Professional Documents

Culture Documents

Atb 011

Uploaded by

tejonmxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atb 011

Uploaded by

tejonmxCopyright:

Available Formats

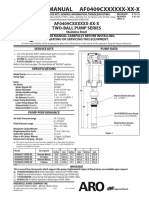

Technical Bulletin #011

Transmission: F3A/KF100

Subject: No movement after rebuild

Issue Date: May, 1990

F3A/KF100

No Movement After Rebuild

Torque Converter Pads

The torque converters used with the F3A/KF100 transaxles are available with two different pad heights. The two

pads have a 3 mm (.120") difference in height. If you use a torque converter with the shorter pads, it reduces the

amount of spline contact, on the pump drive shaft.

If you have an F3A/KF100 that won't move, check the line pressure. Normal line pressure is 43-57 psi.

If there is no line pressure, remove the pump and pump drive shaft. Put the pump drive shaft back into the

transaxle, but just enough to contact the splines in the torque converter. The pump drive shaft shouldn't turn. If it

does, the splines in the torque converter are stripped. Remove the transaxle and check the torque converter

mounting pads. They may be the wrong height.

The long mounting pad has a grove on it.

Copyright © 2003 ATRA. All Rights Reserved. ! Page 1 of 1

You might also like

- White MA30-MA50 Operator ManualDocument277 pagesWhite MA30-MA50 Operator ManualОлег СкладремонтNo ratings yet

- PANTERA 1500: Technical Specification 03515-3 2003-08-13Document4 pagesPANTERA 1500: Technical Specification 03515-3 2003-08-13Martín VarelaNo ratings yet

- 10 Automatic Transaxle System PDFDocument65 pages10 Automatic Transaxle System PDFcorporacion corprosinfroNo ratings yet

- White Fork Lift Ma30 Ma50 Parts Operation Maintenance ManualDocument20 pagesWhite Fork Lift Ma30 Ma50 Parts Operation Maintenance ManualJames100% (46)

- Bulletin - 610 - JUN13 BLOWERS PDFDocument8 pagesBulletin - 610 - JUN13 BLOWERS PDFJuan David Muriel CastilloNo ratings yet

- F1 Service ManualDocument14 pagesF1 Service ManualArko Roos100% (1)

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- Flexible Shaft MachinesDocument2 pagesFlexible Shaft MachinesArnold StevenNo ratings yet

- Turffontein Corridor MP Items Backlog&CIP Upgrades 2014-08Document5 pagesTurffontein Corridor MP Items Backlog&CIP Upgrades 2014-08david selekaNo ratings yet

- Bomb HDR f1Document14 pagesBomb HDR f1Denis Chui MamaniNo ratings yet

- MT PDFDocument103 pagesMT PDFDomingo Arias Feliz100% (1)

- Amb 1050 Fme-U / 1050 Fme-U DiDocument2 pagesAmb 1050 Fme-U / 1050 Fme-U DisthollanderNo ratings yet

- Motor CharlynDocument47 pagesMotor Charlyngleisongg86No ratings yet

- Manual Caja Automatica Chysler A413-3 Velocidades PDFDocument188 pagesManual Caja Automatica Chysler A413-3 Velocidades PDFfernandoNo ratings yet

- Class 10000 Fans Owners ManualDocument19 pagesClass 10000 Fans Owners Manualshivakumar bairojuNo ratings yet

- Specifications PDFDocument4 pagesSpecifications PDFrisal doNo ratings yet

- Underwing Nozzles: Carter Ground FuelingDocument12 pagesUnderwing Nozzles: Carter Ground FuelingHenryNo ratings yet

- Amc CrowerDocument3 pagesAmc CrowerPablo Etp100% (1)

- Hot Water High-Pressure Cleaner: Standard EquipmentDocument1 pageHot Water High-Pressure Cleaner: Standard EquipmentHow to channelNo ratings yet

- Industrial Bolting SolutionsDocument16 pagesIndustrial Bolting SolutionsChristian AcrNo ratings yet

- Dayton Axial EspecificacionesDocument32 pagesDayton Axial Especificacionesmanuel cabralNo ratings yet

- MANUAL BOMBA MARCH-TE - 7,5kDocument2 pagesMANUAL BOMBA MARCH-TE - 7,5kjoseNo ratings yet

- Technical Service Information: Acura Legend With G4, L5 & Pl5X TransaxlesDocument4 pagesTechnical Service Information: Acura Legend With G4, L5 & Pl5X TransaxlesCarlos MontielNo ratings yet

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionjo_cfo257388% (17)

- 08a Airetool HoseDocument1 page08a Airetool HoseNestor Junior LarezNo ratings yet

- Cofimco Fan ManualDocument8 pagesCofimco Fan ManualShivakumarNo ratings yet

- Tamrock Pantera 1500 SMDocument3 pagesTamrock Pantera 1500 SMRaul Apaza Lujan100% (1)

- U340 Manual PDFDocument25 pagesU340 Manual PDFOliverFrancoCruzAranibar100% (2)

- B WI C200-C1000 Non-Bolted Combustor Liner ReplacementDocument17 pagesB WI C200-C1000 Non-Bolted Combustor Liner ReplacementJefferson Mosquera PerezNo ratings yet

- Keystone Atuador de Dupla Ação Pneumático PDFDocument8 pagesKeystone Atuador de Dupla Ação Pneumático PDFdiforaNo ratings yet

- Rcrit 10e019 1234Document12 pagesRcrit 10e019 1234alvinNo ratings yet

- FD FanDocument42 pagesFD FanJAYKUMAR SINGHNo ratings yet

- F 416 Ex Compressed Air Motor EnglishDocument4 pagesF 416 Ex Compressed Air Motor EnglishUriel LvNo ratings yet

- Falcon Die ProfilerDocument21 pagesFalcon Die ProfilerDavid ScribnerNo ratings yet

- 30RH & 32RH Automatic TransmissionDocument90 pages30RH & 32RH Automatic Transmissionapi-26140644100% (15)

- Lp51 54 PressDocument23 pagesLp51 54 PressKyle McdonaldNo ratings yet

- Atb 016Document1 pageAtb 016tejonmxNo ratings yet

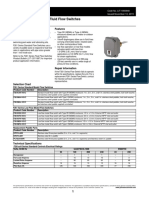

- Johnson Controls F261 DATASHEET 11-2015Document2 pagesJohnson Controls F261 DATASHEET 11-2015Ardian P NoviatmokoNo ratings yet

- Float Type Level SwitchDocument8 pagesFloat Type Level SwitchRupesh Kumar SINGHNo ratings yet

- Eaton Truck Components Bulletin: TRIB-9712Document2 pagesEaton Truck Components Bulletin: TRIB-9712Adal VeraNo ratings yet

- TZ, TZE, TZB Desiccant Compressed Air Dryer Technicians GuideDocument30 pagesTZ, TZE, TZB Desiccant Compressed Air Dryer Technicians GuideJoel100% (1)

- GMN2Document24 pagesGMN2maqvereNo ratings yet

- Reciprocating Compressors-HIT Dryers - ENGDocument16 pagesReciprocating Compressors-HIT Dryers - ENGJavier Moctezuma MNo ratings yet

- "A" Series: Gas MetersDocument4 pages"A" Series: Gas Meterszeeshan tanveerNo ratings yet

- Allison Transmission Oil Change IntervalDocument28 pagesAllison Transmission Oil Change IntervalJeremy Martin0% (1)

- Single Inlet Centrifugal FanDocument43 pagesSingle Inlet Centrifugal Fan4uengineerNo ratings yet

- Planos Electrico Champion KB44Document195 pagesPlanos Electrico Champion KB44mitchellltdaNo ratings yet

- Fisher 1301F1 O&MDocument8 pagesFisher 1301F1 O&MjoshNo ratings yet

- Mine FanDocument10 pagesMine Fanrajanrane420No ratings yet

- Operator'S Manual Af0409Cxxxxxx-Xx-XDocument4 pagesOperator'S Manual Af0409Cxxxxxx-Xx-Xtaller.copiapoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Atb 014Document3 pagesAtb 014tejonmxNo ratings yet

- Technical Bulletin #012: Front Seal BlowoutDocument1 pageTechnical Bulletin #012: Front Seal BlowoutMario MastronardiNo ratings yet

- Atb015 No Sobre Socar Los Tornillos Del ConvertidorDocument2 pagesAtb015 No Sobre Socar Los Tornillos Del ConvertidorAleNo ratings yet

- Caja Del CarroDocument1 pageCaja Del CarroNATHALYNo ratings yet

- Atb 019Document1 pageAtb 019tejonmxNo ratings yet

- Atb 016Document1 pageAtb 016tejonmxNo ratings yet

- Atb 018Document1 pageAtb 018tejonmxNo ratings yet

- Atb 017Document11 pagesAtb 017tejonmxNo ratings yet

- PrintableHeroes RugOfSmothering FreeDocument1 pagePrintableHeroes RugOfSmothering FreetejonmxNo ratings yet

- (TM) Ford Manual de Taller Fusion Milan MKZ 2007 en InglesDocument246 pages(TM) Ford Manual de Taller Fusion Milan MKZ 2007 en InglesArturo ColmenaresNo ratings yet

- PrintableHeroes Roper FreeDocument1 pagePrintableHeroes Roper FreetejonmxNo ratings yet

- 2010 Web ImportDocument95 pages2010 Web Importjuanjo100% (4)

- PrintableHeroes StarWars Empire 01 LineArtDocument1 pagePrintableHeroes StarWars Empire 01 LineArttejonmxNo ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90Document5 pagesTransmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90tejonmx67% (3)

- U660e Case BoreDocument8 pagesU660e Case BoretejonmxNo ratings yet

- Amork zf8hpDocument24 pagesAmork zf8hpDerick Viana Reis100% (12)

- ZF4HP16 OptraDocument241 pagesZF4HP16 OptraDavid Chalker100% (36)

- Sonnax 6T70 6F50 Webinar PDFDocument57 pagesSonnax 6T70 6F50 Webinar PDFMothana Husban100% (1)

- 3K Service Manual 4th Gen SM4013EN 200906Document308 pages3K Service Manual 4th Gen SM4013EN 200906tejonmxNo ratings yet

- 6T40 45 Diag FixesDocument69 pages6T40 45 Diag Fixesjosue100% (12)

- A760EDocument47 pagesA760ENeqcer Martínez100% (3)

- Transmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90Document5 pagesTransmission Control Module (TCM) Adaptation - 8HP45 - 845re - 8HP70 - 8HP90tejonmx67% (3)

- 845RE Introduction: Presented By: Bill Brayton ATRA Senior Research TechnicianDocument42 pages845RE Introduction: Presented By: Bill Brayton ATRA Senior Research Techniciantejonmx0% (1)

- Attention: A245E & A246E Product Bulletin A245E & A246E Product BulletinDocument2 pagesAttention: A245E & A246E Product Bulletin A245E & A246E Product Bulletinchoco84100% (1)

- 42rle Automatic TransmissionDocument128 pages42rle Automatic Transmissionapi-2614064490% (48)

- 2010 Cadillac CTS Wagon AWD V6-3 6L50Document5 pages2010 Cadillac CTS Wagon AWD V6-3 6L50tejonmxNo ratings yet

- Dodge 45RFE/545RFE Service ManualDocument263 pagesDodge 45RFE/545RFE Service Manuallilfroger94% (51)

- 6R80 Service Manual Rev 1Document427 pages6R80 Service Manual Rev 1Jeff93% (29)

- Honda Civic 2006-Up SPCADocument12 pagesHonda Civic 2006-Up SPCANOne100% (1)

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)