0% found this document useful (0 votes)

509 views6 pagesA. General Notes

The document provides construction notes for a building project. It outlines general notes applying to all drawings, as well as specific notes for concrete and reinforcement, masonry and concrete blocks, foundations, steel, and a table of lap splice and anchorage lengths. The notes specify requirements for materials, dimensions, reinforcement, structural elements, and inspections/approvals.

Uploaded by

Natalie WrightCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

509 views6 pagesA. General Notes

The document provides construction notes for a building project. It outlines general notes applying to all drawings, as well as specific notes for concrete and reinforcement, masonry and concrete blocks, foundations, steel, and a table of lap splice and anchorage lengths. The notes specify requirements for materials, dimensions, reinforcement, structural elements, and inspections/approvals.

Uploaded by

Natalie WrightCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

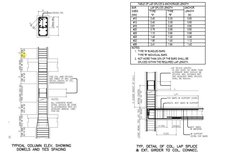

- Concrete & Reinforcement: Details on materials and workmanship for concrete, including specifications for reinforcing bars.

- General Notes: Overview of general construction notes, applicable to all structural, miscellaneous, and iron-precast concrete work.

- Masonry & Concrete Blocks: Guidelines for masonry work and specifications for concrete blocks used in construction.

- Foundation: Guidelines for foundation construction including footing, pilecap designs, and contractor requirements.

- Steel: Specifications for the design, fabrication, and erection of structural steel, including material and workmanship requirements.

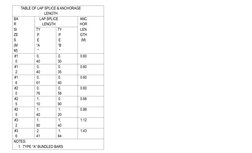

- Table of Lap Splice & Anchorage: Table detailing the lap splice and anchorage length for various bar sizes with notes for application.