Professional Documents

Culture Documents

SSCX International Company Profile-2

Uploaded by

novietha anggraini0 ratings0% found this document useful (0 votes)

12 views19 pagesCompany profile

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCompany profile

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views19 pagesSSCX International Company Profile-2

Uploaded by

novietha anggrainiCompany profile

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

SSCX

Delivering Breakthrough Results

SSCX

PT SSCX International

Menara Rajawali 8th Floor

JI. Mega Kuningan Lot 5.1

Jakarta 12950 Indonesia

+62 21576 3020

08175763021

SSCX International

SSCX International

info@sscx.asia

Founded in 2004, SSCX is consulting fm in Operational Excelence and

Productivity Improvement. SSCX helps companies to Imorove Quality,

Productivity, and Efficiency through Transformation in People, Process,

and Technology. Whether you are a Fortune 500 company or @ small

local manufacturer, we have deployed uniquely tailored solutions to each

scale of the industry. Our solutions produced results that are proven

slobally and our

This is what we cal here at SSCX the

ecialty is consistently delivering breakthrough results,

‘Why we are your Best Partner in achieving Operational Excellence?

+ A. group of experienced Consultants who will provide you with 2

deep understanding of operational excellence and continuous

+ Leading productivity and operational excellence consulting frm with

{an end-to-end problem-solving strategy,

+ Experienced in providing solutions with a deep understanding of local

culture, We translate your complex problem into a Simple Language.

Douerscm INO'KA ( KIDECO EA}sinarmas SB sBuma

are JEM Golycore 7 rertamna uscporal ig

ete, BE A PR EES iocosat® Grace

Tee ance “ Meoansunen aM oe

BCA Excimaniaca mandint ~ PermatabankY ANZA BANK@DKI OWI.

7

Praia WENZING fh sovo com aroha connonar(™ 4

‘ i) anor

7B Wpawer Pie wecas traveloka” enh _ SE

& MISSION

SERVICES

IMPLEMENTATION

Improve quality and productivity

improve efi

limprove people behavior and the effectiveness of stems

Y Improve profitably

lemplement Sustainable Operational Eeallnce Systems

in every engagement is straightforward

Working with Key indlviduals, we conduct a detailed

‘expert analysis of your operation.

We design a custom operational excellence program with

@ compelling business case,

We help you deliver the agreed objectives and

helping you to achieve ambitious targets,

\We support and ensure you h

behaviors in place to oper

at

CONTINUOUS IMPROVEMENTS

INDUSTRY

‘SSCX international has helped mining companies both private

‘and state-owned company to Improve their business process,

‘and increase the efficiency and effectiveness of the domestic

company.

Operational Excellence Methodology:

Highlighted continuous improvement initiatives:

Optimize planning and operation process in mining

Improve activity and cost control system effectiveness

Optimize fue! consumption

Optimize heavy equipment rental cost

Improve process control in coal handling process

Improve capacity in coal handling process

Improve machine and equipment reliability

Reduce penalty of demurrage charges

Field operation behavior change program

PLANT

'SSCX International has helped many power plant

companies to Improve productivity, save costs,

and improve machine availabilty.

Operational Excellence Methodology:

Highlighted continuous improvement initiatives:

Reduce operational cost

Reduce vibration level

Reduce numberof fase alarm

Reduce coal consumption in power plant

Improve effectiveness and efficiency of biofuelling system

INDUSTRY

‘SSX International helps tens of companies

within financial industry Including banking,

Insurance, and mull finance, private and

state-owned companies to improve their

business process.

‘Some of highlighted continuous improvement intatves:

1L Improve processing time and capacity of funding area

Improve process time and capacity of lending area

3. Improve process time and capacity of back office (shared service) area

4, Improve quality/ effectiveness of funding, lending, and support area

5, Idle cash optimization Bank Wide (atm, branches, and treasury)

6, Visual operation and office implementation using visual management

‘and work area management best practice

Improve process performance of customer contact center

Improve processing time and quality of un

9. Optimize number of full ime equivalent of officers

iting area

INDUSTRY

SSCX International has helped both private and

state-owned manufacturing company to improve

their business process that has resulted in bilions of

rupiahs of efficiency per year.

Operational Excellence Methodology:

ighlighted continuous improvement initiatives:

Reduce defect/waste quantity & percentage

Reduce process lead time of manufacturing value stream

Reduce downtime of eaulpment and due to engineering loss time

Reduce the setup time of the machine

Reduce inventory

Improve internal chemical praduction capacity to support

2, Reduce c

cal cost

8, Improve production capacity

9, Implementation of Total Productive Maintenance

10.Implementation of Lean Manufacturing

1 Plant behavior change proaram

INDUSTRY

Some ofthe highlighted continuous improvernent initiatives:

1. improve yale

‘SSX International has helped the Agro

Company to improve their @ business

process that has resulted in billions of

Rupiah of efficiency per year

2. Reduce free fatty acid

5, improve oll extraction rate

4 Improve mills machine availablity

5, Reduce group equipment spare part inventory

6

Operational Excellence Methodology: aa

TRAINING

TERN

By

TRAINING PROGRAM NE SOX

a

3

7

— ;

TRAINING PROGRAM

WHAT THEY'VE SAID ABOUT SSCX TRAINING

SSCX

ans

Peer CUE)

CIRC a UAC re oa)

eee uC un eta Tt

eg meter}

eure nee aaorog

See na ane d

BER are elie)

® +62 21576 3020

Steer]

Seamer

Ce qari

CT oe eeoo

Pe eet eR}

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Job Fair Unmul 2023Document1 pageJob Fair Unmul 2023novietha anggrainiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

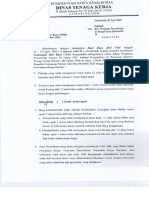

- Surat THR DisnakerDocument2 pagesSurat THR Disnakernovietha anggrainiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Simple Present Tense: English Grammar RulesDocument6 pagesSimple Present Tense: English Grammar Rulesrosmaniza ismailNo ratings yet

- Group Behaviour - NotesDocument31 pagesGroup Behaviour - NotesDaisy AllenNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

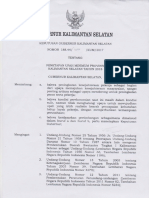

- Ump Kalsel 18Document3 pagesUmp Kalsel 18novietha anggraini0% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Creative Recruiting IdeasDocument10 pagesCreative Recruiting IdeasOana Georgiana100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Umk SMD 2016Document2 pagesUmk SMD 2016novietha anggrainiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)