Professional Documents

Culture Documents

File PDF

File PDF

Uploaded by

yslin mrgthOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

File PDF

File PDF

Uploaded by

yslin mrgthCopyright:

Available Formats

Anggota Kelompok 5

212114009_Cristin Anastasia Remetwa

212114023_Dominica Angela

212114032_Elisabeth Hera Huby

212114037_Trifonia Anjeli Mete

212114048_Rosalia Anjadalu

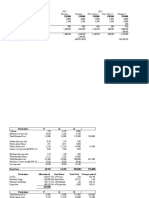

Product Data

Model A Model B

Units produced per year 10.000 100.000

Prime costs 150.000 1.500.000

Direct Labir hours 150.000 300.000

Machine hours 30.000 200.000

Production runs 40 60

Inspection hours 800 1.200

Maintenance hours 10.000 90.000

Overhead costs:

Setup costs 290.000

Inspection costs 210.000

Machining 240.000

Maintenance 270.000

Total 1.010.000

1. Compute the overhead cost per unit for each product by using a plantwide rate based on machine hours

2. Compute the overhead cost per unit for each product by using ABC

3. Compute the overhead cost per unit for each product by using departmental rates

1. Estimated overhead cost 1.010.000

Estimated machine hours 230.000

Overhead rate per hour 4,39

Product Data

Model A Model B

Prime costs 150.000 1.500.000

Overhead costs 131.739,13

878.260,87

281.739,13 2.378.260,87

Overhead cost per unit 13,17 8,78

Unit cost 28,17 23,78

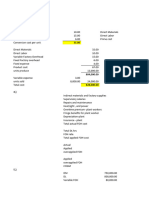

Product Data

Model A Model B

Cost pool Estimated Overhead Cost driver level Recover rate Cost driver OH Applied Cost driver OH Applied

A B C=A/B D E = D *C F G=F*C

Set up 290.000,00 100,00 2.900,00 40,00 116.000,00 60,00 174.000,00

Inspection 210.000,00 2.000,00 105,00 800,00 84.000,00 1.200,00 126.000,00

Machining 240.000,00 230.000,00 1,04 30.000,00 31.304,35 200.000,00 208.695,65

Maintenance 270.000,00 100.000,00 2,70 10.000,00 27.000,00 90.000,00 243.000,00

Total Overhead applies 258.304,35 751.695,65

Production 10.000,00 100.000,00

OH Cost per unit 25,83 7,52

Overhead rate Department 1 3.50/ machine hours Department 2 0.90/direct labor hours

Product Data

Model A Model B

Prime costs 150.000,00 1.500.000,00

Overhead costs 258.304,35

243.000,00

408.304,35 1.743.000,00

Unit cost 40,83 17,43

Model A Model B

Prime costs 150.000 1.500.000

Overhead costs 35.000,00

595.000,00

117.000,00

243.000,00

152.000,00 838.000,00

Overhead cost per unit 15,20 8,38

Unit cost 30,20 23,38

Product Data

Model A Model B

Units produced per year 10.000 100.000

Prime costs 150.000 1.500.000

Direct Labir hours 150.000 300.000

Machine hours 30.000 200.000

Production runs 40 60

Inspection hours 800 1.200

Maintenance hours 10.000 90.000

Overhead costs:

Setup costs 290.000

Inspection costs 210.000

Machining 240.000

Maintenance 270.000

Total 1.010.000

1. Compute the overhead cost per unit for each product by using a plantwide rate based on machine hours

2. Compute the overhead cost per unit for each product by using ABC

3. Compute the overhead cost per unit for each product by using departmental rates

1. Estimated overhead cost 1.010.000

Estimated machine hours 230.000

Overhead rate per hour 4,39

Product Data

Model A Model B

Prime costs 150.000 1.500.000

Overhead costs 131.739,13

878.260,87

281.739,13 2.378.260,87

Overhead cost per unit 13,17 8,78

Unit cost 28,17 23,78

2. Product Data

Model A Model B

Cost pool Estimated overhead Cost driver level Recover rate Cost driver OH Applied Cost driver OH Applied

A B C=A/B D E = D *C F G=F*C

Set up 290.000,00 100,00 2.900,00 40,00 116.000,00 60,00 174.000,00

Inspection 210.000,00 2.000,00 105,00 800,00 84.000,00 1.200,00 126.000,00

Machining 240.000,00 230.000,00 1,04 30.000,00 31.304,35 200.000,00 208.695,65

Maintenance 270.000,00 100.000,00 2,70 10.000,00 27.000,00 90.000,00 243.000,00

Total Overhead applies 258.304,35 751.695,65

Production 10.000,00 100.000,00

OH Cost per unit 25,83 7,52

Model A Model B

Prime costs 150.000,00 1.500.000,00

Overhead costs 258.304,35

243.000,00

408.304,35 1.743.000,00

Unit cost 40,83 17,43

Model A Model B

Prime costs 150.000 1.500.000

Overhead costs 35.000,00

595.000,00

117.000,00

243.000,00

152.000,00 838.000,00

Overhead cost per unit 15,20 8,38

Unit cost 30,20 23,38

3 Overhead rate Department 1 3,50 /machine hours

Department 2 0,90 /direct labor hours

You might also like

- Online LQDocument8 pagesOnline LQIsabella GimaoNo ratings yet

- Management Accounting - Laundry ServicesDocument5 pagesManagement Accounting - Laundry Serviceshasziahyazid50% (4)

- Machinery and Capitl ExpendituresDocument18 pagesMachinery and Capitl ExpendituresAnne Estrella0% (1)

- Marketing Research and Market IntelligenceDocument10 pagesMarketing Research and Market IntelligenceSatyender Kumar JainNo ratings yet

- F5 Mapit Workbook Questions - Solutions PDFDocument206 pagesF5 Mapit Workbook Questions - Solutions PDFAmanda7100% (2)

- Marketing Through Sports PaperDocument13 pagesMarketing Through Sports Paperapi-283754716No ratings yet

- Analysis For A New Beauty SalonDocument2 pagesAnalysis For A New Beauty SalonJulio Cesar H.G.No ratings yet

- CH5 CostDocument33 pagesCH5 CostNickey DickeyNo ratings yet

- Brocher Solution Problem 5-51Document5 pagesBrocher Solution Problem 5-51Alif ArmadanaNo ratings yet

- Problem 5-51 BlocherDocument2 pagesProblem 5-51 BlocherAlif ArmadanaNo ratings yet

- FAMA '22 SolutionDocument4 pagesFAMA '22 SolutionRushil JoshiNo ratings yet

- Tugas Kasus Akuntansi Manajemen ABCDocument3 pagesTugas Kasus Akuntansi Manajemen ABCutari yani dewiNo ratings yet

- Tugas-Kasus - 4.12Document3 pagesTugas-Kasus - 4.12niti dsNo ratings yet

- Problems 4-14 Manajemen BiayaDocument2 pagesProblems 4-14 Manajemen BiayaAlif ArmadanaNo ratings yet

- F5 Solution 1 & 2Document2 pagesF5 Solution 1 & 2dy sovathNo ratings yet

- ABC - Suggested Answer - 0Document8 pagesABC - Suggested Answer - 0pam pamNo ratings yet

- Unit Cost Computation: Plantwide RatesDocument2 pagesUnit Cost Computation: Plantwide RatesAlif ArmadanaNo ratings yet

- Sba AssignmentDocument8 pagesSba AssignmentjuniordelossantospenasNo ratings yet

- ABC - Practice Set Answer and SolutionDocument4 pagesABC - Practice Set Answer and SolutionYvone Ehnnery BumosaoNo ratings yet

- Arcadia and Enterprise Co. Worked ExamplesDocument22 pagesArcadia and Enterprise Co. Worked ExamplesIvy TulesiNo ratings yet

- 5 - ABC (Solution)Document32 pages5 - ABC (Solution)Mubashir HasanNo ratings yet

- Job Components ValuesDocument5 pagesJob Components ValuesIrish Nicole RouraNo ratings yet

- 2.2 PM - Activity Based Costing - 250622Document26 pages2.2 PM - Activity Based Costing - 250622abhijit tikekarNo ratings yet

- ABC Practice Problems Answer KeyDocument10 pagesABC Practice Problems Answer KeyKemberly AribanNo ratings yet

- Activity Based Costing SystemDocument18 pagesActivity Based Costing SystemMAXA FASHIONNo ratings yet

- Hand-Out 4 - ABC and Support Cost AllocationDocument2 pagesHand-Out 4 - ABC and Support Cost AllocationJerric CristobalNo ratings yet

- (w8) ABC Class ExerciseDocument6 pages(w8) ABC Class ExerciseDarya KoroviyNo ratings yet

- Managerial AccountingDocument6 pagesManagerial Accountingnischal subediNo ratings yet

- Cost Accounting: Allocation Basis Alpha Beta Gamma TotalDocument6 pagesCost Accounting: Allocation Basis Alpha Beta Gamma TotalShehrozSTNo ratings yet

- 015 Ashish Kumar Cost Accounting ExamDocument13 pages015 Ashish Kumar Cost Accounting ExamAshish KumarNo ratings yet

- Activity-Based Costing Answers To End of Chapter Exercises: A) Tradtional Costing ApproachDocument4 pagesActivity-Based Costing Answers To End of Chapter Exercises: A) Tradtional Costing ApproachJay BrockNo ratings yet

- TCS Vs ABCDocument12 pagesTCS Vs ABCBulelwa HarrisNo ratings yet

- Montex Pens - ABCDocument2 pagesMontex Pens - ABCRocket BhatNo ratings yet

- Hoi An Shoes Case Study SolutionDocument3 pagesHoi An Shoes Case Study SolutionNguyet Vy Dao NguyenNo ratings yet

- AccountingDocument4 pagesAccountingFerrNo ratings yet

- 12914sugg Pe2 gp2 1Document33 pages12914sugg Pe2 gp2 1harshrathore17579No ratings yet

- 2023 Answer CHAPTER 6 PDFDocument8 pages2023 Answer CHAPTER 6 PDFRianne NavidadNo ratings yet

- Alaire CorporationDocument2 pagesAlaire CorporationChleo EsperaNo ratings yet

- Overhead Analysis Solution 1Document2 pagesOverhead Analysis Solution 1Humphrey OsaigbeNo ratings yet

- Why The Old Costing System Would Not Work For Wilkerson?Document3 pagesWhy The Old Costing System Would Not Work For Wilkerson?Abhijit KumarNo ratings yet

- Chapter 27Document7 pagesChapter 27Shane Ivory ClaudioNo ratings yet

- Pricing Decisions and Cost ManagementDocument18 pagesPricing Decisions and Cost ManagementAmrit PrasadNo ratings yet

- Business Accounting and Finance: QUESTION 1 (P17-2A)Document9 pagesBusiness Accounting and Finance: QUESTION 1 (P17-2A)sang_ratu_1No ratings yet

- Quantity Schdule: Beginning Work in Process 5,000.00 Started in Process 100,000.00 105,000.00Document7 pagesQuantity Schdule: Beginning Work in Process 5,000.00 Started in Process 100,000.00 105,000.00Anne MendozaNo ratings yet

- ABC Case - PCMR ElectronicsDocument1 pageABC Case - PCMR ElectronicsOrduna Mae Ann0% (1)

- Cost Charged To Department II Total in Process Added Unit Cost 1-Oct This Month EUP CostDocument7 pagesCost Charged To Department II Total in Process Added Unit Cost 1-Oct This Month EUP CostCristel BautistaNo ratings yet

- Asist Ambl - Kuis #2Document8 pagesAsist Ambl - Kuis #2margatzy090No ratings yet

- Tugas Manajemen Biaya Activity Base Costing & Volume Base Costing Rifky Adrianson - 2011000071Document8 pagesTugas Manajemen Biaya Activity Base Costing & Volume Base Costing Rifky Adrianson - 2011000071AnblueNo ratings yet

- Raw Materials InventoryDocument4 pagesRaw Materials InventoryMikias DegwaleNo ratings yet

- SPK GENAP - Silfina WasrilDocument16 pagesSPK GENAP - Silfina WasrilnanaNo ratings yet

- Answer To Exercises To AnswerDocument9 pagesAnswer To Exercises To AnswerLEONNA BEATRIZ LOPEZNo ratings yet

- Answers To 11 - 16 Assignment in ABC PDFDocument3 pagesAnswers To 11 - 16 Assignment in ABC PDFMubarrach MatabalaoNo ratings yet

- Activity Centre Pool Rate ($/driver) Zodiac NovelleDocument5 pagesActivity Centre Pool Rate ($/driver) Zodiac NovelleShewanti ShendeNo ratings yet

- Accounting For FOH Part 11Document16 pagesAccounting For FOH Part 11Shania LiwanagNo ratings yet

- Master PDFDocument4 pagesMaster PDFNasiru029No ratings yet

- Cost of Table Water ProductionDocument4 pagesCost of Table Water ProductionNasiru029No ratings yet

- Homework For ABCDocument6 pagesHomework For ABCLikey CruzNo ratings yet

- Overheads - IBADocument6 pagesOverheads - IBAZehra HussainNo ratings yet

- P.assignment No.1Document10 pagesP.assignment No.1Alexandria EvangelistaNo ratings yet

- Accounting - Activity 2Document10 pagesAccounting - Activity 2PATRICIA CHUANo ratings yet

- Management and Financial Accounting Assessment-2Document6 pagesManagement and Financial Accounting Assessment-2saranyaNo ratings yet

- Table 1: Resources Used in The Production of DenimDocument13 pagesTable 1: Resources Used in The Production of DenimKarma SherpaNo ratings yet

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- Steinway & Sons: Buying A Legend: Presented By: Group 4Document20 pagesSteinway & Sons: Buying A Legend: Presented By: Group 4adiNo ratings yet

- Montreaux Chocolate Usa: Case Analysis by Group 7Document10 pagesMontreaux Chocolate Usa: Case Analysis by Group 7Nikhil PathakNo ratings yet

- Project Sponsor - Coffee ShopDocument2 pagesProject Sponsor - Coffee Shopsrps669wrdNo ratings yet

- Economics Key WordsDocument30 pagesEconomics Key WordsJanetNo ratings yet

- Ling Shou Tong: Alibaba'S Next Innovative Disruptor?Document13 pagesLing Shou Tong: Alibaba'S Next Innovative Disruptor?victornodaNo ratings yet

- Production and Operations Management: Ch. 6: Design of Goods and ServicesDocument53 pagesProduction and Operations Management: Ch. 6: Design of Goods and ServicesTrina Mae OcampoNo ratings yet

- Impact of Advertising On Customers Decision Making ProcessDocument53 pagesImpact of Advertising On Customers Decision Making Processchetansharma11No ratings yet

- IJSER15814Document4 pagesIJSER15814Aravinda ShettyNo ratings yet

- Starting A Caf or Coffee Shop BusinessDocument11 pagesStarting A Caf or Coffee Shop Businessastral05No ratings yet

- Olutoye Chater 1&2Document27 pagesOlutoye Chater 1&2YUSUF DABONo ratings yet

- Conworl Journal 4Document2 pagesConworl Journal 4cl4rr3znNo ratings yet

- ECO200 Sample Term Test 2 - Winter 2024Document10 pagesECO200 Sample Term Test 2 - Winter 2024yitongli1024No ratings yet

- Transactions and Strategies 1st Edition Michaels Test BankDocument19 pagesTransactions and Strategies 1st Edition Michaels Test Bankmatthewelmerwjxqf100% (24)

- International Journal Administration, Business & OrganizationDocument8 pagesInternational Journal Administration, Business & OrganizationMuch FachrudeenNo ratings yet

- Supply Demand Cheat SheetDocument2 pagesSupply Demand Cheat SheetAdongo BrightNo ratings yet

- Assignment Questions For ISMDocument17 pagesAssignment Questions For ISMTeetu TomarNo ratings yet

- Market Analysis EntrepreneurshipDocument6 pagesMarket Analysis EntrepreneurshipDian AnonuevoNo ratings yet

- Urban Clothing Feasibility StudyDocument22 pagesUrban Clothing Feasibility Studylarry delos reyeNo ratings yet

- Cma ArttDocument427 pagesCma ArttMUHAMMAD ALINo ratings yet

- 3 EcoDocument33 pages3 EcoChandan VermaNo ratings yet

- DBM IV Cardiff Final ProgrammeDocument53 pagesDBM IV Cardiff Final ProgrammeNur SyakirahNo ratings yet

- The Factors of Information System Success: An Example of Customer Relationship Management Implementation in Food & Beverage IndustryDocument15 pagesThe Factors of Information System Success: An Example of Customer Relationship Management Implementation in Food & Beverage IndustryKevin PhamNo ratings yet

- MCQDocument10 pagesMCQSHAHID ALINo ratings yet

- The Hermeneutics of Branding: Mary Jo HatchDocument21 pagesThe Hermeneutics of Branding: Mary Jo HatchSilvina TatavittoNo ratings yet

- Feasibility Study Final Na Ba To Haha 1Document126 pagesFeasibility Study Final Na Ba To Haha 1Neil Frank A. LorenzoNo ratings yet

- ALsa's ThriftDocument8 pagesALsa's ThriftChairaniNo ratings yet

- Professional Salesmanship Week 1Document6 pagesProfessional Salesmanship Week 1Ronnie Jay100% (2)