Professional Documents

Culture Documents

Catalog 8FDG10-35

Uploaded by

Simon manoen0 ratings0% found this document useful (0 votes)

39 views9 pagesFor 8 series forks lift

Original Title

Catalog_8FDG10-35 (2)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFor 8 series forks lift

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views9 pagesCatalog 8FDG10-35

Uploaded by

Simon manoenFor 8 series forks lift

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

ENGINE POWERED FORKLIFT 8FG/8FD 1.0 to 3.5 ton

SERIES

The Mastery of True Potential

Mastery of any undertaking can only be achieved if there is true potential

and unwavering dedication to excellence. To Toyota, the & Series is the

proud culmination of 50 years in the pursuit of mastery in the development

and manufacture of forklifts.

All who experience the level of mastery in the 8 Series will be inspired to

reach for higher goals.

Here, Toyota integrated outstanding comfort and excellent operability into

operator's compartment that realizes operator friendliness. The 8 Series

is also equipped with high technology that contributes to the creation of a

safe workplace.

True Potential Through

Outstanding Comfort and Visibility

Comfort is a Toyota tradition. With the 8 Series, it starts from the time you

enter. Grab the large assist grip, place your foot on the wide, low step and

slide into the operator's seat that provides comfort, support and retention.

Once you have been seated and wrapped your hands around the small-

diameter steering wheel you will intuitively fee! that everything you need for

operating the forklift is within natural reach. You will also instantly realize that

you have a clear view of the forks and load. This comfort sets the stage for

reaching the true potential of the forklift from Toyota.

Easy Entry and Exit

[large assist rip, A deep wide stop and a

spatous opening team up for easy entry

nt the frit

Comfort and Support ORS* Seat Outstanding Visibility

‘The ORS seat can be adustod

180 mm forward and backward

te provide comfort ang support

to almost al sizes of operators

“ORS: Operator Restrain System

The overhead guard, mast and

Instrument panel have been

designed to prove excl

‘sb ofthe fork tis a

most frequent used it heights

Wide Floor Space

floor area enable 2

xed operating postion

that contebute to comfor,

True Potential Through Outstanding Operability

Toyota used the latest technology to reexamine forklift operation in its

search for enhanced operability. Motion-capture technolagy monitored

every aspect of operator movement looking for ways to make operation

more efficient. Based on these findings, well-thought-out design changes

were combined to make the 8 Series ready to transform every action of

the operator into smooth and efficient operation.

( a Te 2

Operator-Friendly Steering Wheel ~— Z

| —S—— S

The smalhdametr steering wee teams up wit he ul hydraulic

power steering systom fo provide excellent marewerably.

The steering column ofersstep-essagustment te accommodate i)

a wide range af operator preferences | il

Foot-Activated Parking Brake (Powershiifi@dels)

The operator simaly depresses the Barking brake pedal to setit

without changing operating gosion. A conveniently located handle

is used to release it i

Rear-Pillar Assist Grip (aa / Swivel

i

o facta operation in reverse

“The seat alo sels to the leftto

mace easier to enter and exit

‘he ori. An optional availble rear-ilar assist rp with 2 horn

button enhances comtor by oferng easy hor operation while

travalng in rovers

Fetinaeat hl Frown oe

Multifunction Display Gav

The Mulfunctionl Dp oes seul ntarmation for opratons. The folowing ae some ofthe

spay sorens

“125,

Combination Meter

Necessary instrumentation, such asthe fuel meter, water temperature indeatar ana hour mater

ae shown in an esy-o-montar digital format

Mini Lever Ga Diton

These small 3s)-"0-oprate

lovers provide ttl load handing

operation and travel

selection. A fatigue

aol

armrests provide. wolew

Joystick Gia [—Peseren ive

Both it and tit operation are

trl by a single ever.

Simultaneous liting and ting

8 operated

Fork Vibration Damper (a

Shock and vibration tothe load

uring lad hanling and ave

are suppressed by an

sccurltrin the hydraulic

sical forthe yiner.

True Potential Through Outstanding Stability

At Toyota, safety is top priority in the quest for attaining true potential. Here, the state-of-the-art technology found in

the System of Active Stability (SAS), which earned high praise on the 7 Series, helps to reduce the potential for

accidents. Other innovative functions, such as the Operator Presence Sensing System (OPS) and optional Travel and

Load Handling Control are ready to assist in protecting the operator and the load. Toyota's continuous efforts toward

safety provide you with a solid foundation for outstanding stability

Active Control Rear Stabilizer a

Note:The Active Control

ginal equipped wit

‘An onboard computer monars the mavemant ofthe fort and locks the swing

ofthe rar ale when necessary, such as dung turns

Stabilizers not installed when the frit is

‘pion dua front ee.

Active Mast Function Controller ca

Aetve Mast Front ik Angle Control

Forward mast tit angles automatically

restctd when heavy loads are bing handled

at ign mast eights.

Active Mast Rear Tt Speed Control

Bear it sped is controlled in elation to it

height. Mas tis slowed for beter control

thigh it heights an allowed to operate at

regular speed when lads ara closer tothe

round.

‘Automatic Fork Leveling Control

The operator simply presses button onthe

tit ever during iting forward operation from

the er tied poston and it will automaticaly

return the forks toa level postion, ready for

the next operation,

Active St

ing Synchronizer SAS CD

‘This function ensures that the poston of

corresponds withthe position of he rar ste

ing whee unvayinghy

wheels

‘Stem of Active Stability Operator Presence Sensing

Operator Presence Sensing System

This amp ituminats and a

signa sounds inform the

ator thal OPS

tobe activated,

‘A waning turction informs

the operator hen the

iret selection eer has

rat bee rtumad to neta,

his system use a switch sansor bul into the operator's seat to detec the

presence ofthe operator. I the operators not inthe normal operating

poston, travel power is interuped and load handling operations are stopped.

Note: OPS does not operate the brakes. Always et the parking brake before

leaving the fori

Travel OPS (snot availble on manual transmission models

Travel and Load Handling Control (aa

1. Li-Hoight and Load-Sensng Voice Speed Control

(Powershitt models)

‘This feature tmitsthe maximum speed the operator temps to travel while

caryng loads at high It heights, thereby reducing the lietnod of insta

due to sudden deceleration,

2 Lift Height and Load-Sensng Sudden Stat Of Prevention Feature

(Powershift mdels)

‘This feature suppresses sudden accleration of the vile to reduce the sk of

load spils in the event that te operator suddenly depresses the accelerator or

parals tha rection selection svtch while caryng loads at high thea.

3. Low-Speed Seting

This feature limits maximum speed toa preset level whan the sutch on the

MutitunctionDisplyis pressed. This canbe usefl at locations suchas customer

worksites that have diferent speed rls for outdoor and indoor operations.

4. Maximum Speed Limitation

This feature enables to lint maximum speed toa preset evel. This helps

operators maintain certain speed limits the wor area while rein ther rom

the ned to contol acceleration, and also reduces the need for forlit managers to

‘monitor he speed ofthe fork

5, Automate lile-Up Deve

The idle revotion of the engin is automatically increased during iting

operations so that loads wl be slowly ted up without depressing the accelerator.

It provides easy and proper load handing operation.

The following shouldbe note in regard to Travel and Load Handling Control

(n upgrade, the st speed may nat be reached due o engin ouput. Also on

own grade, gravy may cause preset sped o be exceeded. Although maximum

speed and sudden acceleration are reduced in ration to load height and weight,

this doesnot ossibily of tp-ovr. Toyota's advanced technology

haps reduce the potenti of fork instability. However, the operator i irataly

responsible for sae operaton.

True Potential Through Outstanding Environmental Friendliness

The & Series is easy to get along with. It is specially designed

to provide the operator and all those working nearby with a

pleasant work environment. Low noise operation, low exhaust

emissions and low vibration all mean that the 8 Series will

hardly be noticed as it diligently enhances productivity at the

workplace. And the 8 Series demonstrates that Toyota is

continuing to make progress in eliminating harmful chemicals

from the components of its forklifts, making them even more

environmentally friendly.

3-Way Catalytic Converter System Gai

Low-Noise Design c tne

Meet your silent partner. Thick-eaing under he flooroards andthe use of sound bal =

absorbing and sound-prooing mater all ork together o give the & Sere ow " 1

nose operation a

H ssem tv

90 aA

90) 4804) Se) Coe

88

wo a ao (80. ecronic contra fs used onthe 4Y engine to regulate the fue injection and

cr igniion systems. This is combines wih the 3-Way Calae Converter Systm to

lar ou carbon monoxide (0), hydrocarbon (HC) and nizogen oxide (NO gases.

"0 rel fer out card ide (CO), hydrocarbon (HC) and nitrogen aide (NOx) g

5FG 7 ‘3D 7D.

{Gasoline models ADL Diesel madee

Low-Vibration Design

Caretuly designed engine and

=

in mounts ramatialy

reduce the amount of vibration fet tthe Nleorboard and aFG

steering wheal

Diesel Particulate Filter DPF-I (aa

Ikuses an enbance tering system (Conaefier) rose

0 provide excellent black smoke

LE a fF 7 particle elimination. The DPF-II

arD 7D provides th additonal benefits of

eer ean tale string and lange

i Environmentally Friendly Design

The 8 Saris is tee of asbestos, mercury and cadmium. The amount of lead and

ea) fra) hexavalent chromium has also been dramatically reduced inorder to minimize the

Diesel medels affect onthe environment

True Potential Through Outstanding Reliability & Serviceability

Reliability is what Toyota forklifts have proven themselves to provide under harsh

conditions the world over. This is because Toyota is always committed to boosting

reliability. The use of resin parts has been reduced as much as possible along with other

steps to enhance durability. The result is a forklift that will offer an extended life.

Tilt Cylinder Boots

ch Bot covers the exposed portion ofthe rod

forthe tit eylinder, protecting it and he ol seas

Water-Resistant Connectors

Connectors for mast electrical components are

hight water-resistant, increasing te relly

of the elect system,

Long Life Tire Cla

Wear resistant tires help reduca running costs

and provide etende It

LED Headlights Ci

LED Rear Working Lights (iad

Power-saving, long-life LED ight ae avalable

forthe heaighs ang rear working lights.

Serviceability can help boost the reliability of a forklift and extend its service life.

The 8 Series has been designed so that anyone can easily inspect it. If service is

needed, easy access can help to reduce downtime.

Cooling System

Ample cooing raises

reliably by preventing

heating. The size of

the opening inthe

counterweght hasbeen

increased to optimize air

‘ow through the engine

compartment and power

unit

Engine Hood

The wide-opeing engine hood provides

easy acess for inspections or servicing.

Brako Fluid

Simply lit up te cover onthe pana to

kth oake fi,

Radiator Cover

No tool ae needed to remove the

radiator coer. The fasteners ean easily

be tured by hand to enable quick

Inspection or seicing

Hood Latch

‘The esy-o-opeate latch provides quick

‘access tothe engine compartment

Floorboard

-Atwopiece design makes th lorboard

easier to it and handle. Remove these

two places for wide open acess tothe

engine and pover tran.

Scheduled-Maintenance Hour

Warning Indicator gman pony)

When the set ime for maintenance is

reached this feature provides visible and

uct ntieation

CMU ACM UT as

ae Cue NM nau eC Cae

DU CS eR eo)

Ee ON eR aS oC ee MRD

the starting point and took a careful look at the forklift itself from every aspect.

The 8 Series stands ready to bring out the true potential in all owners and operators.

to make the aestast contribution to customer

prota

armoniaing the SAS tee Environmental alors ae eenirl to our

tna em nkng Cstomers have algo expressed a

that hae 7 nee forthe arronmer. a cancer that

Hisao Nagata hire, We hav adresses thi 6 sing 3

saltghaeine tse, Ths eld of ergonomis ii -pranged apprasch, I the antag

aa weep work Process, we recused and eliminated the se ot

The operatorto workin comforts an exremely materia tht ae envronmentaly sense,

During the developmen ofthe 8S Imparat faetorsn desig wt he highspeed also devslaped frit wih opel

ammamed our Sngomg gal provement ofthe presen-day logis business By

Selivbas th more than 4500 customer atenion

rye ants lged Us fo fal ree . re Metis tthe

he cura foo ¢ ementsin testy acteaner

na what those needs would beh :

‘The ret led us to conclude thatthe best sean

meta or sastyng caster needs west: hatha

iC makes «good ration fv, 2 wall ae ered he svalest deals ~neliding

onthe? Sens fatgue ach sere sea in fri tancrilay —

2a by fare tusing Tool’ stengths into fo ensure th dvelogment of tert bres

shat esi. Cost of ounersipis ls ‘ori unts tat uly sey custome pads

ef ralaby i crete ers of ok

‘continuing ou evolution tom the 7 Sei ane he epuation at Tojo

med for advances nth areas aly, tv a er te years

‘of oomethip ane

nental considerations ch 2 2

hrough making maintenance easier to ie

relation nada tothe siting Wwe have developed afore seres thats able enonages

—

TOYOTA

Development

Water Resistance Testing

‘The development and design ofthe & Series was done at the Toyota Takaha

Plant in Ach, Jaan, During pment sage, state-of-the-art technology

was used to get attr understanding of operator movement during fori

operation. This data was caefly analyzed and used to enhance the design ofthe

8 Series. Then the 8 Seis was exposed to tst condos far harsher thant will

rer experience on heb. The results remarabl okie series tat wil be

providing producti for years ana years to om

Date Sampling

MODEL VARIATION

IPA

1 Ton Series 2 Ton Sores 3Ton Sores

MAIN SPECIFICATIONS

Model TEN aT Ea Wa a cE

EDEL eME Lana) Me a Cc PM ea Le ERE]

Engine Model sen | 620 | 20 | wW20 [wet or] wen |roeto2| 20 [rot oz] wet oe

Load Capacity kg | 1,000 | 1,500 | 1,750 | 2,000 | 2,000 | 2,500 | 2500 | 3,000 | 3,000 | 3,500

Load Center mm| 500 | 00 | 500 | 500 | 500 | 500 | 500 | soo | soo | 500

(Overall Width

Turing Raus(utside)

(Overhead Guard Height

Length to Fork Face

NOTE: Powerahit models

mm] 1,045 | 1070 | 1,070 | 1,185 | 1.150 [1158 [1.150 | 1,255 | 1.240 [ 1,200

mm| 1910 | 1,990 | 2010 | 2040 | 2200 | 2090 | 2280 | 2190 | 2,430 | 2,490

mm| 2,080 | 2,080 | 2080 | 2,085 | 2110 | 2085 | 2110 | 2,085 | 2,170 | 2,180

mm| 2,240 | 2,285 | 2310 | 2360 | 2550 | 2420 | 2620 | 2505 | 2775 | 2,845

elole[>

ENGINE SPECIFICATIONS

Model areas I

Piston Displacement | ce 2,287 A Be eS

Rated Powertip | KW a) | J

RatedTorqelcpm. [Nm] 162,800

NOTE: { or 3(82}-9F080. 8185

Model Pe Ammer

pital Prra)

Piston Displacement | co 2.486 3,469

Rated Powerlp.m kW] tao) 492,200

Rated Torquelripm. Nm] 167,600 216/1,600

or {62-8020 253085,

‘Align reseed by Toyota hausves Comraon

@TOYOT, TOYOTA MATERIAL HANDLING INTERNATIONAL

Ce

‘CAT.AFG/AFD10-35(E)407/=)Prntes in Japan/No.71120060/1500,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bell B30E Tech ManualDocument24 pagesBell B30E Tech ManualSimon manoen50% (4)

- FuelSafe-brochure VIEWDocument8 pagesFuelSafe-brochure VIEWSimon manoenNo ratings yet

- Lecture - 11 - System - Design - Dev - Pneumatics and HydraulicsDocument54 pagesLecture - 11 - System - Design - Dev - Pneumatics and HydraulicsSimon manoenNo ratings yet

- Hydraulic Systems: Analysis and DesignDocument169 pagesHydraulic Systems: Analysis and DesignSimon manoenNo ratings yet

- UntitledDocument26 pagesUntitledSimon manoenNo ratings yet

- HD465-7, HD605-7, PresentationDocument36 pagesHD465-7, HD605-7, PresentationSimon manoen100% (1)

- Operation & Parts Manual Document No: 0062-D-84 REV 0Document31 pagesOperation & Parts Manual Document No: 0062-D-84 REV 0Simon manoenNo ratings yet

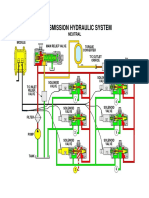

- Transmission Hyd SystemDocument4 pagesTransmission Hyd SystemSimon manoenNo ratings yet