Professional Documents

Culture Documents

Module - M28: NOTE-15

Module - M28: NOTE-15

Uploaded by

Prabha KaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module - M28: NOTE-15

Module - M28: NOTE-15

Uploaded by

Prabha KaranCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

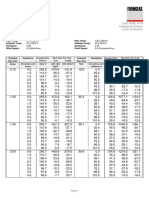

EQUIPMENT TAG NO 29TB812 29CM814 29CM813 EQUIPMENT TAG NO 29PA814A/B EQUIPMENT TAG NO 29FE811 LEVEL DIAGRAM

DESCRIPTION CIP MEMBRANE CLEANING TANK SRU CIP MEMBRANE CLEANING FILTER (NOTE-3) UF CIP MEMBRANE CLEANING FILTER (NOTE-3) DESCRIPTION CIP MEMBRANE CLEANING PUMPS (CENTRIFUGAL) DESCRIPTION CIP MEMBRANE CLEANING HEATER HHLL 2820 NOTES:

TYPE RECTANGULAR CARTRIDGE CARTRIDGE CONFIGURATION 2x100% CONFIGURATION 1X100% HLL 2620 1. FRESH WATER FOR CLEANING SHALL BE FREE CHLORINE AND IRON FREE <0.05 PPM.

A CONFIGURATION 1x100% 1x100% 1x100% DESIGN 12 PRESSURE DESIGN 3.5 NLL 2000 2. HEATER SHALL BE CONTROLLED BY THYRISTOR CONTROL PANEL. A

PRESSURE (BARG) 3. SRU CARTRIDGE FILTER RATED FOR pH(2) AND pH(12) SOLUTION. REMOVAL OF PARTICLE SIZE SHALL BE >5

PRESSURE DESIGN (MIN/MAX) FOL + 0.07 barg FV / 12 FV / 12 OPERATING 6 (BARG) OPERATING ATM LLL 800

DESIGN 0/60 MICRON. AND UF CARTRIDGE FILTER SHALL REMOVE PARTICLES > 200 MICRONS.

(BARG) OPERATING ATM 6 6 TEMPERATURE DESIGN 0/60 LLLL 600

TEMPERATURE (°C) 4. CATCHMENT POT SHALL BE PROVIDED FOR ALL EQUIPMENT.

TEMPERATURE DESIGN (MIN/MAX) 0 / 60 0 / 60 0 / 60 OPERATING 35 (°C) OPERATING 35 BOTTOM OF TANK 0 5. MAGNETOSTRICTIVE LEVEL TRANSMITTER WITH GAUGE.

(°C) OPERATING 35 35 C1 35 C1 DIFFERENTIAL PRESSURE (BAR) 6 DUTY (kW) 710 (NOTE-19) (HOLD-6) 6. CIP TANK LEVEL HIGH HIGH 29LZT8106 WILL INITIATE HIGH PRIORITY ALARM. NO TRIP ACTION REQUIRED.

DIMENSION (IDxLENGTH OR HEIGHT) mm 4000 (L) x 2750 (W) x 3170 (H) 508 (O/D) x 2540 (TL/WL) 457 (O/D) x 2413 (TL/WL) DESIGN CAPACITY (BWPD) 51627 (342m³/hr) (NOTE-18) DESIGN CODE ASME SEC VIII DIV-1 7. PIPING SHALL BE PROVIDED WITH STRAIGHT LENGTH OF 20D UPSTREAM AND 10D DOWNSTREAM FOR ORIFICE

DESIGN CAPACITY 20 (NETT) / 34.88 (GROSS) 51627 (INCLUDED 10% MARGIN) 25210 (INCLUDING 10% MARGIN) MOTOR DUTY (kW) 90 (HOLD-5) MATERIAL OF CONSTRUCTION INCOLOY 800 TYPE FLOW TRANSMITTER.

ABSORBED POWER (kW) 76.4 (HOLD-4) 8. HEATER AND PUMP TO TRIP ON LSLL.

DESIGN CODE

MATERIAL OF CONSTRUCTION

ASTM D3299

FRP

ASME SEC VIII DIV-1

SDSS

ASME SEC VIII DIV-1

SDSS DESIGN CODE

MATERIAL OF CONSTRUCTION

API-610

SDSS C1

MODULE – M28 9. SAMPLING POINT FOR CONDUCTIVITY AND pH CONTROL MEASUREMENTS.

10. OVER FLOW LINE.

NOTE-46 11. DIP PIPE SHALL HAVE ANTI SIPHON HOLE.

B 0075-CR-42-8153-AT70 1:100 NOTE-46 3/4" HCL INJECTION 12. DIP PIPE SHALL BE PROVIDED TILL LOW LOW LIQUID LEVEL.

B

2101-VME2-42-P-XB-00001_01 13. SAMPLE PROBE VALVE WITH MANUAL EXTRACTION ASSEMBLY IS SUPPLIED BY ANALYZER VENDOR.

FROM POTABLE WATER SUPPLY 0300-WD-53-8102-AC21 NO POCKETS

14. TAP-OFF BE LOCATED AT A MINIMUM DISTANCE FROM TANK NOZZLE AND ENSURE FREE FLOW TANK FROM THE

42BLV3746 42BLV3744

2101-VME2-00-P-XB-00001_01 42BLV3745 TAP-OFF.

NOTE-1,14 NC 3/4" 15. MINIMUM RECYCLE FLOW DURING UF, SRU CLEANING.

M025-CO-42-8105-TS01 1" O2/CHLORINE SCAVENGER INJECTION 16. PUMP HAS LOCAL START AND EMERGENCY STOP.

FROM SRU MEMBRANE PACKAGE 1:100 NOTE-46 2101-VME2-42-P-XB-00006_01 17. O₂/CHLORINE SCAVENGER INJECTION IS REQUIRED FOR PRESERVATION OF MEMBRANES OR NEUTRALIZATION OF

2101-VME2-29-P-XB-00016_01 NO POCKETS

NOTE-17 NaOCl.

42BLV3747

29BLV7722

18. CIP CLEANING CAPACITY (WITH 10% MARGIN).

2" NC 3/4"

SRU (1st STAGE) - 51627 BPD

1" CAUSTIC INJECTION SRU (2nd STAGE) - 25813 BPD

0100-CR-42-8154-AS20 1:100 NOTE-46

NO POCKETS

2101-VME2-42-P-XB-00002_01 UF- 25210 BPD

29 SC-E

SI

C 42BLV3748 19. HEATER DUTY BASED ON 1 HOUR HEATING FOR CIP SOLUTION. C

42BLV3751 42BLV3749

8386 53BLV8101 NC 20. ECCENTRIC REDUCER WITH FLAT TOP.

NOTE-46

3/4" 21. ORIFICE TYPE FLOW TRANSMITTER.

3" 3/4" SODIUM HYPOCHLORITE INJECTION 22. VESSEL LID FITTED WITH DAVIT FOR OPENING & CLOSING.

0600-CR-29-8104-AP03 0075-CS-42-8104-AT70 1:100 NOTE-46 23. SAMPLE POINT SHALL BE LOCATED AT MINIMUM DISTANCE FROM SOURCE.

2101-VME2-42-P-XB-00004_01

NO POCKETS 24. DELETED.

FROM ULTRAFILTRATION MEMBRANE SYSTEM 1 42BLV3750 25. pH ANALYZER.

2101-VME2-29-P-XB-00004_01 N.7 NC 26. TOTAL CHLORINE ANALYZER.

3/4"

29

SI C1 0200-CR-29-8177-AP03

27. DELETED.

2" 1:100 28. CIP MEMBRANE CLEANING HEATER (NOZZLE N11) AND TEMPERATURE TRANSMITTER (NOZZLE K1 & K5) SHALL

3/4"x2"

3025 NO POCKETS BE LOCATED BELOW TANK LOW LOW LIQUID LEVEL.

1"x2"

53 43

SI SI 29. SIGNAL ACCESSIBLE IN CCR WITH ALARM REPEATED IN PCS.

29 29

D

SI SC-E SI

8201 29

8297 C1 30. DELETED.

31. DP TYPE LEVEL TRANSMITTER (DIRECT MOUNTED). D

3/4"x2"

8387 8198

42 42 SI VENT TO SAFE LOCATION 32. CIP MEMBRANE CLEANING TANK SHALL BE LOCATED AS CLOSE AS POSSIBLE TO MEMBRANE TO AVOID FOAMING

29BUV8264

SI 42 42

29BUV8265

SI SI SI

8390 FIRE CASE C1 DUE TO ANY VERTICAL DROP.

FB

8250 8251 8252 8253 33. SLOPE TOWARDS DRAIN NOZZLE N10.

N.7 2 6" 8" C1 SET @ 11.5 barg

C1 34. REMOVABLE SPOOL PIECE FOR MAINTENANCE PURPOSE.

29BLV3432

29

SI 29 1" D 2"

2" 2" 2" 6" SET @17813 BWPD FV 35. ALL SHUTDOWN INSTRUMENTS SHALL BE PROVIDED WITH MINIMUM SIL-2 RATING.

6" 8" 3" 2" 2" HOLD-3 1"

N13 N1 N2 N3 N4 N6 N5 N14 N7 8207 C1 8112

29

36. PUMP SUCTION PIPING STRAIGHT LENGTH SHALL BE PROVIDED AS PER PIPING DESIGN CRITERIA.

6"x4" 37. TEMPORARY CONICAL STRAINER.

NOTE-12

29 NOTE-43 N9 6" 4"x6" PSV 2"

SI

29TB812 1:100

NO POCKETS

NOTE-15 8107 C11:100 38. RS LENGTH SHALL BE LARGER THAN THE LENGTH OF CONICAL STRAINER.

56 NO POCKETS 39. THE SET POINTS FOR FLOW TRANSMITTER 29FT7713 AND 29FT8111 ARE GIVEN FOR THE FOLLOWING.

29 8200 NOTE-32 6" SI 29BUV8272 4″

0200-CR-29-8176-AP03

29 HH:39°C 29 29

29BLV3430 L1 = 21772 BPD (LOW FLOW SET POINT FOR CIP TO ULTRAFILTRATION UNIT).

TZI TZT TZE TW FO

29BLV7712

PSD 8113 8113 8113 8113

8208

HOLD-2 FB.LO L2 = 22293 BPD (LOW FLOW SET POINT FOR CIP TO SRU (2nd STAGE) UNIT).

N12

NOTE-11,12

NOTE-11,12

NOTE-11,12

E E

NOTE-11,12

L3 = 44587 BPD (LOW FLOW SET POINT FOR CIP TO SRU (1st STAGE) UNIT).

NOTE-11,12

NOTE-11,12

1"

NOTE-11,12

NOTE-11,12

0400-DO-56-8111-AP03 H1 = 24064 BPD (HIGH FLOW SET POINT FOR CIP TO ULTRAFILTRATION UNIT).

29BLV7540

2"x1"

NOTE-10

29 HH:39°C 29 29 29 3"

TZI TZT TZE TW FIRE CASE H2 = 24640 BPD (HIGH FLOW SET POINT FOR CIP TO SRU (2nd STAGE) UNIT).

1"

0200-CR-29-8151-AP03

PSD 8112 8112 8112 8112

SET @ 11.5barg H3 = 49280 BPD (HIGH FLOW SET POINT FOR CIP TO SRU (1st STAGE) UNIT).

2"

1:100

10" 2" 1" D 2" 40. THE CC DISTANCE AND ELEVATION SHOULD BE ALIGNED FOR NOZZLES K2A/B AND K6 TO ENSURE SAME

1"

0600-CR-29-8150-AP03

NO POCKETS

29BLV3433

F04B K2A HOLD-3 MEASURING RANGE FOR LEVEL TRANSMITTERS.

29EC811 N11 NOTE-12 C1 41. LOW POINT DRAIN.

NO POCKETS

29FE811 29BLV7542 1"

L HEATER 29 29 29 H: 2620mm 29BLV3415 29 42. 29LG/LT8105 DRAIN SHALL BE ROUTED TO DRIP TRAY.

PANEL HEATER LG LT LI PSV

8105 8105 8105 8108 2" 43. THE NOZZLES N9 AND N8 SHALL BELOCATED AT OPPOSITE SIDES (LONG) OF CIP MEMBRANE

1:100

PCS

2" L: 800mm

29 H: 37°C 29 29 29 2" CLEANING TANK TO ENSURE PROPER MIXING OF CHEMICALS WITHIN THE TANK.

3" 3" 29 29 HH: 2820mm

K2B NOTE-5,40,42 44. ANY MAINTENANCE ACTIVITY IN THE CIP SYSTEM SHALL BE AFTER ALL THE LINES ARE DRAINED

TI TT TE TW

LZT LZI 29 HH: 8barg 29BLV3431

29BLV7541

F PCS 8111 8111 8111 8111

NOTE-2,8,28 K6 8106 PSD 8106 29BLV7543 PZI FB.LO AND NEUTRALIZED THIS WILL BE SPECIFIED IN OPERATION AND MAINTENANCE MANUAL. F

LL: 600mm PSD 8135

29 H: 37°C 29 29

2"

29BLV7539 NOTE-13,25 1" NOTE-39 LL: 4barg 2"x1" 45. ISOLATION VALVE COMES ALONG WITH ANALYSER PROBE WHICH SHALL BE SUPPLIED BY VENDOR.

TI TT TW

K1 LO NOTE-6,31,40,42 2" 2" 29 29 29 C1 46. THE VALVE CAN BE OPEN/CLOSE WHEN NEEDED.

PCS 8110 8110 8110 AIT AI H: 9pH FIC

K3 29 HH: 39°C 47. HIGH POINT VENT.

C1 8107 PCS 8107 L: 5pH PCS 8112 29 1"

0200-CR-29-8152-AP03

TZI

29 HH:39°C 29 29 2" 2" 29 PSD 8114 PDG 48. ALL INSTRUMENTS DRAIN SHALL BE ROUTED TO DRAIN HEADER.

TZI TZT TW 2" AIT L: 17058 BWPD 8137 29 H

NOTE-43 NOTE-33 LL: 30°C

29BLV7551

8109 8109 8109

K5 K4 8106

PSD FI 29BLV3414 HOLDS:

3" N10 10" N8

29 29 1" PCS 8111

L 1. PUMP SUCTION AND DISCHARGE NOZZLE SIZE WILL BE CONFIRMED.

C1

NOTE-13,25 FT PZT 1"

1/4" 29 29 2. CONTROL VALVE SIZE WILL BE CONFIRMED.

56BUV8266

56 29 HH: 0.1PPM

56BLV7552

29 8135

SI SI TUBING AI NOTE-47

8112 TZT PG 3. PSV SIZE SIZE WILL BE CONFIRMED.

A 8114

NC

8214 3" PCS 8106 8136 29 2"

29 4. ABSORBED POWER TO BE CONFIRMED.

56BLV8120 M012-DN-56-8178-TD01

8209 SI

29BLV7548

FT

5. MOTOR DUTY TYPE AND ASSOCIATED SIGNAL DETAILS WILL BE CONFIRMED.

29BLV7713

G 29 G

29BLV3447

8111

29BLV7549

C1

1/2"

SDSS AP03 TW 8220 2" 6. HEATER DUTY WILL BE CONFIRMED.

1000-CR-29-8144-AP03

29BLV7550

1/2"

8114

LO

N5

29BLV7554

29BLV7555

29 29 29PA814A 1" 1" 1"

RS 2"

NOTE-36

8" 29BUV8269

1/2"

PZI PZT 3/4" NOTE-8,16 N4

29BLV7553

1/2"

PSD 8134A 8134A N2

HOLD-1 4" RS 4"x8" 29CHV8124 LO 1.5" 8" 8" 1"

LL: 0.5bar

56BLV7569

N1

29BLV7544

29

2" SI NOTE-34 8" 29BUV8292

LO

HOLD-1 20D 10D 8"

0300-DO-56-8107-AP03

29BLV3417

8324 1" 29 NOTE-7,21 8" 8" 29GBV8123 8" 8" CIP TO SRU MEMBRANE PACKAGE

NOTE-37,38 NOTE-34 SI 29

29 N2 2101-VME2-29-P-XB-00012_01

NOTE-23

10"x6" RS 6"N1

10" 1" FE SI

8212 20D 10D

8112 8" 29BUV8293 29CHV8123 29BUV8271

8218 29CM814 29

0800-CR-29-8122-AP03

29BUV8268 NOTE-20 NOTE-22

29BLV7556

FE

H N3 H

3/4"

29BLV3416

FB.LO 29 8111

56BLV7568

2"

1000-CR-29-8146-AP03

SI 1"

B1

0600-CR-29-8156-AP03

56BLV7560

29

2" 1" 8210 2" SI

AP03 SDSS NOTE-7,21

29BUV8299

2"

NOTE-36

8219

56BLV7563

SC-E 6"

NOTE-41

0800-CR-29-8148-AP03

29PA814A-M01

NC

C1 M

2"

S02 29

SI

VME VENDOR NOTE-16,18,29 8388

NOTE-4 HOLD-5 CIP TO ULTRAFILTRATION MEMBRANE PACKAGE

0200-DO-56-8117-AP03

2101-VME2-29-P-XB-00002_01 {StampHere}

2"

0600-CR-29-8157-AP03

29

0200-DO-56-8108-AP03

PZI C1

0200-DO-56-8112-AP03

PSD 8134B

L LL: 0.5 bar SDSS AP03 L

29BLV3448

29BUV8270

29

29PA814B

LC

PZT 1" 8"

8134B 3/4" NOTE-8,16 29

29 N2 RS

SI HOLD-1 4" 8" PDG

1:100

8138

29BLV7545

29 8211

NO POCKETS

SI

4"x8" 29CHV8125 0200-DO-56-8124-AP03

LO

8325 1" HOLD-1 NOTE-34

29BLV3419

G.4 NOTE-37,38 NOTE-34 29

56BLV7575

SI 1"

29BLV7562

C1 10" 10"x6" RS

8213

A 2"

1:100

6" 1"

NOTE-20

NO POCKETS

29BUV8267

29BLV7561

M M

FB.LC 3/4" N5 2"

NOTE-4

29BLV3418

1" 29

AP03 SDSS SI B1* EX-DE 02 08-APR-2023 RS SR CS --- ---

0200-DO-56-8109-AP03

0200-DO-56-8113-AP03

1" 8217 B1 EX-DE 01 07-FEB-2023 Issued for Design RS SR CS --- ---

2" C1 6" 6"

N4

2" RS A1 EX-DE 00 29-DEC-2022 RS SR CS --- ---

N1

0200-DO-56-8125-AP03

29PA814B-M01 29BUV8294

Company Validity Revision

Rev. No. Status Number

Date Description Prepared by Checked by Approved by Company Client

Approved Approved

1:100 S02 6" 6" Index Revision

M NOTE-16,18,29 29

SI N2

Client Logo and Business Name LCI Activity Code

LCI-AO-2022-0006

Client Document ID:

363006DPFM00212

HOLD-5 8215 NOTE-22 29BUV8295 LCI Activity Code

VENDOR VME Eni Angola S.P.A.

0200-DO-56-8131-AP03 1:100 NOTE-4 29CM813 000576 Job No.: -

1:100

N 2" N3 29

Company Logo and Business Name Company Document ID:

N

C.2 D.2 2" SI 2101-VME2-29-P-XB-00017_01

56BLV7574

Yinson Azalea Production Pte. Ltd.

1:100

1:100 1 2 8216

Contract No.: -

2"

1:100 C1 Contractor/Vendor Logo and Business Name Contractor/Vendor Document ID:

210480-VME2-29-P-XB-00017_01

0400-DO-56-8111-AP03 HAZARDOUS OPEN DRAIN HEADER

1:100

NO POCKETS

2101-VME2-29-P-XB-00008_01 Unit/Package RFQ No.: RFQ-002

Facility and Sub Facility Name Project and SoW Description Scale: Sheet of Sheets:

AGOGO FULL FIELD - FPSO Agogo Integrated West Hub Development NTS 1 of 1

Document Title: Superseded No.: -

P PIPING & INSTRUMENTATION DIAGRAM Superseded by No.: - P

CIP SYSTEM Plant Area Functional Unit

n.a n.a

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

This document is property of Eni S.p.A. It shall neither be shown to Third Parties, nor used for purposes other than those for which it has been sent. A1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DEM 2 ManualDocument8 pagesDEM 2 ManualPrabha KaranNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Davit Arm Calculation-5mtDocument2 pagesDavit Arm Calculation-5mtPrabha Karan0% (1)

- Weighbridge - Spec Write-UpDocument1 pageWeighbridge - Spec Write-UpPrabha KaranNo ratings yet

- Manual 28-06ap ExDocument31 pagesManual 28-06ap ExPrabha KaranNo ratings yet

- 9.3 Burner DS KG98-2-ONT-OMF-ME-HOTH-VD-081 - Rev.1 - CODE-1 (02.04.2021)Document7 pages9.3 Burner DS KG98-2-ONT-OMF-ME-HOTH-VD-081 - Rev.1 - CODE-1 (02.04.2021)Prabha KaranNo ratings yet

- API 610 ChecklistDocument6 pagesAPI 610 ChecklistPrabha KaranNo ratings yet

- Stair - Copy Ne DWG - Sheet1Document1 pageStair - Copy Ne DWG - Sheet1Prabha KaranNo ratings yet

- Papers BrochureDocument13 pagesPapers BrochurePrabha KaranNo ratings yet

- Bison Catalog LatestDocument37 pagesBison Catalog LatestPrabha KaranNo ratings yet

- Divine Education Hub Sandeep Choudhary: Mathematics & Reasoning Faculty MOBILE NO.-96492-03888Document9 pagesDivine Education Hub Sandeep Choudhary: Mathematics & Reasoning Faculty MOBILE NO.-96492-03888Prabha KaranNo ratings yet

- 33counter Balance Floor CraneDocument10 pages33counter Balance Floor CranePrabha KaranNo ratings yet

- Hand Pallet Truck 5 TonDocument1 pageHand Pallet Truck 5 TonPrabha KaranNo ratings yet

- Cellular Glass - Thickness CalculationDocument15 pagesCellular Glass - Thickness CalculationPrabha KaranNo ratings yet

- Divine Education Hub Sandeep Choudhary: Mathematics and Reasoning Faculty MOBILE NO.-96492-03888Document9 pagesDivine Education Hub Sandeep Choudhary: Mathematics and Reasoning Faculty MOBILE NO.-96492-03888Prabha KaranNo ratings yet

- Valve Weight PDFDocument10 pagesValve Weight PDFPrabha KaranNo ratings yet