Professional Documents

Culture Documents

9MM E0 Test Report

9MM E0 Test Report

Uploaded by

Lawrence Lau0 ratings0% found this document useful (0 votes)

10 views4 pagesOriginal Title

9MM E0 TEST REPORT

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pages9MM E0 Test Report

9MM E0 Test Report

Uploaded by

Lawrence LauCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

FPDU 16 Revd

r PT DOVER CHEMICAL

oe Jalan Raya Merak Km.117, Merak, Banten - Indonesia

Tel: +62 254571084 Fax: +62 254 571224

Our reference: Date January 10%, 2022

‘Atta: Bp. Dedi

Dear Sin,

With eference to the above, culosed isthe test result for Plywood 72 £0, according to MAFF notification No.683,

March 29°, 2018 (JAS 2018 for Plywood).

Formaldehyde emission elagsficatlon according to JAS 2018 For Plywood

performance ‘Average value (mg/L) Niaximum vi

Faves os wt

os oT

i Fee TS ~ 21 ~

i FF L 30 - 70 |

Bonding Strength test me

Clasiction a od

— Tes ioe aero hot tater oP 60 eFC Tor) hoa i mend in|

(te __ ster at rom temperatre util get oo, and tested in wet condition

Delamination test method according to JAS 2018 For Plywood:

ON Cusiteation Delamination Test Method

Pest pia are immersed hot water of 70 + 3°C for 2 hours, and hen ed a We

“temperature of 03°C for hours

‘length ofthe part which is ot dlaminaed in the same bonding layer of test piece shal

be no ess than 50 mm at each se

Type 2

Molsture content nccording fo JAS 2018 For Plywood :

Standard 5

isture Content Test Method

airs ‘Measure mass of test piece and dy them in a dryer at temperature of 10342°C,

™ "4% its weight constant (mass diffrent between two measurement not more than 0.1%)

‘Comment:

‘+ Sample Type 2 EO complied to F#** according to JAS 2018 for Plywood

‘+ Sample Type 2 £0 complied to Type 2 Bonding strength est according to JAS 2018 for Plywood.

‘+ Sample Type 2 EO complied to Type 2 Delamination test according o JAS 2018 for Plywood.

+ Sample Type 2 £0 complied to Moisture content tet according 19 JAS 2018 for Plywood,

Thank you

Yours sincerely,

SAID AFeF

PT. Dover Chemical

Producten Dovelment Unt Laberatry

'BT Dover Chemica!

(Tot +82 254571 054 Fax 62254 871 224, mal developmenaovecrem.c.)

PT DOVER CHEMICAL

Jalan Raya Merak Km.117, Merak, Banten — Indonesia

Tel: +62 254 571064

FPDU.OIG Revo

Fax: +62 254 571224

ar ralerenes

ReporNo-

[This rportconsiss of 2

ages

january 10°, 2022

TEST REPORT

[ob Na pemormraONT

Page | of

This por isnot a certificate of quality and nat an approval cerifcse. This report covers only tothe sample supplied

bya

ents to be tested at PT Dover Chemical, PT Dover Chemical was not responsibie in selection of sample for

testing This testing i subject only tothe sample supplied by the clients. This report or any pat ot eannot be published

‘or being use for any other purpose except with the permission from PT. Dover Cheinica -

CUSTOMER

Name and Address

SAMPLE DESCRIPTION

Material identity:

Date of Receipt

Dimension and Quantity:

TEST METHOD

Purpose of tes:

Sampling and testing Method:

Plywood 1? 60

January 074, 2021,

5 pieces of Plywood with dimension a 9m x 350 mm

1350 mm. Production 3 ~ 4 Januaty 2022

To determine Formaldehyde Emission . Bonding

Strength, Moisture Content and Delamination according

10JAS 2018 for plywood

‘Upon arrival, the samples were tasted according to

specifies standards

Days of conditioning: 2 days

Date oftesting - 09" ~ 109 January, 2022

[ Prvaredin | Chegledby: - ‘Approved by

|

| [=~

Producten Development Unt Laboratory

bt Cover Cnemest

(081 +62256 575 O64, Fax +62 264 571224, Ema development@dovechem co)

FPDU.OISRevo

i PT DOVER CHEMICAL

ey Jalan Raya Merak Km.117, Merak, Banten ~ Indonesia

Tel: +62 254 571064 Fax: +62 254 571224

‘Our reference: = Date : January 10, 2022

TEST REPORT

Report No. [a _

This pot consis oF 2 pages [Page 2of 2

“This ep is not a setiieat of quality and naan approval ceric. This eport covers only othe sample supplied

ty elens tobe tested a PT Dover Chemical, PT Dover Chemical was not responsible in selection of sample for |

testing This testing is subject nly tothe sample supplied by the clients. This report or any art of it canna be

‘TEST RESULT

yde emission:

Sample

"Plywood 12 EO Fee

“ype 2 Bonding strength est:

r Bonding strength (Wrmmnt)——~—SS*YSudgement |

sa = J

oe Aeeruge | Maxima |

Pipwood TP ED 12 B

‘ype 2 Delamination Test

[ Senge | Deannation ie Pea) Tadgement]

Plywood T2 E0 ~ ‘Pass:

Moisture conten:

[Moisture Content (%) Tudgement —

t wb fi

‘+ Sample Type 2 EO complied o F##* according to JAS 2018 for Plywood

+ Sample Type 2 60 complied to Type 2 Bonding strength test according to JAS 2018 for Plywood,

+ Sample Type 2 £0 complied to Type 2 Delamination test according to JAS 2018 for Plywood.

‘© Sample Type 2 G0 complied to Moisture content test according t0 JAS 2018 for Plywood,

Freed Cialis Taped

(Desi oe (Adia Syatri) (Said ABE)

Supinizor sonar Monoger

Production Dovelopman Unt Laboratory

Dover Chem

(et +82 254571084, Fax +62 254571 724, Emel: developmentaovecrem.co.)

ee ee

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASM Development (KL) SDN BHD V Econpile (M) SDN BHD (2020) MLJU 282 PDFDocument32 pagesASM Development (KL) SDN BHD V Econpile (M) SDN BHD (2020) MLJU 282 PDFLawrence LauNo ratings yet

- SGBC Goodrich PP Carpet TileDocument1 pageSGBC Goodrich PP Carpet TileLawrence LauNo ratings yet

- 1556320638TDS - SN-501 100 RTV Neutral Silicone SealantDocument2 pages1556320638TDS - SN-501 100 RTV Neutral Silicone SealantLawrence LauNo ratings yet

- GREENGUARD Certification (20220603) - HPL - Formica AsiaDocument2 pagesGREENGUARD Certification (20220603) - HPL - Formica AsiaLawrence LauNo ratings yet

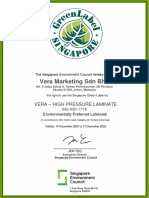

- Green Label 2020 - 2022Document1 pageGreen Label 2020 - 2022Lawrence LauNo ratings yet

- UntitledDocument20 pagesUntitledLawrence LauNo ratings yet

- Green Cert - Pentalite - Anti - MouldDocument2 pagesGreen Cert - Pentalite - Anti - MouldLawrence LauNo ratings yet

- UntitledDocument10 pagesUntitledLawrence LauNo ratings yet

- SGBC Goodrich Nylon Carpet TileDocument1 pageSGBC Goodrich Nylon Carpet TileLawrence LauNo ratings yet

- Enforcing Conditional Payment Clauses post-CIPAA - CIPAAMalaysia PDFDocument5 pagesEnforcing Conditional Payment Clauses post-CIPAA - CIPAAMalaysia PDFLawrence LauNo ratings yet

- UntitledDocument17 pagesUntitledLawrence LauNo ratings yet

- Casmet SDN BHD V Nte Engineering SDN BHD and Another Suit (2017) MLJU 2382Document8 pagesCasmet SDN BHD V Nte Engineering SDN BHD and Another Suit (2017) MLJU 2382Lawrence LauNo ratings yet

- Casaria Construction SDN BHD V Albilt Resources SDN BHD (2009) MLJU 43Document4 pagesCasaria Construction SDN BHD V Albilt Resources SDN BHD (2009) MLJU 43Lawrence LauNo ratings yet

- 20200428-Arbitration - An Overiding PromisesDocument3 pages20200428-Arbitration - An Overiding PromisesLawrence LauNo ratings yet

- Ceylon Builders SDN BHD V Ultimate Pursuit SDN BHD and Another Appeal (2018) MLJU 1918Document11 pagesCeylon Builders SDN BHD V Ultimate Pursuit SDN BHD and Another Appeal (2018) MLJU 1918Lawrence LauNo ratings yet

- 12027-Tender Documents-Supply and Installation of Tvet Equipment and Tools (4) (23) Feb FinalDocument157 pages12027-Tender Documents-Supply and Installation of Tvet Equipment and Tools (4) (23) Feb FinalLawrence LauNo ratings yet

- Bertam Development SDN BHD V R&C Cergas Teguh SDN BHD (2017) MLJU 1571 PDFDocument12 pagesBertam Development SDN BHD V R&C Cergas Teguh SDN BHD (2017) MLJU 1571 PDFLawrence LauNo ratings yet

- Binastra Ablebuild SDN BHD V JPS Holdings SDN BHD and Another Case (2017) MLJU 1260 PDFDocument15 pagesBinastra Ablebuild SDN BHD V JPS Holdings SDN BHD and Another Case (2017) MLJU 1260 PDFLawrence Lau100% (1)

- Bhaskaran AL Thiruppuvanam V Ong Chong Realty SDN BHD & Anor (2017) MLJU 644 PDFDocument15 pagesBhaskaran AL Thiruppuvanam V Ong Chong Realty SDN BHD & Anor (2017) MLJU 644 PDFLawrence LauNo ratings yet

- BM City Realty & Construction SDN BHD V Merger Insight (M) SDN BHD and Another Case (2016) MLJU 1567 PDFDocument17 pagesBM City Realty & Construction SDN BHD V Merger Insight (M) SDN BHD and Another Case (2016) MLJU 1567 PDFLawrence LauNo ratings yet

- Effect On CMCO To EOT & L&E PDFDocument4 pagesEffect On CMCO To EOT & L&E PDFLawrence LauNo ratings yet

- Ban Soon Aik Construction SDN BHD V Berjaya Land Development SDN BHD and Another Appeal (2019) MLJU 1232 PDFDocument15 pagesBan Soon Aik Construction SDN BHD V Berjaya Land Development SDN BHD and Another Appeal (2019) MLJU 1232 PDFLawrence LauNo ratings yet

- Aston Villa SDN BHD V Infra Segi SDN BHD and Another Case (2018) MLJU 438 PDFDocument12 pagesAston Villa SDN BHD V Infra Segi SDN BHD and Another Case (2018) MLJU 438 PDFLawrence LauNo ratings yet

- Bakti Dinamik SDN BHD V Bauer (Malaysia) SDN BHD (2016) MLJU 916 PDFDocument11 pagesBakti Dinamik SDN BHD V Bauer (Malaysia) SDN BHD (2016) MLJU 916 PDFLawrence LauNo ratings yet

- Bakti Dinamik SDN BHD V Bauer (M) SDN BHD (2016) MLJU 1878 PDFDocument17 pagesBakti Dinamik SDN BHD V Bauer (M) SDN BHD (2016) MLJU 1878 PDFLawrence LauNo ratings yet

- LauSiewSoonMFAB2017 PDFDocument35 pagesLauSiewSoonMFAB2017 PDFLawrence LauNo ratings yet

- Albilt Resources SDN BHD V Casaria Construction SDN BHD (Dissenting Avail MLJU (09) 1546) (2009) MLJU 1545Document6 pagesAlbilt Resources SDN BHD V Casaria Construction SDN BHD (Dissenting Avail MLJU (09) 1546) (2009) MLJU 1545Lawrence LauNo ratings yet