjustments for exemple.

During a motion, a problem may occur and an error message is displayed. It appears in the

message window on the right handside of the screen. As instrument is blocked, itis necessary

to press the «ENTER» key to acknowledge the error and to be able to continue. If several

errors occurs simultaneously, it is sometimes useful to acknowledge them all. This can be

done in the «ERROR ACKNOWLEDGE» command.

RAAOTAInd.B - “Page 38 TeOWS8

3. MECHANIC PRINCIPLES & DESCRIPTION

[CHANIC DESCRIPTION

3.3.1, Radke

The sample rack holds 10 to 15

piercable (rubber-stoppered)

‘specimen tubes.

Each rack is identified by means

of a barcode label located on the

bottom part of the rack.

One rack holds the same type of

requested results : 5 part

differential result or cell blood

count only

Different sample racks can be

mixed in the rack holder.

Diag.11

Presence of specimen tubes in a radk is detected by an optical system including an emission

transistor and a reception diode. 5

Each tube contained in a rack is identifietgby its position in the rack and by its barcode label

%

8,

Racks are made of special plastic algwing a perfect cleaning and desinfection

NOTE | Most of the cleaning products can be Wged such as bleach, alcohol or solvants,

‘do not place sample racks into heated steNjzer as high temperature may

1

CAUTION! | provoque a loss of shape.

3.3.2. Rack loader

‘The rack loader is constituted with

~ rack loading tray

a stepper motor with its reduction gears and home detection device

-2 rack shutters

+2 rack retainers

~ 3 microswitches to allow a rack presence and faulty position detections

The rack loader mechanical adjustment is described in the maintenance procedure : RAS 10

A.

z

Z|

5

ind.

3. MECHANIC PRINCIPLES & DESCRIPTION

A Rack loading tray

The rack loading tray holds up to 13 sample racks which gives a minimum of 1

tubes and a maximum of 150 sample tubes to be analyzed on a «walkaway» modgabout one

hour without operator intervention). Sample racks can be added in the loading yy at any time

without stopping the instrument operation.

The rack loading tray is designed in a way that itis impossible for the opgtor to load sample

racks improperly. Sample racks have to be loaded with their identiicayn number facing the

front of the instrument,

B - Rack shutters

“The rack shutters located at the bottom of the rack loading tray,

loading tray to the rotative tray (rack mixer).

pw the rack transfer from the

C- Rack retainers

2 rack retainers are associated to the rack shutters ar

to allow only the passage of the bottom rack of the

fare activated when the shutters open

Page 3/17 _ ~F8/07799

3. MECHANIC PRINCIPLES & DESCRIPTION

D- Stepper motor

The loading tray stepper motor allows the bottom

rack of the pile to be loaded in the rotation tray.

This motor turns always in the same direction

and has an home given by an index and an

optical detection.

The motor home position is detected by an in-

trated detection cell located at the rear of the

loading tray. The home detection index is located

on the motor gear (see Diag.13).

The rack loader stepper motor is controled by

the JCM340 board through the stepper motor

command board. It is powered through the

stepper motor power board (see Diag. 14).

Diag. 14

FAAOO7 And.

Page 3/12

TeOT55

RAAOO7Aind B

Diag. 15

Diag.16

3. MECHANIC PRINCIPLES & DESCRIPTION

E- Rack detection

1; Rack presence detection

Flack presence detection is done with the 2 microswitches located at the bottom font of the

loading tray (see Diag.15). These 2 switches have to be OPEN (no rack) or CLOSED (racks)

simultaneously for a correct rack detection

2» Rack position default

ion

A third switch allows the default detection. Itis situated above the left handside presence

detection (see Diag. 16]

age 07705

3.3.2\Qack rotation tray

Diag.17

3. MECHANIC PRINCIPLES & DESCRIPTION

‘A- Mechanical description

he rack rotation tray allows the transfer of the cassette from the loading position to the sampling

ition. The rotation tray has 4 stopping positions according to the mechanical cycles

Cadgette loading position.

e identification position,

= Tube ddgbbing position.

- Cassett\jection position.

The rack rotatyp tray has a rotative axis which holds 2 sample racks, The rack rotation speed

is XXX turns peNQour approximately.

‘The rotation tray meWpanical adjustment is described in the maintenance procedure : RAS 102

B - Stepper motor

The rotation tray stepper motoPallows the mixing of the rack samples before piercing, It allows

also the correct stop in the piercin@ position. This motor turns always in the same direction and

has an home given by an index ané an optical detection located on a detection wheel.

The rotation tray poston is detected ysng the 4 slots in the detection wheel and an optical

detector (see Diag.17) %

1 - Home position detection 2 - Tray position detection

RAAOOTAInd.B Page 3/14 TSS

Diag.18

3.3.3, Rack sampler

3. MECHANIC PRINCIPLES & DESCRIPTION

‘The rotation tray stepper motor is controled by the JCM340 board through the steppey

command board. It is powered through the stepper motor power board (see Diag. 18)

ROTATIVE TRAY COMMAND.

sierra

Toro :

rower

soanD AN) one

Jom oro — posmon

340 coum NN cornot

oan

‘A- Mechanical description

‘The rack sampler which is mobIfé from the back to the front of the instrument includes the

following devices =

The manual sampling neg

- The sample tube grab!

- The piercing needle

The commutation v

- The sampling va)

~The short samy

The barcode

le and its rinsing mechanism.

fh its rinsing mechanism.

/e between manual and automatic sampling,

detection photocells C1 and C2.

er.

A sampler carriage

- 2 EOR detection photocell

‘The sampler mechanical adjustment is described in the maintenance procedure : RAS 102 A.

RAA007 Aind.B Page 3115, 7810793,

3. MECHANIC PRINCIPLES & DESCRIPTION

EOR2

0

Endless screw

ENCODER

Diag.19

B- Stepper motor Ww

4

The stepper motor drives the sampler(arriage to the correct sampling position for the tube

piercing. The associated encoder control Poston of each carage stp below the sampling

tubes.

The EORI gives the rotation position for Hiren tray and the EOR2 gives the manual

sampling position.

‘The sampler stepper motor is controled by thé JCM340 board through the stepper motor

command board. It is powered through the steppé\motor power board (see Diag.20).

Bus

cPU STEPPER

om. fet MOTOR

coumano

340 BOARD

ASE Wo.

painreR BoaRo]

oisTABUTION

BOAR

Diag.20

RAAOO7AIndB SS Page

3. MECHANIC PRINCIPLES & DESCRIPTION

3.3.4. Ejection tray

A- Mechanical description

flection tray mechanism includes

9.21) :

1 - An ejection carriage.

2- A “ray full” switch.

3 - An endless screw.

4 - Astepper motor.

5 - An Home switch.

6 - An EOR switch,

7 - An ejection shutter with its drive

cable and shutter switch.

‘When the ejection starts, the ejection carriage

catches the rack on each side by the slots of

the rack and extracts the rack from the rota-

tion tray (Diag.22).

‘As the ejection shutter is linked to the ejection

carriage, when the carriage starts to move,

the shutter drive cable lifts up the ejection

shutter to allow the ejection of the rack.

AA stop retains the rack into the ejection tray

when the carriage moves back in its home

position.

When the carriage reaches the EOR switch, the tray full switch has been already activated.

When the ejection tray is full, the carriage cannot reach the tray full switch and the tray full

alarm is triggered (Diag.23). The remaining space on the ejection tray allows to receive the 2

additional racks contained in to the rotation tray. The piercing mode then automatically stops.

RAA0O7 Aind.B 7 Page 3117 T8019

3. MECHANIC PRINCIPLES & DESCRIPTION

Diag.23

B - Stepper motor

‘The stepper motor drives the ejection carriage from the rotation tra\\to the ejection tray. The

stepper motor is controled in 2 phases :

~ the first step requires a low speed and an important torque in order to Move the cassette

from the clips of the rotation tray.

- the second step requires and lower torque but an increased speed to push the Agsette on the

ejection tray.

The ejection stepper motor is controled by the JCM340 board through the step

command board. It is powered through the stepper motor power board (see Diag. 24).

RAAOO7AInd.B Page 07105

Diag.24

RAKOOTAInG.B

3. MECHANIC PRINCIPLES & DESCRIPTION

EJECTION TRAY COMMAND

SONA

JOM

BOARD L

ee

ref exeren an

fee} ay FUL

ee}

TION SHUTTER

C - Ejection shutter

The ejection shutter is a protection for the opegator to prevent any object introduction during

the rotation of the cassettes. The shutter opgtis only when the rotation tray is stopped in its

ejection position. The closed position is deigtted by a switch,

e y

a

Page 3/18 Te0T793

4. ELECTRICAL DESCRIPTION

CONTENT

4.1, POWER SUPPLY MODULE.

4.1.1, Description ener

4.1.2. Main supply socket

4.1.3. Main suppiy filter...

4.1.4. Toric transformer

4.1.5. Power supply board

4.1.6. Cooling fan

4.1.7. Vacuumipressure board

4.2, BOARD LOCATIONS PENTRA 120 VE

4.2.1. Mother board PENTRA 120 VE ir

4.2.2 OD signal and OD preampliter boards 8

4.2.2. Peumatical door area (backside) ......¢2....

4.2.3. Instrument backside area rs

4.3. BOARD LOCATION PENTRA 120 VEC ANS VER ..

4.3.1, Mother board PENTRA 120 VEC land VER.

4.3.2. OD signal board nnn

4.3.3. OD preampliter board

4.3.4, Pneumatical door area (b

4.3.5, Laser bench board -

4.3.6. Instrument backside aga.

4.3. INPUTS/OUTPUTS 16

4.4, FLAT CABLES AND WIpAIGS se a 16

INECTION DIAGRAM 66

Page 471 TsI0T798

RAAT Bind.

4, ELECTRICAL DESCRIPTION

4.1. POWER SUPPLY MODULE

‘The PENTRA 120 power supply is a complete module providing required supplies to the different

parts of the instrument. It also provides aperture currents for the blood cell counts and the 5V

logic voltage. It also controls the vacuum and pressure signals through the vacuum pressure

g2"d located in the module.

‘The power supply module can be operated separately from the instrument.

The maxitlqm usable power is 800VA. Instrument needs a maximum power of 750VA in peaks.

The module Weltage selector allows the instrument operation under the following voltages (50/

60Hz) : 100V, ov, 220v, 240V.

‘The power supply module’

-a main supply socket,

a main supply filter q

a toric transformer ¢

- a power supply board +

~ a cooling fan Q

a vacuum/pressur board SS

in supply socket y

- The main supply socket is equipped with the @N/OFF switch, 2 primary fuses and a voltage

selector,

When instrument is operated on 100/120V, main

When instrument is operating on 220/240V, main fu

'S Must be BA, slow-blow 120V.

Must be 4A, slow-blow 250V.

Main supply filter

- A large band main supply filter is installed in the module to

luce the electrical interferences.

This shielded fiter is located behind the power supply board!

4.1.4. Toric transformer

toric transformer provides the secondary voltages. This transform is equipped with a ther-

‘mal protection switch and gives the following secondary voltages :

120Vac for the compressor supply through a compressor relay (K‘1).

150Va¢ for the aperture currents.

~ 30Vac for the electrovalve operation.

~ 30Vac for the heater supplies.

30Vac for the SV logic supply.

30Va¢ for the 8V optical bench lamp supply.

22Vac for the +18V/ -18V for the preamplifier boards and the linear regulators.

~ 30Vac for the +12V logic and hard disk drive supplies.

= 25Vac for the -24V (Pump motor driver board) and the -12V (RS232/FIFO printer boar

RAAO07 Bind. A Page 472 1801789

4.1.5. Power supply board

‘The power supply board includes :

4, ELECTRICAL DESCRIPTION

- Switching power supplies which provide the different direct and filtered supplies requyéd for

the instrument operation

* +5V logic voltage.

Ji

Diag.1 ¢

fev]

Lane

AA 007 B ind.A Page 4/3

TeOTS

4. ELECTRICAL DESCRIPTION

* +12V logic voltage / hard disk supply.

[Frey]

* 424V electrovalve supply. -y

The switching supplies are protected in short-circuits, the +5V athe +12V

NOTE | are over voltage protected

RAA0O7 Bind. A Page 414

4, ELECTRICAL DESCRIPTION

* 424V heaters and robotic transfers.

Jo

Fo) fam

| ae

| Teese] oat robotic

| LEILTER

ba

Diag.5

- Linear power supplies and high voltages for the gferture currents : +60V RBC aperture

current, +60V WBC aperture current, +100V BASQAAperture current, and +60V LMNE aper-

ture current

a0

VAG-PRESS Board

XAAI26

Pi

Page 45 e019

4. ELECTRICAL DESCRIPTION

* +18V/-18V for the preamplifiers :

Diag.7

* -24 for the SDIFF pump motor ©

*-12V for the RS232 +,

te

Diag.8

RAA007 Bind. A Page 416 Te0T95

4. ELECTRICAL DESCRIPTION

- Electrical connectors directly installed on the board to reduce the electrical wirings meaning

less possible electrical interferences.

* J5/S7/58

Vo%e@ |:

ore ®

\@ @ @

he cove hh» |

5

@

(CURRENTS: ‘AND BARCODE READER. 38 TO FANS

oe

* S29

aN WN

2D 1a ® ON

On ey (5) 62 o fa) Oh BY 2

Retey) HEY NOY) Ct aoa aoa Naga

A a “4 1 e or (7 4 ae

By Oo? 5 O® @ Gy

/J2 To oreamoli boards + (J9 From rectifiers:

peta z

_

wd

9 wn

azavy \yaavay gay \ 38

favs)

a\(e\ (mw) (1m) (18%

seve Nava’ \yzave’ avn’ av) \ aay /

a \(7\(" 6 1g) (23

\ezava’ \ezava! Sezeval Gi \ te) stay

(6) (Ce) C8) (PY (ae

wn Neon Naan ti) Gai) say

J1 To hydraulic / pneumatic door

Fa70T798

4. ELECTRICAL DESCRIPTION

Diag. 13,

tn OW.

8

sai) 0)

5 19 4

a) ain) av

go -

rH) (45

%

ie

TB) (16

J8 To mother Bard

7

“sv

21

204,

(2

2

sy

24

aw

“sn

Diag.14

RAA007 Bind. A

“Page 4/8

TB10T793

4. ELECTRICAL DESCRIPTION

= Control LEDs for each of the provides electrical supply, associated with a test point, a protec,

tion fuse and an adjustment potentiometer.

‘A commun ground point for all test points and adjustments,

Test points are for control only, they should not debit

(oscilloscope or amperemeter are prohibited).

- Fuses characteristics are as follow :

Fi: 3.18A 250 Siow biow

F2: 315A 250V Slow blow

F3: 2.58 250V Siow blow

Fa: 6.3A 250V Slow blow

F5: 10A 250V Slow blow

F6: 0.2A 250V Slow blow

F7: 1,254 250V Slow blow

FB: 1:25A 250V Slow blow

F9: 1.254 250V Slow blow .

$

Fi2andF13: For 220/240V : 4A 250V glow biow

For 110/120V : 8A 250\Siow blow

a

é

Voltage selector positions

1: 100V

120V

-3:220V

4: 240V

RAAOO7 Bind. A Page 419 180195

4, ELECTRICAL DESCRIPTION

Cooling fan

The power supply module cooling fan is supplied in +12V and is located at the rear of the

module. This fan aspirates air from the bottom of the instrument through the removable dust

filters

Diag. 15

1 - Cardcage fan

2 - Cardeage fan

- Power supply module fan

Compressor fan

4.1.7. Vacuumipressure board

Purpose of the board :

~ Transforms vacuum and pressure into analogie signals.

- Drives the front panel LED signals.

Drives the compressor command signal from interface board to compres

Board description and strap position : see Section 6.

RAAOO7Bind.A Page aio Ta0T99

4. ELECTRICAL DESCRIPTION

4.2. BOARD LOCATIONS PENTRA 120 VE

4.2.1. Mother board PENTRA 120 VE

| | E

(Ss) |e)

S ,

Fe (ie

3 |e

Seer E

14 13° 12 WW 10 9g 8 7

1 JOM340 CPU board

2 RS232 FIFO printer board 9 -Pulse #1 board

3 - Interface #1 board 19° Pulse #2 board

4- Interface #2 board oft - RBC/WBC/PLT/HGB board

5- LCD board $12 Resistive BASO signal board

6-Free P 13-Free

7- Pump motor driver board 44-14 Stepper motor command board

SCSI adaptor boar and SCSI hard disk drive are located in the slots on the far

NOTE | right of the mother board.

4.2.2. OD signal and OD preamp!

1 - OD signal board : This board is located

on the right hand side of the mother board,

next to the pressure and vacuum adjustment

knobs and is identified with its 2 holes giving

access to the absorbance signal and

reference potentiometers (see Diag.17)

[i

2 - OD preamplifier board : This board is

located on the top of the optical bench in

RAA007 Bind.A Page ait TSOTSS

4. ELECTRICAL DESCRIPTION

neumatical door area (backside)

1+ Preamplifier #1 board

2 - Preamplifier #2 board

3 - Temperature control board

4- Cell board

Diag. 18

4.2.3. Instrument backside area

Stepper motor power board : This board can be seen

when the instrument back panel on the left handside

['Ws,removed. Its located next to the vacuum/pressure

tabs (Diag. 19).

%,

Vacuumipressure board : ING located at the bottom

part of the power supply modi¥e. This board can be

| seen from the left handside of We instrument when

the cover is in its upper position (Neg.20)..

RAAOO7BInd.A Page ait 1807799

4.3. BOARD LOCATION PENTRA 120 VEC AND VER

4

1, Mother board PENTRA 120 VEC and VER

4. ELECTRICAL DESCRIPTION

CI

°“Weuls

es

I

J

I J

“Gaal

ra I

M4 13°12 «11 «10° 8

Diag.21

1 - Stepper motor command board o

2 Pump motor driver board $

3 - Fluologic board (VER or Free (VEC) .>*

4 Alarm board s

5 - Pulse #1 board

6 - Pulse #2 board

7 -RBCIWBC/PLT/HGB board

v

8 - Resistive BASO signal board

9 - Interface #1 board

10 - Interface #2 board

41-LCD board

12 - JCM340 CPU board

13 - RS232 FIFO printer board

14- Free

NOTE

4.3.2. OD signal board

FAA007BInd.A

Page aia

This board is located on the right hand

side of the mother board, next to the

RETIC laser bench location and is

identified with its 2 holes giving access

to the absorbance signal and reference

potentiometers (see Diag.22).

T8019

4, ELECTRICAL DESCRIPTION

3-3. OD preamplifer board

OD preamplifier board : This board is located on the

top of the optical bench in order to receive the optical

ss signal given by the optical flowcell (See Diag.23).

Preamplifier #1 board

- Preamplifier #2 board

3 “femperature control board

RAKOO7BIngA TOT

3

4, ELECTRICAL DESCRIPTION

4.36. Instrument backside area

\Vacuum/pressure board : itis located at the bottom

part of the power supply module. This board can be

J) seen from the left handside of the instrument when

the cover is in its upper position (Diag.27)

RAAOO7 Bind. A “Page 415 1801789

4, ELECTRICAL DESCRIPTION

.3. INPUTS/OUTPUTS,

PENTRA 120 instrument has different Inputs/Outputs facilities. From the rear side (Diag.21)

can be connected

1 - An external barcode reader

2- A graphie printer

‘An external computer through a RS232 output

modem through a RS232 out put

SCSI device such as an external SCSI hard disk drive.

LN

As

A

i i iy

= i

Diag 21

- An IBM PC type keyboard may ajso be connected instead of the integrated keyboard without

modification. ¢

4.4. FLAT CABLES AND WIRINGS a

8

For an easier troubleshooting action, all"fat cables and wirings in use in the PENTRA 120

instrument are described in the following pais with their connecting diagrams.

<

DESCRIPTION © RGGeeE

Cable _| Barcode and scanner cable DAC 016 A

Fat | Res-BASO signal board RBC-WBC-PLTNGB signal board | Gap ogi a

WBC-RBC-PLT-HGB board/Pulse board DAD 082 A

BUS SCSI DAD 083 A

SCSI adaptortioppy disk drive DAD 084 A

CPUILCD board DAD 085 A

Display/LCD board DAD 086 A

Matrix keyboard/LCD board DAD 087 A

‘Stepper motor power boardimotor command board AD 088 A

Cell board/alarm board Dp 089 A

RS ovtowRS printer board DAD 90 A

Vacuum-pressure boardiinterlace board DAD os

Barcode distribution board/RS printer board DAD 092

Vacuum-pressure board/power supply board DAD 097 A

Backlightmatrix keyboard DAD 101A

RAA007B ind. A Page 416 1801/55

4. ELECTRICAL DESCRIPTION

DOCUMENT

DESCRIPTION

Wirings | Pneumatic door wirings

Preamplifier boards/Power supply module

Mother board/Power supply module BA 284 AS

Power supply module/Front boards XBA 285 AS

Floppy-Barcode-compressor-reagents XBA 286 AS

Power supply module/rectifer bridge XBA 287 AS

Power supply module/compressor XBA 288 AS

HGB assy XBA 289 AS

Pump motor filter board/pump motor g XBA 290 AS

Tube presence and cover LED XBA 291 AS.

PC keyboard and vacuum-prgsGure board XBA 293 AS

‘Stepper motors oe XBA 294 AS

tegrated reagents © XBA 295 AS

Piercing carriag XBA 296 AS.

Optical fowc output XBA 302 A

Blood dgfction cel XBA 304 AS

1 M2 stielding XBA 307 AS.

XBA 308 AS

Barcode/tube detection XBA 309 AS

WBC electrodes XBA314 AS

Cell boardichamber XBA319 AS

DESCRIPTION MBER

Compressor cable XCA 179 AS

BASOLYSE heater assy XDA 499 AS

RAAQO?BIngA ~~~ Pageaiy———SSCSCSCSC~S~S«w OTTO

4, ELECTRICAL DESCRIPTION

DAC 016 AS Ind.A : DISTRIBUTION BOARD - BARCODE

D

J1-DISTAIBUTION BOARD

uaewe/e

(FEF ALCATEL: 012 04 88 oF EF ALCATEL: 6012 01 98 0)

NOTA: Respecter le cablage de 1 vers 1 (pas d’affectat:

de couleurs)

1/0 PORT-BAR CODE SCANNER

Modification

Désignation: CORDON SCANNER CODE A BARRES

DACOIEA

Ind Modif: A

REF du document: DACOIGAS

Plan dessiné le: 26/04/94 | Par: A. DA COSTA

Ge plan est 1a propradté on ia société sBX et ne peut Sire reproguit ov commnlaud sane outer iaation

RAAOO7B Ind A Page 4716

18/07/89

4. ELECTRICAL DESCRIPTION

DAD 081 AS Ind.A : RESISTIVE BASO SIGNAL BOARD - RESISTIVE SIGNAL BOARD

Long. de coupe 70 nm

‘Conducteurs 40

en

P3 PI

J3_RES-BASO [) Y8_RBC-WBC-PLT-HGB

SIGNAL BOARD 4] fag >=| SIGNAL BOARD

HE10-F 10 He 10-F 10

NOTA: se rétéref a 10 procédure de fabrication des limandes : ACFOI3A

x [967077

fin [om | 03; Modification

fon: CIWANDE RES-BASO ‘DADOSIA

Ind Modif: &

Plan _dessiné le: 01/03/94 | Par: A. DA COSTA 2

foe alan est 10 propriété de Ta société ABK et ne peut Btre repraduit ou communiqué i

RAA007 BInd.A Page 419 E1019

4. ELECTRICAL DESCRIPTION

DAD 082 AS Ind.A : RESISTIVE SI

IGNAL BOARD - PULSE BOARD FLAT CABLE

Conducteurs 10 J

ce B

ss =

ao @ @

2a 7 Ss

38 77.00

eF eee

55 ww

aa P6/) Pa Sa

od za

3g ay be aa

tT cae

ae = ae

ce 4 _

on vetorio Vy HEAO-F10 35

$5 swe + sumoue

S

%,

NOTA: Se référer 3 1a procédure de fabrication ges 1¥enaes : ACFOISA

A }96/07/34] Création. =

fin [ow] bate ogi fication

Désignation: LIMANDE RES/BASO-GA-HB DADOB2A

PLA-GB Ind Modif: A

REF du document: DADOS2AS.

- Nore 4

Pian dessin le: 04703/94 | Par: A, DA COSTA piagnoatica

Te plan est 1a propriété ae Ta société Ask

FAA 0076 ind. A

‘et ne peut kre reproduit ou Comminiaué sans autorisation

Page 4/20 TSOT95

4. ELECTRICAL DESCRIPTION

DAD 083 AS Ind.A : SCSI ADAPTOR 6 SCSI OUTPUT FLAT CABLE

anaino 1898

wag CISK

Pe

Pa

ouvoe vorvidvay 1s9s-2r

re10-780

fo bet Rr ret TON

Bian gaas iad Te 07 eae [Bark Ga COSTE

By | ge

aa Eb

ei 7

i i

|g

\ Ig

1/4

Ha

We

RAAKOOT Bnd. A

Page 4/27

4. ELECTRICAL DESCRIPTION

DAD 084 AS Ind.A : Floppy-SCSI adaptor flat cable

STO Aadons-er

Ca

ih di 4]

‘uvos ovewor nao-er

"BETO CEMANGE FLOPPY-AGAPTATEDR S051

OATS [Bara GR EOSTE

Pian gessiné- Te

FEE ay eocunent OMOSERS

RAAOO7BInd.A

Page 422

Te0T99

4. ELECTRICAL DESCRIPTION

DAD 085 AS Ind.A : CPU-LCD flat cable

| |

|

| 2

2

g

| 3 e

z &

J] 2

2) gS 8

al) is 8 g

a2 | |g 8 z

8B Bas ae

q13) =

gigsa ae < }

Hage g &

3 é

| 8

+

>

2

| °

| ¥| i

4) 3

nota: se rgfrer & 18 crocésure de Faorication des Tamances > ACFOISA

[args

3 Wea LESE ION

f-ion: CIMANDE CPU-LCD i DADOBSA