Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

argmsf0 ratings0% found this document useful (0 votes)

8 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesUntitled

Untitled

Uploaded by

argmsfCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

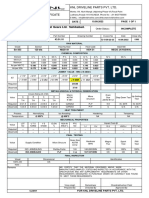

McD Submission Form TIMKEN

(Material Cert Database ) Where You Turn

soporte. Fig ~]sipatetone, fac dae: mee]

Purchase Order No,_[sts/R0/2223/00906 _] HeatNumber :fwies1s2 7 j

Ntsouce ame fiURANDSUMINETACPROCESING TD

‘tt Source Location [THANE MAHARASHTRA

‘Timken Specification “aM

cde fie) fa) fe

Receiving Plant Location: JKOLABIRASERAILKELA KHARSWANJHARKHAND

(Complete alliformation on this form.

Print form and e-mail or Fax this form along witha legible copy ofthe of the Original Melt Source

Steel Certificate,

!f'you have any questions contact your Supplier Qualty or Purchasing Representative.

'E-mail to : ter-mfgtech@timken.com

“\Fax to: 001-330-458+ 6888,

This form i located nthe Timken Supple Network at hoi/sniimken com

Peet ant hemionneededopecenjoutunbicas, [TS

Mateslak Receive. :

Po-d06

f+ Sf

TEST’ CERTIFICATESTECHNICAL SERVICES DEPT MUKAND SUMI SPECIAL STEEL LIMITED

37049398/08 HEAT NO: M163152 CIN:U2731@MH2@15PLC260936

SIGMA HTS. INVOICE NO: 22/10080/08

INVOICE DT: 11/12/22

T.C.DATE : 11/12/22

SPECNO 3M.6-S405

TCNO: —1C22121117049398/08

THE MATERIAL SUPPLIED CONFORMS TO THE SPECIFICATION MENTIONED PAGEN(

WR WD DE

wa

GRADE SAE 8319 cons 1 coLour

NIL

SIZE 18,70 MM OIA. WT(MT) + @.664 SUPPLY COND:HR+ANNEALED+CD

ROUTE! MBF-EOF-LF-VO-Ce ‘

naw Nax ACTUAL nnn MAX ACTUAL

ox :1708 -2300 +2028 H2ppm 2.00 Ba

Nn % 1,05@@ «© 1.4000 «1.3408 As & -0300 0012

Siz \1500 13500 12350 Sb x 10150 $0002

> 10250 e140

sk 0056 10150 10080

sn x 10200 ‘e018

Nix 2080 24500 £2830

cre 14500 £7500 16620

qj cu % +3000 10210

a Me x -08e0 12800 11730

Tx 10050 20023

al %. .0120 10500 10278

O2pon 45 ua ,

‘MECHANICAL, NIN nax ACTUAL TEST COND: HR+ANNEALEDS CD

SUIS (MPA) 650.00 770.08 690.09 &

HARDNESS HRB 92.00 | 98.08 94.80 - 96.00

METALLURGICAL NIN max SACTL

., GRN STZE(ASTH E222) 6 7-8

SWACRO (ASTM E382) c3R2s2 c3n2s2

Mernctuson A 8

TASTH E-454 JT T

ST.MAX 2,58 1.50 2,00

actual 1188 se 50

SPEC NO.: 3M.6 DT. 2016-09-26, 3M.16 DT, 2219-06-05

NO ABNORMAL OR HARMFUL RADIOACTIVITY LEVELS IN MATERIAL; 100% COILS

COATING (SPEC LIME COATING 1.5 G/MZ)-ACTUAL PHOSPHATE COATING 12-15

DI VALUE: 2.82(SPEC = 2.73-3.01) ; 0S (SPEC 2.0(38 MICRON)) = @.5

DECARB = 0.15 MM ; 100% BILLET UT TESTED

Ne Ated ers coomuninted do anc a

In case of any dissatisfaction contac

Chief of Projects & Operations

GENERATED BY COMPUTER IRC HR.O.P.Singh, Nobile « e333891122

MAIL: opsingh@mukandsumi.com

ECT TESTED

Gus /m2

sslieia ounce oe me anres tsi 022-21727500

sbape-ae

omnis Saab pur Road,Kalwe, Thane, Maharashtra re) cepitentent-cos

Dom emmetawee ;

et ee ay cheer) verific) on

comin 79 Gra $319

ge

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 550HV EhtDocument1 page550HV EhtargmsfNo ratings yet

- 550HV EhtDocument1 page550HV EhtargmsfNo ratings yet

- Riday: Eotf On 3CDocument1 pageRiday: Eotf On 3CargmsfNo ratings yet

- HT LayoutDocument6 pagesHT LayoutargmsfNo ratings yet

- HT Zone Layout SampleDocument5 pagesHT Zone Layout SampleargmsfNo ratings yet

- TodyDocument1 pageTodyargmsfNo ratings yet

- UntitledDocument1 pageUntitledargmsfNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- HsuejdjDocument1 pageHsuejdjargmsfNo ratings yet

- UntitledDocument2 pagesUntitledargmsfNo ratings yet

- Wi For Surface Grinding and Sample Cutting MachineDocument2 pagesWi For Surface Grinding and Sample Cutting MachineargmsfNo ratings yet

- Stronger.: Metallurgical RequestDocument2 pagesStronger.: Metallurgical RequestargmsfNo ratings yet

- Scientific Heat Treatment Services PVT LTD Metallurgical Inspection ReportDocument1 pageScientific Heat Treatment Services PVT LTD Metallurgical Inspection ReportargmsfNo ratings yet

- Dhiraj: Operator Wise Production For The Month Feb'23Document55 pagesDhiraj: Operator Wise Production For The Month Feb'23argmsfNo ratings yet

- Payment Receipt: Service Provider PayerDocument1 pagePayment Receipt: Service Provider PayerargmsfNo ratings yet