Professional Documents

Culture Documents

Attachemnt 6160

Uploaded by

ponyot aOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachemnt 6160

Uploaded by

ponyot aCopyright:

Available Formats

Practice 000 250 2040

This copy is intended for use solely with Date 11Feb00

Piping Design Layout Training.

For other purposes, refer to the original document Page 2 of 5

available through Knowledge Online.

PLANT ARRANGEMENT - TYPICAL UNIT PLOT ARRANGEMENT

Stacking two or more vertical vessels shall be investigated. This investigation shall

consider the process conditions (commodities, temperatures, pressures), vertical

height limitations, and piping layout for economic advantages. The stacking of

vessels requires the acceptance of Process and Vessel engineering.

Horizontal

Vessels

Horizontal vessels (A2) will have the head of the largest vessel line up with the

aisleway reference line. All other horizontal vessels in the same vicinity will have a

common tangent line coordinate with the largest vessel. It may be economical for

adjacent vessels to share a common saddle coordinate to utilize a common

foundation.

The minimum elevation from grade is usually shown on the P&ID if it is critical for

process reasons. If no elevation is expressed and minimum is required, care should

be taken to allow adequate clearance for piping.

Exchangers

Shell and tube heat exchangers (A3.1) will be lined up with their channel heads away

from the pipeways, so that tube withdrawal is toward the outside of the unit.

The shell heads will be lined up so that the largest head is in line with the aisleway

reference line. All other exchangers are to be lined up to have a common channel

nozzle coordinate. It may be economical for adjacent exchangers to share a common

saddle coordinate to utilize a common foundation.

"G"- fin or fin tube type exchangers will be located (A3.2) with the centerline of the

shell nozzles lined up and located such that all piping remains clear of the aisleway

reference line.

Horizontal reboilers (A3.3) will preferably be located next to the equipment they

service.

Pumps

Locate pumps close to the equipment from which they take suction (A4.1). Pumps

handling flammable products are not to be located under pipeways carrying major

product lines, air coolers, or vessels. Pumps handling non-flammable products may

be located under pipeways and air cooled exchangers.

Pumps located between pipeways and equipment row should be located to avoid

being hazardous to pipeway and equipment. Industrial Risk Insurers IM.2.5.2 (IRI)

indicates the minimum distance to be 10 feet clear (A4.2); this distance should be

verified by the clients requirements.

Layout pump suctions and discharges on common centerlines, allowing the use of

common pipe supports (A4.3).

Aircoolers

Aircoolers will normally be located above the pipeways (A5).

/0002502040.doc Piping Engineering

You might also like

- No No NanetteDocument110 pagesNo No NanetteFrank Raso100% (4)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Piping Layout UDLDocument24 pagesPiping Layout UDLLegend Anbu100% (1)

- Design PipelineDocument9 pagesDesign Pipelineengr_asad364No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Capstone Project FileDocument48 pagesCapstone Project FileParveen KumarNo ratings yet

- BreathControl PDFDocument11 pagesBreathControl PDFClaudio Andrés Mendez CerdaNo ratings yet

- PVE Piping Layout Presentation - Part 2Document117 pagesPVE Piping Layout Presentation - Part 2Nguyen Quang NghiaNo ratings yet

- Pipe Rack PipingDocument28 pagesPipe Rack Pipingardikurniawan100% (2)

- Air Cooled Heat ExchangerDocument15 pagesAir Cooled Heat Exchangerros56No ratings yet

- BASF Engineered Pipe Support CatalogueDocument108 pagesBASF Engineered Pipe Support CatalogueHITESH100% (1)

- 2-Plant Layout - Pipeway DesignDocument25 pages2-Plant Layout - Pipeway DesignLaxmikant Sawleshwarkar100% (1)

- Pipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuideDocument8 pagesPipe Ways Steel Structures in Industry: 10.3.4 Pipe-Rack Elevation 5.4.1 Pipe Rack Design GuidesinisacarNo ratings yet

- Column Piping Study Layout NoDocument21 pagesColumn Piping Study Layout NoTAMIZHKARTHIKNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Bicon Surgical ManualDocument24 pagesBicon Surgical ManualBicon Implant InaNo ratings yet

- Pipe Routing InstructionsDocument37 pagesPipe Routing InstructionsDANLIN ENGINEERS100% (1)

- DBR For PipingDocument50 pagesDBR For Pipingrajachem100% (1)

- PVE Piping Layout Presentation - Part 1Document68 pagesPVE Piping Layout Presentation - Part 1Nguyen Quang NghiaNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pipe RackDocument20 pagesPipe RackKehinde AdebayoNo ratings yet

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- Pipe RackDocument25 pagesPipe RackVernie SorianoNo ratings yet

- Functional Biology NOTESDocument113 pagesFunctional Biology NOTESRebecca Amy JennerNo ratings yet

- Basic Engineering SpecificationDocument16 pagesBasic Engineering SpecificationOvaisNo ratings yet

- Column Piping - Study Layout, Nozzle Orientation & Platforms RequirementsDocument37 pagesColumn Piping - Study Layout, Nozzle Orientation & Platforms RequirementsvasuNo ratings yet

- Pipe Rack 1Document17 pagesPipe Rack 1bipin_pmkNo ratings yet

- EGE16B22Document21 pagesEGE16B22Jhonny Rafael Blanco CauraNo ratings yet

- Air Cooled Heat ExchangerDocument24 pagesAir Cooled Heat Exchangeriaft100% (2)

- Pig Trap Design and Assessment ConsiderationsDocument4 pagesPig Trap Design and Assessment Considerationsjemfus10No ratings yet

- Layouts FOR Oil and Gas InstallationsDocument21 pagesLayouts FOR Oil and Gas Installationsashishntpc1309No ratings yet

- Section II Equipment Piping and Assembly ApplicationsDocument47 pagesSection II Equipment Piping and Assembly ApplicationsAndy ChongNo ratings yet

- Piping Design Guide: Reliance Engineering Associates Private LimitedDocument6 pagesPiping Design Guide: Reliance Engineering Associates Private Limitedrishit_aNo ratings yet

- Ryan Ronquillo ComplaintDocument39 pagesRyan Ronquillo ComplaintMichael_Lee_RobertsNo ratings yet

- General Guidelines For Equipment and Piping Location, Spacing, Distances and ClearancesDocument6 pagesGeneral Guidelines For Equipment and Piping Location, Spacing, Distances and Clearanceskomail0% (1)

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocument21 pagesChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNo ratings yet

- S. No Name and Address Form 25 Dated Validupto Form 28 Dated Validupto 1 List of Pharmaceuticals Manufacturing CompaniesDocument58 pagesS. No Name and Address Form 25 Dated Validupto Form 28 Dated Validupto 1 List of Pharmaceuticals Manufacturing CompaniesCampaign Media0% (1)

- Capacity Enhancement Technique in GSM VAMOSDocument8 pagesCapacity Enhancement Technique in GSM VAMOSRadhey S SardaNo ratings yet

- Sec 06 - Process VesselsDocument4 pagesSec 06 - Process VesselseujualNo ratings yet

- 764 15.dynamic Analysis of Pipe Rack System Subjected To 858585Document9 pages764 15.dynamic Analysis of Pipe Rack System Subjected To 858585pankaj645924No ratings yet

- Pipeline Inspection: Pipe RackDocument4 pagesPipeline Inspection: Pipe RackAnushi DahariaNo ratings yet

- WI-P-004 - Rev - Equipment LayoutDocument25 pagesWI-P-004 - Rev - Equipment Layoutvishal bhamreNo ratings yet

- Air Valves GuideDocument2 pagesAir Valves GuideMussa ElbarraniNo ratings yet

- 1.Chiều dài ống gió mềm-SMACNA 1995Document4 pages1.Chiều dài ống gió mềm-SMACNA 1995Long MaiNo ratings yet

- WI-P-001 - Rev 1 - Equipment LayoutDocument26 pagesWI-P-001 - Rev 1 - Equipment Layoutvishal bhamreNo ratings yet

- Hvac Checklist: Project InformationDocument6 pagesHvac Checklist: Project InformationCraig MubaiwaNo ratings yet

- Venturi Style Air Movers Desplazadores de Aire Venturi Appareils Aérauliques de Type VenturiDocument8 pagesVenturi Style Air Movers Desplazadores de Aire Venturi Appareils Aérauliques de Type VenturiALEXNo ratings yet

- Importance of Low Point DrainDocument10 pagesImportance of Low Point Drainpesuk100% (1)

- Plant 1Document6 pagesPlant 1Janardhana PaiNo ratings yet

- 1083ch1 7Document8 pages1083ch1 7José GarciaNo ratings yet

- Optimization of Piping Expansion Loop in Process Plant: January 2015Document6 pagesOptimization of Piping Expansion Loop in Process Plant: January 2015Roberto Montano RuizNo ratings yet

- BN-DS-C49 Typical Air Fin Cooler Piping and DataDocument5 pagesBN-DS-C49 Typical Air Fin Cooler Piping and DataENG_JUVENo ratings yet

- KLM TechnologyDocument12 pagesKLM TechnologyBari Ipung GunturNo ratings yet

- Piping Design Guide: Reliance Engineering Associates Private LimitedDocument6 pagesPiping Design Guide: Reliance Engineering Associates Private Limitedrishit_aNo ratings yet

- Amarinth Plan 53B Scalable, Configurable Automatic Top Up Units Delivered On Short Lead-TimesDocument4 pagesAmarinth Plan 53B Scalable, Configurable Automatic Top Up Units Delivered On Short Lead-TimesMdp DhandapaniNo ratings yet

- HEI Typ Specs For Steam Surface Condensers Data SheetDocument5 pagesHEI Typ Specs For Steam Surface Condensers Data Sheetraden_aditiya39No ratings yet

- Development of Advanced Compressor Airfoils For Heavy-Duty Gas Turbines Part I: Design and OptimizationDocument10 pagesDevelopment of Advanced Compressor Airfoils For Heavy-Duty Gas Turbines Part I: Design and OptimizationermkermkNo ratings yet

- An Experimental Investigation On The Aerodynamic Characteristics of NACA 4412 With WingletsDocument10 pagesAn Experimental Investigation On The Aerodynamic Characteristics of NACA 4412 With Wingletsyewise4645No ratings yet

- Saravel Air Hanling UnitDocument92 pagesSaravel Air Hanling UnitClaire ApapNo ratings yet

- Pipe Rack / Ways & Rack Piping: Akshaya SharmaDocument23 pagesPipe Rack / Ways & Rack Piping: Akshaya SharmaWahyu IrwansyahNo ratings yet

- Piping Design Group Technical Training Flexibility in Piping Design Doc. No. IND-TM-L-008 Rev.0 Date: Aug. 25, 2008Document22 pagesPiping Design Group Technical Training Flexibility in Piping Design Doc. No. IND-TM-L-008 Rev.0 Date: Aug. 25, 2008Christopher BrownNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFAmjadali ChoudhariNo ratings yet

- AE03Document5 pagesAE03jawadalurdaniNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Attachemnt 690Document1 pageAttachemnt 690ponyot aNo ratings yet

- Attachemnt 684Document1 pageAttachemnt 684ponyot aNo ratings yet

- Attachemnt 692Document1 pageAttachemnt 692ponyot aNo ratings yet

- Attachemnt 674Document1 pageAttachemnt 674ponyot aNo ratings yet

- Attachemnt 680Document1 pageAttachemnt 680ponyot aNo ratings yet

- Attachemnt 663Document1 pageAttachemnt 663ponyot aNo ratings yet

- Export Demo History 23654024 1632225497Document4 pagesExport Demo History 23654024 1632225497ponyot aNo ratings yet

- Determination of Trace Element Contents of Baby Foods From TurkeyDocument6 pagesDetermination of Trace Element Contents of Baby Foods From TurkeyYel LieNo ratings yet

- Served POsDocument21 pagesServed POsYay DumaliNo ratings yet

- Imagining Persons Robert Duncans Lectures On Charles Olson (Robert Duncan) (Z-Library)Document265 pagesImagining Persons Robert Duncans Lectures On Charles Olson (Robert Duncan) (Z-Library)markNo ratings yet

- Supplemental Type Certificate: N UmberDocument2 pagesSupplemental Type Certificate: N UmberJuan C BalderasNo ratings yet

- Ursina CollisionDocument3 pagesUrsina CollisionGilniro JúniorNo ratings yet

- Numerical ReasoningDocument10 pagesNumerical ReasoningJen LeonardoNo ratings yet

- 2 Megabit (256 K X 8-Bit) CMOS EPROM: Distinctive CharacteristicsDocument12 pages2 Megabit (256 K X 8-Bit) CMOS EPROM: Distinctive CharacteristicsVictor TruccoNo ratings yet

- Service Manual: LCI-100/200 Illumination and Imaging SystemDocument69 pagesService Manual: LCI-100/200 Illumination and Imaging SystemfugarisaNo ratings yet

- Nursing Care Plan: Clustered Cues Nursing Diagnosis Rationale Outcome Criteria Nursing Interventions Rationale EvaluationDocument2 pagesNursing Care Plan: Clustered Cues Nursing Diagnosis Rationale Outcome Criteria Nursing Interventions Rationale EvaluationCLEMENT, EUGENE CHADNo ratings yet

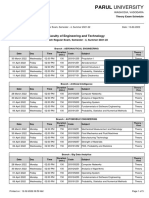

- Parul University: Faculty of Engineering and TechnologyDocument5 pagesParul University: Faculty of Engineering and TechnologySudhanshu SinghNo ratings yet

- 02 - Catalogue - ENDocument27 pages02 - Catalogue - ENAlejandro SiavisnomNo ratings yet

- CV Fire Catalog PDFDocument112 pagesCV Fire Catalog PDFArul SankaranNo ratings yet

- Martin Gwapo JheroDocument8 pagesMartin Gwapo Jherokent baboys19No ratings yet

- Sithkop005 AnswersDocument46 pagesSithkop005 AnswersSid SharmaNo ratings yet

- Active Vision-Based Attention Monitoring System FoDocument19 pagesActive Vision-Based Attention Monitoring System FoZaima Sartaj TaheriNo ratings yet

- Learning Guide-34: Participate in Rehabilitationand Restoration of Degraded AreasDocument50 pagesLearning Guide-34: Participate in Rehabilitationand Restoration of Degraded AreasRafez JoneNo ratings yet

- OriginalDocument19 pagesOriginalGoma SelvaraniNo ratings yet

- Simple Clean Minimalist Ancient Egypt History Class Presentation A4 Lands - 20231116 - 143549 - 0000Document9 pagesSimple Clean Minimalist Ancient Egypt History Class Presentation A4 Lands - 20231116 - 143549 - 0000carlajanebaribaraleriaNo ratings yet

- Lecture 7 Rock ExcavationDocument24 pagesLecture 7 Rock ExcavationMoiz Ahmed KapadiaNo ratings yet

- FILE - 20211123 - 141203 - de Thi Mau Tieng AnhDocument17 pagesFILE - 20211123 - 141203 - de Thi Mau Tieng AnhDo Le Quoc LapNo ratings yet

- How Clean' Must A Cavity Be Before Restoration?: E.A.M. KiddDocument2 pagesHow Clean' Must A Cavity Be Before Restoration?: E.A.M. KiddABNo ratings yet

- Chinese Worksheet SuppliDocument19 pagesChinese Worksheet SuppliEliza LimNo ratings yet