Professional Documents

Culture Documents

Niosh 7903 SKC

Uploaded by

Silvina AmbrosolioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Niosh 7903 SKC

Uploaded by

Silvina AmbrosolioCopyright:

Available Formats

Chemical Fact File ®

Acids, inorganic — NIOSH 7903

NIOSH Method 7903 is a revision of NIOSH P&CAM 339. This method measures the total concentration of six airborne anions. The

working range is 0.01 to 5 mg/m3 for a 20 L air sample. Particulate salts of all the acids will give a positive interference.

Required Equipment: loose end of the flexible tubing to the pump inlet. Request SKC

1. An air sampling pump capable of sampling at the recom- Application Guide #1168 for more information on preparing sorbent

mended flow rate with the sampling medium in line, such as: tube sampling trains.

• SKC 224-XR Series Universal Sampler with Low Flow 2. For calibrating the pump, use the sampling train described

Holder Cat. No. 224-26-01 and Protective Cover Cat. No. above except connect the sorbent tube inlet to the calibrator with a

224-29B piece of flexible tubing. Calibrate the pump flow rate to the rate

• SKC AirChek® 2000 Sampler with Constant Pressure specified in the method. When calibration has been completed,

Controller Cat. No. 224-26-CPC, Low Flow Holder Cat. No. remove the sorbent tube, cap it with the end caps provided, and

224-26-01, and Protective Cover Cat. No. 224-29B save it for recalibration at the end of sampling. Request SKC

Application Guide #1366 or #1163 for more information on calibrat-

• SKC AirChek 52 Sampler with Constant Pressure Controller ing a pump.

Cat. No. 224-26-CPC, Low Flow Holder Cat. No. 224-26-

01, and Protective Cover Cat. No. 224-29B 3. For sampling, set up a sampling train as above except use a

• SKC 210 Series Pocket Pump® Sampler with Tube new sorbent tube and do not break off the ends until ready to

Holder Cat. No. 222-3L-1 sample. The larger section of sorbent should be facing away from

the pump. Place the protective cover over the sorbent tube. Attach

2. An air flow calibrator, such as: the clip on the protective cover to a worker's clothing near the

breathing zone and the pump to the worker's belt. The sorbent tube

• SKC UltraFlo® Calibrator Cat. No. 709 should remain in a vertical position during sampling. Turn the pump

• DC-Lite Flowmeter Cat. No. 717-01 on.

3. SKC Sorbent Tube Cat. No. 226-10-03 4. Sample at an accurately known flow rate for the recommended

period of time.

Optional Equipment:

1. SKC Tube Breaker Cat. No. 222-3-51 5. At the end of the sampling period, turn the pump off and note

the ending time. Remove the sorbent tube, seal the ends of the tube

SKC Application Guides: with the end caps provided, and record any pertinent sampling

1. Sampling Train—Sorbent Sample Tubes, #1168 information.

2. Calibrating a Pump Using a Film Flowmeter, #1163

3. Calibrating a Pump Using an Electronic Calibrator, #1366 6. Calibrate the pump with the representative sampling media in

line to verify that the flow has not changed by more than 5%.

TWA 7. Submit field blanks from the same lot number as the sample

Flow Rate 200 ml/min tubes. Field blanks should be subjected to exactly the same han-

Sample Time 4 hours dling as the samples (open, seal, and transport) except that no air is

Air Volume 48 L drawn through them.

NIOSH REL varies, see specific acid

(NIOSH Manual of Analytical Methods [NMAM], Fourth Edition, 8/15/94) 8. Pack sample sorbent tubes, field blanks, and all pertinent

information securely for shipment to a laboratory for analysis.

Storage:

Sampling and Analysis: Store samples at room temperature. Analyze within 3 weeks of

1. To set up a sorbent tube sampling train, break open both ends collecting the sample.

of a sorbent tube using the optional SKC sorbent tube breaker.

Insert the sorbent tube into the rubber sleeve of the adjustable low

flow holder or tube holder. The arrow on the sorbent tube indicates

Analyzing Method:

air flow and should point toward the tube holder and pump. In the Ion chromatography (IC)

absence of an arrow, insert the end of the tube with the smallest Copyright 1992 - 2002

sorbent section (backup section) into the tube holder. Connect the

Notice: This publication is intended for general information only and should not be used as a substitute for reviewing applicable government regulations, equipment operating instructions, or legal standards. The information

contained in this document should not be construed as legal advice or opinion nor as a final authority on legal or regulatory procedures.

Publication 1016 Rev 0208

SKC Inc. 724-941-9701 SKC South 434-352-7149 SKC Gulf Coast 281-859-8050 SKC West 714-992-2780

www.skcinc.com

You might also like

- KIZAD GuidelinesDocument4 pagesKIZAD GuidelinesAliNo ratings yet

- Generic Well Test ProgramDocument9 pagesGeneric Well Test Programinyene ekereNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- SEALING SENSE: Understanding the Key Differences Between ISO 15848-1 and API 641 Valve Testing StandardsDocument3 pagesSEALING SENSE: Understanding the Key Differences Between ISO 15848-1 and API 641 Valve Testing StandardsCricri CriNo ratings yet

- Test Furnace Ducts LeaksDocument9 pagesTest Furnace Ducts LeaksRajeevAgrawal67% (3)

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- Workover Programme - Tubing Change OutDocument11 pagesWorkover Programme - Tubing Change OutE_Amr_SorourNo ratings yet

- FE 900 Field Testing of FansDocument6 pagesFE 900 Field Testing of FansAvery OppegardNo ratings yet

- Quantitative Analysis Laboratory ManualDocument141 pagesQuantitative Analysis Laboratory ManualMuhammad Husnul KhuluqNo ratings yet

- Installation of Pipeline by HDD For NGN Pipeline ProjectDocument48 pagesInstallation of Pipeline by HDD For NGN Pipeline ProjectDie HArd100% (1)

- HP by Pass System-ModifiedDocument21 pagesHP by Pass System-Modifiedsrigirisetty208100% (1)

- Gases and Vacua: Handbook of Vacuum PhysicsFrom EverandGases and Vacua: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- 30 Mainline Hydrotesting 111Document25 pages30 Mainline Hydrotesting 111rexNo ratings yet

- Condenser ManualDocument48 pagesCondenser ManualVishal Kumar Laddha100% (1)

- Aquaxyl: Hydraconcept: An Innovative Moisturizing and Restructuring TechnologyDocument38 pagesAquaxyl: Hydraconcept: An Innovative Moisturizing and Restructuring TechnologyMihaNo ratings yet

- Mass Transfer Treybal Solution ManualDocument2 pagesMass Transfer Treybal Solution Manualahmad24% (33)

- 4.8 Bunker Line Test ProcedureDocument2 pages4.8 Bunker Line Test ProcedureGouri100% (2)

- SKC HFDocument1 pageSKC HFSilvina AmbrosolioNo ratings yet

- Chemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600Document1 pageChemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600megacobNo ratings yet

- Sampling Train - Single Sorbent Sample TubeDocument2 pagesSampling Train - Single Sorbent Sample TubeKanjariya AjayNo ratings yet

- 1035Document1 page1035Lisna UtamiNo ratings yet

- 1165Document2 pages1165Sthefen Andrade Da RonchNo ratings yet

- MS (Hydrotest - Heat Exchanger)Document4 pagesMS (Hydrotest - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- Astm D 4888-2006 PDFDocument3 pagesAstm D 4888-2006 PDFJaneth MartínezNo ratings yet

- Hydrostatic Testing Specification for PipelinesDocument12 pagesHydrostatic Testing Specification for PipelinesMoaatazz NouisriNo ratings yet

- Status of Drill-Stem Testing Techniques and Analysis: H. K. Van PoollenDocument7 pagesStatus of Drill-Stem Testing Techniques and Analysis: H. K. Van Poollenvictor gerardoNo ratings yet

- Phase Behavior PresentationDocument15 pagesPhase Behavior Presentationallahverdi.huseynNo ratings yet

- 1986 - Chilvers - Measuring Vacuum Pump PerformanceDocument5 pages1986 - Chilvers - Measuring Vacuum Pump PerformanceNARAYANA RAO PUPPALANo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Hydrogen Sulfide in Natural Gas Using Length-of-Stain Detector TubesDocument3 pagesHydrogen Sulfide in Natural Gas Using Length-of-Stain Detector TubesDavid CazorlaNo ratings yet

- Job Procedure FOR Hydrotesting of Underground Mov (Api 6D Valve)Document6 pagesJob Procedure FOR Hydrotesting of Underground Mov (Api 6D Valve)sojeckNo ratings yet

- Techniques For Spot Sampling GasDocument7 pagesTechniques For Spot Sampling GasAhmed Abo FornNo ratings yet

- Qualification of Tunnel Sterilizing Machine-1Document5 pagesQualification of Tunnel Sterilizing Machine-1jeyapragash RamadassNo ratings yet

- Astm D 4888-2006Document3 pagesAstm D 4888-2006JanethNo ratings yet

- Guia de Instalación de Columnas (GNBX1098C-UNV)Document12 pagesGuia de Instalación de Columnas (GNBX1098C-UNV)Flor ArenasNo ratings yet

- Osborne Reynolds' Experiment Visualises Laminar and Turbulent FlowDocument9 pagesOsborne Reynolds' Experiment Visualises Laminar and Turbulent Flowwasiq999No ratings yet

- FE900 - Field Testing of FansDocument6 pagesFE900 - Field Testing of FansAhmad NilNo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- Barometer Test Kit, Model 3613 (King Nutronics Corporation, Part No. 3613-1-1)Document4 pagesBarometer Test Kit, Model 3613 (King Nutronics Corporation, Part No. 3613-1-1)영민No ratings yet

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 pagesBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Parker Steam Boiler Quarterly Inspection Report: QTR 101-5Document2 pagesParker Steam Boiler Quarterly Inspection Report: QTR 101-5Danu KautsarNo ratings yet

- EGCSA Scrubber Water Sampling Point Specification v1Document20 pagesEGCSA Scrubber Water Sampling Point Specification v1ИгорьNo ratings yet

- Laboratory Fume Hood Performance TestingDocument4 pagesLaboratory Fume Hood Performance TestingIvva RohmawatiNo ratings yet

- Leak Standard LS-20B-instruction-manualDocument20 pagesLeak Standard LS-20B-instruction-manualVadim RiabovNo ratings yet

- Ex BHydrot 24'' 5KmDocument9 pagesEx BHydrot 24'' 5KmJabel Oil Services Technical DPTNo ratings yet

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaNo ratings yet

- Testing OverviewDocument30 pagesTesting Overviewashish7541No ratings yet

- Test Specification Nyt-1664-CDocument18 pagesTest Specification Nyt-1664-CMauro Antonio BergantiniNo ratings yet

- Lab Manual - FM and M LabDocument64 pagesLab Manual - FM and M LabRavichandran GNo ratings yet

- Fluid Mechanics Lab ManualDocument89 pagesFluid Mechanics Lab ManualJVC MaliackalNo ratings yet

- Accumulator and Bop Test ProceduresDocument7 pagesAccumulator and Bop Test Proceduresyefersson morales lopezNo ratings yet

- API冲洗方式 PDFDocument52 pagesAPI冲洗方式 PDF唐文义No ratings yet

- Davis Butler API StandardsDocument27 pagesDavis Butler API StandardsAnkit GandhiNo ratings yet

- Standard Operating Procedures for Stack SamplerDocument6 pagesStandard Operating Procedures for Stack SamplerSangam SharmaNo ratings yet

- Propac: Flushing Procedure For Hydraulic Piping, Tubing & HoseDocument4 pagesPropac: Flushing Procedure For Hydraulic Piping, Tubing & HoseClaudio Hernández PobleteNo ratings yet

- SPE 68081 Cased Hole Formation Resistivity Tool TrialDocument10 pagesSPE 68081 Cased Hole Formation Resistivity Tool TrialkigiNo ratings yet

- Well Completions, Maintenance and Abandonment: Please NoteDocument55 pagesWell Completions, Maintenance and Abandonment: Please NoteRamesh kannanNo ratings yet

- Astm D153Document5 pagesAstm D153EngrWasiAhmadNo ratings yet

- Procedure 06 V 305Document13 pagesProcedure 06 V 305Hendra SetiawanNo ratings yet

- Maintain Ventilator PerformanceDocument8 pagesMaintain Ventilator PerformanceCarolina Diaz MurillasNo ratings yet

- CLSI iRICELL Procedure TemplateDocument38 pagesCLSI iRICELL Procedure TemplateKarla Chariz Fernandez BayagNo ratings yet

- Yang Et Al. (2011) PDFDocument7 pagesYang Et Al. (2011) PDFLucas SantosNo ratings yet

- Laboratory Study of Slurry Seal: CoatsDocument128 pagesLaboratory Study of Slurry Seal: CoatsHaresh NaikNo ratings yet

- National Science Talent Search Examination: SyllabusDocument4 pagesNational Science Talent Search Examination: SyllabusankitabindalNo ratings yet

- Ammeraal Endless JointDocument24 pagesAmmeraal Endless JointVictor MoralesNo ratings yet

- Furan Acid On Fish OilDocument12 pagesFuran Acid On Fish OilmisaelNo ratings yet

- Half-Life MM LabDocument5 pagesHalf-Life MM Labapi-1107897020% (1)

- Chromium Free Zinc-Flake Composite, With or Without Integral Lubricant, Corrosion Protective Coatings For FastenersDocument4 pagesChromium Free Zinc-Flake Composite, With or Without Integral Lubricant, Corrosion Protective Coatings For FastenersManuel Antonio Santos Vargas100% (1)

- CSO201A 12012023 (Lecture From 50123 To 120123)Document38 pagesCSO201A 12012023 (Lecture From 50123 To 120123)Abhishek ChaudharyNo ratings yet

- Semester 2 Lesson 11 Extra Pratice For Naming Covalent CompoundsDocument2 pagesSemester 2 Lesson 11 Extra Pratice For Naming Covalent CompoundsKelvin RequenaNo ratings yet

- E1061 E1063 HW Installation EnglishDocument26 pagesE1061 E1063 HW Installation EnglishAxicelNo ratings yet

- How cell size affects diffusionDocument5 pagesHow cell size affects diffusionAlgrin Acosta0% (1)

- Hao 2000Document58 pagesHao 2000Gerson JoelNo ratings yet

- Tego® Addbond - For Maximum AdhesionDocument8 pagesTego® Addbond - For Maximum AdhesionDanail AkuzovNo ratings yet

- Sample Concentrator: LSCO-B1 SeriesDocument3 pagesSample Concentrator: LSCO-B1 SerieslabtrondigitalNo ratings yet

- Determine Phosphoric Acid Content in Soft DrinksDocument4 pagesDetermine Phosphoric Acid Content in Soft DrinksNaveen KumarNo ratings yet

- M.SC - Chemistry - 2018Document24 pagesM.SC - Chemistry - 2018Abdi mohammedNo ratings yet

- Plasite 4550SDocument3 pagesPlasite 4550SMuhammad RizwanNo ratings yet

- Material Specifications Forged Products Manufactured With The Forging Rev.04Document13 pagesMaterial Specifications Forged Products Manufactured With The Forging Rev.04Emre TekinNo ratings yet

- Sist en 12370 2020Document9 pagesSist en 12370 2020AnelNo ratings yet

- Module 2A Notes - Effect of Electrolytes On Chemical EquilibriumDocument10 pagesModule 2A Notes - Effect of Electrolytes On Chemical EquilibriumMaputol YuleheberNo ratings yet

- The Scope of ChemistryDocument6 pagesThe Scope of ChemistryOsa EmmauelNo ratings yet

- Test Method T659: Methylene Blue Adsorption Value of Road Construction MaterialDocument5 pagesTest Method T659: Methylene Blue Adsorption Value of Road Construction Materialparvej alamNo ratings yet

- Paracetamol Solubility in Various SolventsDocument6 pagesParacetamol Solubility in Various SolventsMilenNo ratings yet

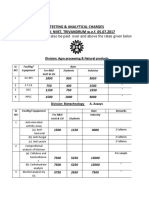

- New Testing ChargesDocument11 pagesNew Testing ChargesRay MrinalNo ratings yet

- YUKOL 5613 Polyol Flexible Foam PropertiesDocument2 pagesYUKOL 5613 Polyol Flexible Foam PropertiesCarlos SiuNo ratings yet

- January 2018 MS - Paper 1C Edexcel Chemistry IGCSEDocument23 pagesJanuary 2018 MS - Paper 1C Edexcel Chemistry IGCSEVideesha AmunugamaNo ratings yet