Professional Documents

Culture Documents

1 Year

1 Year

Uploaded by

vinay0 ratings0% found this document useful (0 votes)

22 views50 pagesSYLLABUS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSYLLABUS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views50 pages1 Year

1 Year

Uploaded by

vinaySYLLABUS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 50

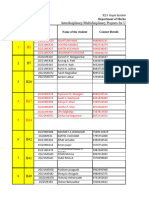

KARNATAK LAW SOCIETY'S

GOGTE INSTITUTE OF TECHNOLOGY

UDYAMBAG, BELAGAVI-590008,

(An Autonomous Institution under Visvesvaraya Technological University, Belagavi)

(APPROVED BY AICTE, NEW DELHI)

Department of Mechanical Engineering

M.Tech. Scheme and Syllabus (2020 Scheme)

1* to 4" Semester Computer Integrated Manufacturing

IN

ITUTION VISION

Gogte Institute of Technology shall stand out as an institution of excellence in technical

education and in training individuals for outstanding caliber, character coupled with creativity

and entrepreneurial skills.

MISSION

nalism and

To train the students to become Quality Engineers with High Standards of Profe:

Ethics who have Positive Attitude, a Perfect blend of Techno-Managerial Skills and Problem,

solving ability with an analytical and innovative mindset.

QUALITY POLICY

+ Imparting value added technical education with state-of-the-art technology in a congenial,

disciplined and a research oriented environment.

* Fostering cultural, ethical, moral and social values in the human resources of the institution.

© Reinforcing our bonds with the Parents, Industry, Alumni, and to seek their suggestions for

innovating and excelling in every sphere of quality education.

DEPARTMENT VISION

To emerge as a center of excellence in technical education and research by molding students with

techno managerial skills coupled with ethies and to eater to the needs of the industry and society

ingeneral

‘MISSION

To impart value based education and to promote research and training in frontier areas to face

thechallenges in the changing global scenario; to provide impetus to industry institute relation, to

imbibe social, ethical, managerial and entrepreneurial values in students.

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

The graduate will acquire core competence in basic science and mechanical engineering

1. | fundamentals necessary to formulate, analyze and solve engineering problems and

pursue advanced study or research.

The graduates will engage in the activities that demonstrate desire for ongoing personal

2. | and professional growth and self confidence to adopt to rapid and major change:

The graduates will maintain high professionalism and ethical standards, effective oral

3, | and witten communication skills, work as part of teams on multi-disciplinary projects

under diverse professional environments and relate engineering issues to the society,

global economy and to emerging technologies.

PROGRAM OUTCOMES (POs)

‘An ability to independently carry out research /investigation and development work to solve

practical problems

2._| An ability to write and present a substantial technical repori/document

Students should be able to demonstrate a degree of mastery over the area as per the specialization

3. | of the program. The mastery should be at a level higher than the requirements in the appropriate

bachelor program

PROGRAM SPECIFIC OUTCOMES (PSOs)

Post graduates in Computer Integrated Manufacturing shall develop an ability to

integrate automation with mechanical systems for manufacturing, assembly and testing.

Post graduates in Computer Integrated Manufacturing shall apply simulation, statist

and computational tools for integrating manufacturing systems.

Post graduates in Computer Integrated Manufacturing shall apply the technical skills for

analyzing industrial projects in the area of modern manufacturing.

cs

i PAA SMOY OMT, (AG) STROM

€ SHON TL i POM] INOW 9UG (TD) AMDT]

z SHAN BO € THALOS aSMHO9 JO SMOT OF

T SHEN FO ¢ THAITOS SSO JO SOY OF

Spe WoREINp eIn09 TUTTO, Spa 3euno9 Jo uoREANG’

Supa sINOD SUID SapeID aay LOST,

88 reo,

w ud soled 9

so ld drysuranuy s

+0 dqysiuersissy Sumypeay, / waundojaaag [Pig / }elorg JOU +

60. 90 GAVAVASS ) ssino9 aurTUO, £

1 ad AANDATET [eUOISSAZOIg z

9 od B40.) [EUOISSAFOIG 1

supaag asano)

pom aumeagy umpnoran

88 88 THOL

& v ¢

or sea pug

& €

wr Ke c reas 1s]

IZ 1

Supa 101, | wagsedsypary | s9\s9urag

88 HtMRIBONg “YD "TW 105 SHIpIAD [RIO],

WDD? WP s0uLg yf OF. - WoNMUTMEXT pux SuYDUDT Jo OWOTPS 17-0207

Wuissas0g Puc SEHOTEPY paoueApy ePIWNOINOe

HUEMSEINUEPY Joy IOSD | —____CPLNDINOT |

SSUBUTSTUTEA Pasee WOTIPUOS THT OINOT

[ENT DOTGNg | _____9poo yoaTqng”

oo aT

SdKy paresoyuy aq PMOGS SORMOT OMT UMUC 6

Suypaad ¢ W169 oF (999mg +5499M F) S954NOD OM YO SH9OK ZI Jo ASANOD BuO Jof 19}S}394 WED IWPMS -IO +

szs 4 54 IZ TeH0L

age

Sunysea

st ST ra I 1-0-0 { waudopsaaq 9

IIS

ofosd tou | 9TINDINOT

; Sam | sno a .

z1-8 WVAVASS | ciowoz

oor os os ol|olr +b O-0-% T-ad T2ano277 XPINOWOT b

Furammersony

ost |se-os|seros] op | 1 € s zo-e | sod pue €

SWISAS IND | ELAOWOT

FaEMSe UEP

powafonuy

ost | sz+0s | sz+0s + T}ole s T-O-£€ | Td | snduroD pur T

uonewoiy 01

Yononponuy TINOWOT

— HEUTE,

oor os os o|;o|r ¢ O-0-% 10d paddy TIWOWOT 1

qas qID d

WHOL | BAS AID | supoas | a | a | 1 | oooaysanoy | -1-"1 osano3 P09 | sorry

wo, [worry] weno [sino < asinoy ‘

one,

pay poeyu03,

{WLW PySwES A

Wid eC WN -dopentmexg pue Tapyses | Jo SUBS 17-0707

SUIISKS SURMSEIMUE UIT EPCOT,

Tonuo) Mipend ansHSTHS CHENOINOT

ToRRUTOMY UF TUEMSENUEPY Oy FUIOOL. IPZWOWOT.

aueN Plans apoa patqns

Tranoor

adky payesBoquy 9q pnogs sosinos QALY, WinME 6

Suypa49 ¢ W169 0} (599mg +5499M F) S94NOD OM YO 549M ZI Jo A84NOD DUO Jo} 49451394 WED UDP

sts [0st [Siz Iz THOT,

Aye

Buyseay /

st 4 z I 1-0-0 auaudojoaad » 9@WOWOT | “9

asmoo asino>

£ sym | 90 euro | stWOWO? | 'S

z-8 IWVAVAS,

oor os | 0s $ ololF $ Oo-r | iraa | teansers | xrewowor | +

wal pue

ost | sz+os| sz+os | r Thole s trong | €od PIN | SZWOWO? |“

yoreasay

BuOoL

ost | sztos| sz+os| > Tlole s t-o-€ | wd orig | TWOWOT |Z

waIsKS,

oor os | os ’ Oo o)F ’ 0-0-% | Idd | wonewoyey | IZWOWOZ | 1

wourateuEYy

: aas | arc a

WLOL| FAS | AID | sypass | a 1 | yaamysanoy | - L.-T smo pop

Teo, | wonesoy | y9eju0y sunoyy . asanog,

SRA,

4pas9, 39HU0D,

TaD SIMIDg puODIG

WID 9 LW Hopeutmexg pue Surysus | yo TuI9yDS 17-0207

(S00, saNpEPN FO WAIST |

SSWOWOT

suiaiskg oumeapAHy (10,

THEWOWOT

juauadeueyy a1BareNg paoueapy

LeSWOWOT

amEN Parag

apoo yoatqns

TAT

addy paywaBayuy aq pmnoys sasinos QALL NMEA, ©

suypaao ¢ Wawa 0} (s999Mg 4599944 F) S9SANOD OM) YO HOM Z] Jo 98409 aU 105 J9ISIO4 URED JU>PNIg JO _*

oss | ost [oor [ & Ter,

5 UT ocwowoz

os os + THI | _sseyy rooforg| 9EWOWOZ | 9

7 50 | OT ower |

© °° wvavans | SENONOC

oor | 0s 70s p [olol® ¥ O-0=% | Mad | reancara | xpeWoWor [>

- - ue | suustmnedxy |

ost | sz+os)szvos, ob | dT} ol € s tone | od yourtssq | SWOWOT |

WSK,

OSI | St+0S | st+0s T}ole¢ s T-O-€ | Za | Suumoenuey | ceWOWoZ | ‘7

2140

sanoqo |

ool | os | os y |olo|r ’ O-0-% | 19d Ppuisnpuy | 'SINOWOZ

TVLOL | das | a10 a[iy7 a-1-7

men E | anpeaa 2 | seiw09, 3

WD 2, PysouDs PAL,

Soeur OT + (AEE JOMIUTEXD [RUADIXa ay PeUIaIUE Jo “Bay) voENeAd Hodes Jo} sysPUE Qs) SHEUE OST

(200A -eata,

AS :990A-RALA 99f0Fd

(aoneuasaid -syreur ¢7 + apind jeuraruy—syzeur ¢7) sxsRUU OS -~FID *¢ aseyq 19ALOIg

(aonenuasaad -syreur ¢7 + pind peursnuy— syreur 7) SHsEUT OS “AID :Z a8eY{q 19/04

ras, p PUR .¢ UaaAAM / WAS, ¢ PUL ,.Z UIOMIaq HOHTIEA TuLMp spops a[dyy[NU Jo JoJs auO UI J9yHO syEaM g oF 9 sdIYSUIDIUYY

OSE 007, ost % TOL

- : 390A-FATA _

ost | (O01+0S)0sT - Oo SM | pue ysoforg go wonenjeag bprWOWOZ +

os = (SZ+S0)0S + Ud £= asvd 19af0ld SPOT €

os = (St+S0)0S ¥ Cad Taseyd alord THNINOT, c

oor 0s os s | spane—9 [id TyWOWOT i

"VLOL| _aas AD] Spa | ypamysano apo; asano3

SUH Teoy, | sey00> f D

RIO wT NMSHMOT

syaeul SL = (TsZ+ (0S -AaS 180.

"VaDD Paw VADS Jo WOHEIND|ED ayy a0} SHATUT

$7.0} paonpad aq [ILM HI "UoHEINp smoy Z/smoy ¢ BuLAeY SEU YS FoF paroMpUOD 24 TTA TL

SHIEH OT S50K-EATA,

oeut g¢ SHeu OL ____tonsanb sour a0

SOU OZ OTSHaNOD pure sar (S)iuatuTredKe Jo yNpTOD

SEU OT dn ay jentay

syuouoduios qe]

‘VdDO PUR VaDS Jo UONRINDTe ay

JOY SUT OS OF Paanpas aq [[!M I ‘VOREMp smoy ¢ Jo SEU OOT JOF ParoNpUoD aq [1M I

2S) WoHRUTUEXY Puy 194s9TIIg Jo 9MIDTDS

(as) wopeurmexs pug sosourag yo aways

Husuodur03 A109

syaeUt SL = (DSZ+ (L) OS AID TEL,

St s OL I eT

TEN ar gey uous mumor qslamjowapuen | snauodue;

sjusuodaros qe]

“VdDD ue WADS Jo woREINITeo ayy 10 SHU Qg OF PooMpar aq TIM SEU ODT

(os 9) pasmpas ) c1oe

os 001 07 o1+0r ostos Aa09u

seu [eu SEW poafoad THN, OME sse Sse swuauoduro3,

(roy prourmiag | OMMJOUOHIPPY | VI om} Jo woRIPPY

2419) WoHENpeag [euI9IUT snonuEUOS Jo ams

Tuouodu0 3 A109qL,

Applied Mathematies

Course Code 20MCMIT Credits L-T-P | 4-0-0

Course type PCI Total credits | 4

Hoursiwee 4-0-0 CIE Marks _ | 50 marks

fotal Hours: Le 50 Hrs; T=0 Hrs: P=OHts | pe Marks | 50 marks

Total = 50 Hrs

Course Learning Objectives

Learn the concept of different types of errors.

Learn mathematical modelingof some physical problems,

Teach the application of regression analysis to engineering problems

Learn the concept of differentiation and integration of a tabulated function.

Lear to solve system of linear algebraic equations and to find Eigenvalues and Eigen

vectors of a given square matrix and also to lea the concept of linear transformation

matrix of linear transformation, linear models and Gram-Schmidt Process.

yee

Pre-requisites : Basics of Engineering Mathematics

Unit -1 08 Hours

Roots of polynomial Polynomials in Engineering and Science, Muller’s method

Graeffe’sRoots Squaring Method.

Self-learning topies: Given’s method.

Unit - 11 12 Hours

Numerical Differentiation and Numerical Integration: Newton-Cotes and Gauss

Quadrature Integration formulae, integration of Equations, Romberg integration,

Numerical Differentiation Applied to Engineering problems

Unit — 11 10 Hours

Data analysis with statistical packages: Correlation and regression analysis, Multiple

regression analysis, Chi-square test, Analysis of variance and covariance.

Self-learning topics: Fisher's test.

Unit -1V 10 Hours

Eigen values and Eigen Vectors: Bounds on Figen Values, Jacobianmethod for

symmetric matrices, Givens method for symmetric matrices, Householder’s method for

symmetric matrices, Power method.

Unit-V 10 Hours

Approximations and round off errors: Significant figures, accuracy and

precision, error definitions, round off errors and truncation errors. Mathematical

modelingand Engineering problem solving: Simple mathematical model, Conservation

aws of Engineering.

Books

SSastry—Numerical Analysis for Engineers— Tata McGraw Hill Edition.

2. Steven C Chapra, Raymond P Canale-Numerical Methods for Engineers—fourth Edition,

Tata Megraw Hill.

3. M KJain, SR Klyengar, R K Jain-Numet

Computation-New Age International Publishers.

1 Methods for Scier

ic and Engg.

a

4. DavidCLay-LinearAlgebraandits Applications-3 Edition, PearsonEducation

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

1, Modelsome simple mathematical models of physical applications and find 5)

the roots of algebraic equations

Use a given data for computing maxima, minima, curvature, radius of

2. curvature, are length, area, surface area and volume using numerical — [L3]

differentiation and integration procedures.

3. Analyze the data by using various regression methods. {L4]

4, Findligen values and Eigen vectors which dealswith the modeling of the fy 4

system and the behaviorof the system.

5. Study the concept of errors by using mathematical models. 113]

Program Outcome of this course (POs) PONo.

Ability to independently carryout research /investigation and development

1 “ [Pol]

work to solve practical problems

2. An ability to write and present a substantial technical reportdocument (Po2]

Program Specific Outcome of this course (PSOs) wo

Post graduates in Computer Integrated Manufacturing shall develop an

ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing.

Post graduates in Computer Integrated Manufacturing shall apply simulation,

statistics and computational tools for integrating manufacturing systems.

Post graduates in Computer Integrated Manufacturing shall apply the

technical skills for analyzing industrial projects in the area of modern [PSO 3]

manufacturing

[PSO 2]

Course delivery methods Assessment methods

1 Black Board Teaching 1 Internal As nent

2. Power Point Presentation 2. Assignment

3, Videos 3. Seminar

4. Minieproject

Scheme of Continuous Internal Evaluation (CH

‘Theory Component:

5 Addition of two Addition of two mina” Total

Components Wo Mini Final marks

TA tests assignments | prong Marks

roject

‘Theory soa4 . 100 s

30+30 1o+10 20 | ceducedtos0), 5

® = 100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

Components | Conduct of the lab | Journal submission | Lab Test | Total

Marks

Lab 10 10 5 25

‘Total CIE: 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

T.] twill be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Initial write up 10 marks

‘Conduct of experiment(s), result and conclusion 20 marks 50 marks

‘One marks question 10 marks

Viva-voce 10 marks

2. | It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared by: S.J.Patil and H.B.Kulkarni

Introduction to Automation and Computer Integrated Manufacturing

Course Code 20MCMI2 Credits L-T-P | 3-0-1

Course type PC2 Total credits [4

Hours/veek: 3-02 CIE Marks [5001250 =

75 matks

7. T= 40 Ais; T=0 Hrs; P= 10H | S0cT #2501) =

Total How Total = 50 Hrs SEE Marks "| 75 marks

Course Learning Objectives

To study the product and production development cycle through CIM.

To study the fundamentals of CAD/CAM, flow lines and transfer mechanisms in

manufacturing

3. To analyze the transfer mechanisms and automated assembly systems

4. To understand the concepts of inspection principle and methods in manufacturing,

5. To learn perception of process and aggregate production planning control.

Pre-requisites : Automation in production systems

Unit -1 8 Hours

Production Development Through CIM: Computers in Industrial manufacturing, Product

cycle & Production development cycle, Introduction of CAD/CAM & CIM, sequential and

concurrent engineering, soft and hard prototyping.

Industry 4.0 A brief History: What is industrial revolution, Overview about Industry 1.0,

Industry 2.0, Industry 3.0, Toyota innovation, Robotics, Artificial Intelligence.

Unit - 1 8 Hours

Computer Integrated Manufacturing and Automation: Fundamentals of CAD/CAM,

Computerized Manufacturing planning systems, Shop floor control and automatic

identification techniques. Computer Network for manufacturing and the future automated

factories.

Detroit Type of Automation: Flow lines, Different Transfer Mechanisms, work part transfer,

Different methods, Numericals.

Unit - 11 8 Hours

Analysis of Automated flow lines: Analysis of transfer lines without storage, with storage

buffer, single stage, Double stage, Multistage with problems, Automated assembly systems,

Design for automated assembly, parts feeding devices, analysis of Multi station assembly

machine, Analysis of Single stage assembly machine, Numericals,

Unit -1V 8 Hours

Computer Aided Quality Control: The computer in Q.C, automated inspection

principles and methods, Contact inspection methods, non-contact inspection methods,

machine vision system, optical inspection method, sensors, coordinate measuring machine,

Integration of CAQC

with CAD/CAM.

Unit-V 8 Hours

Process Planning and Concurrent Engineering: Process planning, Computer Aided

Process Planning, Concurrent Engineering and Design for Manufacturing.

Production Planning & Control system: Aggregate production planning and master

production schedule, Material requirement planning, Capacity planning, Inventory

control.

Self-learning topics: Computer-Aided testing.

Unit VI 10 Hours

List of Experiments

1, Demonstration on 3D seanning and 3D printing

2. Modelling &Simulation of milling exercises ( minimum 6 exercises)

3. Modelling &Simulation of turning exercises ( minimum 2 exercises)

4, Modelling &Simulation of drilling exercises ( minimum I exercises)

5. Demonstration on FMC setup.

Books

1. MP. Groover, Automation, Production Systems and Computer Integrated

Manufacturing, Automation, Pearson India Education Services Pvt. Ltd, 2016.

2. Zimmer and Groover, CAD/CAM, Prentice hall, NJ.1984.

3. P.Radhakrishna CAD/CAM/CIM, New Age International, New Delhi,2004.

Course Outcome (COs)

Av the end of the course, the student will be able to Bloom's

Level

Understand the importance of product development through CIM, Get

1. knowledge of shop floor control, Computer Integrated Manufacturing and [L2]

Automation

Acquire the knowledge of flow lines and different work part transport 9)

mechanisms

3. Analyze single and multi-station assembly machines. [L4]

4. Discuss the automated inspection principles and methods in manufacturing. [L3]

Program Outcome of this course (POs) PO No.

Ability to independently carryout research investigation and development pq)

work to solve practical problems

2. Anability to write and present a substantial technical report/document [P02]

Program Specific Outcome of this course (PSOs) PSO No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing,

Post graduates in Computer Integrated Manufacturing shall apply

2. simulation, statistics and computational tools for integrating manufacturing [PSO 2]

systems.

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing,

Course delivery methods Assessment methods

Black Board Teaching Internal Assessment

1

Power Point Presentation 2. Assignment

Videos 3. Seminar

4, Minieproject

Scheme of Continuous Internal Evaluation (CIE):

‘Theory Component:

5 Addition of two Addition of two Sin Total .

Components ition ition oF 0 Mini we Final marks

ests assignments project Marks

Theory 30430 10+10 20 100 50

(reduced to 50)

M100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA,

Lab component:

Components | Conduct ofthe lab | Journal submission | Lab Test etl

jarks

Lab 10 10 5 2s |

Total CIE: 50 (1) #25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

T.] It will be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA

Lab component:

Initial write up 10 marks

Conduct of experiment(s), result and conclusion 20 marks

1 50 marks

‘One marks question 10 marks

Viva-voce 10 marks

2. | It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

‘Total SEE: 50(T) +25(L) = 75 marks

Prepared By: Dr.S.C.Kulkami

CNC Systems and Programming

Course Code 20MCMI3 Credits L-T-P | 3-0-1

Course type PCS Total credits [4

Hours/veek: 3-02 CIE Marks [5001250 =

75 matks

7. T= 40 Ais; T=0 Hrs; P= 10H | S0cT #2501) =

Total How Total = 50 Hrs SEE Marks "| 75 marks

Course Learning Objectives

1. To teach the basic concepts in manufacturing systems and fundamentals of NC & CNC

system

2. To impart the knowledge of use of computers for control and planning in the field of

manufacturing, machining centers and tooling for CNC machines

3. To create awareness in system devices that includes feedback dev:

converters and Inspection technologies

4, To train the different programming methods for CNC systems

To be able to develop a part program for a given geometry

s, counters, DAC

Pre-requisites: Basics of Machining, functions of CNC

Unit -1 8 Hours

Fundamentals of Numerical Control: Introduction to numerical control, Classification of

NC/CNC machines and axis nomenclature, PTP and Continuous Contouring, Absolute and

Incremental Programming, Difference between NC and CNC, Different types of sofiware’s in

CNC

Self learning topies: Advantages of CNC.

Unit -11 8 Hours

CNC Machine Tools: General architecture of CNC Machine, Components of the CNC

Systems: Machine Control Unit, CNC Driving system components: Hydraulic, Servo Motors,

Stepper Motors,

Feedback Devices: Encoder, Resolver, Inductosyn, Tachometers, Counting devices, Digital to

analog converters,

Self learning topies: Transducers.

Unit - 111 8 Hours

‘Computerized numerical control: CNC Technology: Functions of CNC Control in Machine

Tools, Advantages of CNC, Direct Numerical Control (DNC Systems): Configuration of DNC

yystem, Functions of DNC, Communication between DNC computer & MCU, Advantages of

DNC.

Self learning topies: Adaptive control optimization system, adaptive control constraint system

Unit -1V 8 Hours

NC programming methods: Manual part programming, Computer assisted part

programming, APT language introduction with simple exercises, Manual data input,

Programming with CAD/CAM integration, CAM packages for CNC part program generation,

Computer automated part programming, Introduction to 4-Axis CNC Machining. Milling

exercises simulation on Master cam, Lathe exercises demo.

Unit-V 8 Hours

Introduction, Manual part programming for turning and milling

Exercises on CNC part programming.

N.C part programminy

canters, G codes, M codes, canned cycles, Pra

Self learning topics: APT language programs

Unit-V 10 Hours

List of Experiments

1. Demonstrate the user interface for FANUC programming and the G/M Codesused

2. Write a program for Drilling/ Reaming ofholes

3. Develop a program for contour with linear and circular interpolation

4. Write @ program to mill a pocket using canned cycle and a slot with

drilling/reamingholes

5. Write a program for facing, step turning and drilling a cylindrical component

6 Develop a program for multiple turningoperation

Books

1. Groover M P, Automation, Production Systems and Computer Integrated Manufacturing

+, Prentice Hall India (P) Lid, 1989.

2. Mikell P. Groover and Emory W. Zimmer, Jr., CAD/CAM Computer Aided Design and

Manufacturing, Prentice Hall India (P) Ltd, 1992.

3. M.Koren —Computer Controls of Manufacturing Systems, McGrawHill, 1983

4. P, Radhakrishna, CAD/CAMICIM, New Age Intemational,

5. P.N. Rao— CAD/CAM Principles and ApplicationsMcGrawhill 2002

6. B.S. Pabla, CNC Machines, New Age International, 2005

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

1. Classify and distinguish NC, CNC and DNC systems {12}

2. Develop manual part programs for given profiles. [L4]

3. Understand CNC machine structures and system drives [12]

Gather knowledge of the concepts of CNC systems and use of

4. [L2]

microprocessors in CNC systems.

5. Understand latest developments in CNC system [12

Program Outcome of this course (POs) PO No.

Ability to independently carryout research /investigation and development p11

work to solve practical problems

2. An ability to write and present a substantial technical report/document [Po2|

Program Specific Outcome of this course (PSs) pso

No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and test

9, Post graduates in Computer Integrated Manufacturing shall apply simulation, ppc oy

statisties and computational tools for integrating manufacturing systems. s

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing.

Course delivery methods Assessment methods

1. Black Board Teaching 1. Internal Assessment

2. Power Point Presentation 2. Assignment

3. Working Models 3. Seminar

4. Videos 4. Minisproject

Scheme of Continuous Internal Evaluation (CIE):

‘Theory Component:

5 Addition of two Addition of two Smne" Total “

Components of Wo” Mini L Final marks

TA tests, assignments pratt Marks

roject

‘Theory 100

30430 10+10 20 | Creduced to50)

= 100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

. Tea | otal

Compone Conduet ofthe lab Journal submission | Lab Test | yt

Lab 10 10 5 23 |

Total CIE: 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

T.] It will be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Initial write up 10 marks

‘Conduct of experiment(s), result and conclusion 20 marks

1 50 marks

[One marks question [10 marks

Viva-voce 10 marks

2. [it will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared By: T.T.Hawal

Condition Based Maintenance

Course Code 20MCMI4I Credits L-T-P | 40-0

Course type PET Total credits | 4

Hours/week: L-T-P | 4-0-0 CIE Marks _ | 50 marks

T= 50 His; T=0 Fis; P= OFrs

fotal Hours: be 30 Hrs seo SEE Marks | 50 marks

Total = 50 Hrs

Course Learning Objectives

To identify various types condition monitoring methods

To understand different analysis techniques.

To understand different techniques in ball & roller bearing vibration

To understand specialized techniques for fault detection,

To understand different fault diagnosis by wear monitoring

weeps

Pre-requisites: Basics of maintenance and sensors

Unit -1T 10 Hours

Condition Based Maintenance: Introduction, Principles, Preventive and Breakdown

maintenance in Industries, Economics and Application, MT’ and MTTR Condition

Monitoring Methods. Economics of Condition Monitoring, Setting up a CM Activity,

Implementation of Condition Based Maintenance, Consequences of implementation of CBM

Unit - 1 10 Hours

Vibration Monitoring And Analysis: Introduction, Machinery signatures, Selection of

Transducers. Analysis Techniques, Machine failure modes, Vibration severity criteria,

Vibration frequency analysis, Permanent Monitoring.

Self learning topies: Measurement locations.

Unit — 1 10 Hours

Vibration Mor ring Of Ball And Roller Bearings: Introduction, Shock pulse method,

SPM for testing Antifriction bearings, Manual Monitoring Continuous monitoring, vibration

signature analysis- significance.

Unit -1V 10 Hours

Specialized Techniques: Acoustic imaging, Ultra sonic triangulation fault location, Acoustic

Emission Technique (AET) - Instrumentation, Magnetic testing Methods, Current flow

Magnetization, Corrosion monitoring, Need for corrosion monitoring, Fields of application,

Monitoring Techniques, Resistance techniques.

Unit-V 10 Hours

Mechanical Fault Diagnosis By Wear Monitoring: Introduction, Source of Contamination,

Significant oil contaminants, Used oil Contamination-time trends, Changes in the cartier

‘Aluid, Wear process monitoring techniques- Direct debris detection methods,

Self learning topic:

Debris collection methods.

Books

R.A. Collacatt Chapman, Mechanical Fault Diagnosis and Condition Monitoring,

Chapman and hall, 1977.

L. F. Pau, Failure Diagnosis and Performance Monitoring, Marcel Deke1

Update CEP, Condition Monitoring and condition based maintenance, IST

Delhi

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

Level

1. Discuss Condition Based Maintenance & Performance Trend Monitoring [13]

2. Explain the relationship between vibrations and machine status (12)

3. Discuss vibration measurements and analysis. [13]

4. Describe Specialized Techniques of condition monitoring, [L3]

5. ifferent fault diagnosis techniques (13)

Program Outcome of this course (POs) PO No.

1 Ability to independently carryout research ‘investigation and development

[Pol]

work to solve practical problems

2. Anability to write and present a substantial technical report/document [p02]

Program Specific Outcome of this course (PSOs) PSO No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing

Post graduates in Computer Integrated Manufacturing shall apply

2. simulation, statistics and computational tools for integrating manufacturing [PSO 2]

systems

Post graduates in Computer Integrated Manufacturing shall apply the

technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing

Course delivery methods Assessment methods

1. Lecture 1, Intemal Assessment

2. Videos 2. Assignment

3. PPT 3. Seminar

4. Case studies 4. Mini-project

Scheme of Continuous Internal Ev

‘Theory Component:

tion (

. Addition of two Addition of two Semin" Total

Components TA tests ecicumente Mini Notts Final marks

sts ‘sig 'S Project s

Theory 30430 10+10 20 100 50

(reduced to 50)

mM 100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

Components Conduct of the lab | Journal submission | Lab Test | Total

Marks

Lab 10 10 3 |

‘Total CIE: 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

Scheme of Semester End Examination (SE

I. Itwill be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Initial write up 10 marks

‘Conduct of experiment(s), result and conclusion 20 marks

1 : 50 marks

‘One marks question 10 marks

Viva-vore 10 marks

2. | It will be conducted for 50 marks having 3 hours/2 hours duration, It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared By: Vinayak V.Kulkami

Sensors for Manufacturing

Course Code 20MCMI42 Credits L-T-P] 4-0-0

Course type PEL Total credits | 4

Hours/week: 4-0-0 CIE Marks 50 marks

Total Hours: Fas Te Otis: PS OHS see Marks | 50 marks

Total = 50 Hrs

Course Learning Objectives

To identify various types of sensors

To understand computer communications, sensors role & networks in manufacturing,

To identify different manufactured components with sensors & digital encoder

To identify various types of sensors used in Industry

To identify various types of sensors used in Flexible Manufacturing systems

weeps

Pre-requisites: Basic knowledge of manufacturing processes and control systems.

Unit -1 10 Hours

Introduction, classification and types of sensors: Introduction, classification of control

processes, open and closed loop control systems, photoelectric sensors, detection methods,

proximity sensors, limit switches, inductive and capacitive sensors in manufacturing,

microwave sensing applications, laser sensors

Unit —11 10 Hours

Networking of Sensors & Control Systems in Manufacturing: Introduction, Number of

products in a flexible system, Network of sensors detecting machinery faults, understanding,

computer communications and sensors role, networks in manufacturing.

Unit - 111 10 Hours

Advanced sensor technology in precision manufacturing applications: Identification of

manufactured components, digital encoder, fuzzy logic for optoelectronic color sensors in

manufacturing, optoelectronic sensor tracking targets on a structure, sensors detecting faults in

dynamic machine parts (bearings)

Self Learning Topie: Sensors for vibration measurement of a structure.

Unit -IV 10 Hours

Industrial sensors and control: Introduction, sensors in manufacturing, temperature sensors

in process control, Pressure sensors, Fiber-optic pressure sensors, ultrasonic non-destructive

evaluation sensor, process control sensors for acceleration

Unit-V 10 Hours

Sensors in flexible manufacturing Systems: Introduction, role of sensors in FMS, Robot

control through vision sensors, robot guidance with vision system, End effector camera sensor

for edge detection and extraction, End effector camera sensor detecting partially visible

objects, ultrasonic end effector.

Self Learning Topic: End effector sound- vision recognition sensors.

Books

1. H.K-Tonshoff, 1. Inasaki,Sensors for Manufacturing, Vol 1, Wiley-VCH.2001

2. SabrieSoloman, Sensors and Control Systems in Manufacturing, Second Edition,

McGraw Hill Education.2009

Clarence W. de Silva,SensorsActuators,SecondEdi

n,CRC Press.2015,

Course Outeome (COs)

Av the end of the course, the student will be able to Bloom’s

Level

1. Identify various types of sensors including thermal, mechanical, electrical, [L2]

electromechanical and optical sensors

2. Discuss on sensors used in detection of machinery faults [13]

3. Describe different sensors used in precision manufacturing applications [13]

4. Discuss. different sensors for physical, chemical, and biochemical — [L3]

applications

Discuss sensors in flexible manufacturing Systems (L3]

Program Outcome of this course (POs) PONo.

Ability to independently carryout research /investigation and development

1 [Pol]

work fo solve practical problems

2, Anability to write and present a substantial technical reportdocument {Po}

Program Specifie Outcome of this course (PSOs) PSON

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for [PSO 1]

‘manufacturing, assembly and testing

Post graduates in Computer Integrated Manufacturing shall apply

2. simulation, statistics and computational tools for integrating [PSO 2]

manufacturing systems.

Post graduates in Computer Integrated Manufacturing shall apply the

technical skills for analyzing industrial projects in the area of modem [PSO3]

manufacturing.

Course delivery methods Assessment methods

1. Lecture 1, Infernal Assessment

2. Videos 2. Assignment

3. PPT 3. Seminar

4. Case studies 4, Mini-project

Scheme of Continuous Internal Evaluai

mn (CIE)

‘Theory Component:

Seminar

c ents | Addition of two Addition of two Total Final marks

‘omponents IA tests, assignments proivot Marks inal marks

‘Theory 100

30+30 10+10 20 (reduced to 50) 50

100 marks will be reduced to $0 marks for the calculation of SGPA and CGPA.

Lab component:

5 5 Test | otal

Components | Conduct of the lab Journal submission Lab Test | yo

Lab 10 10 5 25

Total CIE: 50 (T) #25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SE

1. It will be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab compone

Initial write up 10 marks

1, Conduct of experiment(s), result and conclusion 20 marks 50 marks

‘One marks question 10 marks °

Viva-vooe 10 marks

2. | It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared By: Vinayak V.Kulkami

Advanced Materials and Processing

Course Code 20MCM143, Credits L-T-P | 4-0-0

Course type PEI Total credits [4

Hourshweek: L-T-P_ | 4-0-0 CIE Marks _ | 50 marks

L= 50 Hrs; T= 0 Hrs: P = OHrs

Total How Total = 50 Hrs

SEE Marks | 50 marks

Course Learning Objectives

1. To orient the students into the knowledge of newer materials, properties and processing

of composites

2. To train about the operational principles, advantages applications, limitations of the

various Nano composites and Powder Metallurgy

3. To make the students understand the characteristics of different materials and its

selection.

To teach the techniques involved in powder metallurgy.

To impart the knowledge of structure property relationship of engineering materials

ws

Pre-requisites: Basic knowledge in material science,

Unit -1 10 Hours

Structure-property relations: Introduction, Atomic structure, atomic bonds, secondary

bonds, crystal structure, packing efficiency, crystal defects, grain structure, elastic and plastic

eformation in single crystals, dislocation theory, strain /work hardening, plastic deformation

in polycrystalline metals, fracture of metals, cold working, re-crystallization and hot working,

grain growth.

Unit —11 10 Hours

‘Composites: Introduction, classification, matrix and reinforcement materials, properties and

applications, rule of mixtures, longitudinal strength and modulus (iso strain model), transverse

strength and modulus (iso stress model), density and Poisson's Ratio.

Plastics: Introduction, Plastics - family - types - selection criteria based on usage, Making

alloy materials in metal and plastics, molecular structure, isomers, polymerization,

thermosetting and thermoplastic materials, Plastic processing - Extrusion, injection,

compression, Dip, Forming, 3D printing, SMC, FRP, Pultrusion, Decoration, properties and

applications of plastics.

Self Learning Topic: Properties and applications of plastics.

Unit - 1 10 Hours

Processing of PMC’s: Hand layup process, filament winding process, pultrusion process.

pressure bag molding, vacuum bag molding, autoclave molding, injection molding process and

thermoforming process of PMC’s.

Processing of MMC’s: Liquid-state process- Duralcan Process, Squeeze casting Spray

forming, solid state process- Diffusion bonding, Deformation processing, Various deposition,

techniques and In-situ processes

Unit -1V 08 Hours

Powder metallurgy: Introduction, Steps in powder metallurgy, Production of Powder,

Characterization & Testing of Powders, Powder Conditioning, Powder Compaction, Sintering,

Finishing operations, Applications of PM components.

Unit-V 12 Hours

Nano composites: Introduction, concept of nanotechnology and nano materials, fabrication of

carbon nano tubes (CNT) by arcing methods, nano material characterization — scanning

electron microscope, atomic force microscopy, Processing of Nano composites- In situ

polymerization, Melt blending, solvent method, Applications of Nano composites.

Self Learning Topic: Applications of Nano composites.

Books

1. E.PaulDegarmo, J.T.Black, Ronald A Kohser, Materials and Processing in

Manufacturing 8th Edition — Prentice Hall India.

2. K.K.Chawla, Composite materials — Science &Engineering, Springer.

3. Nanotechnology- Basic Science and Emerging Technologies, -Mick Wilson,

KamaliKannangara, Overseas Press India Private Limited, First Indian Edition 2005

4. AutarK.Kaw, Mechanics of composite materials, Taylor and Francis grouy

5. AK. Sinha, Powder Metallurgy 2nd Edition -. DhanpatRai Publications.

Course Outcome (COs)

Bloom’s

Level

Decide the application of various newer materials to engineering applications 5)

satisfying requirement of machinability, strength and weight requirements.

At the end of the course, the student will be able to

2. Understand the of concepts of composite materials [12]

3. Get an insight of choosing a particular material for the required application. [13]

4. Understand the various composite material processing techniques [12]

5. Implementnanomaterials for suitable engineering applications. [12]

Program Outcome of this course (POs) PO No.

1, Ability to independently camyout research finvestigation and development p17

work to solve practical problems

2. Anability to write and present a substantial technical report/document [Po2]

Speci i 5 PSO

Program Specific Outcome of this course (PSOs) No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing.

Post graduates in Computer Integrated Manufacturing shall apply simulation,

a < pso

statistics and computational tools for integrating manufacturing systems, [PSO 2]

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing

Course delivery methods Assessment methods

1. Black Board Teaching 1. Internal Assessment

2. Power Point Presentation 2. Assignment

3. Working Models 3. Seminar

4. Vide 4. Minieproject

Scheme of Continuous Internal Evaluation (CIE)

‘Theory Component:

Addition of two Addition of two Seeuna” Total

‘Components of Wo Mini , Final marks

TA tests assignments projec Marks

roject

Theory 043 100 5

30430 10+10 20 | (educed to 50) 50

100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA

Lab component:

; . Tea | otal

Components | Conduct of the lab | Journal submission | Lab Test | yal

Lab 10 10 5 [2s |

Total CIE: 50 (1) #25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

T.] It will be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Tnitial write up 10 marks

‘Conduct of experiment(s), result and conclusion 20 marks

50 marks

‘One marks question 10 marks

Viva-voce 10 marks

2. [It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared By: T.T.Hawal

Management Information System

Course Code 20MCM21 Credits L-T-P | 44

Course type Pcl Total eredits | 4

Hours/week: L-T-P_| 4-0-0 CIE Marks | 50 marks

L= 50 Hts; T= 0 Hrs; P= OHrs

Total Hours: Total ~ 50 Iles

SEE Marks | 50 marks

Course Learning Objectives

1. Introduce various aspects of MIS as applied to engineering problems in a systematic

manner.

2. Impart the knowledge of data base fundamentals.

3. Apply MIS for business applications.

4. Understand systems concepts and systems engineering

5 Understand the concepts of organizational structure and management.

Pre-requisites : NIL,

Unit-1 10 Hours

Introduction: MIS: Definition, Importance of MIS, Evolution of MIS, Computers and MIS,

Organizational Structure, Logical Foundations of MIS, Typical MIS Systems, and Future of

MIS.

Information Systems and Organizations: Structure, Data and Information, Management

and Decision Making, Classification of MIS, Information support for functional areas of

Management, Impact of business on Information Systems, Absorption of MIS in

Organizations.

Unit - 1 10 Hours

Database Technology: Introduction, Database and Enterprise Management, File Processing

Systems and Database Systems, Data Independence, Database Approach, Data base

Architecture. Relational Database Management Systems (RDBMS): DBMS:

Introduction, Structured Query Language (SQL), Data Administration, Current

Developments in Databases.

Unit — 11 10 Hours

Decision Support Systems: Introduction, Definition, Evolution of DSS, Characteristics,

Model Management, DSS Generators, Multi-criteria Modelling, Using DSS; What if

analysis, Sensitivity Analysis, Goal-seeking Analysis, Data Mining

Expert Systems and Artificial Intelligence: Introduction, Al-Definition, Evolution of Al,

Components of Al, Expert Systems, Benefits and Limitations, Applications.

Unit-1V 10 Hours

Systems Analysis and Design: Introduction, Organizational Context of Systems Analysis,

Role of Systems Analyst, Systems Development Life Cycle (SDLC), Requirement Analysis,

Requirement Specifications, Feasibility Analysis, Feasibility Report, Case Studies.

Self learning topics: Development, Implementation and Management of MIS Resources:

Developing and Implementing Application Systems, Quality Assurance and Evaluation of

Information Systems.

Unit -V 10 Hours

Organization and Management: The basic model of organizational structure, Information

processing model of organizational structure, Organizational change, management theories,

organizations as sociotechnical systems.

Self learning topics: Developing a Long Range Information System Plan: Master Plan,

The Nolan Stage Model, Strategie Planning Stage, Analysis of Organizational Information

Requirement.

Books

WSS Jawadekar , Management Information systems, TMH, 4"d,2002.

2. Davis G.B., Management Information Systems-Conceptual foundations, Structure and

development, MeGraw Hill Intl. Book Co., 6!"Ed,2001

.Sadagopan, Management Information Systems, PHI,2005

4, James A O’Brien, George M.Markas, Ramesh Behl, Management Information

Systems, Tata McGraw Hill, 9th Ed, 2008

Course Outcome (COs)

At the end of the course, the student will be able to : Bloom's

Level

1, Understand fundamentals of MIS and be able to compare it with other 5)

"approaches.

9, Mlemtify and discus the fundamentals of database management as applicd 4 5

to respective tasks.

3, Demonstrate the ability to define and state the properties and jy)

3+ characteristics ofdata base management by any engineer. -

Program Outcome of this course (POs) PONo.

Ability to independently carryout research investigation and development

1 [Pol]

work to solve practical problems

2. Anability to write and present a substantial technical reportidocument [P02]

Program Specific Outcome of this course (PSOs) Ny

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing.

>, Post graduates in Computer Integrated Manufacturing shall apply

. . « S = SO 2]

simulation, statistics and computational tools for integrating manufacturing 'PS© 21

systems,

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing.

Course delivery methods Assessment methods

1. Black board teaching 1, Internal Assessment Tests

PPT 2. Assignments

Scheme of Continuous Internal Evaluation (CIE)

‘Theory Component:

Seminar/

Components Addition oftwo Addition ofwo fini | POUL Final marks

tests assignments pyyitey |—_—_-Marks

Theory 100

, sors 0 y

30450 To+10 20 (reduced to 50) *°

100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

Components Conduct of the lab | Journal submission | Lab Test | 1ot@l

Marks

Lab 10 10 5 2s |

‘Total CIE: 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

1. ] [twill be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Initial write up 10 marks

‘Conduct of experiment(s), result and conclusion’ 20 marks

‘One marks question 10 marks

Viva-voce 10 marks

50 marks

2, [It will be conducted for 50 marks having 3 hours/2 hours duration, It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared by: Vinayak V.Kulkami

Rapid Prototyping and Tooling

Course Code 20MCM22 Credits L-T-P| 3-0-1

Course type PC2 Total eredits [4

25(L) =

Hourshveek: L-T-P. | 3-0-2 CE Marks | 50D #25.)

75 marks

Total Hours: C= 40 Hiss T= 0 Hiss P= TORS | oe waaay | S025) =

Total = 50 Hrs 75 marks

Pre-requisites: Elementary knowledge of Conventional (Subtractive) manufacturing

techniques like Casting, Welding & Forming processes.

Unit -1 8 Hours

Introduction to Rapid Prototyping (Additive Manufacturing): Definition of a Prototype,

Types of prototype, Need for the compression in product development, History of RP

systems, Survey of applications, Additive versus conventional manufacturing process,

Classification of RP systems, General steps involved in Additive manufacturing process.

Self learning topics: Application of 3D printing to Investment Casting, Automobile and

Health Care sectors.

8 Hours

Additive Manufacturing Techniques: SLA, SLS, FDM, LOM, LENS - Principle of

operation, Process parameters and Applications, Concept Modellers — 3DP — Principle of

operation and application.

Self learning topics: Principle of operation of Solid Ground Curing

Unit - 111 8 Hours

Definition, Importance, Application, Steps involved in a Scanning

process — Acquisition, Alignment, Mesh Generation, Post Processing, Simplification,

Reverse Engineering Hardware — Contact and non-contact types.

Reverse Engineerin;

Unit -1V 8 Hours

Rapid Tooling: Definition, Classification — Direct and indirect, Silicon Rubber Tooling,

Aluminium Filed Epoxy tooling, Metal Spray Tooling, Direct AIM, Sand Casting Tooling,

Soft versus hard tooling, Advantages and limitations of Rapid Tooling.

Unit -V Hours

Software RP: The STL file, Problems with STL file, STL file manipulation, Beyond STL

file, NETFABB, KISSLICER, Post processing requirements and techniques, Influence of the

build orientation, Business opportunities and future directions.

Unit -VI 10 Hours

List of Experiments

1, Practical demonstration of the steps (Including CAD solid modelling STL conversion,

File transfer to the FDM machine, Machine setup, Part building, Part removal and

Post-processing) involved in printing a component in the FDM printer.

2, Study the effect of process parameters and post processing techniques on the surface

finish (Using Telesurf) of a 3D printed components.

3. Hands on experience on 3D printing a complex component starting from creating a

sketch,3D modelling it by modelling software and then printing it in the FDM printer.

4, Practical demonstration of the general steps (including Calibration, Acquisition,

Alignment, Mesh generation, Post processing and simplification) involved in reverse

engineering by scanning a component using a 3D scanner.

5. Study the effect of process parameters and post processing techniques on the

Dimensional Accuracy (Using a 3D scanner) of a 3D printed components

Books

1 Ian Gibson, David Rosen, Bent Stucker, Additive Manufacturing Technologies, 3D

printing, Rapid Prototyping, and Direct Digital Manufacturing, Springer, 2015, 2nd

Edition, 2015.

2. Ramesh S., Rapid Prototyping, Ane books Pvt. Ltd., 2016,

3. E-Resources:https://learn-xpro.mit.edwadditive-

manufacturing?utm_medium=sem&utm_source=google&utm_campaign=amx-r6-

sp20&utm_term=3d%20printing%20courseduim_content=awee (MIT xPRO)

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

Level

1. Understand the principles of Rapid prototyping (Additive Manufacturing). [2]

2, Select a 3D printing process for the given application. [13]

3. Understand the concepts of Reverse Engineering. [12]

4. Understand the application of Additive manufacturing in making of tools. [L2]

5. Produce a product using a 3D printing technique (FDM). (L3]

Program Outcome of this course (POs) PONo.

Ability to independently carryout research /investgation and development poy)

work to solve practical problems

2. Anability to write and present a substantial technical report/document [Po2]

Program Specific Outcome of this course (PSOs) PSO No.

Post graduates in Computer Integrated Manufacturing shall develop an

1, ability to integrate automation with mechanical systems for [PSO 1]

manufacturing, assembly and testing.

>, Post graduates in Computer Integrated Manufacturing shall apply

simulation, statistics and computational tools for integrating [PS 2]

manufacturing systems.

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem — [PSO 3]

manufacturing.

Course delivery methods Assessment methods

Black Board Teaching Internal Assessment

1 1

2. Power Point Presentation 2. Assignment

3. Working Models 3. Seminar

4. Videos 4. Mini-project

Scheme of Continuous Internal Evaluat

Theory Component:

mn (CIE)

Seminar/

Components Aion oftwo “Addon of 60 "Nf Toa Final marks

ests assignments project Marks

Theory 30430 10+10 20 100 50

(reduced to 50)

M100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA,

Lab component:

omponents | Conduet ofthe lab | Journal submission | Lab Testy 1

Lab 10 10 5 25

‘Total CIE: 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE)

T.] Itwill be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Initial write up 10 marks

[Conduct of experiment(s), result and conclusion | _20 marks 50 marks

[One marks question [10 marks

Viva-voce 10 marks

2. | It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25,

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared by: VG Tiwari/ Dr.Arunkumar P

RESEARCH METHODOLOGY AND IPR (Integrated)

Course Code 20MCM2S Credits TP 0-1

Course type PC Total credits [4

Hoursiweek: L-T-P | 3-0-2 Cle Marks | 300250) ~

‘75 marks

L= 408s; T= OHrs;P =10Hrs

Total Hours: SEE Marks

Total = SOHrs

S0(1)125(L) =

75 marks

‘Course learning objectives

Understand the basic concepts of research and its methodologies

Identify and select the appropriate research/sampling design methods.

‘Analyze and interpret the data to enable hypothesis testing

Create the awareness about Intellectual Property Rights for the protection of inventions.

Pre-requisites : Nil

T 08 Hours

Meaning, Objectives, types, Research Approaches. Significance of Research, Research Methods versus

Methodology, Research and scientific method, research Process, criteria of good research, Problems

encountered by researchers,

Research Problem:

Defining a research problem, Selecting a research problem, necessity and techniques involved in

defining the research problem

Self learning topies: NIL.

Unit =I [08 Hours

Research Design:

Meaning, need sign, for research design, features of a good design, important concepts relating to

research design, different research designs, Basic principles of experimental designs, developing a

research plan

Sampling design:

Implications of a sample design, Steps in sample design, criteria of selecting a sampling procedure,

characteristics of a good sample design, different types of sample designs, Random Sample and

complex random sample designs.

Self learning topies: NIL

Tait [Tours

Data Collection Methods:

Collection of Primary Data, Observation Method, Interview Method, Questionnaires, Schedules, Other

Methods of Data Collection, Collection of Secondary Data, Case study method.

Processing and Analysis of Data

Processing operations, Elements/ types of analysis, Statistics in research- measures of central tendency

or statistical averages, measures of dispersion, measures of asymmetry (skewness), measures of

relationship, Simple regression analysis, Multiple correlation and regression, Partial correlation,

Association in case of attributes, Other measures- Index numbers, Time series analysis

Self learning topies: NIL.

(08 Hours

Testing of hypotheses- Basic concepts, procedure for hypothesis testing, flow diagram, Test of

hypothesis, procedure for hypothesis testing, Hypothesis for means, difference between means,

comparing two related samples, proportions, difference between proportions, comparing. a variance to

some hypothesized population variance, power of test, limitations of test of hypothesis

Chi-sqaure test: 72 test and their applications in research studies.

Analysis of variance: Basic principles of ANOVA, ANOVA technique, setting up of analysis of

variance table, one way. ANOVA, two way ANOVA, ANOVA in Latin square Design.

‘Self learningtopics: Analysis of Co-variance,

Unit-V (08 Hours

Tntellectual Property Rights — IPR- Invention and Creativity- Intellectual Property-Importance and

Protection of Intellectual Property Rights (IPRs)- A brief summary of: Patents, Copyrights,

Trademarks, Industrial Designs- Integrated Circuits-Geographical Indications-Establishment of

WIPO-Application and Procedures. Research ethics, Plagiarism, Prior art _ search.

Interpretation and Report Writing: Meaning of interpretation, Why interpretation, Technique of

interpretation, Precaution in interpretation, Significance of report writing, Different steps in writing

report, Layout of the research report, Types of reports, Mechanics of writing research report, Precautions

for writing research reports.

Self learning topies: Oral presentation

Unit— VI 10 Hours

List of experiments

1. Selection of sample design for a given research problem using different sample design

procedures.

2. Techniques for data collection [Primary, Secondary].

3.__Data Analyties relevant to various applications

4. Data Analytics relevant to various applications under probability theory’

'5,_ Regression and Correlation analysis.

6. Research design techniques, like: factorial design, L S design, randomized block design,

response surface methodology.

7. Testing an Hypothesis using ANOVA (I way and 2 way ANOVA) and other Multivariate

analysis

Books

‘Text Books:

1. [CR Kothari, Research Methodology, New Age Intemational Publishers, 2nd edition,

2007.

Reference Books:

1._| Paneer Selvam, Research Methodology, PHI Learning Pvt. Ltd., 2007.

2. | Dr. B.L. Wadhera -Intellectual Property Rights, Universal Law Publishing Co. Ltd..

2002

3._| William G Zikmund, Business Research Methods, Indian edition, South westem

Publishers, 8th Indian Reprint - 2009.

Course delivery methods ‘Assessment methods

T. | Lecture and Board 1. ] Assignments and Open Book Assignments

2. | NPTEL/ Edusat 2. Quizzes

PowerPoint Presentation Internal Assessment Tests

4, | Videos 4,_| Semester End Examination

‘Course Outcome (COs)

‘Outcomes usually follow the format: “At the end of the course, students will be able to“insert action

verb here + insert knowledge, skills, or attitudes the student is expected to develop'J(Highlight the

action verb representing the Bloom’s level.)

At the end of the course, the student will be able to Bloom's

T_| Identify and select an appropriate methodology Tor research, [Lt]

9, Design and Apply suitable researeh/sampling procedure for the research 13]

problem. 3

3._| Analyze and interpret data collected, {L4]

4._| Evaluate various approaches for hypothesis testing Ls]

5.__[Disouss the significance of Intellectual Property Rights & report waiting [12]

Program Outcome of this course (POs) PON.

1, At ability to independently carry out researeWinvestgation and development Wor | po 4

to solve practical problems.

2._[An ability to write and presenta substantial technical report? document PO2

Students should be able to demonstrate a degree of mastery over the area as per the

specialization of the program. The mastery should be at a level higher than the | PO 3

requirements in the appropriate bachelor program,

Program Specific Outcome of this course (PSOs)

Post graduates in Computer Integrated Manufacturing shall develop an

1, ability to integrate automation with mechanical systems for [PSO 1]

manufacturing, assembly and testing,

Post graduates in Computer Integrated Manufacturing shall apply

2, simulation, statistics and computational tools for integrating [PSO 2]

manufacturing systems.

Post graduates in Computer Integrated Manufacturing shall apply the

technical skills for analyzing industrial projects in the area of modern [PSO 3]

manufacturing,

Scheme of Continuous Internal Evaluation (CIE)

Theory Component:

Addition of [Addition of two. Sen Total

5 Addition of two Addition of two Mini otal canal ma

Components IA tests assignments | project Marks Final marks

Theory 30430 10+10 20 100 50

(reduced to 50)

100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

Components Conduct of the lab Journal submission Lab Test TotalMarks

Lab 10 10 5 25

Total CIE: 50 (T) +25(L) = 75 marks

Minimum score to be eligible to SEE for this course : 40% in each component

Not eligible in any one of the component will be considered as NOT eligible for the Course

‘Scheme of Semester End Examination (SEE)

‘Scheme of Semester End Examination (SEE):

‘Theory Component:

1. ] Itwill be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

2. | Minimum marks required in SEE to pass: 40 out of 100

3. | Question paper contains two questions from each unit each carrying 20 marks. Students

have to answer one full question from each unit

Lab component:

1. | Initial write up 10 marks

Conduct of experiment(s), result and conclusion 20 marks

One marks qu

Viva-voce

50 marks

ion 10 marks mans

10 marks

2. | Towill be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to

25 marks for the calculation of SGPA and CGPA,

3. | Viva-voce is conducted for individual student.

Total SEE: 50(T) +25(L) = 75 marks

Minimum score for passing this course : 40% in each component compulsory

Not eligible in any one of the component will be considered as NOT eligible for the

Course

Tooling for Manufacturing in Automation

Course Code 20MCM241 Credits L-T-P | 4-0-0

Course type PE-IL Total credits | 4

Hoursiweek: L 4-0-0 CIE Marks | 50 marks

Total Hours: L® 50 Hrs, T= 0 Hrs P= OHS | sep Marks | 50 marks

Total = 50 Hrs

Course Learning Objectives

1. Interpret the geometrical and dimensional details of a production drawing and design

of single point and multi point cutting tools.

2. Yo understand principles of location and need for clamping system.

3. To study the design consideration and types of drill jigs.

4. To study the different type’s fixtures and steps invoived in designing the fixture.

5. To understand the concepts of tooling requirement and tool management for CN

machines.

6. To learn perception of plastic tooling material in industry

Pre-requisites: Basic knowledge of Design of Machine Elements, Manufacturing

Technology, Computer Aided Machine Drawing, Measurements and Metrology.

Unit -1 10 Hours

Introduction to tool design: Tooling, requirements of a tool designer, general tool design

procedure, tool engineering functions and its importance to enhance productivity and

quality.

Design of cutting tools: Introduction to cutting tools.

of drill bit, Design of milling cutter.

Location and clamping methods: Basic principles of locating, locating methods and

devices, Basic principles of clamping, Clamping methods, Power clamping.

Design of single point tool, Design

Unit 10 Hours

Drill jigs: Definitions, General considerations, Machine considerations, Process

considerations, Types of drill jigs Chip formation in drilling, General considerations in design

of drill jigs, Drill bushings, Steps involved in jig design,

Self-learning topics: Design of drill jig for simple component.

Unit — 101 10 Hours

Fixtures: Definitions, General considerations, Machine considerations, Process.

considerations, Product considerations, Types of fixtures —Vice fixture, Milling fixture,

Boring fixture, Broaching fixture, Lathe fixtures, Grinding fixtures, Steps involved in

designing fixture.

Self-learning topics: Design of Lathe/Milling fixture for simple component.

Unit -1V 10 Hours

Brief introduction of NC machines work holding devices: Tool design for NC

machines-An introduction, Fixture design for NC Machine, Cutting tools for NC Machine,

Tool holding methods for NC Machine, ATC and APC for N

NC Machine

Machine, Tool pre-setting for

Unit -V 10 Hours

Plastics for tooling materials: Introduction, Commonly used plastics for tooling, Epoxy

tools, Construction methods, Urethane dies, Force calculation for Urethane pressure

pads.

Books

1, Cyrol Donaldson, Tool Design, Tata McGraw Hill India, 2010,

2. F.W.Wilson, Fundamentals of tool design ASME, PHI, New Delhi, 2010.

3. David A. Stephenson, Metal Cutting Theory and Practice, CRC press, 2005

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

Level

Classify different types of cutting tools and ability to design/seleet suitable

1. locating and clamping devices for a given component for various (12)

operations

2. Design a jig for a given simple component, [L4]

3. Design a fixture for a given simple component. [La]

3. Understand of various tool holders and tool pre-setting for NC machines. (L2]

4. Classify and distinguish appropriate plastics for tooling [12]

Program Outcome of this course (POs) PO No.

1, Ability to independently carryout research investigation and development pq)

work to solve practical problems

2. An ability to write and present a substantial technical report/document [P02]

Program Specific Outcome of this course (PSOs) PSO No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing

Post graduates in Computer Integrated Manufacturing shall apply

simulation, statistics and computational tools for integrating manufacturing [PSO 2]

systems.

Post graduates in Computer Integrated Manufacturing shall apply the

technical skills for analyzing industrial projects in the area of modern [PSO 3]

manufacturing,

Course delivery methods Assessment methods

Black Board Teaching 1, Internal Assessment

Power Point Presentation 2. Assignment

Working Models 3. Seminar

4. Videos 4. Mini-project

Scheme of Continuous Internal Evaluation (CIE)

‘Theory Component:

on on Seminad

Components | Mion oftwo Adon oftwo finn” Toll Fin marks

ests assignments payee (at

Theory 30430 10410 20 100 30

(reduced to 50)

= 100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component:

Components | Conduct of the lab | Journal submission Lab Test | Total

Marks

Lab 10 10 5 25

‘Tots

= 50 (T) +25(L) = 75 marks

Scheme of Semester End Examination (SEE)

‘Theory Component:

‘Scheme of Semester End Examination (SEE):

1. ] It will be conducted for 100 marks of 3 hours duration. It will be reduced to 50 marks for

the calculation of SGPA and CGPA.

Lab component:

Thitial write uj 10 marks

nduct of experiment( 20 marl

‘One marks question 10 marks

Viva-voce 10 marks

50 marks

2, | It will be conducted for 50 marks having 3 hours/2 hours duration. It will be reduced to 25

marks for the calculation of SGPA and CGPA.

Total SEE: 50(T) +25(L) = 75 marks

Prepared By: Dr.S.C.Kulkami

Quality Control and Reliability

Course Code 20MCM242 Credits L-T-P | 4

Course type PE-I Total credits | 4

Hoursiweek: L-T-P | 4-0-0 CIE Marks | 50 marks

Total Hours: L® 50 Hrs, T= 0 Hiss P=OHts | Sep Marks — | 50 marks

Total = 50 Hrs

Course Learning Objectives

1. To understand the theoretical aspects of quality

2. To study quality control tools and their implementation in the organization and control

charts for variable data,

To understand and interpret the attribute data and to construct control chart for

attribute data

4. To understand the basic concepts of acceptance sampling,

To study the reliability of the system , system configuration and to understand failure

mode of the product

Unit—1 10 Hours

Quality and Quality Control: Inspection, objectives of inspection, advantages of inspection,

stages of inspection, purpose of inspection, inspection procedures, demerits of inspection,

Quality control meaning, Factors Affecting Quality, objectives of quality, statistical quality

control, tools of statistical quality control, quality characteristics.

Probability-Introduction, hyper geometric distribution, binomial Poisson and normal

distribution (solved examples only)

Unit -11 10 Hours

Statistical process control: Introduction, Quality systems used in industries: SPC, SQC,

7QC, Lean, 58, PPAP, APQP, 8D, Fish bone, 5 why, causes of variation in qualit

Control Charts For Variables: Introduction, central limit theorem, interpretation of control

charts, Controls Charts for X Bar and Range (R) (numerical)

Self-learning topics: Implementation of control charts in a machine shop

Unit - 111 10 Hours

Control charts for attributes-Introduction, p chart, np chart, C chart or U chart Numerical,

‘Type I and Type II errors with respect to control charts.

Unit-1V 10 Hours

Acceptance sampling- Introduction, advantages and disadvantages of sampling, guidelines

for formation of lots, types of sampling plans, single sampling plan Operating Characteristic

curve(OC curve),type A and type B OC curve, relation between consumer and producer,

double sampling plan, sequential sampling plan, numerical

Unit-V 10 Hours

Reliability and Life testing: for reliable product, Definition of reliability, failure data,

Failure models of components, definition of reliability, MTBF, Failure rate, common failure

rate curve, types of failure, reliability evaluation in simple cases of exponential failures in

series, parallel and series-parallel device configurations, Redundancy and improvement

factors evaluation.

Failure Mode, Effect and Criticality Analysis Introduction, procedure, stages and

benefits

Self-learning topies: Benefits of Failure Mode, Effect and Criticality Analysis

Books

1. Grant and Leavenworth, Statistical Quality Control, Pearson Education. McGraw Hill

6th Edition,

2. JM Juran, Frank M Gryna, Quality Planning & Analysis, Tata MeGraw Hill - 3rd

edition

3. NVR Naidu, K.M Babu, G Rajendra, “Total Quality Management”, Ne

International publishers 2012 reprint.

4, LS Srinath, Reliability Engineering, 4" edition,east-west press

5. M.Mahajan, “Statistical quality control” dhanpatrai and co 2011

ge

Course Outcome (COs)

At the end of the course, the student will be able to Bloom's

Level

1. Understand and basic concepts of quality and quality control aspects, {LI}

2. Analyze the variable data and to use quality control tools, LA]

Analyze attribute data of manufacturing process and different problems

3 yee attr {L4]

associated with attribute data

4. Analyze samples to accept and reject the universe. (4)

5. Evaluate system reliability and redundancy [LS]

Program Outcome of this course (POs) PONo.

1, Ability to independently carryout research /investigation and development jp)

work to solve practical problems [pol]

2. Amabi ite and present a substantial technical report/document (Po2]

Program Specific Outcome of this course (PSOs) PSO No.

Post graduates in Computer Integrated Manufacturing shall develop an

1. ability to integrate automation with mechanical systems for manufacturing, [PSO 1]

assembly and testing

Post graduates in Computer Integrated Manufacturing shall apply

2. simulation, statistics and computational tools for integrating manufacturing [PSO 2]

systems.

Post graduates in Computer Integrated Manufacturing shall apply the

3. technical skills for analyzing industrial projects in the area of modem [PSO 3]

manufacturing.

Scheme of Continuous Internal Evaluation (CIE):

Course delivery methods Assessment methods

1 Black Board Teaching 1 Internal Assessment

2. Power Point Presentation 2. Assignment

3. Working Models 3. Seminar

4. Videos 4. Mini-project

5. Lab experiments

‘Theory Component:

5 Addition of two Addition of two SSN Total “

Components 2 Mini Final marks

TA tests assignments prose Marks

roject

Theory 30430 10+10 20 100 50

(reduced to 50)

™ 100 marks will be reduced to 50 marks for the calculation of SGPA and CGPA.

Lab component: