Professional Documents

Culture Documents

118-Titan Railgen 13

Uploaded by

Ahmed KabbajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

118-Titan Railgen 13

Uploaded by

Ahmed KabbajCopyright:

Available Formats

TITAN RAILGEN 13 SAE 40

High Performance Rail Locomotive Mono-grade Engine Oil according to API CF

utilizing zinc and chlorine free additive technology.

Description Advantages/Benefits

TITAN RAILGEN 13 SAE 40 is a mono-grade The use of TITAN RAILGEN 13 SAE 40 will ensure

high performance, API CF level lubricating oil protection of the engine and all of its critical components

specialty formulated to meet the requirements of TITAN RAILGEN 13 SAE 40 is fully inhibited for

Rail Locomotive diesel engines. TITAN protection against corrosion

RAILGEN 13 SAE 40 provides the necessary TITAN RAILGEN 13 SAE 40 has a high level of

extra alkalinity to effectively neutralize acidic by- oxidation resistance to prevent premature ageing

products of combustion during operation and and to give longer oil life.

gives a high level of detergency to keep pistons TITAN RAILGEN 13 SAE 40 offers optimum

and piston rings free of deposits. alkalinity to neutralize acidic by products of

combustion e.g. when the diesel fuel contains sulfur

Application TITAN RAILGEN 13 SAE 40 utilizes zinc and

TITAN RAILGEN 13 SAE 40 is blended with the chlorine free additive technologies

latest Zinc and Chlorine free additive

technology, developed especially for use in Rail Specifications

Locomotive diesel engines.

API CF

The zinc free additive technology is especially

compatible to engines with silver bearings. The

absence of chlorine in the formulation is Approvals

beneficial for the environment and eases GE Generation 4LL

disposal and recycling of the used fluid. GM - EMD GENERATION 5

The additive system has been extensively tested

in GE, LMOA & Caterpillar engines with good FUCHS Recommendations

field results. LMOA GENERATION 5

CATERPILLAR 3600

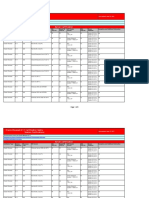

CHARACTERISTICS

TITAN RAILGEN 13 SAE 40

Density @ 35 °C 0.884 g/ml ASTM D 4052

Flash Point, CoC 252 °C ASTM D 92

Pour Point -15 °C ASTM D 97

Kinematic Viscosity @ 40 °C 147 mm²/s ASTM D 445

Kinematic Viscosity @ 100 °C 14.9 mm²/s ASTM D 445

Viscosity index 101 - ASTM D 2270

Product Code 118 - 01/01/2019 Page 1

While the information and figures given here are typical of current production and confirm to specification, minor variations may occur. No warranty

expressed or implied is given concerning the accuracy of the information or the suitability of the product

ALHAMRANI FUCHS PETROLEUM SAUDI ARABIA LIMITED ISO 9001:2015

ISO 14001:2015

P. O. Box 7103, Jeddah 21462, Saudi Arabia OHSAS 18001:2007

CERTIFIED

Telephone +966 2 6635 666 FAX +966 2 6634 094 www.fuchs.com.sa

You might also like

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- Section - : Exit To Main MenuDocument186 pagesSection - : Exit To Main Menuadi67% (3)

- Iso 17632 2015 en PDFDocument11 pagesIso 17632 2015 en PDFalok9870% (1)

- Cat DEO (Diesel Engine Oil) PEHJ0021 PDFDocument2 pagesCat DEO (Diesel Engine Oil) PEHJ0021 PDFfjaristizabalNo ratings yet

- Hidden Beam DesignDocument8 pagesHidden Beam DesignAnil kumar R100% (1)

- ISO 16923-2016 Text - Natural Gas Fuelling Stations - CNGDocument50 pagesISO 16923-2016 Text - Natural Gas Fuelling Stations - CNGمحمد مجدي100% (2)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Getting Started With PIC Microcontroller - CCS C Compiler PDFDocument19 pagesGetting Started With PIC Microcontroller - CCS C Compiler PDFNithya100% (2)

- Gpcdoc Gtds Shell Argina T 40 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 40 (2005) (En) Tdscesar_lub100% (1)

- Simple Quiz App Using PythonDocument47 pagesSimple Quiz App Using Pythonatozdhiyanes100% (1)

- Lubrex Guide BookDocument209 pagesLubrex Guide BookPawel PawelNo ratings yet

- CSC662 - Computer Security Short NoteDocument10 pagesCSC662 - Computer Security Short NoteMohamad YusriNo ratings yet

- Shell Argina X 40 - TDSDocument2 pagesShell Argina X 40 - TDSHUM CIREBON DFLTS100% (1)

- Titan Atf 4000: Alhamrani Fuchs Petroleum Saudi Arabia LimitedDocument1 pageTitan Atf 4000: Alhamrani Fuchs Petroleum Saudi Arabia LimitedM.TayyabNo ratings yet

- 210-Titan PSW 15Document2 pages210-Titan PSW 15jafaristsNo ratings yet

- Shell Rimula R3 40Document2 pagesShell Rimula R3 40francisNo ratings yet

- Gpcdoc Gtds Shell Argina T 30 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 30 (2005) (En) TdsEdgar Leonel CortésNo ratings yet

- Shell Rimula R1 SAE 50Document2 pagesShell Rimula R1 SAE 50Álgøkár ÁhmēdNo ratings yet

- Shell Argina S 30 - TDSDocument2 pagesShell Argina S 30 - TDSHUM CIREBON DFLTSNo ratings yet

- 209-Titan PSW 12Document2 pages209-Titan PSW 12jafaristsNo ratings yet

- Shell Rimula R2 SAE 40Document2 pagesShell Rimula R2 SAE 40Álgøkár ÁhmēdNo ratings yet

- R2 40 Heavy Duty Diesel Engine OilDocument2 pagesR2 40 Heavy Duty Diesel Engine OilRaden ArdyNo ratings yet

- R2 30 (CF 10TBN) TDSDocument2 pagesR2 30 (CF 10TBN) TDSMozesTobingNo ratings yet

- Shell Rimula R2 40 (CF) : Performance, Features & BenefitsDocument2 pagesShell Rimula R2 40 (CF) : Performance, Features & BenefitsMuhammad SaputraNo ratings yet

- PI Titan Truck Plus SAE 15W-40Document2 pagesPI Titan Truck Plus SAE 15W-40Axel Mahya AvichenaNo ratings yet

- Shell Rimula r3+40Document2 pagesShell Rimula r3+40Aaron LieNo ratings yet

- Shell Rimula R3+ 40: Performance, Features & BenefitsDocument2 pagesShell Rimula R3+ 40: Performance, Features & BenefitsHUM CIREBON DFLTSNo ratings yet

- Cat Oil Filtros CodPartDocument2 pagesCat Oil Filtros CodPartKaly7No ratings yet

- Dewmare Marine Oil 4040Document1 pageDewmare Marine Oil 4040ednsmnNo ratings yet

- Rimula All Purpose Disel Engine Oil 20W 40Document2 pagesRimula All Purpose Disel Engine Oil 20W 40HAAWK INTERNATIONAL RAAVINDRA GODENo ratings yet

- Pegasus 805 PdsDocument2 pagesPegasus 805 PdsBudi NaisNo ratings yet

- Cofran Sintolux Di 5w40 enDocument1 pageCofran Sintolux Di 5w40 enAhmed KabbajNo ratings yet

- GPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Document2 pagesGPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Nokiabhre WijayaNo ratings yet

- Chevron Regal RO PDSDocument4 pagesChevron Regal RO PDSVivekyathi BowanNo ratings yet

- Made in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnDocument2 pagesMade in Usa: Engine Oil (Dual) 15W40 Api Ci4+ Ci4/SnsheilaNo ratings yet

- Rimula r2 15w 40Document2 pagesRimula r2 15w 40nanunaaau2005No ratings yet

- Shell Helix Ultra 5W-40: Performance, Features & BenefitsDocument2 pagesShell Helix Ultra 5W-40: Performance, Features & BenefitsMuhNo ratings yet

- Shell Argina S5 40: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Argina S5 40: Performance, Features & Benefits Main ApplicationsJAHIDUL ISLAMNo ratings yet

- GPCDOC GTDS Shell Rimula D Extra 40 1 PDFDocument2 pagesGPCDOC GTDS Shell Rimula D Extra 40 1 PDFphucdc095041No ratings yet

- Argina s5 40 TdsDocument2 pagesArgina s5 40 TdsWajahat RasoolNo ratings yet

- Shell Rimula D Extra 40: High Quality, Heavy Duty Monograde Diesel Engine OilDocument2 pagesShell Rimula D Extra 40: High Quality, Heavy Duty Monograde Diesel Engine Oilphucdc095041No ratings yet

- AP IN Mobil Super Diesel TM CI 4 Plus 15W40Document2 pagesAP IN Mobil Super Diesel TM CI 4 Plus 15W40Sandeep NikhilNo ratings yet

- Shell Gadinia S3 40: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadinia S3 40: Performance, Features & Benefits Main ApplicationssanathcgrNo ratings yet

- Shell Spirax S3 G80WDocument2 pagesShell Spirax S3 G80WNokiabhre WijayaNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- Aral Hightronic 5w-40 Germany English PDB 467316Document2 pagesAral Hightronic 5w-40 Germany English PDB 467316Cristina OlaruNo ratings yet

- PDS Castrol RLX Super 40Document2 pagesPDS Castrol RLX Super 40epesanoNo ratings yet

- Shell Rimula R2 Extra 15W-40Document2 pagesShell Rimula R2 Extra 15W-40Muhammad SaputraNo ratings yet

- Mobilgard 450Document2 pagesMobilgard 450Jeef100% (1)

- Shell Caprinus XS 40Document2 pagesShell Caprinus XS 40cesar_lubNo ratings yet

- Shell Caprinus XS 40 PDFDocument2 pagesShell Caprinus XS 40 PDFcesar_lubNo ratings yet

- Shell Caprinus Fefefeef PDFDocument2 pagesShell Caprinus Fefefeef PDFcesar_lubNo ratings yet

- Shell IVeco 1811Document2 pagesShell IVeco 1811Jorge Arrieta TorresNo ratings yet

- Technical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Document2 pagesTechnical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Mohamed IsmailNo ratings yet

- Shell Rimula R3+ 30: Performance, Features & BenefitsDocument2 pagesShell Rimula R3+ 30: Performance, Features & BenefitsAMITNo ratings yet

- Rimula R2 Extra 15W40Document2 pagesRimula R2 Extra 15W40AMITNo ratings yet

- Rimula r2 0w 50Document2 pagesRimula r2 0w 50Aji WibowoNo ratings yet

- Shell Argina S5 40: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Argina S5 40: Performance, Features & Benefits Main ApplicationsKurniawanNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- Geo Sng-4 Sae 40-Pi SheetDocument2 pagesGeo Sng-4 Sae 40-Pi SheetDana Group - Valvoline LubricantNo ratings yet

- Servo LubesDocument2 pagesServo LubesVignesh VickyNo ratings yet

- Shell Rimula R4 15W-40: Performance, Features & BenefitsDocument2 pagesShell Rimula R4 15W-40: Performance, Features & Benefitsreport2510No ratings yet

- Mobil Delvac 1400 SuperDocument2 pagesMobil Delvac 1400 SuperMichaelNo ratings yet

- Titan Universal HDDocument1 pageTitan Universal HDomar alayashNo ratings yet

- Shell Argina X: Medium-Speed Trunk-Piston Diesel Engine OilDocument3 pagesShell Argina X: Medium-Speed Trunk-Piston Diesel Engine OilengrsurifNo ratings yet

- 403 Renolin BDocument2 pages403 Renolin BWasimraja NanjwaniNo ratings yet

- Cofran Challenger Star 10w40 enDocument1 pageCofran Challenger Star 10w40 enAhmed KabbajNo ratings yet

- Cassida Chain Oil 150Document3 pagesCassida Chain Oil 150Ahmed KabbajNo ratings yet

- Adblue BasfDocument1 pageAdblue BasfAhmed KabbajNo ratings yet

- Agrifarm Mot 15W-40Document3 pagesAgrifarm Mot 15W-40Ahmed KabbajNo ratings yet

- Lubuklinggau Price 2017Document59 pagesLubuklinggau Price 2017akhmad hidayatNo ratings yet

- 2020 - Roadroid University Registration FormDocument2 pages2020 - Roadroid University Registration FormAiidil SuwandiNo ratings yet

- Progress Test 2 (Units 4-6) : Name - ClassDocument6 pagesProgress Test 2 (Units 4-6) : Name - ClassРусланNo ratings yet

- Cryptocurrency System Using Body Activity Data Wo2020060606 2 of 6Document1 pageCryptocurrency System Using Body Activity Data Wo2020060606 2 of 6Nemo NemoNo ratings yet

- SHS SEPNAS Paper-Formatting-guidelines Pr2 Quantitative ReserachDocument24 pagesSHS SEPNAS Paper-Formatting-guidelines Pr2 Quantitative ReserachAnalyn RosarioNo ratings yet

- Tech M Service LetterDocument1 pageTech M Service LetterRahul upadhyayNo ratings yet

- PolyBrick+3 0Document16 pagesPolyBrick+3 0Sachal AbdullahNo ratings yet

- UST - A1100 Guardian Overfill Prevention ValveDocument1 pageUST - A1100 Guardian Overfill Prevention ValvelauraNo ratings yet

- Assignment 4 Forward KinematicsDocument2 pagesAssignment 4 Forward KinematicsVaibhav KulkarniNo ratings yet

- Huawei FusionServer RH8100 V3 Data SheetDocument4 pagesHuawei FusionServer RH8100 V3 Data Sheetpramod BhattNo ratings yet

- Supply Chain ManagementDocument16 pagesSupply Chain ManagementHaider AyyNo ratings yet

- Spun Pipe RCC Pipe Hume PipeDocument1 pageSpun Pipe RCC Pipe Hume PipeAbhiishek SinghNo ratings yet

- 1 Correlation Between Na2SiO3 NaOH Ratio ADocument6 pages1 Correlation Between Na2SiO3 NaOH Ratio AedwardcolmeNo ratings yet

- First Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerDocument24 pagesFirst Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerKhizrah RafiqueNo ratings yet

- Fuel Temperature SensorDocument12 pagesFuel Temperature SensorAakarsh Verma100% (2)

- B-0018-1-Al Khayal Gen. Cont. (Hordi Block) (Comp. Strength)Document1 pageB-0018-1-Al Khayal Gen. Cont. (Hordi Block) (Comp. Strength)Matrix LaboratoryNo ratings yet

- Guide To Computer Forensics and Investigations 5th Edition Bill Test BankDocument11 pagesGuide To Computer Forensics and Investigations 5th Edition Bill Test Bankshelleyrandolphikeaxjqwcr100% (30)

- Betelhem MekuriaDocument59 pagesBetelhem MekuriaabenuzzionNo ratings yet

- Avamar-4.1-Technical-Addendum. Avamar Commandspdf PDFDocument537 pagesAvamar-4.1-Technical-Addendum. Avamar Commandspdf PDFdanilaix50% (2)

- 50Document5 pages50Pedro Ivan100% (1)

- Oracle Ow811 Certification Matrix 161594Document8 pagesOracle Ow811 Certification Matrix 161594ps.calado5870No ratings yet

- ECE114 LogicCrkt&SwtchngTheory CM4Document13 pagesECE114 LogicCrkt&SwtchngTheory CM4Kai MoraNo ratings yet

- M580 HSBY System Planning GuideDocument217 pagesM580 HSBY System Planning GuideISLAMIC LECTURESNo ratings yet