Professional Documents

Culture Documents

Astm G109 - 07

Uploaded by

Elizabete NakanishiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm G109 - 07

Uploaded by

Elizabete NakanishiCopyright:

Available Formats

Designation: G 109 – 07

Standard Test Method for

Determining Effects of Chemical Admixtures on Corrosion

of Embedded Steel Reinforcement in Concrete Exposed to

Chloride Environments1

This standard is issued under the fixed designation G 109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 876 Test Method for Half-Cell Potentials of Uncoated

1.1 This test method covers a procedure for determining the Reinforcing Steel in Concrete

effects of chemical admixtures on the corrosion of metals in C 881/C 881M Specification for Epoxy-Resin-Base Bond-

concrete. This test method can be used to evaluate materials ing Systems for Concrete

intended to inhibit chloride-induced corrosion of steel in C 1152/C 1152M Test Method for Acid-Soluble Chloride in

concrete. It can also be used to evaluate the corrosivity of Mortar and Concrete

admixtures in a chloride environment. D 448 Classification for Sizes of Aggregate for Road and

1.2 The values stated in SI units are to be regarded as the Bridge Construction

standard. The values given in parentheses are for information D 632 Specification for Sodium Chloride

only. E 177 Practice for Use of the Terms Precision and Bias in

1.3 This standard does not purport to address all of the ASTM Test Methods

safety concerns, if any, associated with its use. It is the E 691 Practice for Conducting an Interlaboratory Study to

responsibility of the user of this standard to establish appro- Determine the Precision of a Test Method

priate safety and health practices and determine the applica- G 3 Practice for Conventions Applicable to Electrochemical

bility of regulatory limitations prior to use. Measurements in Corrosion Testing

G 15 Terminology Relating to Corrosion and Corrosion

2. Referenced Documents Testing

2.1 ASTM Standards: 2 G 33 Practice for Recording Data from Atmospheric Cor-

A 615/A 615M Specification for Deformed and Plain rosion Tests of Metallic-Coated Steel Specimens

Carbon-Steel Bars for Concrete Reinforcement G 46 Guide for Examination and Evaluation of Pitting

C 33 Specification for Concrete Aggregates Corrosion

C 143/C 143M Test Method for Slump of Hydraulic- 2.2 NACE Standards:3

Cement Concrete SSPC-SP 5/NACE No. 1 White Metal Blast Cleaning

C 150 Specification for Portland Cement

3. Significance and Use

C 173/C 173M Test Method for Air Content of Freshly

Mixed Concrete by the Volumetric Method 3.1 This test method provides a reliable means for predict-

C 192/C 192M Practice for Making and Curing Concrete ing the inhibiting or corrosive properties of admixtures to be

Test Specimens in the Laboratory used in concrete.

C 231 Test Method for Air Content of Freshly Mixed 3.2 This test method is useful for development studies of

Concrete by the Pressure Method corrosion inhibitors to be used in concrete.

C 511 Specification for Mixing Rooms, Moist Cabinets, 3.3 This test method has been used elsewhere with good

Moist Rooms, and Water Storage Tanks Used in the agreement between corrosion as measured by this test method

Testing of Hydraulic Cements and Concretes and corrosion damage on the embedded steel (1-4).4 This test

method might not properly rank the performance of different

corrosion inhibitors, especially at concrete covers over the steel

1

This test method is under the jurisdiction of ASTM Committee G01 on less than 40 mm (1.5 in.) or water-to-cement ratios above 0.45.

Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on The concrete mixture proportions and cover over the steel are

Corrosion of Metals in Construction Materials.

Current edition approved Nov. 1, 2007. Published December 2007. Originally

approved in 1992. Last previous edition approved in 2005 as G 109–99a(2005).

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from The Society for Protective Coatings (SSPC), 40 24th St., 6th

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Floor, Pittsburgh, PA 15222-4656.

4

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

G 109 – 07

chosen to accelerate chloride ingress. Some inhibitors might

have an effect on this process, which could lead to results that

would differ from what would be expected in actual use (5).

4. Apparatus

4.1 The apparatus required for the evaluation of corrosion

inhibitors includes a high impedance voltmeter (at least one

Mohm) capable of measuring to 0.01 mV, a 100 V (65 %)

resistor.

5. Reagents and Materials

5.1 Cement, that conforms to Type I or Type II of Specifi-

cation C 150. Coarse aggregate shall conform to Specification

C 33 and Classification D 448, with nominal maximum size

between 9.5 and 19 mm (3⁄8 and 3⁄4 in.).

NOTE 1—Preferred maximum size aggregate is 12.5 mm (0.5 in.).

5.2 Steel Reinforcement Bars, deformed, meeting the re-

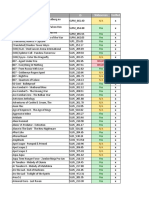

quirement of Specification A 615/A 615M; with a diameter NOTE—All measurements in inches (25.4 mm = 1 in.).

FIG. 1 Concrete Beam

between 10 mm (0.4 in.) and 16 mm (0.6 in.), and a length of

360 mm (14 in.), drilled and tapped at one end to be fitted with

coarse-thread stainless steel and nuts, as described in 5.3 and

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

5.4. These bars shall be used to manufacture the test specimens, 5.13 Silicone Caulk, for sealing the outside of the plastic

as described in Section 6. dam to the top of the concrete specimen.6,9

5.14 Reference Electrode, such as a saturated calomel or

NOTE 2—Interlaboratory test program and statistical data in Section 11 silver/silver chloride electrode for measuring the corrosion

are based upon 13-mm (0.5-in.) steel bars, 12.5-mm maximum size

potential of the bars, as defined in Terminology G 15.

aggregate, and 19-mm (0.75-in.) and 25-mm (1 in.) cover.

5.15 Hexane.

5.3 316 Stainless Steel Screws, with diameter smaller than

bar diameter (coarse thread < 5 mm (0.2 in.)), 25 to 35-mm (1 6. Preparation of Test Specimens

to 1.5-in.) long (one per bar).

6.1 Power wire brush or sand blast the bars to near white

5.4 316 Stainless Steel Nuts, two per bar to fit stainless steel

metal (see SSPC-SP 5/NACE No. 1), clean by soaking in

screws, as described in 5.3.

hexane, and allow to air dry.

5.5 Two-part Waterproof Epoxy5,6—This epoxy shall meet

the chemical resistance requirements of a Type IV, Grade 3, NOTE 3—Pickling the bars with 10 % sulfuric acid for 10 to 15 min and

Class E of Specification C 881/C 881M. rinsing with potable water prior to wire brushing is recommended when

5.6 Sulfuric Acid, 10 % by mass, for pickling (optional). the bars have an excessive amount of rust.

5.7 Electroplater’s Tape.6,7 6.2 Use the same method to clean all bars in the test

5.8 Neoprene Tubing, with 3-mm (1⁄8-in.) wall thickness and program.

the same ID as the diameter of the bar used. 6.3 Drill and tap one end of each bar, attach a stainless steel

5.9 Sodium Chloride, complying with Specification D 632. screw and two nuts, as described in 5.3 and 5.4, and tape each

5.10 Salt Solution, prepared by dissolving 3 parts of sodium end of the bar with electroplater’s tape so that a 200-mm (8-in.)

chloride (as described in 5.9) in 97 parts of water mass. portion in the middle of the bar is bare. Place a 90-mm (3.5 in.)

5.11 Epoxy Sealer, for application to the concrete specimens length of neoprene tubing, as described in 5.8, over the

after manufacture. This sealer shall be of Type III, Grade 1, electroplater’s tape at each end of the bar, and fill the length of

Class C in accordance with Specification C 881/C 881M.6,8 tubing protruding from the bar ends with the two-part epoxy, as

5.12 Plastic Dams, 75-mm (3-in.) wide and 150-mm (6-in.) described in 5.5.

long with a minimum height of 75 mm (3 in.) for placement on 6.4 Specimen size is 280 3 150 3 115 mm (11 3 6 3

the test specimens. The wall thickness shall be 61 mm (1⁄8 6 4.5 in.). Place two bars, as described in 5.2, 25 mm (1 in.) from

1⁄32 in. the bottom, and one bar at the top such that the distance from

its top to the top surface of the specimen is twice the maximum

5

aggregate size, as shown in Fig. 1.

The sole source of supply of the apparatus known to the committee at this time

is PC-Epoxy, made by Protective Coating Co., Allentown, PA. NOTE 4—For example, for a 12.5-mm (0.5 in.) aggregate, place the top

6

If you are aware of alternative suppliers, please provide this information to bar 25 mm (1 in.) from the surface. For a 9.5-mm (0.375-in.) aggregate,

ASTM International Headquarters. Your comments will receive careful consider- place the bar 19 mm (0.75 in.) from the top surface.

ation at a meeting of the responsible technical committee,1 which you may attend.

7

The sole source of supply of the apparatus known to the committee at this time

is Minnesota Mining and Manufacturing Company (3M), 1999 Mt. Read Boulevard,

Rochester, NY 14615.

8 9

The sole source of supply of the apparatus known to the committee at this time The sole source of supply of the apparatus known to the committee at this time

is Epoxy Concrete Scaler # 12560, made by Devcon. is 3M Marine Adhesive 5200.

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

G 109 – 07

6.5 Place the bars in the molds so that 40 mm (approxi-

mately 1.5 in.) of the bars are protected within each exit end

from the concrete (minimizes edge effects). This will expose

200 mm (8 in.) of steel. Place the bars with the longitudinal ribs

so that they are nearer the side of the beam, that is, both ridges

are equidistant from the top or bottom of the specimen.

6.6 Make the concrete specimens (controls and those with

admixtures to be tested) in accordance with Practice C 192/

C 192M, using the same source of materials. Determine the air

content, using either Test Method C 231 or C 173/C 173M. The

water-to-cement ratio (w/c) shall not exceed 0.5. The minimum

slump is 50 mm (2 in.) (See Test Method C 143/C 143M).

Place and consolidate the concrete in the molds containing the

bars in accordance with Practice C 192/C 192M.

NOTE 5—The concrete parameters used in the interlaboratory test were

as follows: cement content of 355 6 3 kg/m3 (600 6 5 lb/yd3), 0.50 6

0.01 w/c (ssd aggregates), and 6 6 1 % air.

6.7 Add the admixture to be tested at the manufacturer’s

recommended dosages. A water reducer is allowed, if needed, NOTE—All measurements in inches (not to scale) (25.4 mm = 1 in.).

to achieve the desired slump. Record the admixtures used. FIG. 2 Concrete Beam (Side View)

Except for the test admixtures, use the same admixtures in all

mixtures. a depth of 40 mm (1.5 in.). Use a plastic loose fitting cover to

6.8 A minimum of three replicates shall be made. Make the minimize evaporation. Maintain a relative humidity around the

same number of replicates per admixture tested and control specimens of 50 6 5 %. After two weeks, vacuum off the

(see Note 6). An addition cylinder 100 3 200 mm (4 3 8 in.) solution and allow the samples to dry for two weeks. Repeat

in diameter shall be produced for background chloride analy- this cycle.

sis. 7.2 Measure the voltage across the resistor at the beginning

of the second week of ponding using the voltmeter defined in

NOTE 6—A larger number of replicates is preferred. 4.1. Calculate the current, Ij, from the measured voltage across

6.9 Apply a wood float finish after consolidation. After the 100 V resistor, Vj, measured in volts (see Note 8) as:

removal from the forms, cure the specimens for 28 days in a Ij 5 Vj /100

moist room in accordance with Test Method C 192/C 192M

NOTE 8—With the common terminal on the bottom bar, negative

and Specification C 511.

voltages correspond to positive galvanic current (that is, the top bar is the

6.10 Upon removal from the moist room, hand wire brush anode).

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

the specimens on the concrete top surface (wood floated

surface). Allow the specimens to dry for two weeks in a 50 % 7.3 At the same time, measure the corrosion potential of the

relative humidity (RH) environment before sealing the four bars against a reference electrode that is placed in the dam

vertical sides with an epoxy sealer, as described in 5.11, in containing the salt solution (see Practice G 3 and Test Method

accordance with the manufacturer’s recommendation. Place a C 876). Connect the voltmeter between the reference electrode

plastic dam with dimensions, as described in 5.12, on the (ground or common terminal) and the bars.

specimen, as shown in Fig. 1, and about 13 mm (0.5 in.) from 8. Period of Testing

each side so that it does not extend over the taped sections of

8.1 Monitor the current as a function of time once every

the bars (see Fig. 2). Use a silicone caulk to seal the dam from

four weeks, as described in 7.2, until the average integrated

the outside, and apply epoxy sealer to the top surface outside of

macrocell current of the control specimens is 150 C or greater,

the dam.

as determined in 10.1.8, and at least half the samples show

NOTE 7—Allowing the specimens to dry before applying the concrete integrated macrocell currents equal to or greater than 150 C

epoxy will make the initial exposure to chloride more severe, and more (see Note 9).

closely follow the interlaboratory test program conditions.

NOTE 9—The value of 150 C is consistent with a macrocell current of

6.11 Attach wires and resistors. 10 µA over six months. The value of 10 µA was measured by all

laboratories on all specimens showing corrosion (controls and samples

7. Procedure with calcium chloride at 19-mm (3⁄4-in.) cover). This degree of integrated

7.1 Support each test specimen on two nonelectrically macrocell current is sufficient to ensure the presence of sufficient

conducting supports at least 13-mm (0.5-in.) thick, thus allow- corrosion for visual evaluation.

ing air flow under most of the specimen. Start the test one 8.2 In those cases where the admixtures being tested are

month after the samples are removed from the 100 % RH corrosive, end the test three full cycles after an average

atmosphere (moist room). Pond the specimens for two weeks at integrated macrocell current of 75 C is observed and the

23 6 3°C (73 6 5°F) with the salt solution, as described in integrated macrocell current of at least half the specimens

5.10. The volume of this solution is approximately 400 mL at being tested is equal or greater than 75 C.

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

G 109 – 07

9. Examination of Embedded Bars

9.1 At the conclusion of testing, break the specimens and

examine the reinforcement bars for extent of corrosion, mea-

sure the corroded area, and record the percentage of corroded

area recorded, as described in Practice G 33.

NOTE 10—Photograph the bars at the end of the test to provide a record

of the corrosion damage.

9.2 Determine the acid soluble chloride content at the depth

corresponding to the cover over the top-reinforcing bar, using

Test Method C 1152/C 1152M.

9.3 Determine the acid soluble chloride content in the

specimen produced for background chloride analysis, using

Test Method C 1152/C 1152M. This value is to be subtracted

from the acid soluble chloride, as determined in 9.2, to provide

a corrected acid soluble chloride content reflecting ingressed

FIG. 3 Standard Deviation of Repeatability

chloride.

10. Report participated in the study. The repeatability and reproducibility

10.1 Report the following information: of the test results were dependent on the magnitude of the mean

10.1.1 Full details of the concrete proportions, air content, macrocell current.

and slump of the concrete used in the control and test 11.2 Precision is as follows:

specimens, 11.2.1 95 % Repeatability Limit (Within Laboratory)—The

10.1.2 A plot of the corrosion current and potential for each within-laboratory precision of the average macrocell current

concrete specimen versus time, (for each laboratory), as expressed by the repeatability limit, r,

10.1.3 A plot of the average integrated current for each is given by the following relation:

condition of concrete versus time, log r 5 0.931 log Iavg 1 0.441 (1)

10.1.4 Time to failure, as considered to be the time for the

11.2.2 95 % Reproducibility Limit (Between

average macrocell current to reach 10 µA and at least half the

Laboratories)—The between-laboratory precision of the aver-

samples showing a current greater than 10 µA,

age macrocell current (for all laboratories), as expressed by the

10.1.5 Results of the visual inspection of each bar. The

reproducibility, R, is given by the following relation:

report shall include the percentage of original exposed steel

surface corroded and optionally the number and depths of log R 5 0.833 log Iavg 1 0.624 (2)

corrosion pits where present, as described in Practice G 46, 11.2.3 The repeatability and reproducibility limits of the

10.1.6 Photographs of the bars at the end of the test average macrocell current were calculated in accordance with

(optional), and Practice E 177. The respective standard deviations of the

10.1.7 Chloride content at the top reinforcing bar depth variation among test results can be obtained by dividing by 2.8

from the surface. This value is the corrected total chloride the values of r and R calculated using (Eq 1) and (Eq 2). The

content, as corrected 9.3. following equations were then obtained:

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

10.1.8 The ratio of total integrated current of the test log Sr 5 0.931 log Iavg 2 0.006 (3)

specimen to that of the control and time the test ended. The

log S R 5 0.833 log Iavg 1 0.177 (4)

total integrated current is:

TCj 5 TC j21 1 [~tj 2 t j21! 3 ~ij 1 i j21!/2]

11.2.4 The data used for compiling the test method preci-

sion, together with the statistical parameters as defined in

where: Practice E 691, are given in the research report.10 The graphi-

TC = total corrosion (coulombs), cal representations of the repeatability and reproducibility

tj = time (seconds) at which measurement of the macro- limits are given in Figs. 3 and 4.

cell current is carried out, and 11.2.5 The time to failure has been analyzed using Practice

ij = macrocell current (amps) at time, tj. E 691. This analysis is given in the research report.10

A sample calculation is given in Appendix X1. 11.2.6 The maximum end of the 95 % confidence interval

for time to failure for control specimens with 19-mm (0.75-in.)

11. Precision and Bias 10 concrete cover is six months for both intralaboratory and

11.1 Information on the precision of the results obtained by interlaboratory tests. The maximum ends of the 95 % confi-

this test method was derived from an interlaboratory test with dence intervals are two and six months for intra- and interlabo-

two to three specimens per laboratory. Eleven laboratories ratory tests respectively for specimens containing calcium

chloride.

11.2.7 The complete data for percent area corroded is given

10

Supporting data have been filed at ASTM International Headquarters and may in the research report.10 In all cases where there was corrosion,

be obtained by requesting Research Report RR: G01–1009. the macrocell current was greater than 9 µA. However, not

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

G 109 – 07

enough laboratories reported percent area corroded to carry out

a statistical analysis following Practice E 691.

11.3 Bias—The procedure given in this test method has no

bias because the effects of chemical admixtures on the corro-

sion of embedded steel of reinforcement are defined only in

terms of this test method.

12. Keywords

12.1 admixtures; concrete; corrosion; corrosivity; inhibitor;

reinforcing steel

FIG. 4 Standard Deviation of Reproducibility

APPENDIX

(Nonmandatory Information)

X1. TOTAL CORROSION CALCULATION

X1.1 Total Corrosion Calculation: X1.1.3 At the end of the 60 day period:

TC j 5 TCj21 1 [~t j 2 tj21! * ~i j 1 ij 21!/2] (X1.1) TC2 5 25.92 1 [60 2 30! * 86400 * ~20 1 27!/2*1026# 5 86.83 C

X1.1.1 Assume the following readings were obtained over a (X1.3)

90 day period of time: X1.1.4 At the end of the 90 day period:

Days 0 30 60 90

imac (µA) 0 20 27 35 TC3 5 86.83 1 [~90 2 60! * 86400 * ~27 1 35!/2*1026# 5 167.18 C

(X1.4)

X1.1.2 At the end of the first 30 day period the total

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

corrosion is: NOTE X1.1—Conversion factor from days to seconds = 24 3 60 3 60

26

TC1 5 0 1 [~30 2 0! * 86400 * ~20 1 0 !/2 * 10 # 5 25.92 C = 86 400.

(X1.2)

REFERENCES

(1) Berke, N. S., Shen, D. F., and Sundberg, K. M., “Comparison of the Admixture or Epoxy-Coated Reinforcing Bars as Corrosion Protection

Polarization Resistance Technique to the Macrocell Corrosion Tech- Systems,” Report No. FHWA/RD-83/-12, Federal Highway Adminis-

nique,” Corrosion Rates of Steel in Concrete, ASTM STP 1065, N. S. tration, Washington DC, 1983, pp. 71.

Berke, V. Chaker, and D. Whitney, editors, ASTM, August 1990, pp. (4) Berke, N. S., Pfeifer, D. W., and Weil, T. G., “Protection Against

38–51. Chloride-Induced Corrosion,” Concrete International, December

(2) Berke, N. S. and Hicks, M. C., “Electrochemical Methods of

1988, pp. 45–55.

Determining the Corrosivity of Steel in Concrete,” Corrosion Testing

and Evaluation: Silver Anniversary Volume, Babraiam/Dean editors, (5) Berke, N. S., Hicks, M. C., Hoopes, R. J., and Tourney, P. J., “Use of

ASTM STP 1000, ASTM, November 1990, pp. 425–440. Laboratory Techniques to Evaluate Long-Term Durability of Steel

(3) Virmani, Y. P., Clear, K. C., and Pasko, T. J., “Time-to Corrosion of Reinforced Concrete Exposed to Chloride Ingress,” ACI SP 145-16,

Reinforcing Steel in Concrete Slabs, Volume 5: Calcium Nitrite 1994, pp. 299-328.

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

G 109 – 07

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International

--```,``,``,``,,,,`,,,``,,,`,`,,-`-`,,`,,`,`,,`---

6

Provided by IHS under license with ASTM Licensee=MHI - NAGOYA related to 3944000/3944000013

No reproduction or networking permitted without license from IHS Not for Resale, 01/09/2008 23:23:13 MST

You might also like

- Determining Effects of Chemical Admixtures On Corrosion of Embedded Steel Reinforcement in Concrete Exposed To Chloride EnvironmentsDocument6 pagesDetermining Effects of Chemical Admixtures On Corrosion of Embedded Steel Reinforcement in Concrete Exposed To Chloride Environmentsmohammed karasnehNo ratings yet

- G 109 - 99 - RzewoqDocument5 pagesG 109 - 99 - RzewoqAhmed Samir SalimNo ratings yet

- C1582C1582M-Aditivos Inhibidores de CorrosionDocument10 pagesC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForEdgardo Humberto GonzálezNo ratings yet

- ASTM C33 - 2007 - Standard Specification For Concrete AggregatesDocument11 pagesASTM C33 - 2007 - Standard Specification For Concrete AggregatesDayana HernandezNo ratings yet

- ASTM C192mDocument5 pagesASTM C192mRidwan baritoNo ratings yet

- C33 - 08 Standard Specification For Concrete Aggregates1Document11 pagesC33 - 08 Standard Specification For Concrete Aggregates1José AlejandroNo ratings yet

- Astm C33Document11 pagesAstm C33JAVIER NAPOLEON COLINA POZO100% (1)

- Standard Specification For Concrete AggregatesDocument12 pagesStandard Specification For Concrete AggregatesKarloDesantaNo ratings yet

- C 33 - 03 QZMZ PDFDocument11 pagesC 33 - 03 QZMZ PDFwafikmh4No ratings yet

- Astm C33Document8 pagesAstm C33Mabel SanchezNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument8 pagesConcrete Aggregates: Standard Specification ForMiguelAngelContrerasOrtizNo ratings yet

- Lightweight Aggregates For Structural ConcreteDocument4 pagesLightweight Aggregates For Structural ConcreteINARQ1979No ratings yet

- Lectura ASTM C33 PDFDocument8 pagesLectura ASTM C33 PDFDiego G AcuñaNo ratings yet

- C33 Coarse AggDocument10 pagesC33 Coarse AggDeepakNo ratings yet

- Astm c33pdfDocument8 pagesAstm c33pdfShahriar NurNo ratings yet

- C1582 PDFDocument10 pagesC1582 PDFAnuradhaPatraNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument8 pagesConcrete Aggregates: Standard Specification ForHasanalmahmudNo ratings yet

- Concrete Aggregates': Standard Specification ForDocument8 pagesConcrete Aggregates': Standard Specification ForAhmed AbidNo ratings yet

- ASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in ConcreteDocument10 pagesASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concretebenedick barquinNo ratings yet

- Making and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForDocument8 pagesMaking and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForIsabel SerracinNo ratings yet

- C 311 02 QZMXMQDocument9 pagesC 311 02 QZMXMQcfmonarquia100% (1)

- Air-Entraining Admixtures For Concrete: Standard Test Method ForDocument5 pagesAir-Entraining Admixtures For Concrete: Standard Test Method ForINARQ1979No ratings yet

- C 311 - 00 Qzmxms0wmaDocument9 pagesC 311 - 00 Qzmxms0wmaTemur LomidzeNo ratings yet

- Astm C-330-04 PDFDocument4 pagesAstm C-330-04 PDFJAlberto LópezNo ratings yet

- Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Document5 pagesPotential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Ahmed AbidNo ratings yet

- Air-Entraining Admixtures For Concrete: Standard Test Method ForDocument5 pagesAir-Entraining Admixtures For Concrete: Standard Test Method ForMaanvir SatyaNo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument7 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationJesús Luis Arce GuillermoNo ratings yet

- Making and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForDocument8 pagesMaking and Curing Concrete Test Specimens in The Laboratory: Standard Practice Forwilliam_m08No ratings yet

- Air-Entraining Admixtures For Concrete: Standard Test Method ForDocument5 pagesAir-Entraining Admixtures For Concrete: Standard Test Method ForJesús Luis Arce GuillermoNo ratings yet

- C 311 Â " 00 QZMXMS0WMEUXDocument9 pagesC 311 Â " 00 QZMXMS0WMEUXJorge CarrascoNo ratings yet

- Astm C192Document8 pagesAstm C192gustavo aguilarNo ratings yet

- C1581 PDFDocument6 pagesC1581 PDFAnthony López HuamanNo ratings yet

- Determination of Length Change of Concrete Due To Alkali-Silica ReactionDocument6 pagesDetermination of Length Change of Concrete Due To Alkali-Silica ReactionEvert RiveraNo ratings yet

- Determination of Length Change of Concrete Due To Alkali-Silica ReactionDocument7 pagesDetermination of Length Change of Concrete Due To Alkali-Silica ReactionDj TaufikNo ratings yet

- Air-Entraining Admixtures For Concrete: Standard Test Method ForDocument5 pagesAir-Entraining Admixtures For Concrete: Standard Test Method ForTemur LomidzeNo ratings yet

- Astm C 33 - 03Document11 pagesAstm C 33 - 03Laziz AtmaniNo ratings yet

- ASTM C1116 - Standard Specification For Fiber Reinforced Concrete PDFDocument7 pagesASTM C1116 - Standard Specification For Fiber Reinforced Concrete PDFibrahimNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForAnas KhallafNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForEjat ISNo ratings yet

- Fiber-Reinforced Concrete: Standard Specification ForDocument7 pagesFiber-Reinforced Concrete: Standard Specification ForNiranjan KumarNo ratings yet

- Petrographic Examination of Hardened Concrete: Standard Practice ForDocument17 pagesPetrographic Examination of Hardened Concrete: Standard Practice ForChavier ManguanaNo ratings yet

- ASME Standard For Concrete Aggreates (C 33 - 99a)Document8 pagesASME Standard For Concrete Aggreates (C 33 - 99a)Jade Al BoodoosinghNo ratings yet

- Length Change of Concrete Due To Alkali-Carbonate Rock ReactionDocument4 pagesLength Change of Concrete Due To Alkali-Carbonate Rock ReactionAntu IsabelNo ratings yet

- Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Document5 pagesPotential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)Ahmed AbidNo ratings yet

- Astm c-192 PDFDocument8 pagesAstm c-192 PDFProbo100% (2)

- Staining and Color Change of Single-Or Multicomponent Joint SealantsDocument2 pagesStaining and Color Change of Single-Or Multicomponent Joint Sealantssales.kendy1010No ratings yet

- Astm C 1260 PDFDocument5 pagesAstm C 1260 PDFSourav BasakNo ratings yet

- ASTM C33 02a Concrete AggregatesDocument11 pagesASTM C33 02a Concrete AggregatesJanice Tatiana Alva DelgadoNo ratings yet

- Astm C876-15Document8 pagesAstm C876-15rached100% (1)

- Astm C1747 C1747M 13Document2 pagesAstm C1747 C1747M 13KarnalPreethNo ratings yet

- C 1084 PDFDocument6 pagesC 1084 PDFashrafNo ratings yet

- Standard Test Method For Electrical Indication of Concrete's AbilityDocument8 pagesStandard Test Method For Electrical Indication of Concrete's AbilityKamila KhoschanovaNo ratings yet

- ASTM C876 - Standard Test Method For Corrosion Potentials of Uncoated Reinforcing Steel in Concrete PDFDocument8 pagesASTM C876 - Standard Test Method For Corrosion Potentials of Uncoated Reinforcing Steel in Concrete PDFCarolina Martínez RojasNo ratings yet

- Astm C-33 Standard Specification For Concrete AggregatesDocument14 pagesAstm C-33 Standard Specification For Concrete AggregatesFebriana PutriyaniNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- MHSS ItalyDocument9 pagesMHSS Italyromedic36No ratings yet

- Functional Materials For Sustainable Energy TechnologiesDocument15 pagesFunctional Materials For Sustainable Energy TechnologiesChristhy Vanessa Ruiz MadroñeroNo ratings yet

- 07 Endodontic RetreatmentDocument64 pages07 Endodontic RetreatmentGayathriNo ratings yet

- IES 2001 - I ScanDocument20 pagesIES 2001 - I ScanK.v.SinghNo ratings yet

- Dimensions and Methodology of Business Studies Dec 2018Document2 pagesDimensions and Methodology of Business Studies Dec 2018Nallavenaaya Unni100% (1)

- Basic Program Structure in C++: Study Guide For Module No. 2Document9 pagesBasic Program Structure in C++: Study Guide For Module No. 2Ji YoungNo ratings yet

- PCBDocument5 pagesPCBarampandey100% (4)

- Staad 4Document37 pagesStaad 4saisssms9116100% (2)

- The Aerodynamics of ParachutesDocument78 pagesThe Aerodynamics of Parachutesstevehuppert50% (2)

- 12 ĀnurũpyenaDocument7 pages12 ĀnurũpyenashuklahouseNo ratings yet

- Assignment 4Document2 pagesAssignment 4Komal SinghNo ratings yet

- Himachal Pradesh Staff Selection Commission Hamirpur - 177001Document2 pagesHimachal Pradesh Staff Selection Commission Hamirpur - 177001Verma JagdeepNo ratings yet

- 1802SupplementaryNotes FullDocument235 pages1802SupplementaryNotes FullCourtney WilliamsNo ratings yet

- Validation For A Login PageDocument2 pagesValidation For A Login PageAmal RajNo ratings yet

- 6000 Most Common Korean Words - For All TOPIK Levels PDFDocument232 pages6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- Term Test Pointers For Review - 1st TermDocument2 pagesTerm Test Pointers For Review - 1st Termjessica holgadoNo ratings yet

- SFN ProfileDocument4 pagesSFN Profiledinesh panchalNo ratings yet

- Interjections NotesDocument2 pagesInterjections NotesKanna ImuiNo ratings yet

- Case Study: Medisys Corp The Intense Care Product Development TeamDocument10 pagesCase Study: Medisys Corp The Intense Care Product Development TeamBig BNo ratings yet

- Ad 9915Document47 pagesAd 9915Jime nitaNo ratings yet

- Sap Retail Two Step PricingDocument4 pagesSap Retail Two Step PricingShams TabrezNo ratings yet

- Laser Diffraction Physics Project: Submitted By, Disha DineshDocument11 pagesLaser Diffraction Physics Project: Submitted By, Disha DineshNidaleeNo ratings yet

- 2022 Cement Lime Manufacturing Ehs Guidelines enDocument39 pages2022 Cement Lime Manufacturing Ehs Guidelines enSamiNo ratings yet

- Union Metal SemiconductorDocument4 pagesUnion Metal SemiconductorskinhugoNo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- Labour Law Assignment - Gross NegligenceDocument6 pagesLabour Law Assignment - Gross NegligenceOlaotse MoletsaneNo ratings yet

- 12.07.20. O&M Manual 41013 - New PLCDocument41 pages12.07.20. O&M Manual 41013 - New PLCFranco Sebastián GenreNo ratings yet

- Detailed Lesson Plan in Mathematics 10 I. ObjectivesDocument4 pagesDetailed Lesson Plan in Mathematics 10 I. ObjectivesLouis Fetilo FabunanNo ratings yet

- Occupational Therapy Examination Review Guide 4th Edition Ebook PDFDocument57 pagesOccupational Therapy Examination Review Guide 4th Edition Ebook PDFrobert.campbell485No ratings yet

- NeedScope On TechnologyDocument22 pagesNeedScope On TechnologyNguyen Ngo Dinh PhuongNo ratings yet