Professional Documents

Culture Documents

Lab 5

Uploaded by

Ayush yadav0 ratings0% found this document useful (0 votes)

9 views7 pagesThe document describes experimenting with a Renishaw Revo-2 coordinate measuring machine (CMM). It discusses how Renishaw has been an industry standard for CMM sensors for over 40 years. The Revo-2 provides high-speed, high-accuracy 5-axis measurement without compromising speed or accuracy. It can measure up to 500 mm/sec with measurement flexibility and minimal stylus wear. Renishaw also provides metrology software to develop measurement programs offline and simulate collisions before running on the CMM.

Original Description:

Original Title

Lab5

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes experimenting with a Renishaw Revo-2 coordinate measuring machine (CMM). It discusses how Renishaw has been an industry standard for CMM sensors for over 40 years. The Revo-2 provides high-speed, high-accuracy 5-axis measurement without compromising speed or accuracy. It can measure up to 500 mm/sec with measurement flexibility and minimal stylus wear. Renishaw also provides metrology software to develop measurement programs offline and simulate collisions before running on the CMM.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views7 pagesLab 5

Uploaded by

Ayush yadavThe document describes experimenting with a Renishaw Revo-2 coordinate measuring machine (CMM). It discusses how Renishaw has been an industry standard for CMM sensors for over 40 years. The Revo-2 provides high-speed, high-accuracy 5-axis measurement without compromising speed or accuracy. It can measure up to 500 mm/sec with measurement flexibility and minimal stylus wear. Renishaw also provides metrology software to develop measurement programs offline and simulate collisions before running on the CMM.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 7

Experiment 05 – Coordinate Measuring

Machine

Name – Ayush Yadav

Roll no – 55

PRN – 12011162

Aim – To study Renishaw Revo – 2 CMM

machine Theory:

For more than 40 years, Renishaw has delivered innovations that have been

milestones in industrial metrology. From the original touch-trigger probe and

motorised indexing head, repeatable stylus changing and modular scanning

systems, Renishaw sensors for co-ordinate measuring machines (CMMs) are an

industry standard.

The 5-axis measurement product range represents the biggest step-change in

measurement capability ever introduced, delivering unprecedented speed and

measurement flexibility, whilst avoiding the speed versus accuracy

compromises inherent in conventional techniques. Whether the REVO

scanning or the PH20 touch-trigger, Renishaw's 5-axis systems boost

measurement throughput, minimise lead times and give manufacturers a more

comprehensive appreciation of the quality of their products.

REVO 2

A highly accurate dynamic measuring head and probe system which maximises

measurement throughput.

High-speed measurement...

Up to 500 mm/sec resulting in increased part throughput

Data collection rates up to 4,000 points per second

Infinite positioning and five-axis motion reduces non-productive

transitions between features

Rapid calibration with all positions inferred means more time measuring

...with high system accuracy

5-axis scanning minimises CMM motion and the associated dynamic

errors

Stylus wear minimised by extremely low scanning forces

Infinite positioning and five-axis motion aid access to difficult features

Flexible tip sensing further adds to the systems' accuracy and flexibility

...and great flexibility

Maximum reach up to 800 mm from centre of head rotation

Multi-sensor probe and stylus changing capability

Renishaw UCC server software application (based on I++ DME command

protocol) provides the interface for REVO-2 control

The removable probe system, used in conjunction with a low cost

changer, provides added system flexibility

Software

Renishaw's metrology software provides a powerful platform for 5-axis

measurement. A configurable user interface allows native DMIS programs to

be developed offline, drawing geometry, embedded dimensions and tolerance

data from CAD, with full simulation and collision detection. The software

includes certified algorithms for feature measurement, feature construction

and part alignment.

Programs can be created offline directly from CAD with on-screen probe path

verification. The CMM environment, the fixture and the location of the part on

the machine can all be defined, enabling full simulation and crash detection of

5-axis measurement programs. This minimises CMM down-time as programs

arrive at the machine ready to run, with little or no prove-out time required.

Measuring Circularity error

Define origin in software for the REVO 2

Define two planes

Put the stylus on four or more points for point measurement of

roundness. The measured value is calculated by least-squares method,

where the sum of the deviations from all measurement points is the

smallest.

Manufacturing Drawing of test piece

Finding the co-ordinates of test piece without drawing

Finding the co-ordinates of test piece with drawing (IGES File)

You might also like

- CMMDocument34 pagesCMMShanti Lal MeenaNo ratings yet

- Assembler TPFDocument178 pagesAssembler TPFHaribabu M100% (1)

- Global Brochure PDFDocument16 pagesGlobal Brochure PDFElsa VelazquezNo ratings yet

- Co-Ordinate Measuring Machines & It's Applications: Introduction ToDocument65 pagesCo-Ordinate Measuring Machines & It's Applications: Introduction Toshiva dNo ratings yet

- Introducing Bluetooth LE Audio BookDocument315 pagesIntroducing Bluetooth LE Audio BookFrancis Justin MarzoNo ratings yet

- Step by Step Renishaw Retrofit PDFDocument4 pagesStep by Step Renishaw Retrofit PDFRizki AdhaNo ratings yet

- Proposal Ready Content NetApp FAS Systems Technical Overview - MAY11 - UKDocument8 pagesProposal Ready Content NetApp FAS Systems Technical Overview - MAY11 - UKMohd Rosman Abd RahmanNo ratings yet

- Functional Module Based Generic Datasource Part IDocument9 pagesFunctional Module Based Generic Datasource Part IKuldeep JainNo ratings yet

- CMMDocument26 pagesCMMSanjeev kumar Verma100% (1)

- Istoria CMM (In Engleza) PDFDocument20 pagesIstoria CMM (In Engleza) PDF26110100% (1)

- Low Power Autonomous Controller Fcn-Rtu: Network-Based Control SystemDocument4 pagesLow Power Autonomous Controller Fcn-Rtu: Network-Based Control SystemosmondmanurungNo ratings yet

- 000-374 IBM WebSphere MQ V7.0 System Administration Exam DumpDocument28 pages000-374 IBM WebSphere MQ V7.0 System Administration Exam DumpSaptadip Sarkar0% (1)

- Nishi Sharma: AWS Cloud EngineerDocument7 pagesNishi Sharma: AWS Cloud EngineerKritika ShuklaNo ratings yet

- PH20 BrochureDocument4 pagesPH20 BrochureCam-ToolsNo ratings yet

- 5-Axis Measurement TechnologyDocument1 page5-Axis Measurement TechnologyDanu MamlukatNo ratings yet

- Ch15-Inspection in FMSDocument25 pagesCh15-Inspection in FMSyogesh jadhavNo ratings yet

- Pocket Guide To Probing Solutions For CNC Machine ToolsDocument40 pagesPocket Guide To Probing Solutions For CNC Machine Toolsgheorghemocanet100% (1)

- Hexagon MI 7107 SF Brochure A4 ENDocument6 pagesHexagon MI 7107 SF Brochure A4 ENAna Gabriela OjedaNo ratings yet

- PH20 Motorised Probe Head: Key Features InnovationsDocument2 pagesPH20 Motorised Probe Head: Key Features InnovationsHassan HabibNo ratings yet

- Portable Laser Measurement and Calibration: Machine Tools and CMMDocument14 pagesPortable Laser Measurement and Calibration: Machine Tools and CMMskidamdnevnoNo ratings yet

- V4i DatasheetDocument2 pagesV4i DatasheetRyanK7686No ratings yet

- Hexagon MI MICRA Brochure 6PP ENDocument6 pagesHexagon MI MICRA Brochure 6PP ENHassan HabibNo ratings yet

- Experiment 3 Contracer - Contour Measureing Machine: Mechatronic Engineering Advanced ProgramDocument10 pagesExperiment 3 Contracer - Contour Measureing Machine: Mechatronic Engineering Advanced ProgramCao KhảiNo ratings yet

- MH Hexagon NCGage Product Brochure enDocument8 pagesMH Hexagon NCGage Product Brochure enphungNo ratings yet

- Fuel Injector Brochure 2019 - FinalDocument8 pagesFuel Injector Brochure 2019 - FinalCarlos RamirezNo ratings yet

- Rohde Schwarz Teisnach CS enDocument4 pagesRohde Schwarz Teisnach CS enDương Tiến ĐạtNo ratings yet

- CMM Inspection FundamentalsDocument60 pagesCMM Inspection FundamentalsChandana DeepthiNo ratings yet

- BROC AutomatedMeasuringSolutions 992-083 en WEBDocument28 pagesBROC AutomatedMeasuringSolutions 992-083 en WEBLe LanNo ratings yet

- Calibration Service Provider Works Faster and Smarter To Create More RevenueDocument3 pagesCalibration Service Provider Works Faster and Smarter To Create More Revenuekamala nandulaNo ratings yet

- Coordinate Measuring Machine (Manual) : Fast、Cool、AccurateDocument4 pagesCoordinate Measuring Machine (Manual) : Fast、Cool、AccurateKailashNo ratings yet

- CalibrationDocument9 pagesCalibrationcooksandNo ratings yet

- Pre 11567 - Mcosmos 5 WebDocument26 pagesPre 11567 - Mcosmos 5 Webhector gonzalezNo ratings yet

- 182DataSheet MEASURE HiDocument2 pages182DataSheet MEASURE HiraduvascautiNo ratings yet

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenNo ratings yet

- Absolute Arm Systems and Accessories: Product CatalogueDocument90 pagesAbsolute Arm Systems and Accessories: Product CatalogueFernando Moreira da silvaNo ratings yet

- Coordinate Measuring Machines - HexagonDocument6 pagesCoordinate Measuring Machines - HexagonAbdulaziz AlrawiNo ratings yet

- (b1264b950ce44583bab73d6b965f7616)Document72 pages(b1264b950ce44583bab73d6b965f7616)jgkothavadeNo ratings yet

- Organisation ProfileDocument18 pagesOrganisation ProfileAtul DwivediNo ratings yet

- Altera Scantek5 CMMDocument8 pagesAltera Scantek5 CMMJorge OliveiraNo ratings yet

- sp25m PDFDocument11 pagessp25m PDFhongoNo ratings yet

- Somatom Emotion 6Document3 pagesSomatom Emotion 6ansarhussain012No ratings yet

- Global S: The Coordinate Measuring Machine Pushing Productivity FurtherDocument20 pagesGlobal S: The Coordinate Measuring Machine Pushing Productivity FurtherRajiv GandhiNo ratings yet

- Leitz Reference Xe Brochure enDocument12 pagesLeitz Reference Xe Brochure entheflamebearerNo ratings yet

- AMBiOS - QscopeSeries - AFM-SPM PDFDocument8 pagesAMBiOS - QscopeSeries - AFM-SPM PDFdejavu77No ratings yet

- The Modular Compact Rheometer SeriesDocument20 pagesThe Modular Compact Rheometer SeriesSupriyo PNo ratings yet

- Tems Investigation 14.0 DatasheetDocument2 pagesTems Investigation 14.0 Datasheet4G_optimizerNo ratings yet

- Global S: The Coordinate Measuring Machine Pushing Productivity FurtherDocument14 pagesGlobal S: The Coordinate Measuring Machine Pushing Productivity FurtherGuest UserNo ratings yet

- Kruss Bro Product Overview 2022 enDocument105 pagesKruss Bro Product Overview 2022 enSanggari MogarajaNo ratings yet

- Powerinspect CNCDocument2 pagesPowerinspect CNCJosephRomeraloNo ratings yet

- EN 60 020 0166II ZEISS Bridge-type-CMMsDocument44 pagesEN 60 020 0166II ZEISS Bridge-type-CMMsRobin ChenNo ratings yet

- Model Contura G2 Manufactured by Carl Zeiss Same YearDocument4 pagesModel Contura G2 Manufactured by Carl Zeiss Same YearB VarunNo ratings yet

- ROMER Absolute Arm BrochureDocument12 pagesROMER Absolute Arm BrochureArvat AlexandruNo ratings yet

- H 1000 6050 03 A CMM Technology Guide enDocument28 pagesH 1000 6050 03 A CMM Technology Guide enHoàng Mạnh ĐứcNo ratings yet

- Physica MCR: The Modular Rheometer SeriesDocument16 pagesPhysica MCR: The Modular Rheometer SeriesSupriyo PNo ratings yet

- AP Instruments RheolabQCDocument6 pagesAP Instruments RheolabQCAndrés MárquezNo ratings yet

- Rotalign Ultra Brochure EnglishDocument12 pagesRotalign Ultra Brochure EnglishAndrews100% (1)

- AutoMET AFM Software-Datasheet-DS106Document2 pagesAutoMET AFM Software-Datasheet-DS106Fabien CazesNo ratings yet

- Leonova CatalogueDocument16 pagesLeonova CatalogueNila AkterNo ratings yet

- Final Qi ReportDocument11 pagesFinal Qi ReportDarshanRavalNo ratings yet

- Unit-8 CMM PVPSIT 2014: Coordinate Measuring Machines (CMM)Document7 pagesUnit-8 CMM PVPSIT 2014: Coordinate Measuring Machines (CMM)Sravanth KondetiNo ratings yet

- Cat Indusensor LVDT enDocument52 pagesCat Indusensor LVDT enAustin Lee100% (1)

- XSENSOR WhitePaper BestPracticesForSelectingPressureImagingSystems 012022Document15 pagesXSENSOR WhitePaper BestPracticesForSelectingPressureImagingSystems 012022czarownikivanovNo ratings yet

- QMSOFT Prospekt ENG 7Document16 pagesQMSOFT Prospekt ENG 7carlosNo ratings yet

- Geosense Brochure 2011 V1.2Document46 pagesGeosense Brochure 2011 V1.2jnfNo ratings yet

- UNIT-5 Advances in MetrologyDocument45 pagesUNIT-5 Advances in MetrologySURESH KUMAR APNo ratings yet

- Special Laser Tracker DocumentDocument2 pagesSpecial Laser Tracker DocumentJavierVeraNo ratings yet

- Researchpaper Modelling and Analysis of A Very Low Head Kaplan Turbine RunnerDocument9 pagesResearchpaper Modelling and Analysis of A Very Low Head Kaplan Turbine RunnerAyush yadavNo ratings yet

- Ek TYO2 Ankl ZFG2 NVDocument7 pagesEk TYO2 Ankl ZFG2 NVAyush yadavNo ratings yet

- y H27 WPGXG NAV7 TWDocument15 pagesy H27 WPGXG NAV7 TWAyush yadavNo ratings yet

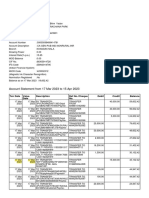

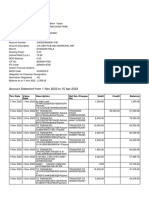

- Account Statement From 1 Nov 2022 To 15 Apr 2023: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument15 pagesAccount Statement From 1 Nov 2022 To 15 Apr 2023: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceAyush yadavNo ratings yet

- Lab 1Document12 pagesLab 1Ayush yadavNo ratings yet

- Lab 6Document8 pagesLab 6Ayush yadavNo ratings yet

- Lab 3Document14 pagesLab 3Ayush yadavNo ratings yet

- Lab 4Document5 pagesLab 4Ayush yadavNo ratings yet

- Oracle Solaris 11.3 Security and Hardening Guidelines: Part No: E54807Document84 pagesOracle Solaris 11.3 Security and Hardening Guidelines: Part No: E54807MomateNo ratings yet

- Number Based-Niven No 7th June21Document2 pagesNumber Based-Niven No 7th June21Shailendra SinghNo ratings yet

- Sonnox Manual PDFDocument22 pagesSonnox Manual PDFAlejandro NietoNo ratings yet

- Appinfo LogDocument44 pagesAppinfo LogRomo Domínguez Luis ManuelNo ratings yet

- Night Security LightDocument30 pagesNight Security LightCarol SoiNo ratings yet

- QStart Windows Software ManualDocument32 pagesQStart Windows Software ManualΜιχάλης ΛαχανάςNo ratings yet

- Create Bootable USB Flash Drive To Install Windows 10 - TutorialsDocument2 pagesCreate Bootable USB Flash Drive To Install Windows 10 - Tutorialsxi siNo ratings yet

- CensobrDocument9 pagesCensobrSergioNo ratings yet

- AOL Questions 11/17/2020: Subba Reddy SDocument41 pagesAOL Questions 11/17/2020: Subba Reddy SAnuNo ratings yet

- 09-STM32 Security WS TFM ExperienceDocument86 pages09-STM32 Security WS TFM ExperiencesolokingNo ratings yet

- Assignment 2 Front Sheet: Qualification BTEC Level 5 HND Diploma in ComputingDocument54 pagesAssignment 2 Front Sheet: Qualification BTEC Level 5 HND Diploma in ComputingĐỗ Hoài NamNo ratings yet

- CV ExampleDocument1 pageCV ExampleIgor SavchukNo ratings yet

- Computer Organisation NSL PDFDocument13 pagesComputer Organisation NSL PDFnihalNo ratings yet

- U-WAS 2000 UserManualDocument106 pagesU-WAS 2000 UserManualEstetNo ratings yet

- 01 Transmission & Access Network Opportunities and Solution 0507Document14 pages01 Transmission & Access Network Opportunities and Solution 0507Giuseppe ManciniNo ratings yet

- Intro To USB-6009 DAQDocument10 pagesIntro To USB-6009 DAQusep syaikal arifinNo ratings yet

- Digital Systems 002Document10 pagesDigital Systems 002David B MwathyNo ratings yet

- LicaDocument99 pagesLicaKhanNo ratings yet

- Buffer OverflowDocument22 pagesBuffer OverflowKövecs IldikóNo ratings yet

- Week 19Document10 pagesWeek 19Ma RkNo ratings yet

- AWS Storage OverviewDocument22 pagesAWS Storage OverviewGustavo Adolfo Gamboa CruzNo ratings yet

- Building The MPP Beach (Rev-E)Document19 pagesBuilding The MPP Beach (Rev-E)Mhuhammad KhanNo ratings yet

- Assignment Report: Simple Operating SystemDocument24 pagesAssignment Report: Simple Operating SystemNguyen Trong Tin50% (2)