0% found this document useful (0 votes)

109 views10 pagesMetal Casting Process Overview

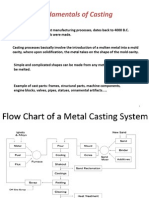

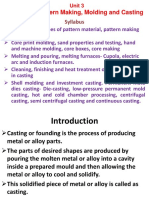

Casting is a process where molten metal is poured into a mold cavity and allowed to solidify. It involves making a pattern, mold cavity, heating metal, pouring liquid metal into the mold, and allowing it to solidify. Casting can produce complex shapes and internal cavities at a relatively low cost compared to other manufacturing processes. However, castings have a rougher surface finish and wider tolerances compared to other processes. Patterns are models of the desired casting that are used to prepare the mold cavity and allow for shrinkage, draft, and machining allowances between the pattern and final casting. Patterns are typically made of wood, metal, plastic, plaster, or wax depending on factors like the number

Uploaded by

Biren kumar SamalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

109 views10 pagesMetal Casting Process Overview

Casting is a process where molten metal is poured into a mold cavity and allowed to solidify. It involves making a pattern, mold cavity, heating metal, pouring liquid metal into the mold, and allowing it to solidify. Casting can produce complex shapes and internal cavities at a relatively low cost compared to other manufacturing processes. However, castings have a rougher surface finish and wider tolerances compared to other processes. Patterns are models of the desired casting that are used to prepare the mold cavity and allow for shrinkage, draft, and machining allowances between the pattern and final casting. Patterns are typically made of wood, metal, plastic, plaster, or wax depending on factors like the number

Uploaded by

Biren kumar SamalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd