Professional Documents

Culture Documents

C Aj 2586 PDF

Uploaded by

Emanuel PastlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C Aj 2586 PDF

Uploaded by

Emanuel PastlCopyright:

Available Formats

Classified by

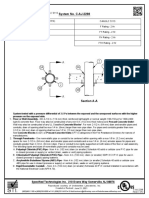

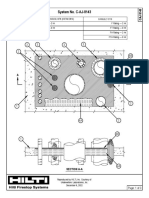

Underwiters Laboratories, Inc. System No. C-AJ-2586

to ASTM/UL1479 (ASTM E814) F Rating - 2 Hr

T Rating - 2 Hr

L Rating At Ambient - Less Than 1 CFM/sq ft

L Rating At 400 F - Less Than 1 CFM/sq ft

W Rating - Class 1 (See Item 4B)

A 3 4B 1

2

4B 2 4A

A

Section A-A

1. Floor or Wall Assembly - Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3)

concrete floor. Floor may also be constructed of any min 6 in. (152 mm) thick hollow-core Precast Concrete Units*. Wall may also

be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 4 in. (102 mm).

See Concrete Blocks (CAZT) or Precast Concrete Units (CFTV) categories in the Fire Resistance Directory for names of

manufacturers.

2. Steel Sleeve - (Optional) - Nom 4 in. (102 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe cast or grouted into floor or wall

assembly, flush with floor or wall surfaces.

3. Through Penetrant - One or more nonmetallic pipes, conduits or tubes to be installed eccentrically or concentrically within the

firestop system. The annular space between the pipe, conduit or tube and the periphery of the opening shall be min 1/4 in. (6 mm) to

max 1-1/8 in. (29 mm). The space between the pipes, conduits or tubes shall be min 1/4 in. (6 mm). Pipes, conduits or tubing to be

rigidly supported on both sides of the floor or wall assembly. The following types and sizes of nonmetallic pipes, conduits and tubes

may be used:

A. Polyvinyl Chloride (PVC) Pipe - Nom 1-1/4 in. (32 mm) diam (or smaller) Schedule 40 polyvinyl chloride (PVC) pipe for use in

closed (process or supply) piping systems.

B. Chlorinated Polyvinyl Chloride (CPVC) Pipe - Nom 1-1/4 in. (32 mm) diam (or smaller) SDR17 chlorinated polyvinyl chloride

(CPVC) pipe for use in closed (process or supply) piping systems.

C. Rigid Nonmetallic Conduit+ - Nom 1-1/4 in. (32 mm) diam (or smaller) Schedule 40 PVC conduit installed in accordance with

Article 347 of the National Electrical Code (NFPA 70).

D. Cross Linked Polyethylene (PEX) Tubing - Nom 1-1/4 in. (32 mm) diam (or smaller) SDR9 PEX tubing for use in closed

(process or supply) piping systems.

4. Firestop System - The firestop system shall consist of the following:

A. Packing Material - Min 4 in. (102 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation compressed and tightly

packed into opening. Packing material recessed from top surface of floor or both surfaces of wall to accommodate the required

thickness of fill material. In floors constructed of precast hollow core units, packing material to extend for full thickness of floor

flush with bottom of floor.

B. Fill, Void or Cavity Material* - Sealant - Min 1/2 in. (13 mm) thickness of fill material installed within annulus, flush with top

surface of floor or both surfaces of wall assembly.

SPECIFIED TECHNOLOGIES INC - SpecSeal Series SSS Sealant, SpecSeal LCI Sealant, Pensil 300 or SpecSeal Series

SIL300 Sealant for floors or walls and Pensil 300 S/L Sealant or SpecSeal Series SIL300SL Sealant for floors only.

W Ratings apply when Pensil 300, SpecSeal Series SIL300, Pensil 300 S/L or SpecSeal Series SIL300SL Sealants are

used.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such

as Canada), respectively.

+Bearing the UL Listing Mark

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: January 23, 2014

STI

R

C-AJ-2586

® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com PAGE 1 OF 1

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 pageSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Quadwall: Product Data SheetDocument2 pagesQuadwall: Product Data SheetAndrei TeacăNo ratings yet

- Nailable Insulation Guide: AcfoamDocument32 pagesNailable Insulation Guide: AcfoamАлександар Але СтојановићNo ratings yet

- Technical - Specification - Group D - Tubing - 2023 07 05 13 16 29Document2 pagesTechnical - Specification - Group D - Tubing - 2023 07 05 13 16 29Chinnaraj SNo ratings yet

- HDPE Pipe SpecificationsDocument2 pagesHDPE Pipe SpecificationsTonoy BanikNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Holti System No. C-AJ-8143Document3 pagesHolti System No. C-AJ-8143S. Priscila Castillo V.No ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlNo ratings yet

- DHT-DHC OverviewDocument39 pagesDHT-DHC OverviewTaras ByloNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Approval Document ASSET DOC LOC 99Document1 pageApproval Document ASSET DOC LOC 99Amir IqbalNo ratings yet

- Anchors For Concrete Applications: Selection GuideDocument4 pagesAnchors For Concrete Applications: Selection Guiderei020282No ratings yet

- Technical Data: 1. DescriptionDocument18 pagesTechnical Data: 1. DescriptionitaloNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- Promatect ® l500: Post Cladding Steel DuctsDocument9 pagesPromatect ® l500: Post Cladding Steel DuctsOwen PerrinNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- TK ConnDocument6 pagesTK ConnPingu3No ratings yet

- Rockwool BoardsDocument12 pagesRockwool BoardsMohammed AwwadNo ratings yet

- Section 610-Pipe Underdrain and Pavement Base DrainDocument5 pagesSection 610-Pipe Underdrain and Pavement Base Drainذوالفقار كريم الابراهيميNo ratings yet

- Catalogo Completo APT PDFDocument54 pagesCatalogo Completo APT PDFJoao SalazarNo ratings yet

- Structural Steel Savings With CoSPECDocument41 pagesStructural Steel Savings With CoSPECIsmael Borrego BelmarNo ratings yet

- Rigid PVC Conduit & FittingsDocument20 pagesRigid PVC Conduit & FittingsArsalan Ullah KhanNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Trubolt Performance DataDocument6 pagesTrubolt Performance DataDiego martinez castellanosNo ratings yet

- Viking VK 503Document6 pagesViking VK 503ozkan28adanaNo ratings yet

- MCXADocument1 pageMCXALiz Fco PérezNo ratings yet

- Ficha Tecnica Trubolt RED HEADDocument6 pagesFicha Tecnica Trubolt RED HEADCristhian Josue Cereceda BautistaNo ratings yet

- ESPCI Design & Material Specs 102403 - LandscapeDocument1 pageESPCI Design & Material Specs 102403 - LandscapeAlin ApoNo ratings yet

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- k11 2Document6 pagesk11 2jeshupunkNo ratings yet

- A Casa SaddleDocument2 pagesA Casa SaddlesalamrefighNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

- Spiralco - Specifications - ASTM A-139Document4 pagesSpiralco - Specifications - ASTM A-139Özgür TuştaşNo ratings yet

- Fiberspar LinePipe TM The Leader in Spoolable Pipeline Systems. Full Reel Program Certified Installer Training. Tuesday, December 07, 2010Document165 pagesFiberspar LinePipe TM The Leader in Spoolable Pipeline Systems. Full Reel Program Certified Installer Training. Tuesday, December 07, 2010jhon alexanderNo ratings yet

- EPR 5KV 100% y 133%Document2 pagesEPR 5KV 100% y 133%ssimental71No ratings yet

- Akg ConduitDocument6 pagesAkg Conduitabhisheksingh4040No ratings yet

- 06 73 00trxDocument6 pages06 73 00trxRonnell RepilNo ratings yet

- MS 02 316Document12 pagesMS 02 316gazwang478No ratings yet

- BIS Hume PipeDocument7 pagesBIS Hume PipeShiv Pratap SinghNo ratings yet

- Future Pipe InfoDocument29 pagesFuture Pipe Infomekag94No ratings yet

- Accesorios de Fibra de Vidrio (Conley)Document43 pagesAccesorios de Fibra de Vidrio (Conley)Juan Carlos Vazquez RosasNo ratings yet

- Rock Plast Pipe BrochureDocument28 pagesRock Plast Pipe BrochureHusna Mega JayaNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8083 PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8083 PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Fa1015 - DL PDFDocument1 pageSystem PDF Files - 1. UL and cUL Systems - Fa1015 - DL PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Fa2246 PDFDocument3 pagesSystem PDF Files - 1. UL and cUL Systems - Fa2246 PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Fa1093 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Fa1093 - DLEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Fa1015 - DL PDFDocument1 pageSystem PDF Files - 1. UL and cUL Systems - Fa1015 - DL PDFEmanuel PastlNo ratings yet