Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

albert0 ratings0% found this document useful (0 votes)

13 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageUntitled

Untitled

Uploaded by

albertCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

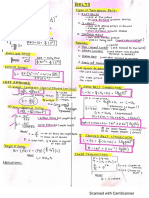

ability of a materiol +o withstond lood

Without failure

— deols wl elostic behavior of loaded moter als

1. Tensile Stress = F+4 > F

2. Compressive Stress + —>—F

3. Shearing ot fp

|

= we

\ Sy

-D-Torsional Stress. ( dete twisting)“ |

nw ts. m 267 id_civalar chal

(Cee TE FER atitcvoer od

where = 40TO

lr 4) Chelle circular shot

2 Toma) >

moduiic

a as Z

= by iret,

S=€& = @lL)e

where

ac~ Fe 2

Actval Legh = L tal

For Sheor Stress *

$3 =G(e?

Ail Sins Brera (0)

= €neigy stored in loaded member is eqval

fo Fhe work veavired +o deform the member

UrgFlau)= 4 eo

40, Shear Modulus /

Modulus of Elasticity in Shear]

E

G > zany

STUFFNEES — amount of force veqvind ty

Cause a unit deforma

keto = & = spring constant

ne

12. COMBINED AXIAL, BENDING,

| . TOR sion a! STRESSES

Senor= [6 «(BY = 2S Ieee

Soman = Se +c} hl |

Semax = CS.) + (48)

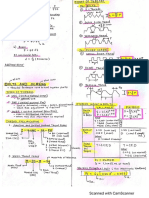

4

DP

s,

may =

TBS = [EAT]

Snmox = & +1E%y GP sellers) ar]

meltiply (Ed) Wy Bm

~ -

Tea | Yi

k= dlq for se

tf

Buckling Factor

Where

as

‘ofiun +

AL = CL (at)

a ; A cao erdbcane

Ve @ V C44)

s ee Aeave te See Sas

=~ Ex = — tater stein | Smt (Sma Swin)

Tong tudinal shi

Foy mos} Moteials!

[O= 028 40 0.35 j

An

sin

Sq = $ (Smax > Sain)

eee.

<

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UntitledDocument1 pageUntitledalbertNo ratings yet

- Machine Design Formula Springs SummaryDocument1 pageMachine Design Formula Springs SummaryalbertNo ratings yet

- Aircon NotesDocument6 pagesAircon NotesalbertNo ratings yet

- Machine Design Formula Spring and Belts SummaryDocument1 pageMachine Design Formula Spring and Belts SummaryalbertNo ratings yet

- Bolts and Screw Machine Design FormulasDocument1 pageBolts and Screw Machine Design FormulasalbertNo ratings yet

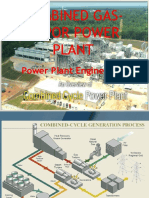

- Combined Gas-Vapor Power PlantDocument20 pagesCombined Gas-Vapor Power PlantalbertNo ratings yet

- Forecasting: Chapte RDocument27 pagesForecasting: Chapte RalbertNo ratings yet

- Parallel Line Method PDFDocument80 pagesParallel Line Method PDFalbertNo ratings yet

- Rotary PumpsDocument31 pagesRotary PumpsalbertNo ratings yet

- XI Geothermal Power PlantDocument11 pagesXI Geothermal Power PlantalbertNo ratings yet

- Types of Turbines: Turbine ClassificationsDocument6 pagesTypes of Turbines: Turbine ClassificationsalbertNo ratings yet

- Safety EngineeringDocument18 pagesSafety EngineeringalbertNo ratings yet