Professional Documents

Culture Documents

Prevent and Eliminate MUDA (Waste)

Uploaded by

Tihitna TirunehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prevent and Eliminate MUDA (Waste)

Uploaded by

Tihitna TirunehCopyright:

Available Formats

Akaki poly Technic Collage

AKAKI POLY TECHNIC COLLAGE

BUSINESS DEPERTEMENT

ACCOUNTING AND FINANCE

Level – III

Learning Guide 17

Unit of Competence: Prevent and Eliminate MUDA

Module Title: Preventing and Eliminating MUDA

This learning guide is developed to provide you the necessary information regarding the following

content coverage and topics:

Business department accounting and finance Page 1

Akaki poly Technic Collage

1. Prepare for work.

2. Identify MUDA.

3. Eliminate wastes/MUDA

4. Prevent occurrence of wastes/MUDA

This guide will also assist you to attain the learning outcome stated in the cover page.

Specifically, upon completion of this Learning Guide, you will be able to:

• Identify Safety equipment and tools

• Tools and techniques are used to draw and analyze current situation of the

work place.

• Wastes/MUDA are identified and measured based on relevant procedures.

• Necessary attitude and the ten basic principles for improvement are adopted

to eliminate waste/MUDA.

• wastes/MUDA are prevented by using visual and auditory control methods.

Learning Instructions:

1. Read the specific objectives of this Learning Guide.

2. Follow the instructions described below 3 to 17.

3. Read the information written in the information “Sheet.

4. Accomplish the “Self-check test.

5. Do the “LAP test”.

Business department accounting and finance Page 2

Akaki poly Technic Collage

What is Waste?

The elimination of waste is the primary goal of any lean system. In effect, lean

declares war on waste – any waste. Waste or muda is anything that does not have

value or does not add value.

Waste is something the customer will not pay for. When the great Italian sculptor

Michelangelo was asked what he was sculpting, he responded he was not

sculpting but releasing the figure (value) inside by removing the unnecessary

rocks (wastes). Like Michelangelo, we should eliminate all forms of wastes in

any process or product until only what is valuable remains. The key is to

spot waste and then stop waste.

There are two types of wastes: obvious wastes and hidden wastes. It is important

to uncover and eliminate the latter since they are usually bigger. Wastes take the

shape of an iceberg, the tip consists of the obvious wastes while the seen bulk

under the water contain the hidden wastes. Wastes are not necessarily ugly, and

most are outside the waste can! Waste can be in the form of unnecessary output,

input, or processing. It can be in the form of materials, stocks, equipment,

facilities, manhours, utilities, documents, expenses, motion, and other activities

that do not add value.

The steps to effective waste elimination are:

1. Make waste visible.

2. Be conscious of the waste.

3. Be accountable for the waste.

4. Measure the waste.

5. Eliminate or reduce the waste

In other words, before one can stop waste, he should able to see it, recognize it as

waste, identify who is responsible, and finally appreciate its size and magnitude.

Waste that is not seen cannot be eliminated. When something is denied as waste,

it also cannot be stopped. When one refuses to accept responsibility for the

waste, then he will not eliminate it. Finally, when the waste is not measured,

people may think it is small or trivial and therefore will not be motivated to stop

it. As the saying goes “What is not measured, is not improved”.

Muda, Mura, Muri

Aside from “muda” or wastes, the lean system also attacks and avoids “mura”

or overload or overburden and “muri” or unevenness. Mura refers more

specifically to overloading an equipment, facility, or human resource beyond its

capacity. This

Business department accounting and finance Page 3

Akaki poly Technic Collage

undue stress may cause downtime, defects, delays, and even disasters. Muri

refers to unevenness in production volume.

The wild fluctuations due to extreme highs (peaks) and lows (valleys) in

production scheduling cause periods of overload and long idle time. One way

to reduce muri is to implement heijunka or production leveling. In a way,

mura and muri also cause wastes but in a particular way. Muda, mura, and

muri cause inefficiencies and high costs in any operation.

What Is Muri?

Muri is a Japanese term meaning “overburden or unreasonable”. It is one of the three types of

waste (Muda, Mura, Muri) and a key concept in the Toyota Production System.

In other words, you create Muri whenever you put your team under stress by demanding

unreasonable or unnecessary work that exceeds their capacity.

Muri can drastically decrease your team’s productivity and efficiency. Putting too much pressure

often translates to extra working hours, which will lead to occupational burnout.

Overburdening can hurt your team’s morale and damage the “health” of the whole work process.

You should try to balance at the optimal capacity – a level at which all parts of the system can

deliver results without the need for extra work.

It is easy to say, but let’s discover what can cause Muri.

What Can Cause Muri?

You can overburden your teams without even realizing it. For example, setting unrealistic

deadlines can force different team members to rush the work. This will often lead to poor quality

and decreased customer satisfaction.

Let’s demonstrate this with an example.

If you tell your designer to make twice more images that she is able to produce for a certain

period of time, she will probably do it, but not all of them will be of the highest quality.

More or less, it is like an assembly line. Imagine you have the workers who check the quality of

products, and the faster you run the assembly line, the higher the chance low-quality products will

go to your customers.

There are many different reasons that can cause Muri.

Over-demanding

Business department accounting and finance Page 4

Akaki poly Technic Collage

The first and more obvious is over-demanding. In the contemporary business world, it is quite

surprising how higher management pushes more work onto their teams, hoping that more inputs

will result in more outputs.

In fact, this leads to a constantly increasing number of waiting tasks, which often results in chaos

and burnouts.

Lack of training

Companies often neglect the need for good training sessions. This is how, at some point, a team

member can end up working on a task much longer than necessary.

Let’s say that you are trained to work as a copywriter. However, the manager decides to use you

as a designer. You will probably need twice more time to deliver good images than a regular

designer will.

Lack of communication

Good communication is crucial for the success of any team. You need to establish clear

communication channels and practices to avoid overburdening.

Imagine that you have a meeting with 3 of your team members, and you decide to make 10 new

landing pages for your website.

Everybody in the meeting agrees and the team starts to work on the project. However, it was just a

verbal agreement, and the designer was not informed of the project until the last day before the

expected deadline.

Respectively, the designer will be overburdened, and she/he will feel the negative effect of Muri

because of miscommunication.

Lack of proper tools and equipment

When proper tools are missing, Muri is inevitable and obvious. If you give new computers to

some of your developers, for example, but the rest work on 5 years old machines, the second

group will definitely feel overburdened because they will need much more time to complete their

tasks using their old equipment.

There could be many other reasons causing Muri. You need to remember that managing all of

them will prevent the whole work process from collapsing.

Now, let’s see how you can deal with Muri.

Business department accounting and finance Page 5

Akaki poly Technic Collage

Different Ways to Deal with Muri

Lean offers various tools and practices that may help you remove the negative effect of

overburdening or reduce it to a minimum level.

Map your team’s workflow

First, let start by mapping your team’s workflow. For this purpose, you can use a Kanban b

What is Mura?

Mura is one of the “3M” forms of waste identified by the Toyota Production System: mura, muda,

and muri. In Japanese, “mura” means variability, unevenness, or inconsistency.

Mura will most often manifest with an uneven takt time, meaning that your team alternates

between being drowned with work and waiting around. There are two general categories of mura

in Lean: inconsistency in the way a team works, and inconsistency in customer demand. Both of

them need to be considered when trying to improve the process.

Along with Lean management’s two overarching goals: maximizing value delivered to the

customer, with reducing waste and any non-value-adding activities, process variability needs to be

minimized.

Mura coexists with other waste factors:

Muri: overburdening, excessiveness, e.g. overburdening machine or machine operator’s capacity

to an impossible level.

Muda: uselessness, futility - unnecessary actions, e.g. excessive transport of unfinished product.

It’s divided into 7 types:

Seven kinds of waste (Muda)

The presence of all these waste factors forces companies to compensate, causing even more

waste! It can create a loop where customers, having once experienced a delay, change their order

patterns, in turn skewing a company’s upcoming delivery plans, which can end up with forced

overtime or - worse still - forced downtime.

Why is process unevenness bad?

Business department accounting and finance Page 6

Akaki poly Technic Collage

All Lean/Six Sigma improvement efforts start with standardization and optimization of the

process, as its variability leads to defects and quality drop - changes that directly affect the value

delivered to the customer.

Reasons for process unevenness are plentiful: team members might have various ways of

working, machines may have different operations and outputs, even the way a team gathers

analytical data and reports on results can differ from person to person! Looking at process

inconsistencies can help you better understand your team’s behavior and ways of working.

By definition, a Six Sigma optimized process is one with variability reduced to the point where

the expected output isn’t achieved only 3.4 times out of 1000000 executions. Being able to deliver

on customer expectations with a success rate this high (quasi “zero-defects”) is the chief selling

point of Six Sigma. The method is sometimes summarized with the following Breakthrough

equation:

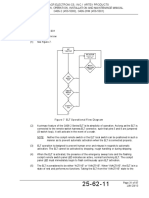

Detecting mura

One of the best ways to detect mura is through graphs. You can spot variation through differences

in lead times as executed by various teams and on different days or weeks. For example, you only

need to take one look at the Cumulative Flow Diagram to tell if the process is stable and

consistent - i.e. in control - or not. Any drops and jumps are a direct indication of variability at

play

What are the seven types of wastes or “muda”?

A lean system declares war on wastes or “muda”. These wastes are classified into

7 types:

1. Over-production waste

2. Processing waste

3. Transport waste

4. Waiting-time waste

5. Inventory waste

6. Motion waste

7. Defects

Business department accounting and finance Page 7

Akaki poly Technic Collage

➢ Over-production waste

✓ Definition

• producing more than what is needed

• producing faster than what is needed

✓ Causes

• volume incentives (sales, pay, purchasing)

• high capacity equipment

• line imbalance; poor scheduling/shifting

• poor production planning

• cost accounting practices that encourage build up of inventory

Effects of Muda of Overproduction

Companies often have overproduction as a result of large-lot manufacturing methods or

Business department accounting and finance Page 8

Akaki poly Technic Collage

mass production. there are several unfortunate effects of over production:

Anticipatory buying of parts and materials

Blocked flow of goods

Increased inventory

No flexibility in planning

Occurance of defects

Over-production waste occurs when more goods are produced than can be sold,

resulting in idle finished goods inventory. Over-produced goods are often hidden

wastes since many think they are assets with value.

Business department accounting and finance Page 9

Akaki poly Technic Collage

be obsolete or costing the company unnecessary expenses just to keep them until they

can be sold if ever. The just-in-time, pull system, and kanban rules prevent over-

production wastes. Also, lean systems favor smaller equipment over large ones to

avoid overproduction due to high but unnecessary capacity utilization.

Producing more than your customer is requesting or before they request it

➢ Processing waste

✓ Definition

• non-value added man processing

• non-value added machine processing

✓ Causes

• unclear customer specifications

• frequent engineering changes

• excessive quality (refinements)

• inadequate value analysis/value engineering

• unclear work instructions

Processing waste comes from unnecessary processing that does not add value

to the item being produced or worked on. Examples are additional steps that

do not

Business department accounting and finance Page 10

Akaki poly Technic Collage

enhance quality or steps that simply adds excess quality which customers do not

require. Unnecessary documentation is also a form of processing waste. Identify

value-adding and non-value adding activities in the process using techniques

such as value stream analysis and the waterfall diagram.

Unnecessary manual work that does not contribute value to the product

➢ Transport waste

✓ Definition

• unnecessary material movement

• unnecessary tools or equipment movement

✓ Causes

• poor route planning

• distant suppliers

• complex material flows

• poor layout

• disorganized workplace

• line imbalance

Business department accounting and finance Page 11

Akaki poly Technic Collage

When anything – people, equipment, supplies, tools, documents, or materials – is

moved or transported unnecessarily from one location to another, transport waste

is generated. Examples are transporting the wrong parts, sending materials to the

wrong location or at the wrong time, transporting defects, and sending documents

that should not be sent at all. One way to cut transport waste is co-location,

wherein customers are served by nearby suppliers, usually less than one-hour

driving distance away. Departments working with each other or serving each other

are also put near each other to cut transport waste. For example, materials and

tools departments may be moved, relocated, or pre-positioned beside or nearer the

user departments or their internal customers.

Unnecessary conveyance ofp roducts, from one location to another, or

handoff from one employee to another

➢ Waiting time waste

✓ Definition

• man idle or waiting time

• machine idle or waiting time

✓ Causes

• unsynchronized processes; line imbalance

• inflexible work force

• over-staffing

• unscheduled machine downtime

• long set-up

Business department accounting and finance Page 12

Akaki poly Technic Collage

• material shortage or delay

• manpower shortage or delay

When resources like people and equipment are forced to wait unnecessarily

because of delays in the arrival or availability of other resources including

information, there is waiting time waste. Waiting for late attendees in a

meeting, waiting for tools to start work, waiting for a signature for a process to

continue, waiting for a late vehicle to transport workers to a project site are

examples of this waste.

Waiting done by customers or by employees

➢ Inventory Waste

✓ Definition

• excessive process (WIP) inventories

• excessive raw material inventories and supplies

✓ Causes

• over-production

• imbalanced line

• long lead times

Business department accounting and finance Page 13

Akaki poly Technic Collage

• large minimum order quantities

• high rework rate

• JIT-incapable suppliers

• lack of material requisition and issuance standards

Inventory wastes come from the purchasing, issuance, storage of excess or

excessive supplies, materials, and other resources. This waste can also be caused

by overproduction as excess materials and work-in-process are accumulated.

Inventory waste is often due to lack of planning and failure to match purchases

with the actual consumption or usage rate of a particular resource. Another

example is the storing of slow-moving and obsolete stocks like tools and

materials.

More materials or information than is required

➢ Motion Waste

✓ Definition

• unnecessary movement and motions of worker

✓ Causes

• poor lay-out and housekeeping

• disorganized work place and storage locations

• unclear, non-standardized work instructions

• unclear process and materials flow

Business department accounting and finance Page 14

Akaki poly Technic Collage

Motion waste happens when unnecessary body movements are made when

performing a task. Examples are searching, reaching, walking, bending, lifting,

and other unnecessary bodily movements. Workers commit this form of waste by

searching for tools or documents when their workplace is cluttered or

disorganized. Motion waste often delays the start of work and disrupts workflow.

Unnecessary physical or mental motion often associated with searching

➢ Defects

✓ Definition

• processing due to the production of defects

• processing due to rework or repair of defects

• materials used due to defect and rework

✓ Causes

• unclear customer specifications

Business department accounting and finance Page 15

Akaki poly Technic Collage

• incapable processes

• lack of process control

• unskilled personnel

• departmental rather than total quality

• incapable suppliers

Quality is doing the right thing right the first time. It is about prevention and

planning, not correction and inspection. Bad quality or defects do not only result

in customer dissatisfaction and damage to company image, but also in wastes due

to additional costs and time to recall, rework, repair, and replace the defective

items. Continuous quality improvement and preventive measures are the most

effective means to cut defect wastes.

A mistake which reaches the customer

Business department accounting and finance Page 16

Akaki poly Technic Collage

Business department accounting and finance Page 17

Akaki poly Technic Collage

Business department accounting and finance Page 18

Akaki poly Technic Collage

Business department accounting and finance Page 19

Akaki poly Technic Collage

Business department accounting and finance Page 20

Akaki poly Technic Collage

Group Assignment (25%)

Maximum member 5

1) What are the benefits of identifying and eliminating wastes/Muda to the workers of a company? (4

points)

2) Write the difference between prevent and eliminate waste?

3) 2. Write down the steps to identify wastes/Muda. (4 points)

4) Write at least two cause and effect of each types of the seven wastes?

Business department accounting and finance Page 21

You might also like

- Accounting Level IIIDocument94 pagesAccounting Level IIIteshome neguse100% (4)

- Process Payment DocumentatioDocument19 pagesProcess Payment DocumentatioAbdi Mucee Tube100% (2)

- Use Business TechnologyDocument35 pagesUse Business Technologyabricobm100% (3)

- Secretarial LIVDocument80 pagesSecretarial LIVteshome neguse100% (2)

- Ethiopian TVET-System: Information Technology Support ServiceDocument11 pagesEthiopian TVET-System: Information Technology Support Servicefikru tesefaye100% (1)

- 11 Processing PayrollDocument22 pages11 Processing PayrollYohannes AdmasuNo ratings yet

- Preparing Matching and Processing Receipts CorrectedDocument14 pagesPreparing Matching and Processing Receipts CorrectedAbdi Mucee Tube100% (1)

- Balancing Cash HoldingsDocument59 pagesBalancing Cash Holdingsabel becheni100% (4)

- Process Financial TNXN TTLM Nigussie BDocument40 pagesProcess Financial TNXN TTLM Nigussie Bnigus100% (1)

- Accounts Receivable Process ReviewDocument66 pagesAccounts Receivable Process Revieweliyas mohammedNo ratings yet

- Prepare bank reconciliation and adjusting entriesDocument4 pagesPrepare bank reconciliation and adjusting entriesGuddataa DheekkamaaNo ratings yet

- Establishing Quality Standards TrainingDocument15 pagesEstablishing Quality Standards Trainingwendi mesele100% (3)

- Perform Financial CalculationsDocument21 pagesPerform Financial Calculationsrame100% (1)

- Processing Payment DocumentationDocument62 pagesProcessing Payment Documentationabel becheni100% (8)

- 1 FNSACC507 Provide Management Accounting InformationDocument79 pages1 FNSACC507 Provide Management Accounting InformationSyed Bilal Ali89% (9)

- Accounting Level IVDocument96 pagesAccounting Level IVteshome neguse100% (3)

- 03.produce, Record & Maintain Business DocumentsDocument14 pages03.produce, Record & Maintain Business Documentsወርቅነህ አወቀ92% (13)

- Administer Financial AccountsDocument22 pagesAdminister Financial Accountsrame100% (2)

- Administer Levies, Fines and Other TaxesDocument17 pagesAdminister Levies, Fines and Other TaxesNigussie Berhanu50% (2)

- Perform Financial CalculationsDocument46 pagesPerform Financial Calculationsnigus89% (9)

- Administer Financial AccountsDocument18 pagesAdminister Financial Accountsnahu a dinNo ratings yet

- Use Business EqipmentsDocument20 pagesUse Business Eqipmentsnigus100% (1)

- Chapter 1 Cost IDocument5 pagesChapter 1 Cost Iyebegashet100% (1)

- Use Business Equipment and ResourcesDocument5 pagesUse Business Equipment and Resourcesnejuway100% (5)

- Acb3 01Document41 pagesAcb3 01lidetu100% (3)

- 314 Calculating Taxes, Fees and ChargesDocument49 pages314 Calculating Taxes, Fees and Chargesdawit Terefe67% (3)

- Evaluate and Authorize Payment RequestsDocument15 pagesEvaluate and Authorize Payment RequestsMagarsaa Hirphaa100% (3)

- Uc 7 Apply Business Communication in The Work PlaceDocument41 pagesUc 7 Apply Business Communication in The Work PlaceJemal SeidNo ratings yet

- Managing Finances and Taxation for MSEsDocument7 pagesManaging Finances and Taxation for MSEsfantahun100% (5)

- 310 Balance Cash HoldingsDocument21 pages310 Balance Cash Holdingsdawit TerefeNo ratings yet

- Establish and Maintain Accrual Accounting SystemDocument28 pagesEstablish and Maintain Accrual Accounting SystemTegene TesfayeNo ratings yet

- Curricullem Accounts and Budget Support Level IIIDocument68 pagesCurricullem Accounts and Budget Support Level IIIeliyas mohammedNo ratings yet

- Establish and Maintain Accrual AccountingDocument26 pagesEstablish and Maintain Accrual AccountingNigussie Berhanu100% (1)

- Setup & ComputerizeDocument107 pagesSetup & Computerizenahu a din100% (2)

- Calculate Taxes Fees & Charges ASSIGNMENT NewDocument2 pagesCalculate Taxes Fees & Charges ASSIGNMENT NewJarra AbdurahmanNo ratings yet

- New millennium University College TVET CurriculumDocument70 pagesNew millennium University College TVET CurriculumMebrahatu Gebrewahad100% (1)

- Payroll ProcessingDocument16 pagesPayroll ProcessingMisiker100% (3)

- Apply Quality Control TTLM Final TvetDocument14 pagesApply Quality Control TTLM Final Tvetmohammed ahmed100% (3)

- Processing Payroll Acc L3Document19 pagesProcessing Payroll Acc L3ADISU HABTAMUNo ratings yet

- Improve Business PracticeDocument45 pagesImprove Business PracticeSatenaw Gojame Satenaw Gojame100% (7)

- 4 6026199395324659830Document30 pages4 6026199395324659830Beka Asra100% (1)

- Leve 2 Coc ExamDocument45 pagesLeve 2 Coc Examsamuel asefa100% (2)

- Manage Overdue Customer AccountDocument17 pagesManage Overdue Customer AccountMagarsaa Hirphaa83% (6)

- Maintaining Inventory RecordsDocument32 pagesMaintaining Inventory RecordsMagarsaa Hirphaa100% (3)

- Manage Overdue Coustmer AccountDocument19 pagesManage Overdue Coustmer AccountNigussie BerhanuNo ratings yet

- 315 Handling Foreign Currency TransactionsDocument48 pages315 Handling Foreign Currency Transactionsdawit Terefe100% (3)

- Use Business EqipmnetDocument20 pagesUse Business EqipmnetMelkamu Endale100% (1)

- Apply Business Communication in Work Place Communication: How To Use This TTLMDocument18 pagesApply Business Communication in Work Place Communication: How To Use This TTLMAb Abel100% (2)

- Paradise Valley College Financial Training GuideDocument34 pagesParadise Valley College Financial Training GuideGuddataa Dheekkamaa100% (6)

- Admas University: Learning GuideDocument19 pagesAdmas University: Learning Guidebirhanu sintayehuNo ratings yet

- COC MODEL LEVEL IV CHOICE SELECTIONDocument22 pagesCOC MODEL LEVEL IV CHOICE SELECTIONBeka Asra100% (3)

- Accounting and Finance: NTQF Level Ii-IvDocument143 pagesAccounting and Finance: NTQF Level Ii-Ivteshome neguse100% (3)

- Level 3 Coc ChooseDocument14 pagesLevel 3 Coc Chooseeferem67% (3)

- PFT Chapter 3Document16 pagesPFT Chapter 3Nati TesfayeNo ratings yet

- COC 1 Level 2 DV1-1Document7 pagesCOC 1 Level 2 DV1-1Ken Lati50% (2)

- Maintain Accurate Cash FloatsDocument22 pagesMaintain Accurate Cash Floatssimon yaikobNo ratings yet

- ASSIGNMENT Operation MGTDocument15 pagesASSIGNMENT Operation MGTzakuan79No ratings yet

- WASTE MEASUREMENT TECHNIQUESDocument16 pagesWASTE MEASUREMENT TECHNIQUESAlexandruNo ratings yet

- Lean NewsletterDocument4 pagesLean NewsletterKomal TagraNo ratings yet

- Waste Management in Lean ManufacturingDocument25 pagesWaste Management in Lean ManufacturingHarshit gargNo ratings yet

- Less Than 60 MilesDocument36 pagesLess Than 60 MilesDavid MckinleyNo ratings yet

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- Question According VDA 6.3 Questionnaire 0 0: VDA - 6.3 - Report - Potential - Analysis - 2016 - V3 - Vollversion Seite 1 Von 1Document1 pageQuestion According VDA 6.3 Questionnaire 0 0: VDA - 6.3 - Report - Potential - Analysis - 2016 - V3 - Vollversion Seite 1 Von 1ssierroNo ratings yet

- 特变电工画册(英文定稿)Document52 pages特变电工画册(英文定稿)Diego MantillaNo ratings yet

- Natural ResourcesDocument5 pagesNatural ResourcesAsrock Loop100% (1)

- Chapter 17Document48 pagesChapter 17MahmoudKhedrNo ratings yet

- Ames Perception ExperimentsDocument108 pagesAmes Perception ExperimentsMichael RoseNo ratings yet

- PSPD Activity 3Document4 pagesPSPD Activity 3laurynnaNo ratings yet

- Effect of Blast Induced Vibrations On GroutDocument55 pagesEffect of Blast Induced Vibrations On GroutDavid marpaungNo ratings yet

- 4.5.1.1 Inside and Outside Control Instructions - IG PDFDocument4 pages4.5.1.1 Inside and Outside Control Instructions - IG PDFMaksim Korsakov100% (4)

- Mbbs BooksDocument7 pagesMbbs Booksbakhem7hbk2002190% (1)

- ABR College Mechanical Mid Exam Questions on MetrologyDocument1 pageABR College Mechanical Mid Exam Questions on MetrologySrinu ArnuriNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- 3204-9-Resource Use and SustainabilityDocument25 pages3204-9-Resource Use and SustainabilityKezia NatashaNo ratings yet

- Modal Analysis of Beams - An Experiment Symposium On Dynamic Problems of MechanicsDocument9 pagesModal Analysis of Beams - An Experiment Symposium On Dynamic Problems of MechanicsnizamshahrinNo ratings yet

- DSBV87ALP Two-Stage Differential Pressure Control Valve SpecsDocument2 pagesDSBV87ALP Two-Stage Differential Pressure Control Valve SpecsadrianioantomaNo ratings yet

- Future Visualized in The Movie BrazilDocument16 pagesFuture Visualized in The Movie BrazilsloutfyNo ratings yet

- Attachment No 2 PDFDocument10 pagesAttachment No 2 PDFTusharRoyNo ratings yet

- White Chicken KormaDocument5 pagesWhite Chicken Kormamkm2rajaNo ratings yet

- Fox em Corporate Presentation 08 2022Document19 pagesFox em Corporate Presentation 08 2022Pierluigi GhioneNo ratings yet

- Life-Science-Grade-12-April-2021-QP-and-memoDocument15 pagesLife-Science-Grade-12-April-2021-QP-and-memokhoza9312No ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- Declaration Letter - Vetagro To GSDocument3 pagesDeclaration Letter - Vetagro To GSVíctor RodríguezNo ratings yet

- 22nd Annual Report 2021-22Document155 pages22nd Annual Report 2021-22Karthic Selvam KandavelNo ratings yet

- La Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesDocument6 pagesLa Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesJhon Christian ManzoNo ratings yet

- Pacemaker 180508042454Document86 pagesPacemaker 180508042454padmaNo ratings yet

- Unit 1.Pptx Autosaved 5bf659481837fDocument39 pagesUnit 1.Pptx Autosaved 5bf659481837fBernadith Manaday BabaloNo ratings yet

- NEDO's Role in International Technical Cooperation ProjectsDocument45 pagesNEDO's Role in International Technical Cooperation Projectsamitsh20072458No ratings yet

- SignaLink USB Product Guide - 02.2018Document22 pagesSignaLink USB Product Guide - 02.2018Rafael D. B. AnellaNo ratings yet

- Cast Steel y Strainer Ansi Class 150Document2 pagesCast Steel y Strainer Ansi Class 150aurinkokelloNo ratings yet