Professional Documents

Culture Documents

Sarco Bcs

Uploaded by

tedy cosmicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sarco Bcs

Uploaded by

tedy cosmicCopyright:

Available Formats

Controls

Boiler

Boiler Blowdown

Recommended Pipeline Components for

& CCD

BCS1 Blowdown System

Blowdown

from

boiler

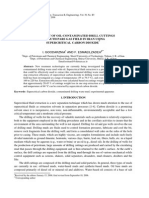

M10S ball valve

1/4" BSP plug

strainer BCV1 blowdown valve

LCV1 check valve

PT2 plug tail

CP10 sensor S10 sensor

chamber

M10S ball valve

Blowdown

to heat recovery

• For TDS systems with probe in pipeline system

• System with standard BCV1 blowdown valve suitable for:

- boiler pressures up to 203 psig

- blowdown rates up to 1,298 lb/h

• System with UL Listed BCV1 blowdown valve suitable for:

- boiler pressures up to 130 psig

- blowdown rates up to 1,050 lb/h

Description Installation

The recommended BCS1 pipeline components listed below will Items have been selected for straightforward installation in accor-

enable straighforward installation of a TDS control system where dance with the Installation and Maintenance Instructions provided

the probe assembly is to be mounted in the pipeline, rather than with each component.

directly in the boiler shell.

The recommended BCS1 pipeline installation consists of the following items: -

Qty Description Materials Stock#

1 S10 Sensor Chamber (1/2" NPT) Stainless Steel 4032090

1 CP10 Sensor & gasket (UL Listed) Stainless steel body & pin, PEEK plastic insulator 4030100

1 PT2 Plug tail (3/8" BSP, UL Listed) Brass body 0870396

1 LCV1 Lift check valve (1/2" NPT) Bronze 293190

1 Y type strainer (1/2" NPT, 20 mesh) Cast Iron 60310

1 Blowoff plug for strainer (3/8" NPT) Forged steel 48846

2 Model 10S Ball valves (1/2" NPT) Zinc plated forged carbon steel 3397310

Either 1 BCV1 (120v, UL Listed, CSA) Brass body, stainless steel seat, PTFE seal 4034098

Or 1 BCV1 (120v, Standard version) Brass body, stainless steel seat, PTFE seal 4034097

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only.

In the interests of development and improvement of the product, we reserve the right to change the specification. TI-9-404-US 04.01

You might also like

- Etymology: History of The AutomobileDocument5 pagesEtymology: History of The Automobilelatchanyanana100% (1)

- Surge ArrestorDocument47 pagesSurge ArrestorKlayNo ratings yet

- Flanged Ball Valves ANSI CLASS 150 & 300: Full BoreDocument20 pagesFlanged Ball Valves ANSI CLASS 150 & 300: Full BoreBayu Aji100% (1)

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Boeing Bond and Ground Job AidDocument8 pagesBoeing Bond and Ground Job AidEdwin ValenciaNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Coordination CompoundDocument34 pagesCoordination CompoundsukoyoNo ratings yet

- STEAMcalcDocument3,270 pagesSTEAMcalcSteve WanNo ratings yet

- CVF-SVF - BaumannDocument16 pagesCVF-SVF - BaumannMwila ChambaNo ratings yet

- SR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataDocument41 pagesSR - Single Package - CO (Const) - Saudi (R410A60Hz) - MFL67452911 - 6CUK0-01A (June 2015) - (7.5 To 15 TR) .Technical DataShaikhMazharAhmedNo ratings yet

- Pipe Material Specs (MCP)Document106 pagesPipe Material Specs (MCP)BoulHich BoulHichNo ratings yet

- Active Public SpaceDocument166 pagesActive Public SpaceWolfang CarvajalNo ratings yet

- TechnipFMC - Pipeline StrainersDocument6 pagesTechnipFMC - Pipeline StrainersYadir SánchezNo ratings yet

- Cryogenic Valves For Industrial Gas Applications-43-44Document2 pagesCryogenic Valves For Industrial Gas Applications-43-44Abdul Hadi RashidNo ratings yet

- Data Sheet Purgador PT65-40Document2 pagesData Sheet Purgador PT65-40Douglas Tondello100% (1)

- Seriestvs 4000Document4 pagesSeriestvs 4000Jimit ShahNo ratings yet

- 8040 NC PilotDocument4 pages8040 NC PilotMaximilianoAlvarezNo ratings yet

- Check Valve Type NRVA: Data SheetDocument8 pagesCheck Valve Type NRVA: Data SheetleticiaNo ratings yet

- 33 50 10BDocument9 pages33 50 10BSumner TingNo ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet

- Cryogenic Pressure RegulatorDocument4 pagesCryogenic Pressure RegulatordhaktodesatyajitNo ratings yet

- Backflow Preventers With Controllable Reduced Pressure Zone: Technical Data SheetDocument4 pagesBackflow Preventers With Controllable Reduced Pressure Zone: Technical Data SheetNeyker FariaNo ratings yet

- Asco Series 210 Gas Shutoff No CatalogDocument2 pagesAsco Series 210 Gas Shutoff No CatalogManuel ParraNo ratings yet

- BOQ For Bought Out Items (Steam) PDFDocument3 pagesBOQ For Bought Out Items (Steam) PDFsppatilNo ratings yet

- Asco Series 040 NC CatalogDocument4 pagesAsco Series 040 NC CatalogrtgeorgeNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- NUTRON Forged Steel Floating Ball Valve Model T3 & B3 - XDocument32 pagesNUTRON Forged Steel Floating Ball Valve Model T3 & B3 - XElinton SarmientoNo ratings yet

- Valvula Bola Trunnion TVDocument6 pagesValvula Bola Trunnion TVRicNo ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Gas Shutoff Valves: FeaturesDocument136 pagesGas Shutoff Valves: FeaturesJuan BejaranoNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- HW39TechSPECIFICATION-Feb2 2021Document7 pagesHW39TechSPECIFICATION-Feb2 2021archteknik.infoNo ratings yet

- Specialties and Accessories: Buffer Tank Hydraulic SeparatorDocument4 pagesSpecialties and Accessories: Buffer Tank Hydraulic SeparatorShoukat Ali ShaikhNo ratings yet

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- General Ducty Valves SpecDocument12 pagesGeneral Ducty Valves SpecpursuitofhappynessinNo ratings yet

- Fig 520 High Lift Safety Valve: Features & BenefitsDocument3 pagesFig 520 High Lift Safety Valve: Features & Benefitst_rajith1179No ratings yet

- Data Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09Document3 pagesData Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09appril26No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- KSB BEV BEV LO PDFDocument36 pagesKSB BEV BEV LO PDFBernardo Salinas GonzalezNo ratings yet

- FCU Link V2 CatalogueDocument17 pagesFCU Link V2 CatalogueVipul JainNo ratings yet

- RT 520 1 VL Valves ListDocument1 pageRT 520 1 VL Valves ListÇAĞATAY ÇALIŞKANNo ratings yet

- CVS10 Ti P029 21 en PDFDocument2 pagesCVS10 Ti P029 21 en PDFAlejandro Medina GómezNo ratings yet

- KBV21i and KBV40i Key Operated Boiler Blowdown Valves-Technical InformationDocument5 pagesKBV21i and KBV40i Key Operated Boiler Blowdown Valves-Technical Informationunnamed90No ratings yet

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- P Series Pipe - Needle Valve CatalogDocument4 pagesP Series Pipe - Needle Valve CatalogHenry PorcoNo ratings yet

- TDC46M Carbon Steel Thermodynamic Steam Trap With Maintainable Seat-Technical InformationDocument5 pagesTDC46M Carbon Steel Thermodynamic Steam Trap With Maintainable Seat-Technical InformationDavid Bottassi PariserNo ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- Movitec VCF: High-Pressure In-Line Pumps 50 HZDocument40 pagesMovitec VCF: High-Pressure In-Line Pumps 50 HZHardik Vavdiya100% (1)

- TLV - Electro-Pneumatic Control Valve For Steam PDFDocument2 pagesTLV - Electro-Pneumatic Control Valve For Steam PDFsirballesterosNo ratings yet

- VG221 - 2 Port Control ValveDocument4 pagesVG221 - 2 Port Control ValveNoah MusundiNo ratings yet

- EMS 003 Class B (HTHW) - Piping Materials Fabrication and Line ClassesDocument3 pagesEMS 003 Class B (HTHW) - Piping Materials Fabrication and Line ClassesclintNo ratings yet

- D.O. 111, S 2017Document8 pagesD.O. 111, S 2017ZA TarraNo ratings yet

- Fig.+MH737 DRVValve Hatt DS 120918Document1 pageFig.+MH737 DRVValve Hatt DS 120918SHINOS 3SNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Pipeline Strainer - SpecsDocument6 pagesPipeline Strainer - SpecsCristhian AyanomeNo ratings yet

- Plumbing Submittal - VIR - BMW SHOWROOM ValvesDocument135 pagesPlumbing Submittal - VIR - BMW SHOWROOM Valvessenthilonline15No ratings yet

- Dfu Ti D148 01 BRDocument2 pagesDfu Ti D148 01 BRNoo SokiNo ratings yet

- Catalog Series 212 Composite Asco Global en 3674082Document5 pagesCatalog Series 212 Composite Asco Global en 3674082LuisNo ratings yet

- HD 282 Butterfly Valves R02 17Document4 pagesHD 282 Butterfly Valves R02 17Satish IndiaNo ratings yet

- AVKDocument2 pagesAVKpiscesguy78No ratings yet

- Cryogenic/Pressure Build Regulator 3/8" and 1/2" NPT, BSPT Inlet 400 Psig (28 Bar)Document2 pagesCryogenic/Pressure Build Regulator 3/8" and 1/2" NPT, BSPT Inlet 400 Psig (28 Bar)Abd NaamiNo ratings yet

- Datasheet 1803 enDocument2 pagesDatasheet 1803 enPhan Việt AnhNo ratings yet

- Brass Ball Valve With Butterfly HandleDocument1 pageBrass Ball Valve With Butterfly HandleS V RAJA LEHRYNo ratings yet

- ST25TechSPECIFICATION JAN2021Document11 pagesST25TechSPECIFICATION JAN2021DHINAKARAN KumarNo ratings yet

- Green by Dhruv Futnani - International Profile Jan 2015Document4 pagesGreen by Dhruv Futnani - International Profile Jan 2015sarikaNo ratings yet

- G5 Low Profile Unit Cooler Ver 2.0Document10 pagesG5 Low Profile Unit Cooler Ver 2.0Wawan NuryanaNo ratings yet

- Yurzhenko - Module1 Last 06.09.22 Marine Diesel EngineDocument38 pagesYurzhenko - Module1 Last 06.09.22 Marine Diesel EngineSasha KaraNo ratings yet

- 1985-D Y Goswami-Heat Transfer Analysis in Enviromental ControlDocument5 pages1985-D Y Goswami-Heat Transfer Analysis in Enviromental ControlraviNo ratings yet

- Product Data: 39T Central Station Air-Handling UnitsDocument100 pagesProduct Data: 39T Central Station Air-Handling UnitsJesus CantuNo ratings yet

- Fundamentals of Transportation EngineeringDocument1 pageFundamentals of Transportation EngineeringDaniel B. BalmoriNo ratings yet

- Gso Adv01 09Document10 pagesGso Adv01 09Riyaz MydeenNo ratings yet

- New Coaching 2Document11 pagesNew Coaching 2jj012586No ratings yet

- Arc Master 160 Carte TehnicaDocument114 pagesArc Master 160 Carte TehnicaIon MoldoveanuNo ratings yet

- Eastman 2380 Tech SheetDocument2 pagesEastman 2380 Tech SheetAndy MaxNo ratings yet

- PDFDocument76 pagesPDFRavishankarNo ratings yet

- Science Notes For Class9th CbseDocument3 pagesScience Notes For Class9th CbseMithilesh Kr PremNo ratings yet

- Civil Designer CVDocument4 pagesCivil Designer CVPratikNo ratings yet

- 2008 27 Summer Wiring Matters Iee Ring Circuit MeetingDocument2 pages2008 27 Summer Wiring Matters Iee Ring Circuit MeetingTriam Patience MundaNo ratings yet

- Toughness of Spider Silk at High and Low TemperaturesDocument5 pagesToughness of Spider Silk at High and Low TemperaturesDanicaNo ratings yet

- Precision Pulse Weld Process GuideDocument10 pagesPrecision Pulse Weld Process GuideJhony ValenciaNo ratings yet

- Treatment of Oil Contaminated Drill CuttingsDocument5 pagesTreatment of Oil Contaminated Drill CuttingsWilliam50% (2)

- PHYF105 Tutorial Questions S3y0809edDocument17 pagesPHYF105 Tutorial Questions S3y0809edfillyana01No ratings yet

- Apparel-New SL PDFDocument9 pagesApparel-New SL PDFNeeraj KumarNo ratings yet

- Kobra CycloneDocument3 pagesKobra CycloneShredman10No ratings yet

- Construction Schedule - FIPAG V1.4Document4 pagesConstruction Schedule - FIPAG V1.4mawanda FranciscoNo ratings yet

- Volvo T450DDocument18 pagesVolvo T450Dgodoy1989100% (1)

- Baknor Cold Plates Liquid and BrazedDocument2 pagesBaknor Cold Plates Liquid and Brazedthemike03No ratings yet