Professional Documents

Culture Documents

Water Tolerance of Petrol-Ethanol Blends PDF

Uploaded by

junaa AlbayatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Tolerance of Petrol-Ethanol Blends PDF

Uploaded by

junaa AlbayatiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/265195562

WATER TOLERANCE OF PETROL-ETHANOL BLENDS

Article

CITATIONS READS

5 1,796

5 authors, including:

Zlata Muzikova Milan Pospisil

University of Chemistry and Technology, Prague University of Chemistry and Technology, Prague

15 PUBLICATIONS 154 CITATIONS 50 PUBLICATIONS 1,206 CITATIONS

SEE PROFILE SEE PROFILE

Gustav Sebor Ivan Zadrazil

University of Chemistry and Technology, Prague Imperial College London

57 PUBLICATIONS 869 CITATIONS 27 PUBLICATIONS 659 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Gustav Sebor on 29 November 2016.

The user has requested enhancement of the downloaded file.

Podnošenje vode... Z. Mužíková et al.

Zlata Mužíková, Milan Pospíšil, Jaroslav Černý, Gustav Šebor, Ivan Zadražil

ISSN 0350-350X

GOMABN 47, 1, 34-53

Preliminary communication

UDK 621.434-631.4 : 66.061.14 : 536.76 : 543.81 : 66.022.362

WATER TOLERANCE OF PETROL-ETHANOL BLENDS

Abstract

Water tolerance of ethanol-petrol blends of various compositions (ethanol, ethers,

aromatics, olefins) was investigated. Tempe-ratures of haze formation as well as

separation of petrol into two phases were measured experimentally. Simulation of long

term storage stability of ethanol-petrol blends was also performed.

1. Introduction

From 2007, January 1st, an addition of biocomponents (ethanol, ETBE, FAME) to

commercial petrol and/or diesel fuel becomes mandatory for all producers and

importers of motor fuels in the Czech Republic. The measure reflects the Directive

2003/30/EC of the European Parliament and of the Council on the promotion of the

use of biofuels or other renewable fuels for transport. According to the current

quality standard EN 228 ethanol content in petrol is limited to 5 vol %, however, an

increase up to 10 vol % in near future is intensively discussed. The addition of

ethanol to petrol can affect the following physical-chemical properties of motor fuel:

• volatility (vapour pressure and distillation properties),

• octane number,

• water solubility,

• compatibility with construction materials,

• heating value

Some ethanol properties differ significantly from those of petrol hydrocarbons.

Namely, it is polar character of ethanol and its high affinity to water (unlike

hydrocarbons ethanol is perfectly miscible with water) [1]. Ethanol therefore

improves significantly the solubility of water in hydrocarbon fuel. It is very useful and

desirable (e.g. prevention of fuel system freezing), however an ability to keep water

in the soluble state in petrol-ethanol blend is strongly affected by temperature. A

decrease of fuel temperature under specific level brings about separation of water

phase, to which main portion of ethanol from fuel blend is transferred. This results in

significant petrol quality degradation – part of oxygen content is disappeared, octane

value goes down and volatility is changed [2]. Thus the use of petrol-ethanol blends

can cause much more problems at regular consumers than ethanol free motor fuel,

for which separated water does not pose a significant risk of petrol quality change.

Problems concerning low stability of petrol-ethanol blends have promptly to solve all

motor fuel producers and distributors to prevent a possible negative public

acceptance of biocompounds as a standard part of motor fuels.

44 goriva i maziva, 47, 1 : 34-53, 2008.

Z. Mužíková et al. Podnošenje vode...

2. Solubility of water in petrol-ethanol blends

High solubility of water in petrol-ethanol fuel blends is affected by polar character of

ethanol and its ability to form hydrogen bridges. Ethanol should practically be water

free (max. 0,3 vol % water according to Czech standard CSN 66 0810) to be

blended into petrol. However, ethanol is strongly hydroscopic and therefore absorbs

easily water in form of air humidity, e.g. during diurnal breathing of storage tanks.

Solubility of water in petrol-ethanol blend is influenced by:

• temperature,

• ethanol content,

• hydrocarbon composition of petrol base (content of aromatics or olefins),

• content of other oxygenates (co-solvents)

The main effect on water solubility in petrol-ethanol fuel blends show ethanol content

and temperature change [1]. Rising content of ethanol in petrol influences the

increase of the water solubility in fuel blend by nonlinear way (see Figure 1). The

solubility of water in petrol containing 10 vol % of ethanol (E10) is approximately 2.5

times higher compared with fuel containing 5 vol % of ethanol (E5) only. The water

solubility decreases linearly with decreasing temperature and is more noticeable for

E10 than E5 fuel blend.

A decrease of temperature from 10 °C to -10 °C resu lts in decrease of water

solubility by approx. 30 % rel for E10 fuel blend and/or approx. 14% rel for E5 fuel

blend (see Figure 2). Thus a change of temperature (e.g. day – night temperature

deviation) or change of ethanol content (e.g. in case of mixing various kinds of

petrol) can cause the phase separation effect. In summer and/or winter period a

“safety” water content in E5 fuel blend should be lower than 2000 ppm w/w. The

content of water dissolved in petrol containing hydrocarbons or MTBE only does not

pass over a limit value of 60 ppm w/w.

Solubility of water in petrol-ethanol fuel blends can also be affected by hydrocarbon

composition of petrol base [1,3-5]. Due to existence of π-bonds in molecule,

aromatics and olefins would easily be miscible with water compared with saturated

hydrocarbons. However, experimental measurements performed didn’t show a

significant effect of hydrocarbon composition on water solubility. Possible

differences in experimental values didn’t pass over standard error of analytical water

determination. Water solubility in fuel blend increases in consequence of the

presence of other oxygen containing compounds (so called co-solvents), which can

be added into petrol together with ethanol up to maximum oxygen content 2.7 wt %.

For example, the addition of 5 vol % of ETBE to E5 fuel blend increases the

solubility of water at 10 °C by approx. 600 ppm w/w (see Figure 2).

Based on facts mentioned above, it is necessary to prevent petrol-ethanol blends from

air moisture intake during their storage and distribution and also to respect possible

“free” capacity of fuel blend in regard to water solubility at given conditions (ethanol

and other co-solvents contents, temperature).

goriva i maziva, 47, 1 : 34-53, 2008. 45

Podnošenje vode... Z. Mužíková et al.

Figure 1: Effect of ethanol in petrol blend on water solubility in petrol-ethanol blends

8000

10°C

7000

Water content (ppm w/w)

6000 0°C

5000

-10°C

4000

3000

2000

1000

0

0 2 4 6 8 10

Ethanol content (vol. % )

Figure 2: Effect of temperature on solubility of water in petrol-ethanol blends

8000

Petrol with 10 vol. % EtOH

7000

Water content (ppm w/w)

6000

5000

Petrol with 5 vol. % EtOH + 5 vol. % ETBE

4000

3000

2000

Petrol with 5 vol. % EtOH

1000

0

-10 -8 -6 -4 -2 0 2 4 6 8 10

Temperature (°C)

46 goriva i maziva, 47, 1 : 34-53, 2008.

Z. Mužíková et al. Podnošenje vode...

3. Phase separation of petrol-ethanol blends

In common praxis the ability of petrol-ethanol blends to retain certain amount of

water is often determined as the temperature of phase separation according to the

ASTM D6422 standard. Before the point of the phase separation there is always

clearly visible another point at which a haze of the blend appears [2]. Sample with

given amount of water is gradually cooled and formation of haze is monitored at the

particular temperature. This temperature is then followed by a point of phase

separation and/or by a formation of ice crystals [6]. There are some cases where the

phase separation cannot be clearly visible and the determination of the phase

separation point can be difficult. On the other hand, formation of the haze in the

sample is always very indicative and there are no problems with determination of the

haze point. The most common reasons for the phase separation are the differences

between the day and night temp. Another possibility can be seen in blending of petrol

with azeotropic ethanol and/or mixing of petrol-ethanol blends with different composition.

The phase separation temperature can thus depend on content of ethanol and water

in the blend, additional factors are e.g. a hydrocarbon composition or content of co-

solvents in the blends [2,7,8]. Keeping the water content constant the haze points as

well as the phase separation temperatures are lowered with increasing content of

aromatic and olefinic hydrocarbons in the petrol (Table 1). Difference of 20 vol % in

the content of aromatic+olefinic compounds can have an effect of about 10 °C in the

temperature of the phase separation. Increased amount of ethanol in the blends

clearly lowered the phase separation temperature while keeping the water content

constant. So, when it is necessary to mix hydrocarbon petrol with petrol-ethanol

blend then the resulted mixture will have lower content of ethanol and, therefore, the

phase separation can occurs at higher temperature than for the original petrol-

ethanol blend. At constant ethanol content the phase separation temperature is

lowered by a lowering the water content. When the phase separation temp. is –27 °C

for the fuel E10 with 5600 ppm of water, for the same fuel with 2200 ppm of water

the phase separation temperature is lowered below –30 °C. For the fuel E5 with the

same 2200 ppm of water is the phase separation temp. again about –27 °C (Tab. 1).

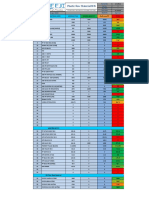

Table 1: Effect of petrol-ethanol fuel composition on the phase separation

EtOH Olefines Aromatics Haze point Phase Water content

(vol %) (vol %) (vol %) (°C) separation (°C) (ppm w/w)

5 5 26 -2 -19 2300

5 5 36 -13 -27 2200

5 15 26 -14 -25 2200

5 15 36 -15 -27 2200

10 5 26 -10 -18 5600

10 5 36 -14 -21 5600

10 15 26 -19 -27 5500

10 15 36 -19 -27 5500

goriva i maziva, 47, 1 : 34-53, 2008. 47

Podnošenje vode... Z. Mužíková et al.

Temperature of the haze appearance is linearly increasing with increase in the water

content. Plot of this relation is shown in Figure 3. For example, when cooling blend

E10 with water content of 6200 ppm (saturation equilibrium at 0 °C) by 10 °C, then

haze appeared due to lesser water solubility by 600 ppm (Figure 3). If effect of fuel

composition can be neglected then an equation for phase separation temperature

assessment can be derived from the linear regression in Figure 3 for the petrol-

ethanol blends with 10 % of ethanol.

Figure 3: Effect of water on the phase separation temperature for petrol

5

Petrol with 10 vol. % EtOH

0

Phase separation (°C)

-5

-10

-15

-20

-25

-30

4500 5000 5500 6000 6500

Water content (ppm w/w)

Co-solvents can lower the phase separation temperature [9,10], e.g. 5 vol % of

ETBE in petrol blend with 5 vol % of ethanol can lower the phase separation

temperature even by 20 °C, see Figure 4.

Based on experimental data it can be concluded that lowering the phase separation

temperature can technically be accomplished:

• by increasing the aromatic and/or olefinic hydrocarbon content in petrol;

however that is not in accordance with the most recent trends of increasing the

non-aromatic hydrocarbons content in automotive fuels,

• by addition of oxygenates (MTBE, ETBE, higher alcohols) in amount within

oxygen limits for automotive petrols of 2.7 wt %,

• by minimisation of humidity access into storage tanks and distribution

systems; technological discipline have to be respected, and storage tank

breathing should be minimised.

48 goriva i maziva, 47, 1 : 34-53, 2008.

Z. Mužíková et al. Podnošenje vode...

Figure 4: Effect of ETBE in the fuel E5 on the haze point

20

Petrol with

5 vol. % EtOH + 3000 ppm w/w water

15

10

Phase separation (°C)

-5

-10

-15

0 2 4 6 8 10 12

ETBE content (vol. %)

4. Extraction of ethanol from petrol blends by water

Phase separation of petrol blends is accompanied by an undesirable effect –

extraction of ethanol into water layer. Due to the loss of ethanol a significant

deterioration of petrol quality should be expected – decrease of octane number

mainly and also a corrosive action of water phase separated on inner metal surfaces

of storage tanks and/or car fuel system lines. After separation of water layer, content

of water dissolved in hydrocarbon phase is generally lower than value that

corresponds to the state of fuel saturation, and content of water in organic phase

further decreases in dependence on volume of water layer separated [11,12].

Extraction of ethanol into water layer represents usually an irreversible process. A

backward dissolution of ethanol and water into hydrocarbons phase should

theoretically be occurred under fully exceptional conditions [13]. The quantity of

ethanol extracted into water layer is generally affected by:

• ratio of water and hydrocarbons layers,

• content of ethanol in petrol,

• hydrocarbon composition of petrol,

• temperature (in minor measure),

• content of co-solvents

goriva i maziva, 47, 1 : 34-53, 2008. 49

Podnošenje vode... Z. Mužíková et al.

Amount of ethanol which can be extracted into water layer generally depends on

content of ethanol in fuel blend and also on amount of free water, which is in direct

contact with fuel blend. In table 2, there are compared relative losses of ethanol from

fuel blends under situation, when the fuel is in direct contact with 0.5 or 1 vol % of

free water.

Table 2: Effect of ethanol concentration and free water amount in petrol blend on

losses of ethanol

Initial EtOH content Losses of EtOH from petrol blend (rel %)

(vol %) 0.5 vol % water 1 vol % water

5 11 20

10 16 28

High contents of aromatics and olefins in petrol show soft co-solvent effect and

minimise amount of ethanol extracted (see Table 3).

Table 3: Effect of hydrocarbons composition on amount of ethanol extracted from

E10 fuel blend by 1 vol % of free water

Olefins+aromatics EtOH losses after EtOH losses after EtOH losses after

(vol % ) 1st extraction (rel %) 2nd extraction (rel %) 3rd extraction (rel %)

5+25=30 31 63 77

5+35=40 27 57 72

15+25=40 28 55 71

15+35=50 24 51 71

More noticeable effect on minimisation of ethanol amount extracted from petrol

blends gives oxygen containing co-solvents. For example, combination of 5 vol % of

ETBE and 5 vol % of ethanol affects in positive way the minimisation of losses of

ethanol extracted into water layer by approx. 10 rel % compared with petrol-ethanol

blend free of ETBE (see Table 4).

Table 4: Effect of ETBE content on amount of ethanol extracted from E5 petrol

blends by 1 vol % of water

Content of EtOH losses after EtOH losses after EtOH losses after

EtOH/ETBE (vol %) 1st extraction (rel %) 2nd extraction (rel %) 3rd extraction (rel %)

5/0 37 60 74

5/3 32 55 70

5/5 27 50 64

5/10 23 42 57

50 goriva i maziva, 47, 1 : 34-53, 2008.

Z. Mužíková et al. Podnošenje vode...

Ethanol extraction rate depends on the way of manipulation with petrol-ethanol

blend. During an intensive agitation of liquid, very fast transition of ethanol into water

layer becomes already within first 10 minutes. If the mixture stays calm, phase

equilibrium is established within approx. 1 week. If the fuel blend is not repeatedly

exposed to contact with free water layer, losses of ethanol from primary petrol blend

don’t pass over 30 rel %. However, a triple extraction results in lose of 70 rel % of

ethanol, i.e. 1.5 vol % of ethanol remains only in the fuel blends compared with

primary 5 vol %. This petrol doesn’t meet standardised value of octane number.

5. Other oxygenates as co-solvents

Except ethanol, there are some other oxygenates that can be blended into petrol as

co-solvents. However, content of oxygen in blend has to be kept below the limit of

2.7 wt %. Co-solvents can be blended into petrol with the aim of [14]:

• better solubility of water in petrol-ethanol blend

• lowering the phase separation temperature

• lowering the amount of ethanol which can overcome into the water phase

• better vapour pressure behaviour of petrols

Often mentioned and recommended in the literature are especially the following co-

solvents:

• branched higher alcohols (TBA, IBA, IPA) usually in 1:1 ratio with ethanol [2]

• higher aliphatic alcohols (1-hexanol, decanol) [15]

• ethers (DIPE, TAME, MTBE) [9,14]

• certain co-solving effect also have some aromatic hydrocarbons

Figure 5: Effect of co-solvents on the phase separation in the E5 fuel

0% 1%MTBE 3%MTBE 1%ETBE 3%ETBE 1%TBA 3%TBA

0

-1

-5

Phase separation or haze (°C)

-5

-10

-13

-15

-15

-17 -17

-20 -19

-21

-25 -23

-25

-27

-30 Haze

-30 -30-30

Phase separation

-35

goriva i maziva, 47, 1 : 34-53, 2008. 51

Podnošenje vode... Z. Mužíková et al.

Effects of some co-solvents on the phase separation were experimentally examined

and results are presented in Figure 5. So, with the respect to oxygen limits in

automotive fuels, about 5 vol % of MTBE or ETBE, or about 4 vol % of TBA, or

about 3 vol % IPA can additionally be blended into petrol with 5 vol % of ethanol. For

the 10 vol % ethanol blends the co-solvent TBA can be very effective. Some results

obtained with that co-solvent are also shown in Figure 5. TBA already at the low

concentration of 3 vol % lowered the haze point below -30°C from initial -1 °C. Water

concentration in that experiment was as high as 6000 ppm. Ethers as co-solvents

(MTBE, ETBE) are less effective. Under the same experimental conditions their

effect was much lesser, see Figure 5. Effect of ETBE on extraction of ethanol into

water phase can be seen in Table 4 for the petrol blends with 5 vol % of ethanol and

different content of ETBE.

Oxygenates utilised as co-solvents in petrol ethanol blends should meet the

requirements of the EN 228 standard. Except that they should also meet some other

demands dealing with:

• good miscibility with all components of petrols,

• solubility in water, which should be as low as possible,

• minimum azeotrope formation with hydrocarbons; low boiling point of the

azeotrope can have impact on increased vapour pressure of the petrol-

ethanol blends.

All these demand on oxygenates are not compatible with methanol [1], on the other

hand very perspective oxygenates could be some ethers.

6. Conclusion

Due to high polarity of ethanol and its affinity to water it is necessary to minimise

contact of petrol blends with water and air moisture during their storage and

distribution. So, by change of temperature, the phase separation of petrol-ethanol

blend becomes real and water-ethanol layer occurs in a storage tank. This results in

a significant decrease of ethanol content in fuel blend and loses of petrol quality

(decrease of octane number value).

Use of some oxygen containing compounds is also recommended to improve phase

stability of petrol-ethanol blends (i.e. reduction of phase separation temperature).

The best effect brings the application of t–butanol (TBA) as the co-solvent. However,

ETBE, which can be produced from bioethanol and therefore is regarded as

biocompounds, is also preferred. A very low affinity of ETBE to water can also be

regarded as an advantage for the use of this ether in petrol blends.

At present, problems concerning an improvement of storage and distribution stability

of petrol-ethanol blends should be treated with the first priority.

Acknowledgement

The work was supported by the company Ceska rafinerska a.s. and by Ministry of

Education of the Czech Republic under the agreement No. 6046137304.

52 goriva i maziva, 47, 1 : 34-53, 2008.

Z. Mužíková et al. Podnošenje vode...

References

[1] Thshiteya R.M et al.: Properties of alcohol transportation fuels, Alcohol Fuel Reference 1, 1991,

www.hawaii.gov/dbedt/ert/afrw.html

[2] Menrad H., König A.: Alkoholkrafstoffe, Springer-Verlag/Wien, 1982.

[3] Stadelman I.: Extraction of alcohols from gasoline using Solid Phase Microextraction.

http://scholar.lib.vt.edu/theses/available/etd-05192001-114455/unrestricted/Thesis.pdf

[4] Letcher T.M., Bricknell B.C.: Phase equilibria for (an alkanol+hept-1-yne+water) at temperature

298,15K. J. Chem. Thermodynamics, 25, 1183-1187, 1993.

[5] Recommended Liquid-Liquid Equilibrium Data.Part 2.Unsaturated Hydrocarbon-Water Systems,

J. Phys. Chem. Ref. Data, 33(2), 579-591, 2004.

[6] Korotney D.: Water Phase Separation in Oxygenated Gasoline,

www.epa.gov/otaq/regs/fuels/rfg/waterphs.pdf

[7] French R., Malone P.: Phase equilibria of ethanol fuel blends. Fluid Phase Equilibria, 228–229,

27–40, 2005.

[8] Gramajo de Doz M. B. et al.: Water Tolerance and Ethanol Concentration in Ethanol-Gasoline

Fuels at Three Temperatures. Energy & Fuels, 18, 334-337, 2004.

[9] Zhongjuan P., Chen J.: Measurement of liquid liquid equilibria for quartenary mixtures of water,

ethanol, diisopropylether and toluen, Chem. J. Internet, 6(12), 2004. www.chemistrymag.org

[10] Cionová E., Kittel H.: Bioethanol as a component of automotive fuels, AUTOTEC 2004 „Modern

fuels and lubricants“, Brno, Czech Republic, 2004(In Czech). www.cappo.cz

[11] Stephenson R.M.: Mutual solubilities: Water –Ketones, Water-Ethers and Water-Gasoline-

Alcohols. J. Chem. Eng. Data, v37, 80-95, 1992.

[12] Powers S.E., Heermann S.E.: Potencial Ground and Surface Water Impacts, Volume 4, Chapter

2: A Critical Review: The Effect of Ethanol Gasoline in the Fate and Transport of BTEX in The

Subsurface, 1999. www.erd.llnl.gov/ethanol/etohdoc/vol4/chap02.pdf

[13] Hammel-Smith C. et al.: Issue Associated with the Use of Higher Ethanol Blends (E17-E24),

Technical Report, National Renewable Energy Laboratory, NREL/TP-510-32206, 2002.

www.nrelgov

[14] Lojkásek M., Růžička Jr. V: Solubility of water in blends of gasoline, methanol and a solubilizer,

Fluid Phase Equilibria, 71, 113-123, 1992.

[15] Osten D.W., Sell N.J.: Methanol-gasoline blends: blending agents to prevent phase separation.

Fuel, 62, 268-270, 1983.

UDK ključne riječi key words

621.434-631.4 benzinsko/etanolno mješano gasoline/ethanol mixed

motorno gorivo engine fuel

66.061.14 otopina tekućina solution of liquids

536.76 separacija vodene faze water phase separation

543.81 kontaminacija vodom contamination by water

66.022.362 stabilnost otopine solution stability

Authors

Zlata Mužíková, Milan Pospíšil, Jaroslav Černý, Gustav Šebor, Ivan Zadražil

Department of Petroleum Technology and Petrochemistry, Institute of Chemical

Technology, Technicka 5, 16628 Prague, Czech Republic

Received

12.7.2006.

goriva i maziva, 47, 1 : 34-53, 2008. 53

View publication stats

You might also like

- Improvement of Lubricity of Water - Ethylene Glycol FluidDocument3 pagesImprovement of Lubricity of Water - Ethylene Glycol Fluidannie.lauNo ratings yet

- Triethanolamine Synthesis in A Continuous Ow Microchannel ReactorDocument6 pagesTriethanolamine Synthesis in A Continuous Ow Microchannel ReactorMido FahmyNo ratings yet

- TEG Improve ProcessDocument7 pagesTEG Improve ProcessRENNY JAIR BASTIDAS PE�ANo ratings yet

- Three PILDocument6 pagesThree PILJohn M. E. PurbaNo ratings yet

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventSaidFerdjallahNo ratings yet

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventAhmed ShaepNo ratings yet

- Vapor Liquid Equilibrium in Extractive Distillation of The Acetone/Methanol System Using Water As Entrainer and Pressure..Document9 pagesVapor Liquid Equilibrium in Extractive Distillation of The Acetone/Methanol System Using Water As Entrainer and Pressure..Cordero JulioNo ratings yet

- Propylene Oxide-Ethylene Oxide Block Copolymers As Demulsifiers For Water-in-Oil Emulsions, I. Effect of Molecular Weight and Hydrophilic-Lipophylic Balance On The Demulsification EfficiencyDocument9 pagesPropylene Oxide-Ethylene Oxide Block Copolymers As Demulsifiers For Water-in-Oil Emulsions, I. Effect of Molecular Weight and Hydrophilic-Lipophylic Balance On The Demulsification EfficiencyLluísNo ratings yet

- Kinetic Modelling For The Dehydration of Methanol To Dimethyl Ether Over gamma-Al2O3Document7 pagesKinetic Modelling For The Dehydration of Methanol To Dimethyl Ether Over gamma-Al2O3Luiz Rodrigo AssisNo ratings yet

- 1 Ammonia Aop TiO2Document6 pages1 Ammonia Aop TiO2achmadinNo ratings yet

- Hydrogen Production The Catalytic Reforming Methanol: Steam ofDocument8 pagesHydrogen Production The Catalytic Reforming Methanol: Steam ofYurie NurmitasariNo ratings yet

- Luk Sich Paper 2004Document7 pagesLuk Sich Paper 2004furkandarNo ratings yet

- Volatility and Distillation Properties of Ethanol-Petrol BlendsDocument10 pagesVolatility and Distillation Properties of Ethanol-Petrol BlendsPopovicMNenadNo ratings yet

- Fault Analysis of High Voltage Power Transformer Using Dissolved Gas AnalysisDocument9 pagesFault Analysis of High Voltage Power Transformer Using Dissolved Gas AnalysisCarlos JaraNo ratings yet

- Pnas00115 0010Document6 pagesPnas00115 0010Get SmartNo ratings yet

- Ind. Eng. Chem. Prod. Res. Dev. Vol. 18 - No. 2 - 1979 135Document8 pagesInd. Eng. Chem. Prod. Res. Dev. Vol. 18 - No. 2 - 1979 135Lindsey BondNo ratings yet

- Production Optimization of Gas Wells Using MBAL: AbstractDocument11 pagesProduction Optimization of Gas Wells Using MBAL: AbstractYamal E Askoul TNo ratings yet

- Hidratación de Oxido de Etileno Cinética PDFDocument5 pagesHidratación de Oxido de Etileno Cinética PDFangieNo ratings yet

- Kinetics and Modeling of Fatty Alcohol Ethoxylation in An Industrial Spray Loop ReactorDocument10 pagesKinetics and Modeling of Fatty Alcohol Ethoxylation in An Industrial Spray Loop ReactorGrizzlybeer Van DyckNo ratings yet

- Studies of The Mechanism of Polyvinyl Alcohol AdsoDocument16 pagesStudies of The Mechanism of Polyvinyl Alcohol AdsoDj TaufikNo ratings yet

- Taller 1Document5 pagesTaller 1José Fernando TerronesNo ratings yet

- Opti 1Document6 pagesOpti 1Thomas StevensNo ratings yet

- The Effect of The Side Group Upon The Properties of The Poly (Epoxides)Document7 pagesThe Effect of The Side Group Upon The Properties of The Poly (Epoxides)Javier Vallejo MontesinosNo ratings yet

- RD Column For Butyl Acetate ProductionDocument8 pagesRD Column For Butyl Acetate ProductionAbuBakar SaleemNo ratings yet

- Kinetics of Petroleum Resin Epoxidation by Peracetic Acid: SciencedirectDocument5 pagesKinetics of Petroleum Resin Epoxidation by Peracetic Acid: SciencedirectArii WAhyudiiNo ratings yet

- Paper Ethanol Corrosion Cavalcanti1987Document3 pagesPaper Ethanol Corrosion Cavalcanti1987Eduardo CavalcantiNo ratings yet

- Extractive Distillation of Acetone-Methanol Mixture Using Dimethyl Sulfoxide As EntrainerDocument3 pagesExtractive Distillation of Acetone-Methanol Mixture Using Dimethyl Sulfoxide As Entrainerprajwal thakareNo ratings yet

- SpectometrieDocument5 pagesSpectometriePopescu BiancaNo ratings yet

- Poloxamer 407Document9 pagesPoloxamer 407Hebert FerneynesNo ratings yet

- Computer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsDocument10 pagesComputer Simulation of Vapor-Liquid Equilibrium in Mixed Solvent Electrolyte SolutionsJoseCastilhoNo ratings yet

- Diffusion Coefficient of Ethanol - Gasoline Blends in Air: June 2019Document11 pagesDiffusion Coefficient of Ethanol - Gasoline Blends in Air: June 2019AmyNo ratings yet

- Partial Molar Volume of Ciprofloxacin in Water HCLDocument4 pagesPartial Molar Volume of Ciprofloxacin in Water HCLzaqiya artha zaharaNo ratings yet

- Various Fuel CombustionDocument34 pagesVarious Fuel CombustionRajivChandranNo ratings yet

- An Overview of Napthenic Acid Corrosion in VDUDocument4 pagesAn Overview of Napthenic Acid Corrosion in VDUMukund PilaniaNo ratings yet

- 1-S2.0-S1452398123111060-Main CorrDocument9 pages1-S2.0-S1452398123111060-Main CorrSoulef ZemzoumNo ratings yet

- Li 2009Document2 pagesLi 2009ari goldNo ratings yet

- Fluid Phase Equilibria: Ling Li, Ting Zeng, Xiaoda Wang, Changshen Ye, Ting Qiu, Zhixian HuangDocument6 pagesFluid Phase Equilibria: Ling Li, Ting Zeng, Xiaoda Wang, Changshen Ye, Ting Qiu, Zhixian HuangvarunNo ratings yet

- Selectivity and Activity Changes Upon Water Addition During Fischer-Tropsch SynthesisDocument6 pagesSelectivity and Activity Changes Upon Water Addition During Fischer-Tropsch SynthesisSơn PhanThanhNo ratings yet

- Catalytic Dehydration of Methanol To DimDocument8 pagesCatalytic Dehydration of Methanol To DimNorma JenarezNo ratings yet

- The Effect of Water, Sulphate and PH On The Corrosion Behaviour of Carbon Steel in Ethanolic SolutionsDocument4 pagesThe Effect of Water, Sulphate and PH On The Corrosion Behaviour of Carbon Steel in Ethanolic SolutionsFrancois BornmanNo ratings yet

- SPE Phase Behavior Monograph CH 5Document27 pagesSPE Phase Behavior Monograph CH 5Juan Marcelo AguirreNo ratings yet

- Solvatochromic and Fluorescence Spectroscopic Studies On Polarity of Ionic Liquid and Ionic Liquid-Based Binary SystemsDocument13 pagesSolvatochromic and Fluorescence Spectroscopic Studies On Polarity of Ionic Liquid and Ionic Liquid-Based Binary SystemsElcasihumano ZNo ratings yet

- Decoloration System Using Rotating Membrane Up Module: Makoto Ohnishi . Yutaka Okuno and Naoki OhkumaDocument9 pagesDecoloration System Using Rotating Membrane Up Module: Makoto Ohnishi . Yutaka Okuno and Naoki OhkumaRohan ChauguleNo ratings yet

- Brackman 1989Document6 pagesBrackman 1989TatianaLaBancaNo ratings yet

- J Fluid 2012 11 003Document6 pagesJ Fluid 2012 11 003Agung PrabowoNo ratings yet

- Garrido, N. M., Folas, G. K., & Kontogeorgis, G. M. Fluid Phase Equilibria - 2008 PDFDocument10 pagesGarrido, N. M., Folas, G. K., & Kontogeorgis, G. M. Fluid Phase Equilibria - 2008 PDFPaulaGF88No ratings yet

- Reaction DieselDocument7 pagesReaction DieselKrizzia Anne ShengNo ratings yet

- Xing-Dong YuanDocument4 pagesXing-Dong YuanAndre JoubertNo ratings yet

- Comparison of Electrical Energy Efficiency of Atmospheric and High Pressure ElectrolisersDocument43 pagesComparison of Electrical Energy Efficiency of Atmospheric and High Pressure ElectrolisersAdrián HerreroNo ratings yet

- Alternative Fuels ForDocument5 pagesAlternative Fuels ForVvn BhaskarNo ratings yet

- Modeling of Nature and Strength of Acid Centres in U - 1999 - Studies in SurfaceDocument4 pagesModeling of Nature and Strength of Acid Centres in U - 1999 - Studies in SurfaceLindsey BondNo ratings yet

- Study of The Reuse of Industrial Wastewater After Electrochemical Treatment of Textile Effluents Without External Addition of ChlorideDocument18 pagesStudy of The Reuse of Industrial Wastewater After Electrochemical Treatment of Textile Effluents Without External Addition of Chloridecharvi shinyNo ratings yet

- Bisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationDocument7 pagesBisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationDaniela JuradoNo ratings yet

- Genki 2Document5 pagesGenki 2Gabriela FloareNo ratings yet

- Separation of Acetic Acid From Aqueous Solution Using Various Organic SolventsDocument10 pagesSeparation of Acetic Acid From Aqueous Solution Using Various Organic SolventsAYALEYDENNo ratings yet

- Kurin Power PDFDocument8 pagesKurin Power PDFarunkumar23101No ratings yet

- Senol 2015Document15 pagesSenol 2015Rajesh KumarNo ratings yet

- Catalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationDocument8 pagesCatalytic Dehydration of Methanol To Dimethyl Ether. Kinetic Investigation and Reactor SimulationLuiz Rodrigo AssisNo ratings yet

- Gas Hydrates 1: Fundamentals, Characterization and ModelingFrom EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaNo ratings yet

- Automatic Distillation UnitDocument8 pagesAutomatic Distillation UnitAlexander Amado QuinteroNo ratings yet

- How To Keep Your Produce Fresh For Weeks - WirecuDocument14 pagesHow To Keep Your Produce Fresh For Weeks - Wirecujunaa Albayati100% (1)

- D93 - NPM450 - 1Document4 pagesD93 - NPM450 - 1junaa AlbayatiNo ratings yet

- Refrigeration Technology For Fruit and Vegetables: in Touch - Solutions For The Food Processing IndustryDocument16 pagesRefrigeration Technology For Fruit and Vegetables: in Touch - Solutions For The Food Processing Industryjunaa AlbayatiNo ratings yet

- SLFA-60Document2 pagesSLFA-60junaa AlbayatiNo ratings yet

- Kennol Touring 15W-40 enDocument1 pageKennol Touring 15W-40 enjunaa AlbayatiNo ratings yet

- Kennol Sae 50 PDFDocument1 pageKennol Sae 50 PDFjunaa AlbayatiNo ratings yet

- D93 NPM-TECH 42100-Leaflet-20 CompressedDocument4 pagesD93 NPM-TECH 42100-Leaflet-20 Compressedjunaa AlbayatiNo ratings yet

- Kennol Touring 10W-30 enDocument1 pageKennol Touring 10W-30 enjunaa AlbayatiNo ratings yet

- Distillation Basic Test in Quality Control of Auto PDFDocument23 pagesDistillation Basic Test in Quality Control of Auto PDFjunaa AlbayatiNo ratings yet

- Polymers: Preparations, Properties, and Applications of Polyaniline and Polyaniline Thin Films-A ReviewDocument46 pagesPolymers: Preparations, Properties, and Applications of Polyaniline and Polyaniline Thin Films-A Reviewanmol sharmaNo ratings yet

- J Synthmet 2010 07 021Document6 pagesJ Synthmet 2010 07 021junaa AlbayatiNo ratings yet

- MethanolassuitablesolventforPANI EBDocument6 pagesMethanolassuitablesolventforPANI EBjunaa AlbayatiNo ratings yet

- InTech-Adhesion of Polyaniline On Metallic SurfacesDocument24 pagesInTech-Adhesion of Polyaniline On Metallic Surfacesjunaa AlbayatiNo ratings yet

- Gumfekar SarangDocument98 pagesGumfekar Sarangjunaa AlbayatiNo ratings yet

- IMDG Class 1-9Document53 pagesIMDG Class 1-9Rheymart FloresNo ratings yet

- Confining Pressure 10 Mpa Von Mises StressDocument2 pagesConfining Pressure 10 Mpa Von Mises StressMoj TabaNo ratings yet

- JAMB Chemistry Past Question 1983 2004Document119 pagesJAMB Chemistry Past Question 1983 2004iamprecious2allNo ratings yet

- 15 - High Temperature Tensile TestingDocument4 pages15 - High Temperature Tensile TestingWalter RuedaNo ratings yet

- Bohler - w302 SuperiorDocument8 pagesBohler - w302 SuperiorHugo Mario Ariza Palacio100% (1)

- Phenol: Carboxylation of Phenol: Kolb-Schmitt ReactionDocument9 pagesPhenol: Carboxylation of Phenol: Kolb-Schmitt ReactionAkhilaNo ratings yet

- BS en 15167 1 2006 PDFDocument24 pagesBS en 15167 1 2006 PDFdidi969650% (2)

- BEC008 - MemsnemsDocument39 pagesBEC008 - MemsnemsACHIEVER MNo ratings yet

- Catalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumDocument12 pagesCatalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumRungrawin NgamkhumNo ratings yet

- Guidelines For Sediment Management in Hydropower Projects CWC 2018Document16 pagesGuidelines For Sediment Management in Hydropower Projects CWC 2018ManojNo ratings yet

- Plastic Raw Material MIS: Date 18-Apr-2022Document3 pagesPlastic Raw Material MIS: Date 18-Apr-2022Office atozNo ratings yet

- Estabilidad de Emulsiones PDFDocument94 pagesEstabilidad de Emulsiones PDFfraniq2007No ratings yet

- Carbon Structural Steel: Standardspecification ForDocument4 pagesCarbon Structural Steel: Standardspecification ForlinaNo ratings yet

- Chemlube 215 229 230 501 751 822Document2 pagesChemlube 215 229 230 501 751 822Suprastowo Bin SarinoNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- The Making Shaping and Treating of SteelDocument198 pagesThe Making Shaping and Treating of SteelJitendra SoniNo ratings yet

- Cobalch Aps - PTFE DetailDocument25 pagesCobalch Aps - PTFE DetailMorteza DianatfarNo ratings yet

- Recommendations & ConclusionDocument3 pagesRecommendations & ConclusionFaez Feakry100% (2)

- Chem Unit 5 Quantitative QuestionsDocument27 pagesChem Unit 5 Quantitative QuestionsRizam UmerNo ratings yet

- Astm D6641 D6641M 09 PDFDocument11 pagesAstm D6641 D6641M 09 PDFBipin SasikumarNo ratings yet

- Experiment 9: Direct Titration of Lead With Eriot and Edta SynopsisDocument2 pagesExperiment 9: Direct Titration of Lead With Eriot and Edta SynopsisAhmed AliNo ratings yet

- Effect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC CastingsDocument24 pagesEffect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC Castingskt rajaNo ratings yet

- Lecture5 AllDocument43 pagesLecture5 Alladeelyj100% (1)

- Green Solvents PresDocument74 pagesGreen Solvents PresTDSNo ratings yet

- Zipper Pull Strength 80 N: Test Results Buyer RequirementDocument1 pageZipper Pull Strength 80 N: Test Results Buyer Requirementyogesh123789No ratings yet

- Gaurav Jayaswal Day2 Green Hydrogen in India April2023Document39 pagesGaurav Jayaswal Day2 Green Hydrogen in India April2023Praneet PayodhiNo ratings yet

- Data Sheet-CF.S10Document1 pageData Sheet-CF.S10nicolasNo ratings yet

- Special Steel Structures - Courses - 2013Document253 pagesSpecial Steel Structures - Courses - 2013Largu George DanielNo ratings yet

- LO1. Kinetic Molecular Model of Solid and LiquidsDocument3 pagesLO1. Kinetic Molecular Model of Solid and Liquidsrandolf wassigNo ratings yet

- Research Paper On PN JunctionDocument4 pagesResearch Paper On PN Junctionogisxnbnd100% (1)