Professional Documents

Culture Documents

TriboDSP - U3800 Brochure

Uploaded by

KSPerBeatzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TriboDSP - U3800 Brochure

Uploaded by

KSPerBeatzCopyright:

Available Formats

TM

TRIBO.dsp U3800

Multichannel Monitor

TRIBO.dsp U3800 is a multichannel particulate monitor for emissions or flow

applications using Auburn’s proprietary TRIBO.dsp, unified DC/AC core technology.

The U3800 can be used as a complete stand-alone system or integrated into existing

plant data management systems using the digital communication protocol (Modbus

TCP, Ethernet/IP). Each unit is capable of connecting up to six remote probes. The

U3800 has an intuitive industrial grade touch screen, displaying user selectable views,

such as line chart; numerical; or bar chart views.

For a comprehensive bag leak detection system, multiple U3800 units can be

managed by AUBURN.vision software.

TRIBO.dsp U3800 features include:

Unified DC and AC signal based processing algorithm, more stable and accurate than AC only signal

Immune to electromagnetic noises, suitable for harsh industrial environments

Continuous automatic zero baseline tracking, no periodic manual zero check required

Continuous self-checking probe alerts to false signals from moisture contamination and fouling

6 channels for remote probe connections

3.5” active matrix touch screen display

Multiple display options: numerical, bar chart, column chart, and line

chart

User configurable channel descriptions, engineering units, scaling, signal

smoothing, alarm levels, and delays for each channel

One SPDT relay output for user programmable alarm output scheme

Modbus RTU, Modbus TCP, Industrial Ethernet (Ethernet/IP)

communication protocol, for easy integration to PLC, HMI/SCADA and

plant automation systems

Optional OPC driver available

Configuration Screen

85 to 260 VAC standard. Optional: 12 VDC, 24 VDC, and P.O.E. (Power

Over Ethernet)

TRIBO.dsp U3000 Series

Auburn’s TRIBO.dsp U3000 series of electrostatic/triboelectric bag leak detectors, emission monitors, and solids flow

monitors effectively measure dust emissions and dry solids flow from a wide variety of industrial processes.

TRIBO.dsp’s Working Principal:

As dust particles collide with, or closely pass by a probe, charge transfers occur. Tribo.dsp series products detect the signal

created by the changes in particulate concentration, as in the onset of a bag leak or an increase or decrease in flow.

Unlike monitors that use only the DC or only the AC induction signals, thereby using only a portion of the complete

electrostatic signal, TRIBO.dsp unified 3000 series combines the benefits of each method, providing the user with a

superior reliable and repeatable signal, with electrical interference resistance - even in harsh industrial environments.

They can activate operational functions such as alarms and relays or can generate continuous 4-20 mA or digital signals for

trending and recording purposes.

© 2014 Auburn Systems, LLC

TM

TRIBO.dsp U3800

ELECTRONICS SPECIFICATIONS

Electronic Enclosure Polycarbonate NEMA 4X with 3/4” conduit fittings

Power 85 to 260 VAC (12 VDC, 24 VDC, or P.O.E. optional)

Power Consumption 5 Watts maximum load

Operating Temperature -4o - 158o F (-20o - 70o C)

Humidity Range 0 - 95% relative; non-condensing

1 pA - 10,000,000 pA - standard

Dynamic Range

0.1 pA - 1,000,000 pA - optional

1 pA standard

Resolution/Precision (pA)

0.1 pA optional

Sensitivity Range Concentrations as low as .005mg/m3 have been detected

1 SPDT relay 5 amp @ 28 VDC or 250 VAC 100VA

Independent alarm set points, high or low (0 -100%), per channel

Output

Independent alarm time delays (0 - 999 sec.) per channel

Industrial Ethernet/IP and Modbus TCP

Display 3.5” active matrix touch screen display

User selectable calibration mode

Other Features Automatic contamination check

Unlimited scaling options

SENSOR SPECIFICATIONS

Remote Sensor Enclosure Cast aluminum, electrostatically applied powder coating, equivalent NEMA 4X

Sensor Probe Probe - 316 stainless steel (standard); other materials available

Wetted Metal Parts All others - 303 stainless steel minimum grade

Extended High Performance (PFA)- standard, -40° - 450°F (-40° - 232°C)

Insulation Ceramic (High Temperature or Pressure) -40° - 1000°F (-40° - 540°C)

Consult factory or your local representative for proper recommendations

Standard probe lengths: 3, 6, 12, 18, 30, 36 inch (7.6, 15.2, 30.5, 45.7, 76.2, 91.4 cm)

Probe Insertion Length

(specify to reach approximately mid-duct or further)

Installation Weld the supplied fitting into the pipe or duct and insert sensor

Special coaxial cable; temperature range: -60° - 400°F (-50° - 200°C)

Remote Sensor Cable

Maximum distance: contact factory

Wiring Connections ¾ inch NPT female conduit fitting

Pipe/Duct Connections ½ inch NPT male fitting or 1” quick release ferrule (other options available)

Options Wire-Rope Sensor; In-Line Ring Sensor; Ambient Fugitive Dust Sensor

Auburn Systems, LLC • 8 Electronics Ave., Danvers, MA 01923 USA

April 2014

sales@auburnsys.com • www.auburnsys.com • Phone: 800-255-5008 or + 978-777-2460 • Fax: 978-777-8820

You might also like

- Techincal Specifications With DetailsDocument11 pagesTechincal Specifications With Detailsruturaj v delekarNo ratings yet

- MCM800 081215Document3 pagesMCM800 081215blbkaNo ratings yet

- DN - 0524 ACS Series Annunciators ACM-AEM-16AT, ACM-AEM-32A Data SheetDocument2 pagesDN - 0524 ACS Series Annunciators ACM-AEM-16AT, ACM-AEM-32A Data Sheetjose medinaNo ratings yet

- Smart Servo 954 Selection Guide A4 ENDocument12 pagesSmart Servo 954 Selection Guide A4 ENmike.stavrianakos2717No ratings yet

- TU8325 TU8525 Datasheet PDFDocument4 pagesTU8325 TU8525 Datasheet PDFAlejandro HernandezNo ratings yet

- MT LevelSensing Control-7.21 PDFDocument12 pagesMT LevelSensing Control-7.21 PDFAndrewcaesarNo ratings yet

- Lios en - Sure: Power Cable MonitoringDocument2 pagesLios en - Sure: Power Cable MonitoringM KhNo ratings yet

- Mts 8000Document16 pagesMts 8000Anonymous LU6nvFNo ratings yet

- 1205 Cxa TDRDocument2 pages1205 Cxa TDRtapasNo ratings yet

- FT3.6.1 - Detector Prin Aspiratie - FAAST LTDocument2 pagesFT3.6.1 - Detector Prin Aspiratie - FAAST LTABBYNo ratings yet

- Elsa 3L-DF-SP & SM50 Catalogue-Mar 2019Document2 pagesElsa 3L-DF-SP & SM50 Catalogue-Mar 2019indran SuppiahNo ratings yet

- MSA UV - IR Flame Detector PDFDocument2 pagesMSA UV - IR Flame Detector PDFwe202No ratings yet

- Ca 7028Document5 pagesCa 7028narse8488No ratings yet

- UL Listed Gas DetectionDocument10 pagesUL Listed Gas DetectionjwiedrickNo ratings yet

- T10. Brosur Sensor Loop DS 0810 - V1Document2 pagesT10. Brosur Sensor Loop DS 0810 - V1aapsrcmsNo ratings yet

- Tzid Data SheetDocument12 pagesTzid Data SheetMohamed MeeranNo ratings yet

- Olp-3x Ds Fop TM AeDocument4 pagesOlp-3x Ds Fop TM AeAghil Ghiasvand MkhNo ratings yet

- (DNV) Controller SC1000 DatasheetDocument4 pages(DNV) Controller SC1000 DatasheetGautamNo ratings yet

- Especificações Do Turbidímetro MicroTOLDocument4 pagesEspecificações Do Turbidímetro MicroTOLBrunella Fernandes MileippNo ratings yet

- DOC053.53.35032.May16 SC1000Document4 pagesDOC053.53.35032.May16 SC1000luzNo ratings yet

- 770MAX Transmitter Catalog PagesDocument4 pages770MAX Transmitter Catalog PagesOctavio FuentesNo ratings yet

- Dräger Polytron 8310 IR Detection of Ammable Gases and VaporsDocument8 pagesDräger Polytron 8310 IR Detection of Ammable Gases and VaporslataNo ratings yet

- PSSU DATASHEET - Hw-PSSU-v9Document4 pagesPSSU DATASHEET - Hw-PSSU-v9workdata2223No ratings yet

- PPT-080 110Document3 pagesPPT-080 110Emanuel CondeNo ratings yet

- PSD DatasheetDocument2 pagesPSD Datasheetmetal_dung2No ratings yet

- DenA2543X000 Monitor AMI Silica PDFDocument2 pagesDenA2543X000 Monitor AMI Silica PDFEldon ArsuloNo ratings yet

- Deteccion de Humo Por Aspiracion Forzada Micra100Document2 pagesDeteccion de Humo Por Aspiracion Forzada Micra100rmsercomNo ratings yet

- Ex 100 1000 DatasheetDocument2 pagesEx 100 1000 DatasheetChico SantanaNo ratings yet

- Keep A On Your Safety: Triple IR (IR3) Flame DetectorDocument2 pagesKeep A On Your Safety: Triple IR (IR3) Flame DetectorYanuar ZulkarnainNo ratings yet

- Eddy Corrent PrubeDocument20 pagesEddy Corrent Prubeeloymark2No ratings yet

- Sensores de Conductividad de ContactoDocument12 pagesSensores de Conductividad de ContactoEduardo Landa GonzalezNo ratings yet

- Spectro 2000 RS SpectrophotometerDocument4 pagesSpectro 2000 RS Spectrophotometerkkpig26No ratings yet

- Dew Point Meter XentourDocument4 pagesDew Point Meter XentourBhaskar KumarNo ratings yet

- Smar Measument MF 8000Document4 pagesSmar Measument MF 8000Yerson JuarezNo ratings yet

- Ex 100p 1000p WebDocument2 pagesEx 100p 1000p WebAnonymous YYsE1BxrNo ratings yet

- NT - CT - Gfps 9900 Datasheet Transmitter enDocument8 pagesNT - CT - Gfps 9900 Datasheet Transmitter enLuís Felipe Coimbra MinelloNo ratings yet

- Signet 9900 TransmitterDocument8 pagesSignet 9900 TransmitterJuan Tirado VarelaNo ratings yet

- Digital Phosphor Oscilloscopes: TDS3000C SeriesDocument8 pagesDigital Phosphor Oscilloscopes: TDS3000C SeriesSebastien DawansNo ratings yet

- Cables - Cable Fault Locating and Test Van and TrailerDocument34 pagesCables - Cable Fault Locating and Test Van and TrailercadtilNo ratings yet

- SONDAR 5000 ManualDocument44 pagesSONDAR 5000 ManualovadircNo ratings yet

- Rot Op Robe ExDocument2 pagesRot Op Robe ExSiva KumarNo ratings yet

- Gefran 2400Document4 pagesGefran 2400Alexandre CamposNo ratings yet

- DB Sherlog CRX 052013 Eng PDFDocument4 pagesDB Sherlog CRX 052013 Eng PDFRuly FanuelNo ratings yet

- System Sensor D4S Data SheetDocument4 pagesSystem Sensor D4S Data SheetJMAC SupplyNo ratings yet

- Product Data Sheet t1056 Clarity II Turbidimeter Rosemount en 69302Document8 pagesProduct Data Sheet t1056 Clarity II Turbidimeter Rosemount en 69302khaldoun samiNo ratings yet

- Shimadzu Uvmini-1240 and Biospec-Mini Uv/Visible Scanning SpectrophotometersDocument1 pageShimadzu Uvmini-1240 and Biospec-Mini Uv/Visible Scanning SpectrophotometersYehya EljoneidNo ratings yet

- Signet 8550Document2 pagesSignet 8550Ricardo AkermanNo ratings yet

- Medicion Fibra OpticaDocument16 pagesMedicion Fibra OpticaJulio Cesar VPNo ratings yet

- Continuous Level Measurement - Ultrasonic ControllersDocument8 pagesContinuous Level Measurement - Ultrasonic ControllersknchnNo ratings yet

- MAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetDocument4 pagesMAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetSebastián Alexander Flores OroscoNo ratings yet

- RepeaterDocument2 pagesRepeaterzqandahNo ratings yet

- Specification MPU600-Series-B ssks003Document6 pagesSpecification MPU600-Series-B ssks003montanovillarroelfabiolalourdeNo ratings yet

- UniSCAN NX - H - V - PrinterDocument7 pagesUniSCAN NX - H - V - PrinterYogesh RamdasiNo ratings yet

- Endress-Hauser Micropilot FMR60 ENDocument4 pagesEndress-Hauser Micropilot FMR60 ENAhmed MoharramNo ratings yet

- Datasheet EddyCheck 605Document15 pagesDatasheet EddyCheck 605vanloc tranNo ratings yet

- Ultrasonic Gas FlowmeterDocument6 pagesUltrasonic Gas Flowmeterhk168100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

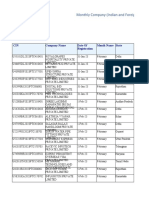

- Monthly-Company (Indian-and-Foreign) - and LLPs-20230301Document724 pagesMonthly-Company (Indian-and-Foreign) - and LLPs-20230301Yogesh Paigude0% (1)

- Sk200-8 Sk210lc-8 Super AsiaDocument16 pagesSk200-8 Sk210lc-8 Super AsiaAnwar Rashid86% (7)

- Training and Development in Consumer IndustriesDocument31 pagesTraining and Development in Consumer IndustriesKiran kumar SahuNo ratings yet

- 9 Principles of Income Tax LawsDocument82 pages9 Principles of Income Tax LawsVyankatesh GotalkarNo ratings yet

- Cost Acctg. Problems 1Document8 pagesCost Acctg. Problems 1Cheese ButterNo ratings yet

- Mobile Scaffold Inspection ChecklistDocument3 pagesMobile Scaffold Inspection Checklistanthony murphyNo ratings yet

- Ch3 Profiles, Password Policies, Privileges, and RolesDocument79 pagesCh3 Profiles, Password Policies, Privileges, and Rolesahlam alzhraniNo ratings yet

- United States Government and PoliticsDocument21 pagesUnited States Government and PoliticsTony BuiNo ratings yet

- Citroen C4 Picasso/Grand Picasso BilmetropolenDocument5 pagesCitroen C4 Picasso/Grand Picasso BilmetropolenAlberto Miglino100% (1)

- Edmonton Report On Flood MitigationDocument6 pagesEdmonton Report On Flood MitigationAnonymous TdomnV9OD4No ratings yet

- Crafted Furniture Business PlanDocument30 pagesCrafted Furniture Business PlanSufianNo ratings yet

- Soy Candle ModuleDocument17 pagesSoy Candle ModuleCla Rence0% (2)

- A Comparative Analysis of Performance of Public & Private Sector Mutual FundsDocument30 pagesA Comparative Analysis of Performance of Public & Private Sector Mutual Fundsk kNo ratings yet

- Optical Burst Switching (OBS)Document27 pagesOptical Burst Switching (OBS)adityaNo ratings yet

- Tall VarietiesDocument23 pagesTall VarietiessakthivelNo ratings yet

- Automatic Transmission System SeminarDocument14 pagesAutomatic Transmission System SeminarAnonymous 2YgIckU0No ratings yet

- PR100 Locks With Aperio Wireless Technology: Key FeaturesDocument2 pagesPR100 Locks With Aperio Wireless Technology: Key FeaturesMay SamboNo ratings yet

- Nameet Kumar Jain: Education ProjectsDocument1 pageNameet Kumar Jain: Education ProjectsNameet JainNo ratings yet

- Liftking Forklift PDIDocument1 pageLiftking Forklift PDIManual ForkliftNo ratings yet

- Topology Optimization of Automotive Brake PedalDocument5 pagesTopology Optimization of Automotive Brake PedalNizam Sudin Dan KhatijahNo ratings yet

- Remote Environment: - Concern The Nature and Direction of Economy in Which A Firm Operates - Types of FactorsDocument27 pagesRemote Environment: - Concern The Nature and Direction of Economy in Which A Firm Operates - Types of FactorsmikiyingNo ratings yet

- Bulk PricesDocument2 pagesBulk PricesMega Byte0% (1)

- Literature Review On School AdministrationDocument6 pagesLiterature Review On School Administrationea7sfn0f100% (1)

- Measuring The Sustainability of Urban Water ServicesDocument10 pagesMeasuring The Sustainability of Urban Water ServicesWalter RodríguezNo ratings yet

- SpirentAutomotiveLV124 LV148VDocument38 pagesSpirentAutomotiveLV124 LV148VNiculcea Cristin100% (3)

- RELAP5 Simulation of CANDU Station Blackout AccideDocument20 pagesRELAP5 Simulation of CANDU Station Blackout AccideWhite HeartNo ratings yet

- 802 11 Qos OverviewDocument38 pages802 11 Qos Overviewswapnil tiwariNo ratings yet

- Power Semiconductor Devices ClassificationDocument9 pagesPower Semiconductor Devices ClassificationdevchandarNo ratings yet

- Strategic Human Resources Planning 5th Edition Belcourt Solutions ManualDocument25 pagesStrategic Human Resources Planning 5th Edition Belcourt Solutions ManualMarioAbbottojqd100% (52)

- Working Capital Management OF: Submitted by Priya BanerjeeDocument102 pagesWorking Capital Management OF: Submitted by Priya BanerjeeSushmita BarlaNo ratings yet