Professional Documents

Culture Documents

Assignment6 - CostAcc - Re Do Exercise - Vanessa

Uploaded by

Vanessa vnss0 ratings0% found this document useful (0 votes)

10 views5 pageschapter 6

Original Title

Assignment6_CostAcc_Re do exercise_Vanessa

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentchapter 6

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views5 pagesAssignment6 - CostAcc - Re Do Exercise - Vanessa

Uploaded by

Vanessa vnsschapter 6

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 5

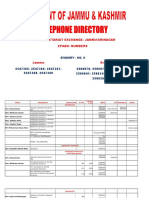

60,000 15,000

simple lenses (S3) Complex lenses (C5)

total per unit total per unit total

[1] [2] = 1 / 60,000 [3] [4] = [3] / 15,000[5] = [1] + [3]

direct materials $1,125,000 $18.75 $675,000 $45 $1,800,000

direct manufacturing labo 600,000 $10.00 195,000 13 795,000

total direct costs $1,725,000 $28.75 $870,000 $58 $2,595,000

indirect costs allocated 1,800,000 30 585,000 $39 2,385,000

total costs $3,525,000 $58.75 $1,455,000 $97 $4,980,000

(step 4) (step 3) (step 5)

budgeted budgeted

cost hierarchy total budgeted quantity of indirect

Activity category indirect costs cost allo base cost rate

[1] [2] [3] [4] [5] = [3] / [4]

design product sustainin $450,000 100 part square feet $4,500

setup molding machinebatch level $300,000 2,000 setup hours $150

machine operations output unit level $300,000 12,750 molding hours $24

shipment setup batch level $81,000 200 shipments $405

distribution output unit level $391,500 67,500 cubic feet deliver $6

administration facility sustaining $255,000 39,750 direct manuf labo $6

hours

(step 5)

budgeted cause n effect

indirect allo base and

cost rate activity cost

[5] = [3] / [4] [6]

per part squer design increase when molds more complex

per setup hourindirect setup cost increase with setup hours

per mold hour indirect cost operate mold increase with molding hours

per shipment shipping costs incurred increase with number of shipment

per cubic delivdistribution cost increase with cubic feet of packages delivered

per direct labothe demand administrative resource increase with direct

hour manuf labor hour

60,000 15,000

simple lenses (S3) Complex lenses (C5)

total per unit total per unit

cost desrciption [1] [2] = 1 / 60,000 [3] [4] = [3] / 15,000

Direct costs:

Direct materials $1,125,000 $19 $675,000 $45

direct manufacturing labor 600,000 10 195,000 13

direct mold cleaning & maintain co 120,000 2 150,000 10

total direct costs $1,845,000 $31 $1,020,000 $68

Indirect costs:

Design:

S3, 30 parts-sq.ft x $4,500 135,000 2.25

C5, 1,500 parts-sq.ft x $4,500 315,000 21

Setup of molding machines:

S3, 30 setup hours x $150 75,000 1.25

C5, 1,500 setup hours x $150 225,000 15

Machine operations:

S3, 900 mold machine hours x $5 450,000 7.5

C5, 3,750 mold machine hours x $550 187,000 12.46666667

Shipment setup:

S3, 100 shipments x $405 40,500 0.675

C5, 100 shipments x $405 40,500 2.7

Distribution:

S3, 45,000 cubic feet x $5,8 261,000 4.35

C5, 22,500 cubic feet x $5,8 130,500 8.7

Administration:

S3, 30,000 dir manuf labor x $6.4 192,453 3.20755

C5, 9750 dir manuf labor x $6.4151 62,547 4.1698

total indirect costs allocated 1,153,953 19.23255 960547 64.03646667

total costs 2,998,953 49.98255 1980547 132.0364667

total

[5] = [1] + [3]

$1,800,000

795,000

270,000

$2,865,000

450,000

300,000

637,000

81,000

391,500

255,000

2114500

4979500

You might also like

- CH 5 - Activity Based CostingDocument12 pagesCH 5 - Activity Based CostingPaRas NaSa100% (1)

- Metrics CGMDocument128 pagesMetrics CGMFrank Galvan100% (1)

- Subramanyam Chapter07Document34 pagesSubramanyam Chapter07Saras Ina Pramesti100% (2)

- Session 11 Chapter 5 Chopra 5thedDocument28 pagesSession 11 Chapter 5 Chopra 5thedNIkhilNo ratings yet

- 05 Wilkerson Company Solution - StudentsDocument9 pages05 Wilkerson Company Solution - StudentsVinyabhooshan Bajpai PGP 2022-24 Batch100% (1)

- UWI Mona ACCT1003 intro to cost mgmt accounting worksheet solutionsDocument5 pagesUWI Mona ACCT1003 intro to cost mgmt accounting worksheet solutionsJustine Powell100% (1)

- IBT Outline F09Document74 pagesIBT Outline F09emin_karimov100% (3)

- IB Economics 1 Resources Ans1Document28 pagesIB Economics 1 Resources Ans1shafNo ratings yet

- Ab Costing - ProblemsDocument8 pagesAb Costing - ProblemsMarcial VillegasNo ratings yet

- Exam Practice Questions: 1.11 Price Controls: IB EconomicsDocument3 pagesExam Practice Questions: 1.11 Price Controls: IB EconomicsSOURAV MONDALNo ratings yet

- Dry Bulk Cargo Handling in Perlis PortDocument5 pagesDry Bulk Cargo Handling in Perlis PortShahrul ShafiqNo ratings yet

- Fashion Pitch Deck With AnimationDocument18 pagesFashion Pitch Deck With AnimationAnya Vilardo100% (2)

- ABC & ABM: Activity-Based Costing and Management ExplainedDocument31 pagesABC & ABM: Activity-Based Costing and Management Explaineddiky supriadiNo ratings yet

- Cost Smoothing or Peanut Butter CostingDocument14 pagesCost Smoothing or Peanut Butter CostingShivangi SinghNo ratings yet

- University of Finance and MarketingDocument8 pagesUniversity of Finance and MarketingQuế Phương NguyễnNo ratings yet

- Management Accounting 1 Group Assignment FIRST SEMESTER 2022 - 2121910004301Document12 pagesManagement Accounting 1 Group Assignment FIRST SEMESTER 2022 - 2121910004301Quế Phương NguyễnNo ratings yet

- This Examples Are Adapted FROM Cost and Management Accounting (1996) Prentice Hall ISBN 0-13-205923-1Document10 pagesThis Examples Are Adapted FROM Cost and Management Accounting (1996) Prentice Hall ISBN 0-13-205923-1pandy1604No ratings yet

- ABC Costing Lecture1Document12 pagesABC Costing Lecture1Nusrat JahanNo ratings yet

- 5-31 Original Activity-Based Costing, Activity-Based ManagementDocument12 pages5-31 Original Activity-Based Costing, Activity-Based ManagementJim ChaNo ratings yet

- EMMPPE ASSOCIATES MONTHLY PRODUCTION REPORTDocument10 pagesEMMPPE ASSOCIATES MONTHLY PRODUCTION REPORTdsivakumarNo ratings yet

- Ch.2 - Job CostingDocument26 pagesCh.2 - Job Costingahmedgalalabdalbaath2003No ratings yet

- ABC Costing Autumn 19Document15 pagesABC Costing Autumn 19Tory IslamNo ratings yet

- ABC Costing Breakdown for Vusani ManufacturersDocument37 pagesABC Costing Breakdown for Vusani ManufacturersVj TjizooNo ratings yet

- Man Acc 2Document11 pagesMan Acc 2KathleneGabrielAzasHaoNo ratings yet

- Pma Test 1 2022Document6 pagesPma Test 1 2022Janielle LambertNo ratings yet

- Cost ManagementDocument10 pagesCost ManagementSuhailNo ratings yet

- F5 Performance Management June 2014 AnswersDocument9 pagesF5 Performance Management June 2014 AnswersĐào Thị Thu ThủyNo ratings yet

- Example-2 With SolutionDocument4 pagesExample-2 With SolutionDeepNo ratings yet

- Kerjakan 4-12 Dan 4 - 17: 1. "Plantwide"Document4 pagesKerjakan 4-12 Dan 4 - 17: 1. "Plantwide"natan. lieNo ratings yet

- Cost allocationDocument10 pagesCost allocationtirigotu57No ratings yet

- Analyze manufacturing costs and variances for Marston, IncDocument11 pagesAnalyze manufacturing costs and variances for Marston, IncCharles GohNo ratings yet

- 11 32 PDFDocument15 pages11 32 PDFNicNo ratings yet

- ABC CostingDocument7 pagesABC CostingNafiz RahmanNo ratings yet

- Chapter 5 - ExercisesDocument6 pagesChapter 5 - Exercisesotaku25488No ratings yet

- Managerial Accounting - Classic Pen Company Case: GMITE7-Group 7Document21 pagesManagerial Accounting - Classic Pen Company Case: GMITE7-Group 7bharathtgNo ratings yet

- Ca Inter Cost Management Accounting Test 2 Unscheduled Solution 598020012022Document14 pagesCa Inter Cost Management Accounting Test 2 Unscheduled Solution 598020012022Deppanshu KhandelwalNo ratings yet

- City Buildings Business PowerPoint TemplateDocument15 pagesCity Buildings Business PowerPoint TemplateSalman SajidNo ratings yet

- Aashutosh Agrawal - Dushyant Singh - 2020MBA027 - 2020MBA013Document8 pagesAashutosh Agrawal - Dushyant Singh - 2020MBA027 - 2020MBA013Ashita PunjabiNo ratings yet

- 7114afe WK5 (WS3) AnsDocument8 pages7114afe WK5 (WS3) AnsFrasat IqbalNo ratings yet

- CVP Analysis and Budgeting ToolsDocument16 pagesCVP Analysis and Budgeting ToolsNavin El NinoNo ratings yet

- ABC COSTING FOR TRIMAKE LIMITEDDocument27 pagesABC COSTING FOR TRIMAKE LIMITEDchina xiNo ratings yet

- Solutions Ch. 7 ABCDocument11 pagesSolutions Ch. 7 ABCThanawat PHURISIRUNGROJNo ratings yet

- Activity Based CostingDocument20 pagesActivity Based CostingArpit SahaiNo ratings yet

- Answers To Test Your Understanding: Cost Accounting Chapter 1 Cost Classification, Concepts and TerminologyDocument10 pagesAnswers To Test Your Understanding: Cost Accounting Chapter 1 Cost Classification, Concepts and TerminologyAnonymous vA2xNfNo ratings yet

- Joint Cost Allocation MethodsDocument29 pagesJoint Cost Allocation MethodsInanda MeitasariNo ratings yet

- Activity-Based Costing and ManagementDocument22 pagesActivity-Based Costing and ManagementDaniel John Cañares LegaspiNo ratings yet

- Code 4Document8 pagesCode 4Đỗ Hải MyNo ratings yet

- Tugas Kasus Akuntansi Manajemen ABCDocument3 pagesTugas Kasus Akuntansi Manajemen ABCutari yani dewiNo ratings yet

- Tugas-Kasus - 4.12Document3 pagesTugas-Kasus - 4.12niti dsNo ratings yet

- ABC and Cost Management ToolsDocument132 pagesABC and Cost Management ToolsAmanda BarkerNo ratings yet

- Allocation and Apportionment and Job and Batch Costing Worked Example Question 20Document2 pagesAllocation and Apportionment and Job and Batch Costing Worked Example Question 20Roshan RamkhalawonNo ratings yet

- Chapter 8 Solutions ExercisesDocument25 pagesChapter 8 Solutions Exerciseswajeeda awadNo ratings yet

- Finch Excel ReportDocument15 pagesFinch Excel ReportshuvorajbhattaNo ratings yet

- Indicative Answers:: N12405 MAD II Seminar 3 Activity-Based CostingDocument2 pagesIndicative Answers:: N12405 MAD II Seminar 3 Activity-Based CostinganalsluttyNo ratings yet

- ABCDocument18 pagesABCRohit VarmaNo ratings yet

- Chapter 5. Activity Based CostingDocument28 pagesChapter 5. Activity Based CostingbellaNo ratings yet

- ABC - Practice Set Answer and SolutionDocument4 pagesABC - Practice Set Answer and SolutionYvone Ehnnery BumosaoNo ratings yet

- BTVN Chap3 Lâm Thị Hiền Linh MSV 2012250042Document3 pagesBTVN Chap3 Lâm Thị Hiền Linh MSV 2012250042Nguyễn Ngọc Hà MyNo ratings yet

- Suggested Answers Certificate in Accounting and Finance - Autumn 2014Document6 pagesSuggested Answers Certificate in Accounting and Finance - Autumn 2014IrfanNo ratings yet

- Group 6 Revised (ABC)Document11 pagesGroup 6 Revised (ABC)Jeremiah NcubeNo ratings yet

- ABC SystemDocument11 pagesABC SystemSyarifatuz Zuhriyah UmarNo ratings yet

- Measuring and Managing Process Performance: QuestionsDocument4 pagesMeasuring and Managing Process Performance: QuestionsAshik Uz ZamanNo ratings yet

- Measuring and Managing Process Performance: QuestionsDocument4 pagesMeasuring and Managing Process Performance: QuestionsAshik Uz ZamanNo ratings yet

- Session 2Document17 pagesSession 2SylvesterNo ratings yet

- 12914sugg_pe2_gp2_1Document33 pages12914sugg_pe2_gp2_1harshrathore17579No ratings yet

- Total Annual Overhead CostsDocument3 pagesTotal Annual Overhead CostsJEYASHREE ESTEBANNo ratings yet

- Final Exam - Inter 1 (Batch 2022) - RevDocument14 pagesFinal Exam - Inter 1 (Batch 2022) - RevVanessa vnssNo ratings yet

- Procedures VanessaDocument1 pageProcedures VanessaVanessa vnssNo ratings yet

- Review Quiz Inter1Document9 pagesReview Quiz Inter1Vanessa vnssNo ratings yet

- Assignment 4 - CostAcc - ExerciseDocument22 pagesAssignment 4 - CostAcc - ExerciseVanessa vnssNo ratings yet

- Midterm Exam Inter1 - Sem20222 Solution OutlineDocument15 pagesMidterm Exam Inter1 - Sem20222 Solution OutlineVanessa vnssNo ratings yet

- UntitledDocument1 pageUntitledVanessa vnssNo ratings yet

- Quiz Inter1 C1Document3 pagesQuiz Inter1 C1Vanessa vnssNo ratings yet

- Assignment12 CostAcc RedoDocument4 pagesAssignment12 CostAcc RedoVanessa vnssNo ratings yet

- Assignment2 CostACC VanessaDocument7 pagesAssignment2 CostACC VanessaVanessa vnssNo ratings yet

- Budget for Casual and Deluxe Granite Tables ProductionDocument6 pagesBudget for Casual and Deluxe Granite Tables ProductionVanessa vnssNo ratings yet

- Assignment7 - CostAcc - Re Do Exercise - VanessaDocument5 pagesAssignment7 - CostAcc - Re Do Exercise - VanessaVanessa vnssNo ratings yet

- Assignment3 CostAcc Summary VanessaDocument5 pagesAssignment3 CostAcc Summary VanessaVanessa vnssNo ratings yet

- Assignment6 CostAcc Summary VanessaDocument2 pagesAssignment6 CostAcc Summary VanessaVanessa vnssNo ratings yet

- Theories of International Trade and InvestmentDocument28 pagesTheories of International Trade and InvestmentSushant YattamNo ratings yet

- Chapter 1 Creating Value in The Service EconomyDocument26 pagesChapter 1 Creating Value in The Service Economyrami elshaheibiNo ratings yet

- GVK Airport Mumbai Bidding ProcessDocument25 pagesGVK Airport Mumbai Bidding ProcessRakesh RaushanNo ratings yet

- MOBILE BILLDocument3 pagesMOBILE BILLAsheesh KumarNo ratings yet

- Directory SrinagarDocument8 pagesDirectory SrinagarShoaib KhanNo ratings yet

- Warm Breezes Luxury Couples Resort Delights ClientsDocument7 pagesWarm Breezes Luxury Couples Resort Delights ClientsWendy ChanNo ratings yet

- AIA Compensation Report 2019 Shows Near-Record GrowthDocument7 pagesAIA Compensation Report 2019 Shows Near-Record GrowthThuy Thanh LeNo ratings yet

- Strategic Chap 6 2022Document33 pagesStrategic Chap 6 2022anwar jemalNo ratings yet

- Russian Exports DADocument23 pagesRussian Exports DACarolineNo ratings yet

- 01 - Arquitectura en AfricaDocument44 pages01 - Arquitectura en AfricaINFRAESTRUCTURA TARAPOTONo ratings yet

- Global Business Environment - The External Macro EnvironmentDocument10 pagesGlobal Business Environment - The External Macro Environmentoureducation.in100% (1)

- Unomboti Jesu NdianiDocument17 pagesUnomboti Jesu NdianiMufundisi_RuvimboNo ratings yet

- Dairy Milk in FranceDocument3 pagesDairy Milk in FrancemeanestNo ratings yet

- CHAPTER 3 Supply and DemandDocument5 pagesCHAPTER 3 Supply and DemandAliah CyrilNo ratings yet

- Talent Labs Private Limited Gurugram Haryana Pay Slip For The Month of April 2022Document1 pageTalent Labs Private Limited Gurugram Haryana Pay Slip For The Month of April 2022Gamer JiNo ratings yet

- IGCSE Business Studies Note Chapter 25Document3 pagesIGCSE Business Studies Note Chapter 25emonimtiazNo ratings yet

- The Ultimate Guide to Calculating Customer Lifetime Value (LTVDocument2 pagesThe Ultimate Guide to Calculating Customer Lifetime Value (LTVSangram PatilNo ratings yet

- Worksheet 2 Integers RevisionDocument2 pagesWorksheet 2 Integers RevisionNaruto Uzumaki100% (1)

- Sub-Agency-Mango 2Document56 pagesSub-Agency-Mango 2Yudhi LatuyNo ratings yet

- Crisil Sme Connect Jul10Document44 pagesCrisil Sme Connect Jul10atia2kNo ratings yet

- Payments Collection Methods in Export Import International TradeDocument4 pagesPayments Collection Methods in Export Import International Tradekrissh_87No ratings yet