Professional Documents

Culture Documents

Bakrie Astm A53b

Bakrie Astm A53b

Uploaded by

Amin Danar Noviyanto0 ratings0% found this document useful (0 votes)

7 views3 pagesOriginal Title

bakrie astm a53b

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesBakrie Astm A53b

Bakrie Astm A53b

Uploaded by

Amin Danar NoviyantoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

PT. Bakrie Pipe Industries is a pioneer of steel

pipe manufacturing with established network

in line with Indonesia's development.

Supported by approximately 600 employees,

mostly spearheading the _ technical

department across the processing plant and

in the field.

Experienced in production process for more

than half a decade with a systematic delivery

process from the start of production process

with high efficiency and accuracy.

Commercial Office :

Bakrie Tower, 7* Floor

Rastina Epicentrum

JLHLR. Rasuna Said

Jakarta Selatan 12940, Indonesia

Telephone : (62-21) 527 7035, 2994 1270

Facsimile : (62-21) 522 5055, 2994 1266 - 69

Email: commercial@e-bakrie.com

GENERAL PURPOSE PIPES

Steel Pipe Mill:

JI, Raya Pejuang, Medan Satria

Kota Bekasi 17131 - Indonesia

Telephone: (62-21) 887 1135

Facsimile: (62-21) 8897 6606, 8897 6705

Website : www.-bakrie.com

ikrie Pipe

Industries

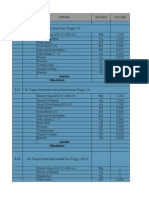

Specification

inch

2

3/4

1/4

v2

212

10

Outside Diameter

inch

0.840)

1.050

1315

1.660

1.900

2375

2875

3.500

mm

213

267

334

42.2.

483

603

730

889

STEEL LINE PIPE

PSV Ce ny

40

40)

Weight

It

085

1.13

1.68

227

272

3.66

5.80

asi

558

666

758

585

7.24

794

867

930

10.02

1080

1136

1267

9.02

10.80

1251

1463

1294

1391

15.00)

17.04

1899

21.06

23.10

25.05

1696

18.28

19.68

2238

2472

27.73

2858

3045

33.07

3567

38.33

43.43

21.23

22.89

2465

28.06

31.23

3427

3827

4052

48.28

5479

2723

2934

3341

37.46

aa8

4381

45.62

4961

5357

57.65

65.48

73.22

kgm

127

169

250

339

405

544

863

672

829

992

11,29

871

10,78

11,85

1291

13,89

1491

1607

16,90

18,87

1341

16,09

18.61

2077

1927

20,76

2231

2536

2826

3132

3439

37,28

2526

27,22

2928

3331

3631

41,24

4255

45,34

49,20

53,08

57.08

64,64

31,62

3408

3667

41,75

46,49)

51,01

5696

60,29

7,87

8152

4055

43/63

49,71

55,75

6169

65,18

67,90

7378

79170

85,82

9743

108,92

si

700

700

700

1300

1300

2500

2500

1500

1870

2260

2500

1170

1460

1610

1750

1900

2040

210

2330

2620

1180

1420

1650

1950

1190)

1290

1390

1580

1780

1980

2180)

2380

920.

1000

1070

1220

1350

1520

1570

1680

1830

2000

2130

2430

730

800

1860

980

1090

1200

1340

1430

1710

1950

670

n0

820

930

1030

1090

1130

1240

1340

1440

1650

1850

kgflem2

49

49

49

an

a1

176

176

105

331

159)

176

82

103

13

123

134

143

155

164

184

33

100

ne

137

91

98

i

125

139

153

167

65

70

75

95

107

no

118

129

141

150

m1

51

56

60

69

7

84

94

101

120

137

a7

51

58

65

n

7

79

87

94

101

116

130

172

172

103

129

156

172

81

101

am

321

131

141

152

161

181

ay

98

4

134

82

89

96

109

123

137

150

164

68

69

74

93

105

108

116

126

138

147

168

50

55

59

75

3

92

na

134

46

50

57

64

n

75

78

85

92

99

4

128

SS SS

XS VCEE SY

Specification

ees

Cr TS

Thickness a i

inch ‘mm

14000 3556

952 STD 30

16000 406.4

18000. 457,2

952 STD

20000 5080

24000 609.6

‘Chemical Composition (96 max):

ASTIMAS3 Carbon Manganese Phosporus Sulfur Copper Nickel Chromium Molybdenum

Grades 030120 005" 0085 040. 040 O40

‘Mechanical Properties :

‘Yield Strength (min) Tensile Strength (in)

GradeB 35000 psi(240MPa) 600000 psi 415 MPa)

Galvanized:

Zine Coating Weight: 550 grrm2 (77 ym) rinienurn

Marking

10071

108,49

115/86

12330

13800

15294

70560

79,24

8775

96,66

105,10

eer)

psi

630

660

750

840

940)

1030

1120

1220

1310

1410

1500

1690

570.

660

740)

820

900)

980

1070

1150

1230

1310

1480

1640

580

660

730

+800

‘880

950

1020

4090

1170

1310

1460

520

590

660

720

730.

850

920

950

1050

1180

1310

440)

490

550

600

660

710

70

820

880

980,

1080

(cd

kgtfema

44

46

33

59

66

R

73

86

92

99

105

119

40

46

52

58

8

69

75

al

86

92

104

5

4

46

51

56

2

o7

R

7

a2

92

103

37

41

46

51

56

60

65

7

74

83

92

31

34

39

a2

46

50

54

58

62

69

7

ASTM AS3-A/E 4°STD SCH40 6000 mm

HEATNO

bar

3

45

52

58

65

n

7

84

90,

97

103

W7

39

45

51

57

62

“68

4

79

85

90

102

113

40

45

50

55

61

66

70

75

al

90

101

36

41

45

50

54

59

63

R

al

30

34

38

41

46

49

53

57

61

68

5

Vanadium CusNi+CH+MoW

08 "100

sakrie Pipe

Industries

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Perbedaan ASD Dan LRFDDocument2 pagesPerbedaan ASD Dan LRFDDony Doanx100% (5)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Ahs SniDocument178 pagesAhs SniDony DoanxNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Brosur A3 BBP 2022Document2 pagesBrosur A3 BBP 2022Dony DoanxNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDony DoanxNo ratings yet

- Studi Geser Friksi Sambungan Tiang Pancang Spun Pile Dengan Pile CapDocument2 pagesStudi Geser Friksi Sambungan Tiang Pancang Spun Pile Dengan Pile CapDony DoanxNo ratings yet