Professional Documents

Culture Documents

Membranas Hydron

Uploaded by

Precision Plating CorreoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membranas Hydron

Uploaded by

Precision Plating CorreoCopyright:

Available Formats

HYDRON BW Membranes

BW-4040

HYDRON BW Membrane Elements with their hard shell fiberglass exterior provide outstanding performance for light industrial

systems. HYDRON Membranes are manufactured in a State-of-the-Art, ISO-9001-2000 certified automatic rolling facility which

provides you with a precise and advanced membrane element. HYDRON Membranes not only deliver an attractive cost to

benefit ratio, but also gives you a membrane that has consistently high quality and performance.

Hydron Membrane Elements can be used in a variety of mid sized light industrial applications, such as car wash, bottling,

BW-4040 manufacturing, water stores, food processing, and many other applications where a reliable, performance membrane is needed.

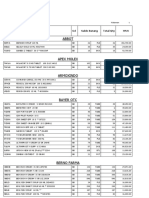

BW Membrane Specifications

Average Permeated Flow

Model Part Number Applied Pressure PSIG (BAR) Stable Rejection Rate (%) Minimum Rejection Rate (%)

GPD (m3/d)

BW BW-4040 150 (10.3) 2400 (9.1) 99.0 98.5

EXTREME OPERATION CONDITIONS MEMBRANE TYPE

Max. Working Pressure 600 psi (4.14 Mpa) (41.4 BAR) Polyamide Compound

Max. Feedwater Flow 16 gpm (3.6 m3/h)

TESTING CONDITIONS

Max. Feedwater Temperature 113°F (45 °C) Testing Pressure 150 psi (1.03Mpa) (10.3 BAR)

Max. Feedwater SDI 5 Temperature of Testing Solution 77 °F (25 °C)

Residual chlorine Concentration Concentration of Testing Solution (NaCl) 1500 ppm

of Feedwater <0.1ppm

pH Value of Testing Solution 7.5

pH Range of Feedwater Recovery Rate of Single Membrane Element 15%

during Continuous Operation 3~10

pH Range of Feedwater

during Chemical Cleaning 2~12

IMPORTANT INFORMATION

Max. Pressure Drop

of Single Membrane Element 15psi (0.1Mpa) (1.03 BAR)

Under certain conditions, the presence of free chlorine and other oxidizing

agents will cause premature membrane failure. Since oxidation damage is not

covered under warranty, HYDRON recommends removing residual free chlorine

by pre treatment prior to membrane exposure. Any specific application must be

limited within the extreme operating conditions. We strongly recommend you

to refer to the latest edition of technology manual and design guide prepared

by HYDRON Membrane Technology or consult experts proficient in membrane

technology. In case the customer fails to follow the operating conditions as

specified in this manual, HYDRON Membrane Technology will assume no

liability for all results. The permeate flow listed in the table is the average value.

This Membrane is Tested and

Certified by NSF International The permeate flow of single membrane element is within a tolerance not

against NSF / ANSI Standard 58

for material requirements only. exceeding ±20% of nominal value. Discard the RO-filtered water produced during

COMPONENT the first one hour after system start-up. During storage time and run time, it is

strictly prohibited to dose any chemical medicament that may be harmful.

DISTRIBUTED BY:

HYDRON | P.O. Box 2235 Chino Hills, CA 91709 USA • www.hydronmembranes.com

LIT-BW-SS-030216

You might also like

- ChE 140 - Sulfur and Sulfuric AcidDocument29 pagesChE 140 - Sulfur and Sulfuric AcidMarialie EnecioNo ratings yet

- FılmtecDocument2 pagesFılmtecBilgi KurumsalNo ratings yet

- Filmtec™ Bw60-1812-75 Element: Product Data SheetDocument4 pagesFilmtec™ Bw60-1812-75 Element: Product Data Sheetnagaraj p sNo ratings yet

- DOW FILMTEC™ Membranes: Product Data SheetDocument3 pagesDOW FILMTEC™ Membranes: Product Data SheetPT Purione MegatamaNo ratings yet

- Dairy Pro Ro and NF Polishing Elements PDFDocument2 pagesDairy Pro Ro and NF Polishing Elements PDFAsepNo ratings yet

- DOW FILMTEC™ ECO Line RO Elements: Product DatasheetDocument2 pagesDOW FILMTEC™ ECO Line RO Elements: Product DatasheetakbarNo ratings yet

- Ficha Tecnica HYDRON BW-8040Document1 pageFicha Tecnica HYDRON BW-8040Daniel HernándezNo ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- NE4040-40 v2.3 (23) 1Document2 pagesNE4040-40 v2.3 (23) 1Andri Sanjaya SembiringNo ratings yet

- DOW FILMTEC™ SW30HRLE-400 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HRLE-400 Element: Descriptiongvnks90No ratings yet

- Filmtec SW30HRLE-400Document3 pagesFilmtec SW30HRLE-400PT Deltapuro IndonesiaNo ratings yet

- Vontron LP22Document2 pagesVontron LP22Thiago NascimentoNo ratings yet

- 3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetDocument2 pages3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetSergioNo ratings yet

- LP21 4040Document2 pagesLP21 4040Kashif ManzoorNo ratings yet

- Hsro 4040 FFDocument3 pagesHsro 4040 FFAlejandro OdioNo ratings yet

- FilmTec SW30XHR 440 PDS 45 D00970 enDocument2 pagesFilmTec SW30XHR 440 PDS 45 D00970 enAndri Sanjaya SembiringNo ratings yet

- VONTRON LP21-4040T RO Element IntroductionDocument2 pagesVONTRON LP21-4040T RO Element Introductionsukiraj RasalingamNo ratings yet

- Membrane SW30XLE-440iDocument3 pagesMembrane SW30XLE-440iecrNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- Vontronfr12 8040en1Document2 pagesVontronfr12 8040en1Von TronNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- Filmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetDocument4 pagesFilmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetfasihulNo ratings yet

- TM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceDocument2 pagesTM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceKeily VilcarromeroNo ratings yet

- Bw30hrle 440Document2 pagesBw30hrle 440Alejandro OdioNo ratings yet

- 5.1 KATALOG Toray - TM800M - v1 - 202201Document2 pages5.1 KATALOG Toray - TM800M - v1 - 202201Diana SulardiNo ratings yet

- Gold Line ManualDocument10 pagesGold Line ManualAnonymous OvwqAMyrWxNo ratings yet

- P SRF Depth Filter ElementsDocument5 pagesP SRF Depth Filter Elementsesmail aliNo ratings yet

- LSR LC-50-2004Document3 pagesLSR LC-50-2004tarot.insights4uNo ratings yet

- Hydromos 50-400SDocument4 pagesHydromos 50-400SRay MartinNo ratings yet

- FilmTec Heat Sanitizable PDS 45 D01511 enDocument4 pagesFilmTec Heat Sanitizable PDS 45 D01511 enali jafNo ratings yet

- DOW FILMTEC™ BW30-400/34 Element: DescriptionDocument2 pagesDOW FILMTEC™ BW30-400/34 Element: DescriptionLam NgọcNo ratings yet

- Bw30xfrle-400 34Document2 pagesBw30xfrle-400 34Alejandro OdioNo ratings yet

- BW30HR 440Document2 pagesBW30HR 440Alejandro OdioNo ratings yet

- Hsro 390 FFDocument3 pagesHsro 390 FFAlejandro OdioNo ratings yet

- 207 EN Conc Reco-Cool-Antifreeze-Coolant Technical-Data-Sheet 1Document2 pages207 EN Conc Reco-Cool-Antifreeze-Coolant Technical-Data-Sheet 1Jon HermanNo ratings yet

- Element Ulp3012-400Document1 pageElement Ulp3012-400بشير المتوكلNo ratings yet

- BW30-400 34Document2 pagesBW30-400 34Alejandro OdioNo ratings yet

- XcfbrochuDocument6 pagesXcfbrochuuniversal8888No ratings yet

- Ionpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesDocument2 pagesIonpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesEdwinNo ratings yet

- Vontronulp21 4021en1Document2 pagesVontronulp21 4021en1sukiraj RasalingamNo ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- BW30XFR-400 34Document2 pagesBW30XFR-400 34Alejandro OdioNo ratings yet

- FSsmAG FR H ENDocument2 pagesFSsmAG FR H ENhamdani sceNo ratings yet

- FILMTEC™ MembranesDocument2 pagesFILMTEC™ MembranesSamir BensitouahNo ratings yet

- FilmTec BW30XHR PRO 440 PDS 45 D03750 enDocument2 pagesFilmTec BW30XHR PRO 440 PDS 45 D03750 enMasoud AmirzadehfardNo ratings yet

- BW30HR-440i - MembranaDocument2 pagesBW30HR-440i - Membranaclaudia gonzalesNo ratings yet

- P-SRF N: Process Sterile Air Filter ElementsDocument6 pagesP-SRF N: Process Sterile Air Filter ElementsParis AnabelNo ratings yet

- DOW FILMTEC™ BW30-400 Element: DescriptionDocument2 pagesDOW FILMTEC™ BW30-400 Element: DescriptionKamal ChokshiNo ratings yet

- Ceramic Water Purifier: Performance Data SheetDocument7 pagesCeramic Water Purifier: Performance Data SheetT.BieniekNo ratings yet

- Dupont Filmtec Xle Pro 4040 LDocument2 pagesDupont Filmtec Xle Pro 4040 Ldavid andres sandi ovaresNo ratings yet

- Hydromos - 30 850 DDocument4 pagesHydromos - 30 850 DRay MartinNo ratings yet

- VONTRON ULP31-4040 Membrane Element: Brief IntroductionDocument2 pagesVONTRON ULP31-4040 Membrane Element: Brief IntroductionJonathan QuintanoNo ratings yet

- FilmTec BW30 PRO 365 PDS 45 D03747 enDocument2 pagesFilmTec BW30 PRO 365 PDS 45 D03747 enMasoud AmirzadehfardNo ratings yet

- PemasangDocument9 pagesPemasangNovy adi syaputra 93No ratings yet

- Membranas BW30 440ienDocument29 pagesMembranas BW30 440ienMarco GonzálezNo ratings yet

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- NiBallast TM BWMS v-2021Document21 pagesNiBallast TM BWMS v-2021王杰No ratings yet

- PFHB filter assemblyDocument7 pagesPFHB filter assemblyOscar NavarroNo ratings yet

- AP Seri S: Extreme Low Pressure Brackish Water RO ElementsDocument1 pageAP Seri S: Extreme Low Pressure Brackish Water RO ElementshermanNo ratings yet

- Structure of Atoms and Symbols of ElementsDocument4 pagesStructure of Atoms and Symbols of ElementsWilrose BarbacionNo ratings yet

- STAR COACHING CLASS - Parshotam Jethani (98982 16776)Document3 pagesSTAR COACHING CLASS - Parshotam Jethani (98982 16776)Kalp JethaniNo ratings yet

- AIGA 074 - 11 Safe Handling of CO2 Containers That Have Lost Pressure - Reformated Jan 12 PDFDocument30 pagesAIGA 074 - 11 Safe Handling of CO2 Containers That Have Lost Pressure - Reformated Jan 12 PDFAnjali Anju100% (1)

- InsufineMineral TDSDocument2 pagesInsufineMineral TDSEgyp XsNo ratings yet

- Plant Adaptations in WaterDocument4 pagesPlant Adaptations in WaterAdelajaDalrympleNo ratings yet

- Microbiology PracticalDocument19 pagesMicrobiology PracticalawangbokNo ratings yet

- 3D Firefighting for Environmental ControlDocument29 pages3D Firefighting for Environmental ControlFagner CarmoNo ratings yet

- BS Iso 5950 (2008)Document16 pagesBS Iso 5950 (2008)makrand87No ratings yet

- Stellar Evolution and NucleosynthesisDocument26 pagesStellar Evolution and NucleosynthesisEzekiel Lapitan100% (1)

- AWWA Standard List 2014Document3 pagesAWWA Standard List 2014VI King Pro100% (1)

- DHANRAJDocument23 pagesDHANRAJDurgesh Patil DspNo ratings yet

- SHN 2Document11 pagesSHN 2Priyanka Dhurvey SinghNo ratings yet

- Avocado Seed Extract AnalysisDocument14 pagesAvocado Seed Extract AnalysisRatna SariNo ratings yet

- Dipanwita94@gmail - Com 20160127134036 PDFDocument3 pagesDipanwita94@gmail - Com 20160127134036 PDFdipanwitaNo ratings yet

- STOK BARANG SAAT INI PT. COMBI PUTRA MANDIRIDocument34 pagesSTOK BARANG SAAT INI PT. COMBI PUTRA MANDIRIAtik Marfu'ahNo ratings yet

- Basic Elements of Any NDTDocument57 pagesBasic Elements of Any NDTR Raj Singh Singh100% (3)

- PRODUCTION OF BIOETHANOL FROM POMELO (Citrus Maxima) PEEL (MANDIA) 2019Document60 pagesPRODUCTION OF BIOETHANOL FROM POMELO (Citrus Maxima) PEEL (MANDIA) 2019Carlo Quinsayas SablanNo ratings yet

- Bun PT Introducere - Removal of Cytostatic Drugs From Aquatic Environment A ReviewDocument18 pagesBun PT Introducere - Removal of Cytostatic Drugs From Aquatic Environment A ReviewsorinamotocNo ratings yet

- NMAT 17 Crash Course Review - Biochemistry ReviewerDocument6 pagesNMAT 17 Crash Course Review - Biochemistry ReviewerMikaela Rome Bigay83% (6)

- Weller 2015Document1 pageWeller 2015Nicolás GrinbergNo ratings yet

- Crystal DefectsDocument3 pagesCrystal DefectsixbreakxawayNo ratings yet

- Series 3000 Cooling Tower SpecificationsDocument9 pagesSeries 3000 Cooling Tower SpecificationsTahseenNo ratings yet

- About Welding Process 43Document1 pageAbout Welding Process 43XerexNo ratings yet

- A-Level Chemistry SyllabusDocument61 pagesA-Level Chemistry SyllabusLabiba GulNo ratings yet

- Case Against Balancing ValvesDocument4 pagesCase Against Balancing Valvesa_salehiNo ratings yet

- ThermalDocument19 pagesThermalEswar BalachandarNo ratings yet

- Thermodynamics SolutionDocument15 pagesThermodynamics SolutionSureshbabu0% (1)

- Chemicals Zetag MSDS LDP Zetag 3940 (US) - 1010Document6 pagesChemicals Zetag MSDS LDP Zetag 3940 (US) - 1010PromagEnviro.comNo ratings yet

- Gas flow calculations: mass to volume conversionsDocument2 pagesGas flow calculations: mass to volume conversionsPangestu Try WibowoNo ratings yet