100%(3)100% found this document useful (3 votes)

2K views94 pagesCentrifugal Compressors

Uploaded by

Cv Aditya SankarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100%(3)100% found this document useful (3 votes)

2K views94 pagesCentrifugal Compressors

Uploaded by

Cv Aditya SankarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

- Compressor Selection: What to specify?: This section discusses the specifications for selecting compressors, including considerations for moisture separators, control systems, and instrumentation.

- Types of Compressors and Design/Constructional Features: Describes various types of compressors, their characteristics, and constructional details including designs and features.

- Principles of Operation of Centrifugal Compressors: Explains the operational principles of centrifugal compressors with detailed diagrams and equations.

- Seals and Sealing Systems: Covers different sealing methods for compressors, emphasizing safety and efficiency in preventing leakages.

- Quality Control Checks and Various Tests: Outlines quality assurance tests and checkpoints in compressor manufacturing to ensure high-quality standards.

- Surging and its Control: Discusses surging phenomena in compressors and control measures implemented to mitigate its effects.

- Instrumentation and Controls: Provides details on the instrumentation and control systems used in operating compressors efficiently.

- Start-Up Loading and Shut Down Procedures: Details procedures for starting up and shutting down compressors, ensuring smooth operation transitions.

- Do’s and Don’ts for Compressor Operation: Lists important operational guidelines to avoid common mistakes and ensure compressor safety.

- Tips for Effective Operation and Maintenance: Provides tips and best practices for effective operation and maintenance to ensure long-term compressor reliability.

©), REFINERY ENGINEERING

a SCHOOL OF TRAINING CENTRIFUGAL COMPRESSORS

CONTENT! H PAGE NO.

1. Compressor Selection: What to specify? 1

2. Types of compressors and Design/Construction

Features 13

3. Principles of operation of Centrifugal

5 Compressors 42

4, Seals and Sealing Systems. 56

8. Wuality Control Checks and various tests 61

6. Surge ana its control 65

7. Instrumentation and Controls 69

6. Start up loading and Shut down Procedures 16

9. Do's and Don'ts for Compressor operation 62

10. 66

Tips for effective operation and maintenance

REFINERY ENGINEERING! centrifugal

]OOL OF TRAININ ne Compressors

Selection

Moistute Separators

No compressor specification is complete without mentioning the need of mois

ture separators following intercoolers or at the inlet of compressor when liv

quids may be present in the gas stream.

If separators are not present or inadequately sized, it may lead to ingress

of liquid particles inside compressor causing high rotor vibrations, pitting and

corrosion/errosion of impellers and seals, clogged gas passages etc.

Suction Filters

Centrifugal compressors are basically gas handling units and effective removal

of foreign particles like dust, ash, tar etc. ahead of compressor will contribute

to minimum maintenance and long trouble’ free operation. Deposits of solids

inside compressor tend to restrict the flow and causesunbalance in rotor.

_Degree of filtration and type of filter, particle size and analysis of dust should

be mutually discussed to ensure machine safety and process compatability.

Excess capability

Due to peculiar drooping characteristic curve of centrifugal ‘compressor at

any speed, virtually no j+ssibility exists for increasing the discharge pressure

for “additional volume of gas over desigged value, In View of this, the compre-,

ssor miust be built with excess capability for achieving’ higher plant loads beyond

rated one. This implies that the driver also must be suitably sized over and

above the ten percent reserve specified in API Standards.

Parallel Operation “ .

In some cases additional compressors are envisaged for augmenting existing

capacity. These compressors are required to operate in parallel with existing

machines. Since no two compressors can’ have identical characteristics, -it

is quite likely that these machines will operate at different loads. In extreme

case, the desired plant load augmentation can not be achieved due to the opera-

ting point of one of the machines shifting towards surge limit. Hence following

points need careful consideration, while deciding parallel operation of compressor.

- System resistance

Un-fortiiiately, many users take it as granted that machine designers are

fully aware of variation in system resistance with plant load. It is there-

fore extremely important that all aspects of system resistance shail -be

al

i =

7 BO REFINERY ENGINEERING centrifugal

23 Compressors

4 SCHOOL OF TRAINING Selection

thoroughly discussed before recommending parallel operation.

= Characteristics of existing machines

The actual characteristics of existing machines under all operating conditions

should be furnished to enable selection of a compressor with optimum mat-

ching characteristrics,

= Control system

Generally, system resistance curve does not follow compressor characteri-

stics. This implies that’ the selection of proper control system is necessary

for successful parallel operation. Ee

Operation at off-design point

Sometimes," compresor is required to operate at conditions which are entirely

differnt {rom shose specified in the contract. This may involve operation at

different suction and discharge conditions and/or with different type of gas

resulting in lower compressor efficiency and higher operational cost. If such

off design conditions are envisaged during contract. stage, an optimum size

of unit could be selected

Third Party Inspection

It is a common practice to insist upon inspection of components during manufa-

cturing stage by an independent agency, However the scope of inspection

is unclear or not defined completely resulting in delays in execution of project

and also involving unnecessary controversies on minpr issues. It is desirable

that various stages of inspection should be clearly defined in the contract

in respect of major equipments.

Information on utilities

The availability of utilities like steam, water, electric power, power factor,

nitrogen should be clearly specified in the contract with their parameters

to enable proper selection and sizing of auxiliary equipments.

The actual quality of cooling water available at site invariably differs from

the quality of cooling water specified in contract. This affects the cooler

performance and reduces tube life. Hence correct cooling water analysis and

fouling factor should be furnished for correct material selection and sizing

of coolers, fitters etc.

Céntrigugal

Compressors

\ai/ SCHOOL OF TRAINING Selection | a

er REFINERY ENGINEERING

Noise control aie

It is generally thought that noise {s generated only by the compressor and little

care is taken in the design, sizing and layout arrangement of various other

‘equipments. 7 :

In order to reduce total noise, the various contributions must be identified

and evaluated. The ideal method for reducing noise is to prevent generation

of noise by better design such as : fe

= use of acoustic abatement in compressox hall

proper dimensioning of compressor hall, to eliminate noise due to resonance

better ventilation in compressor hall with preferably sides open atleast

upto working level.

a

“use of special low noise valves. ' cs

Isolation of background plant noise.

proper location of high noise auxiliary equipment. tay

But this may involve higher cost. Practical approach would be to try to reduce

noise level after the compressor and auxiliary equipments are installed by use

of acoustic abatement. 2 Ef

instrumentation & Controls

The objective of any compressor control is to achieve smooth capacity regualtion |:

and to prevent the compressor from surging, even though the process flow

reduces below the surge limit of compressor. In order to achieve this objective

effectively it is advisable to include complete compressor control in the scope 7

‘of machine manufacturer, who has better knowledge about the performance

characteristic of machine and correct type of instruments necessary for the

services 5 . ;

Splitting the scope of instrumentation and controls between the user and the :

vendor can cause misunderstandings due to enormous. work involved in mutual ,

discussion, approval of drawings and specifications and defining scope of ca

supply in every case. Any communication gap can lead to delays in commi- i

ssioning of units particularly when special instruments are involved which are :

not readily available. .

a

Oy REFINERY ENGINEERING Scecaeaeactae

Compressors

La/ SCHOOL OF TRAINING Selection

Electric motor for compressor drive

The Choice of electrical motor as a drive for compressor is being favoured

due to lower installation cost and where cheap and reliable electric power

supply is available. Although electric motors are considered more reliable,

following points if not properly taken care of, may cause serious problems

while running the unit.

Motor voltage

During start up motor draws high currents resulting in line voltage dip,

the magnitude of which depends upon size of electrical system. "In cases

where motor driving the compressor is the largest in the plant, voltage

dip can be 20% or more.

Since reduced applicd voltage reduces motor torque by square of applicd

voltage thé matching of motor torque under worst voltage condition to

that of compressor torque should be ensured.

It is a common practice to have a minimum of ten percent margin between

torque capability of motor and the torque required by the compressor

from zero full speed.

Compressor torque

‘Compressor torque comprises of [riction, inerti. and’ thermodynainic power.

The often neglected factor is the inertia. To ensure safe acceleration

the inertia of total train reierred to motor speed should be correctly evalua-

ted.

The starting of motor with a load inertia larger than the inertia for which

the motor was designed may cause increase in starting time and it will

be detrimental to the motor.

Sealing system

Taking into account the type of gas and process limitation, customer should

select a simple sealing system.

= Simple labyrinth sealing

This ledds to leakage of considerable amount of process gas to the opera-

ting floor. The limitation should be considered before the selection.

= ;

Pg ; ¢EFINERY ENGINEERIN¢ centrifugal

6 c

SCHOOL OF TRAINING compressors

Selection Rn

= Injection system ‘

If the process gas accepts the contamination’by the sealing gas then

this type of sealing is best advisable.

= Injection and ejection system :

With this system, a little amount of process gas is thrown to atmosphere.

Therefore customer should design his plant for this continuous leakage

of the gas. :

= Oil seals (floating seals) |

~

Seal oil system is slightly complicated to the one said above. During normal ;

operation, the sealing of process gas is achieved. owever during seal -

oil failure the trapped gas should be (evacuated) vented.

= Mechanica! Seals

In this type ‘of sealing system a continuous contact will be there between

stationery & rotating parts of. equipment. During seal oil failure these

seal seal the trapped gas. Thus loss of parent gas is kept very minimum.

However maintenance point of view these seals are very disadvantageous

’ to the operating personnel. .

Conclusion

It may be noted that customer/consultant are requested to indicate as much

as details to manufacturer during enquiry stage. As such a good specification

and enquiry will contribute the reliability of the unit as well as a reasonable :

cost. é

rin ‘REFINERY ENGINEERING

SCHOOL OF TRAINING

Data required ©

to make out

a tender ;

Listed below are tho essential

technical information needed in

each enquity, in ordor to solect the

most suitable compressor and

diive for a given duty :

1) Type of gas and its main charact-

eristics, such as molecular

weight, specific heat ratio,

compressibility factor, relative

humidity, or otherwise the

‘938 composition,

pressure is actual and

not absolute, the atmospheric

pressure to which it rofers

should also be indicated)

Temperature

ii) Temperature

4) Cooling wi

i) Temperature

ii) Prossure :

iil) - Analysis :

labl

In addition, the customer should

pacify all operating characteristics

with regard ta his equiremonts,

type of control, etc. It should also

be indicated whether the compressor

isto be installed indoors or in the

‘opon, as well as details of the ambient’

conditions.

Centrifugal

a Compressors

Selection

Selection of

Compressor type

and caiculation

of shaft power

cexample)

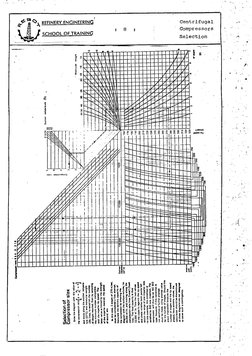

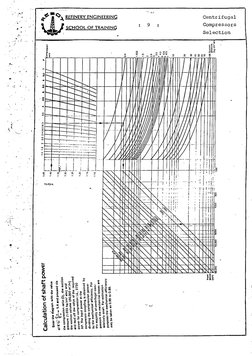

Tho following two diagrams

give an approximate method of

selecting the type of compressor

for a givon duty and calculating

its absorbed power. The resulting

date should not be taken as exact,

Bear in mind that the diagrams

are not valid for ‘isothermal’

machines, those with intercoolers

or other sppcial types.

To illustrate the practical use of

the diagrams, the following exampio

will help:

= Gas to be compressed Nitrogen

= Molecular weight 28

of specific heats 1

= Capaci 46,000m*

ihe

= ‘Suction pressure 1.033 kg]

om’ abs.

= Suction temperature 37°C

Discharge pressure 3.1 Kg/

‘om! abs.

Centrifugal

Compressors

Selection

‘azis sosssidwiop

0 YoRs325,

{QOL OF TRAINING

s

‘©, REFINERY ENGINEERING

o

é

Tree phe oaTeemery

4

2

g

3

&

g

3

€

8

Compressors

Selection

1OOL OF TRAINING

REFINERY ENGINEERING,

ie g ooyon at wu 8198

iantess Te ity? samiod 384s Jo UOHEINIED

ss.

‘Oy REFINERY ENGINEERING

4 Las |OOL OF TRAINING

centrifugal

Compressors

Selection

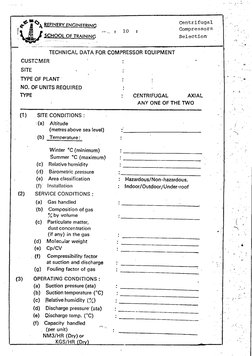

TECHNICAL DATA FOR COMPRESSOR EQUIPMENT

CUSTCMER

TYPE OF PLANT

NO. OF UNITS REQUIRED

SITE CONDITIONS :

(a) Altitude

(metres above sea level)

(b) Temperature:

Winter °C (minimum)

Summer °C (maximum)

(c) Relative humidity

() Barometric pressure

(e) Area classification

(f° Installation

SERVICE CONDITIONS :

(a) Gas handled

(b) Composition of gas

% by volume

(c) Particulate matter,

dust concentration

(if any) in the gas

(d) Molecular weight

{e) Cp/cv

(ft) Compressibility fector

at suction and discharge

Fouling factor of gas

(9

OPERATING CONDITIONS :

{a) Suction pressure (ata)

(b) Suction temperature (°C)

(c) Relative humidity (%)

(d) Discharge pressure’ (ata)

{e) Discharge temp. (°C)

(f) Capacity handled

(per unit)

NM3/HR (Dry) or

KGS/HR (Dry)

CENTRIFUGAL AXIAL

ANY ONE OF THE TWO.

Hazardous/Non-hazardous.

Indoor/Outdoor/Under-roof

: ‘Sy REFINERY ENGINEERING. centrifugal

peeps ‘SCHOOL OF TRAINING roa. Compressors

(ga) Injection/Extraction

(if any)

Copacity (NM? /-HA)

Pressure (ata)

. Temperature (°C)

Gas/composition

(4) TYPE OF DRIVE :

© Steam turbine 0 Electric motor © Gas turbine

s (a) Steam parameters for

Go. | drive turbine.

YS

.Steam inlet Min, (ata/*C)

Nor. (ata/°Cy

ere Max. (ata/°C)

Extraction Min. (ata/°C)

Nor, (ata/*C)

Max. (ata/°C)

Exhaust Min. (ata/°C)

Nor. (ata/°C)

: Min. (ata/°C)

cn Extr. Quantity Min./

: Nor. /Max. (t/h)

| : (b) Electric motor:

ve Type

Supply voltage

Cycles

Phaso

Construction

: (c) i) Parameters for gas :

turbine and composi-

tion of fuel :

_ i) Method of start up

(power/steam parametres

ee 5

0 Dy REFINERY ENGINEERING centetfugal

Las SCHOOL OF TRAINING + 123 Compressors |

Selection

(5) UTILITY CONDITIONS :

(a) Steam for auxiliaries. » ..

pressure (min./ Nor./ max.)

temp. (min./ nor./ max.) £

exhaust pressure (min./nor./

max.)

(b) Electrivity for auxitiaries

Supply voltage

Cycle

Phase

Perce eeeeeeeeeee eee eee eeeeeemeee

——

PEEeeee ence eee cence

SE ee er eee ee ee

pease renee eae Pee

(c) Cooling water

Temp. °C (max./min) : Preeeeeeeee cece

Pressure (ata) pL

Allowabletemp. raise (°C) 9:

Fouling factor Eee eee

Type of water Cen Eee een et eee coerce

(d) Electricity for instruments

Supply voltage (AC/DC)

Cycle

Phase

e) Instrument air (Kg Cm?)

(f) Pressure

N: available (pressure/°C)

Any gas available for

injection/ejection sealing

system (if needed)

Type of gas

Pressure (ata)

Temperature (°C)

(6) ANY OTHER INFORMATION : SPECIFIC REQUIREMENT ETC. (IF ANY)

eee

In case more than one unit is required, : SEPERATE FOR EACH UNIT

Whether lube oil system shouldbe =: COMMON FOR ALL THE UNITS

: 13:

mo,

¢ > REFINERY ENGINEERING cowpRTPUGAL COMPRESSORS

SCHOOL OF TRAINING TYPES AND CHARACTERISTICS

Types and characteristics

of | i

production of

Centrifugal Compressors :

Mc TYPE ISOTHERMAL TYPE !

‘Mulistage Compressors for low and Multistage Compressors

‘medium pressures with horizontaly medium preseures with hot

‘pli casings. They can bo used in split casings that allow ins

i + ethylene plants, lube oil plants, cof two high efiiency itor

inary processes, ciy gas distibu- coolers after each compression stage.

tion, ete, “They avo mainly used in factionating

plants, for insicumont aie and for

2 mc TYPE process arin largo synthesis plants.

Maitstage Compressors for low and

modi prossutes with horaontaly WC TYPE

split casings provided with intermedi- Multistage Compressors for high

i ‘Mo,uction and discharge nozzies. pressures with vorically split casings.

Used in tho same fild as MC, they Mainly uted for make-up and recycle

allow grouping of two comprossion _aarvice in high prssure proceusea

- + stages inthe samo machine wit ‘of rolinoios, petiochemical plants,

Inarmadiata cooling. ammonie, methanol and urea

‘ : ‘yobs plans.

‘Machining 2 2MCL compressor in closed condition

8A & Vo TYPE

‘Single Suge Compressor for low

rossvies mainly used aa blowers

‘or boostors In industies,relinsios

‘end petrochemical processes when

Iaxge volumes of gases have to be

‘handled ot tow pressure

PR & PC TYPE

Single and Multistage Comprassors

for high prossuros with votically,

split easings. Those are mainly

Used in pipe line booster suations, for

naturel ges gathering end for recycle

‘services In medium high pressure

processes,

= :

‘Oy REFINERY ENGINEFRIN centrifugal

1: Compressors

SCHOOL OF TRAININ qypes and

Characteristics

MC type : “"""""2MC type

low and medium low and medium

pressure multistage pressure multistage

Compressors , Compressors

‘This type of compressor comes in ' special duties, this is obtained by “Their charactoristics are similar to

the form of one ofthe thitean soles, using fully enclosed cl seals, The the MC ones but exch casing houses,

characte by Internal sealing between tho various two compression stagot In

stogas i gonoralyetfected by back-to-back arangoment. tn this

ot ofthe brine ps, suplenanary eucon nd

rexsot and the suction an charge nozzles alto ean

uch ancl in The Impaler and its provided for pocial requirement.

designed withthe required characte fata used are the sam as for

tic of tha machine asthe prime AC rype compressors. However,

waren Getenaing on te compression consiveration (surge limit slope pele raqurements due to the .

tato requed andthe type of gas oF the basic capacly-compreasion cular sence, as for instance

handled ratio plots oc). tow temperatures or cortosivecom-

nents ofthe gas handled are

‘The horizontally split casing is “howe comprassors canbe proved Ta neal consisreon.

‘thor mada from special cast ron with Itarmadlage wction “They ara used whan latormediate*

pec cat on pd entacionnazoe ruled fr TY

‘toa accordiag the duty othe eas ech x raigerting _Co0Kna pte ge necesay,

eeopmmner ‘yetes. For compression of very “Thess machines are widely ompoy-

‘The Journal beings ae ofthe ‘igh volumes they are also avATABIe gd ag charge gee compressor in

leave ypa andthe rust basing In double ow veson This soliton eiytane plant in ct caching

wot the sting ped type. parts th comoressor rota plant In 60, comprasion tine

Spoods to be maintained within the for ute plants for extraction of ue

“The shat end seating ie achloved by speed renge of soum turbines {gen lube ol plone, In

abn aia by extcion oro thoy can be det coupled dn onan

Injection sytane. Wowove, tor tothe comprewor ‘atigoalng parte.

Sy REFINERY ENGINEERING

SCHOOL OF TRAINING

centrifugal

Compressors Types

and Characteristicg

BC type

high pressure

multistage

Compressors

Eight series of machines covor

the capacity range of

type of compressor with operating:

pressures up to 100 ata.

The numbor of impellers varies from

2 10 9 for oach series. The outer

teasing is formed of a barrel, normally

in forged steel, closed at each end

by a cover. The rotor diaphragm

assembly is introduced axially into

the casing. Tho bearings, the

housing of which is integral with

tho ond covers, ily access

“The end seals aro genorally of the

oil type. Main bearings, thrust

beating impollors and internal

compressor parte are identical with

those of the MC type. This type of

‘compressor Ia characterised by

‘exceptional sturdinoss.

Isothermal

Cornpressors

with built-in

intercoolers

Five series of machines cover

the entira range of this type of com-

pressor which has been designed

‘0 compress air oF nitrogen from

atmospheric pressure up to 18 ata of

‘even higher. They are normally

manufactured with 4 or § impollors.

‘When passing from one stage to

tho next the compressed gas passes

through two built-in cooler

artangad in parallal which limit

the discharge temperature and thereby

reduce tha power required for

* compression.

coolers with thoir high

1 finned tubes, ate 6:

removable through the cover

provi-

‘This type of compressor is suitable

for continuous operation for

‘oxfemely tong periods in tho open

undar widely differing climatic

conditions and demand vary little

attention, '

‘When gas inter-cooling is required

these comprossors are provided

‘with intermediate suction and dolivery

nozzles. In this case the impellers

ara arranged back to back in

‘two groups to minimise axial thrust.

‘Special versions for highor

ta6 (up to 360 ata) aro also

for use in ammonia and

‘methanol synthesis plants.

dad in the upper compressor casing.

Downstream of each:cooler,

moisture trap is incorporated.

Spocial cast iron is used for

the casing itself. The bearings,

impellers and ond seals have tho

‘same characteristics as those of

the MC compressor.

Due to high thermodynamic effici-

‘oncy and advanced consteuctional

dusign of this type of compressor,

considerable saving in power, and

reduction in the mass of foundation,

‘erection and maintenance cost,

are achieved.

—

art REFINERY ENGINEERING

SCHOOL OF TRAINING

Centrifugal

Compressors Types

and Characteristics

High pressure

Low pressure

single and multistage single stage

PRand PC

"closed type impstet. The single

place cast o forged stasl casing is

designed for presque up to 100 at

‘The suction and dolivery soz

are suzably arranged t init the

‘haut on the easing. Depending on

‘the method of deving, the casing

In elthor aupolid with is own,

‘pedestal or flanged to the goar box

‘a8 forthe fow pressure single stage

‘machines. Oil seals are generally

‘usad for shalt ond sealing

‘These comprossora are specially

‘dauigned for gas pipeline boosting

stations, natural gas gathering

fond recycle sanvicos fn medium snd,

high pressure processes.

PCL comprossor fot Natural gas

service undergoing post test

‘manipulations

SR and VC

Compressors

These have a single open or closed

type impair. Th casing ls ther

‘rom cast ron or tabvicated sto

‘The infot nozzle is usually onthe

sama exis as tha of the compressor

shaft while tho discharge nozzle is

genstatly verically upwards. When

driven trough @ geer box,

‘compass casing ts usually Hanged.

to the goar box is

‘ovor-hung on the high speed shat

‘of tho goar ox. The enti unt Is

‘generally mounted on # common base

‘late which houses the lube cil

‘osowit, The rest of the lubscating

‘equipment (1. standby motor Rese

‘compact packsge unit for esty yoy

Inuallatlon. +

7). es 2 olds

wo eae

CENTRIFUGAL COMPRESSORS

Las SCHOOL OF TRAININS CONSTRUCTIONAL FEATURES

Casings

Gonuitugat compressors have two

\ypes of ca

Hotizonally spt or Voricaliy spit

sod whan the working

vit, ‘and have complete access tothe pressure and type of gas demand

ts, the main dividing flange such an arrangoment. All intenal

one hove tobe urectwedprt ote pe aaa stn a

lich the bongs, inpsioe, Hose the hetanay alt,

HORIORT ANE Seu: ‘but in addition, itis enclosed in a

boc forged se eye

a : {Bay top one wich

{ensily accessibe som the outido

ee eee ‘Tho tower half of tha besring

pie ee ‘housing is intagrel withthe end

* ‘Tho casings of MC, 2MC and Titesebn woes oe ce

itis possible to withdraw the

{SOTHERMAL compressors fal ee Say ee

In thi group, plete internal eesornbly

the varlous paris without

VERTICALLY SPLIT

In this typo, the compressor casing

is divided fa the hovizonta piano in

the middla and conssis of an

Lupper and lower part. All nevossary

‘auachments, nists and outers

‘uch as suction and discharye noedlos

(and intermediate ones where thoy

(exist) and lubo ol pipany connec

tion are usually built into the

lower halt so that ths upp hall

an bo eal ited. With tis wrange-

iting olf and ges passeges in high pressure

‘compressor end cover

.

Diaphragms

‘The diaphragms form the dynamic

slow path of she gas within tho

stationary pat of the compross

‘They are divided into thee typ

Auction, Intermediate and discharge.

‘The suction disphragm guides

the gas into the eye of the fst

iempeter and con be provided with

‘adjustable Inter guide vanas to vary

the inlet engle ofthe gos.

Tho intermediate diaphregms

‘perform the dual task of forming the

diffusion passages In which

‘the gas velocity is transformed into

pressure and the return passages to

[Buide the gaa to the eye of the next

Impaler.

‘The difturere can bo either tho free

vortex aype oF the vane type. The

diftusar blading, while improving

the thermodynamic efficlency,

‘cent exty of the machine

I

Final nachnung operations on 4

+ HP compressor dilvayms pack

GC REFINERY ENGINEERING

Aas SCHOOL OF TRAINING

18

dlifusor of the last impolor ax wall

4&8 discharge volume.

Tho diaphragms aro usually spit

{two halves, In the MC and

ISOTHERMAL satas the upper halvos

‘ate fixed to tha upper hall ofthe

‘casing to facilitate easy Inepacion of

thy tor. Each diaphragm

labyrinth rings to fact tho sealing

‘or the impellor shroud and prevent @

return flow from the discharge

‘pace to suction of each impeller,

{and on the shaft spacer sleavas

‘ut out interstage lonkage. Tho

sanling rings are easly removable,

Centrifugal

Compressors ~

Constructional

+ | reariegy tnonced ar undoqoes

Centrifugal

2 Dy RELINERY ENGINEERING”

| | Compressors =

SCHOOL OF TRAINING 7 f Constructional

Features

‘The fotor consists of shal, im-

pally, balancing drum and thrust

calla.

Te ghaf i usuaty mad rom soy

staat and te inpatoe and baluncing

dia ao shrunk on it Spacers of

-Aultablp, material are used to

ta oft opan

or losed ypu. The closed onc, rm |

backwards, depending on the equited

aed cure,

‘The open Impeliers are machined — |

tomtatilaciaeiea |

Meet ets om as. |

Brcatsiintstnette |

‘Ean overspeed test before being

(ried tp Fe shat.

“The balancing drum nude of oxysd

‘ape a designed f0 balance the axial

‘ thausts acting an the impelire duo

‘to the gat. Tho thrust buxing

‘absorbs tha reskdua tnust. i

Al tts ao dynamical talon. | > 4

for han tas which hve a sie

the

amo bihunce bs checked alton

‘hvlnking each imple

Lubrication system

A carefully designed tube ot system

fensures an uninterupted supply of

fed lube cil othe journal and

‘thrust boariags. The entire console

1a dosigned es a compact unit,

suitable for quaranteed continuous

‘operation af the compressor,

All ancillary equifment mentionad

Dbalow are Intagraly mounted on.

‘ot ecarval

4)" Ol pump driven by a steam,

turbine or en electric motor.

1b) Full flow oll cooter.

©) Twin titers (6 microns degree

‘of fivation) allowing oplace-

‘mont of fitoring sloment without

Interrupting the oil ow.

14) Automatie bypass valve for maln-

~ At vattous points on the intercon-

‘pecting piping. apart trom the valves

‘te. indicating instruments and

safoty aquipmont, are incorporated

{for auiomatic and manual conuol of

‘sha unit. For continuously operating

‘compressors, tho ua oi systum is

provided with two pumps, two

‘coolers and two liters such thatthe

‘change-over from one to the othar

sakat place without interrupting

Ww of oil, Even in such cases

i pump is driven diectly

stam i supplied complato with on

ary pump for operation during

‘tart-up and shut down.

Bearings

auallyfres-od plain typo bear

Inge ne ied. They ore oxenaly

‘mounted and can thersters

bo inspucted without roloasing the

prtaur inside tho compress

Depending onthe elastic buheviout

Oo he ror, aliptcal or iting ped

type main bauings ar used, nich

se highly effective in dampening

Pibrationg. Thoy redesigned Tn con-

ion ‘uh. ary alactzqnic cqmputer

bin Ryne OPE

ay REFINERY ENGINEERING

SCHOOL OF TRAINING

‘that vibration requoncy while

taking Into

‘lect of tha impatior,

‘The thrust boating ie of the

pad type to enaure equal thrust

dietbution and hes a conto! ring

10 minimise the fucitonal losses

‘due fo oll entrainment.

20

;ount the gyroscopic

centrifugal

Compressors =

Constructional

Features

Simpliied tube oll scheme

Shaft end seals

These serve to eliminate or reduce

to aminimum: (2) theleakooe

‘of comaresand ges form, oF (B) the

‘enw of ale Into the compressor

‘casing. The choice of the type of

foal ls made keeping In view. tho

(te chavacteristcs and its condition.

LABYRINTH SEALS

Whore sight loakago of gus can

bbe pormitted, a cores of abyrinun

‘sale ae used to minimise the

Taakage. In this case, the gas tying

10 excape fiom the shalt end is

of thin ngs

ey are mado

{rom light alloy or other coxosion

‘odatant matefal loss hard than th

aa easily removable.

Thetounbe of lobe and

their clearance depends on tho

‘operating conditions.

When po leakage whatsouver is

‘perissibie (poisonous or explosive

shaft isl to prevunt damagu tothe

Shainin avant cont. aomae woe

“gatoa, ato) in the compressor

‘house, labyrinth seals ere combi

‘with extraction of Inaction syetams,

‘which prevent leakage of gaa tothe

saumozpher

Ol SEALS

The ail seals consist of two

outing tings. Tho

preasure. This flows through the

Clearance space batwoen tho shaft

‘nd the seal sings. Tho oil escaping

‘on the low pressure side retuene

to the reservoir und ia ecirculated,

ingross of cil nto the gas

_space is provonted by # la

{abyringh og provided with an

Intermediate prossure balancing

‘chambor placed betwoon the oll seat

‘and the compressor isl

‘Simpliiad oll seal scheme :

s.

& ‘Oy REFINERY ENGINEERIN Centrifugal

c =

SCHOOL OF TRAINING ‘cea eee

Constructional

Features

i

!

|

'

SEAL OWL CIRCUIT

‘The soa oll clicut supplies clean,

{itor ol tothe oll seas at the

‘cones presaure and temperature,

‘Tha ean! ol clagiam shows a

‘ypleal oil ecu for tha seal elements

BC type compressor.

‘The main aloments ere dataled in

‘he diagiem.

COMPRESSOR AUXILIARIES

‘Apart trom comptesson and

dive turbines, auxilrios euch as

Ibo and sea ol aystom, heat

‘exchanger, ppg etc. are aupelied

bby BHEL.

|

a7 Dy REFINERY ENGINEERING

SCHOOL OF TRAINING

Control systems

|. toe totowing metods or ave SUCTION THROTTLING

| abe for malnalnng the cnpaciy, This method is fraquonty used and

| the suction or diacherge pressures

constant under varying process

conditions

VARIATION OF COMPRESSOR

SPEED

minimum obtainable capacity 1

dictated by the surge limit of the

compressor.

ADJUSTABLE INLET GUIDE

VANES

or gas turbine, an

and hydraulic torque convertor or

‘any other vatable speed drive.

DISCHARGE THROTTLING

A throttling valv is ited in the

lscherge piping. The prossure at

the compressor outlet nozzle wil

‘increase in order to recover the

rormal value down streaen of th

valve. The miimurh cepacty is

aicerained by drawing a vartical line

‘passing trough tha tit of com-

(reetor stably.

Those vanes induce a pre-rotation

‘of the gas by altering its dection

of flow, thus varying the compression

ratio and capacity of the compressor.

‘In multistage machines, for cons-

tructional reasons, hese guide

vanes can only be fitted Before the

first stage

‘or through a sarva-mot

centrifugal

Compressors =

Constructional

Features

‘Tho eystom Ia standard on ll planta

‘and cons into opention aso relat

rmachanipm, or when the other control

aystemaata no longer capable of

handling excess capacity or praseure,

Capac conto

RR oy aussie gute vane

Maint 27 ctor cring

3 eZee ov sed sain

FMM by icbuge rcrtng

at >) ReFIN ete Hee

ve 4 NGINTFRIN CENTRIFUGAL COMPRESSORS

SCHOOL OF TRAINING DESIGN FEATURES

1 qe

4 1.1

432

Introduction:

Centrifugal compressors find their application

in a variety of the industries associated with the

manufacture of fertilisers, petrochemicals, oil

refineries and steel plants for various services

covering the range from a suction capacity of 1000m?/hr

to 350000m*/hr and for a pressure ratio. as high as

10.

Based on the type of casing design, compressors are

classified into two types

1, Horizontally split casing

2. Vertically split casing design

Horizontally split casing design(MCL’ type)

This design is used for low working pressures

below 40ate, ‘These casings are in two halves with

horizontal parting plane. Main nozzles and auxiliary

connections are provided in the lower half of casing

and the upper half serves only as a cover which may

be lifted by removing the bolts on the parting plane

giving free access to the internale of the compressor

for inspection and maintenance.

VERTICALLY SPLIT CASING DESIGN(BCL type) is made of

parrel construction closed of the sides by end covers

with the help of studs, This type of construction ig

suitablé for high pressure operations ppto 750 xe/ en?

Sealing is provided between the casing and closing

flanges with the help of endless '0' rings.

Compressors are aleo built in single casing with two

identical compression stages in parallel arranged

pack to back which.handle double the quantity to that

of a single stage compressor. In case of. two 4

compression stages in series, the outlet gas from the

firet phase is cooled in a heat exchanger and the

cooled gas is compressed in the second stage. In

=

G27 AETINERY ENGINEERING oe

aL? SCHOOL OF TRAINING : 24: Compressors =

Design Features

these types ‘of compressors also, the dompresaion

stages are arranged bark to back.

Two types of BHEL compressors have been mentioned -

MCL and BCL, It has been said that the first have

horizontally split casings and are suitable for pressures

upto 40 ke/cm®, whilst the second are of the barrel

type in one piece, suitable for high pressures and

having closures in the vertical plane,

Another type of compressor is the PCL, which

has casing in the form of a cup with a single closing

flange in the vertical plane instead of two as with

the BOL, It is used exclusively for the transfer of

gas in gas pipeline service and it is for this reason

easily recognised by the two flanged nozzles projecting

from the casing: suitable for connecting directly into

the line. The flexibility of being able to use from

one to three impellers in the same forged casing,

together with the robust, simple construction, render

this type of machine easily adaptable and excellent 4

for continuous “heavy duty" service.

The SR and VC compressors have a single stage {

and are suitable for low pressures, The first have Bee

normally a cast-iron case, whilst the others are

fabricated. The overhung impeller can be of the open

or closed type, ‘The suction flange is, in general, ,

on the axis of the machine dhaft, whilst the delivery

ie in the vertical plane at the termination of the _

volute, These compressors are used as blowers or

“boosters” in industry, refineries and in petrochemical | vt

processes when large volumes of low pressure gas are :

involved.

The DMCL compressors have two stages of compression

in parallel in a single casing. The two stages are

PRESSE eee HEH

=

a 2d REFINERY ENGINEER paren

‘SCHOOL OF TRAINING #25 3 ‘ Compressors -

Design Features

identical and their delivery is on the vertical centre

line. This solution 1s the most balanced possible.

The last impeller of each stage, that is, the one

nearest the centre-line of the compressor is a double

flow type. A machine designed in this way enables a

Particular quantity of gas to be compressed with

Ampellers of lower diameter. The other aspects of

construction are the same as for the MCL compressor.

The 2MCL is a type of compression with compressor stages

in counter opposed sets. It is used when intermediate

cooling of the compressed gas is required. For

particular requirements, it is possible to use supple

mentary volutes on intake and delivery.

The 3MCL compressors have 2 or more stages in line with

extraction on injection of side loads. The number of

extractions and injections varies from instance to

instance (the number 3 before the frame designation is

conventional.) ‘he weight flow through the machine ia

not constant during the compression. 5

There remains finally the 28CL compressor, a barrel

| type machine and therefore suitable for high pressures.

This type also has the compression stages arranged in

counter-opposed stages.

1,3 The designation that distinguishes BHEL compressors is

formed by two groups, one of letters and one of numbers.

The groups of letters define the characteristics of the

stationary part with particular reference to the case

(1,e. BCL indicates the compressor 1s a barrel type

suitable for high pressures whilst MCL indicates

compressore suitable for relatively low pressures with

horizontal split casings). A letter or a number before

‘this group defines the arrangement of the compressor

‘ stages or alternatively refers to intermediate extraction

= i

ao ‘O), REFINERY ENGINEERIN : centrifugal

2 26 4 Compressors =

SCHOOL OF TRAINING

Design Features

2.0

201

or injection.

Por example: 2BCL 457 designates a barrel type

compressor with counter-opposed compression stages in

series with impellers of 450m diameter having seven

stages compression. In addition to. the normal BCL

suitable for pressures upto 70kg/¢m2,, Classes BCL/a-b-6,

have been developed for pressures upto 200ke/cm2,

350ke/em2, 500kg/cm2 and 700kg/cm2, respectively.

Compressors are also designed with intermediate extraction °

or with injection quantity in which case the mass flow :

through the compressor is not the same, However the

constructional features are basically same as those of

other types of compressors indicated above except for

the additional nozzles required for the purpose of

injection or extraction.

Design features ‘

The performance of the compressor is assumed on the

following criteria.

a) Thermodynamic performance achieving the required

compression with the minimum power consumption and

optimum sizing of impellers.

b) rouble free_run of the unit.

This is achieved by proper dimensioning of the

mechanical parts followed by the study of flexural

and torsional behavior of the rotors and finally by

a proper assembly of the unit.

The important elements of the centrifugal compressors

are casings, diaphragms, rotors, seals, bearings, couplings.

REFINERY ENGINEERING ae

COMPRI OR_ASSEMBLY BCL

Li SCHOOL OF IRAINING =

COMPRESSOR ASSEMBLY = 2 BCL

07 Bs, REFINERY ENGINEERING : 28 :

Ah / sion OF TRAINING

7 Dy REFINERY ENGINEERING

Ah / seu JOOL OF TRAINING

+ 290 4

COMPRESSOR ASSEMBLY ~ MCL

2

Pn

FS, REFINERY ENGINEERING’

30

Va SCHOOL OF TRAINING COMPRESSOR ass

he Se.

27 HO REFINERY ENIGINEERIN Heer

AL SCHOOLOF TRAINING COMPRESSOR ASSEMBLY = 2 MCL

i

Pol

J

3

J}

oo 8 Oy REFINERY ENGINEERING ane

COMPRESSOR ASSEMBLY - 2 MCL

SCHOOL C7 TRAINING

ete

>, REFINERY ENGINEERING centrifugal

Af J sot octu SCHOOL OF TRAINING 7 Poteet oeeet

Design Features

Materials

It is now necessary to consider the materials used for

construction of the principal components that make up

@ compressor,

The materiais used for the various compressor types

differ, mainly for the external parts of the machine.

The materials used for the rotor and the other internal

parts differs more on account of the temperature, the

corrosive nature of the gas or the stress levels involved

than the machine type.

Casings

As already said, the case of the BCL type hao a barrel

form with nozzles and supports welded to it, The barrel

is a forging; this method of production renders the

material more homogeneous and therefore more resistant

to stress.

Normally, carbon steel is used for the barrel nozzles

and the supports and for the covers. The material

ASTM A105 GR.II (with carbon content of 0,2 - 0,25%

instead of 0,35% as in the stds.) sufficient to obtain

good mechanical characteristics and at the same time

suitable for welding.

The POL also has a Casing and ‘forged cover in ASTM,

A 105-the nozzles however aro cast because they have a

complicated form :

The: MCL compressor casing is machined from cast iron

or steel as statel in API standard or stated by the

client. In general a grade of steel called mechanite

CD cast iron with a tensile atrength of 25-30kg/mm2 and

a compressive strength of 70kg/mm2 which is better

than many steels ip used, When it is necessary to use

=

7 Hy REFINERY ENGINEERING Centrifugal

Compressors ~

SCHOOL OF yf) SCHOOL OF TRANING a + ret

Design Features

a cast steel the material ASTM, A.216 WCA ie used. For

low temperature operation one of the four grades of the

steel ASTM A 352 1s used depending on. the actual

temperature conditions, Finally for corrosive fluids,

ASTM. A, 351 Gr. Cai5 (13% Cr) steel or alternatively

Gr, CFS is employed.

Diaphragms: The diaphragns constitute the dynamic profile

of the stator parte of the compressor. . They are divided

into three types viz., suction, intermediate and delivery.

Suction diaphragms guide the gas to the first impeller.

Intermediate diaphragms have the function of transforming

the kinetic energy into pressure, serves return channel

to guide the gas to the next impeller with shocklese

entry. Delivery diaphragm forms the diffuser for the

last impeller ana delivery spiral.

Diffuser ean bo free vortex design or bladed type.

Bladed diffusers are generally not used! as they restrict

the operating range and compressor cha: f teristics are

very much sensitive to change in volume flows.

Diaphragus are almost always cast, on account of their

complicated form, Normally, Mechanite type GD or

spheroidale cast iron are used sometimes with additions

of nickel to improve the resilience characteristics at

low temperature (1 + 1,5% Mi).

If the operating temperature is less then = 100°C, ASTM,

A 352 steel is used in one of the six grades available”

or alternatively ASTM:4;331 grade CFS,

For the intermediate diaphragms of the 2CM and 2BCL

compressor or for any diaphragms supporting high A p,

a more“suitable material such as carbon steel plate or’

forging which has higher mechanical strength than cast

iron is required.

2.6

2.7

8

29S ket NGINFERING centrifugal

ey: SCHOOL IN Design Features

_mechanical characteristics than is generally required for

35 or , Compressors -

End_covers: These components are used for the purpose

of closing either side of the barrel which also house

the bearings and seala oil seals, Various oil and gas

connections are made on the end covers, Generally the

end covers are made out of solid forgings. Depending

upon the gas medium either carbon steels or stainless

steels are selected.

Rotor: The heart of the compressor is the rotor consisting

of the shaft, impellers, balancing drum, shaft sleeves,

thrust collar. The shaft is made of heattreated low

alloy steel on which the impellers are hot shrunk and

keyed. Sleeves of special material are mounted on the

shaft to protect the shaft from the contact of the gas

medium,

Shafts

The material used for the shafts of all types of compressor

is 40 NiCrMo7 Steel. In reality, this material has better

normal usage by centrifugal compressors and it is for this

reason that other manufacturers use carbon steel.

This material reacts very well to heat treatment, infact,

shafts of normal dimension made of this material are

treated throughout their section, contrary to the normal

practice with carbon steel of undergoing only a surface

treatment. Since there is little interest in obtaining.

very high rupture on yield loads but rather toughness and

ductility, tempering is at aibigher temperature than

normal, sufficient however, to reach a rupture load higher

than 100 kg/mm2 and 2 yield of 65 + 75 ke/u2.

a” 2s REEINERY ENGINEERING centrifugal

: 36 Compressors -

A gL F scoot or mans esi acatures

2.9

a

Impellers Ee i

The impellers are the most stressed component, in fact,

there is the tendency to exploit them to a maximum so

ag to reduce the number of stages. They are constructed

in 9 steel with high mechonical characteristics but low

carbon content to ensure satisfactory welding of the

vanes. Except in special cases KMN COGNE a low alloy

steel is normally used,

This material is (also good for low temperatures) having

2% chrome 1% molybdenum and 0.13+0.17% carbon. Certain

other manufacturers use a steel having a higher carbon

content, obtaining thereby superior mechanical characteri-

stics but giving rise to doubts about the soundness of

the welds. Given that the weld and the surround zone

are the same, a phenomenon of intergranular corrosion ,

would appear to occur, It is for this reason that there

is a need to call for a limit on the carbon content,

The intergranular corrosion weakens the metallurgical

bond between each grain which leads to the mechanical

degeneration of the material.

The presence of carbon in the steel greater than that

soluble in the austinitic matrix determines the potential

sensitivity of the material to intergranular corrosion.

This 1s s0 since carbon is principally responsible for

the precipitation of the carbides and for the impoverishment

in chromium at the grain boundaries. The carbides

precipitated to the grain boundaries can be points initiating

failure while the impoverishment of chromium renders

the material sensitive to corrosion.

The t{me the material is subjected to a temperature of

(400+900°0) whether during the process of refinement,

after heat restment, preheating or during welding this

can provoke the precipitation of the carbides of chromium

eat EEE

REFINERY ENGINEERING at

SCHOOL OF TRAINING CENTRIFUGAL COMPRESSoRS =

METHODS OF MANUFACTURE

in quantities much greater, the greater the quantities

of carbon in the steel.

When the impeller is to be used in a corrosive fluid

@ steel with a high chromium content is used such as

X120r13 (13% of Cr), in particularly corrosive conditions

a greater percentage of chromium may be required KX02

grade (15-1980r); if finally 1t is not the problem of

Corrosion there is a further problem concerning stress

level, recourse can be made to ateel of 17-4 PH, 17% Or

4% Ni precipitation hardened at low temperature.

This steel with 9% Ni is used for impellers required

for low temperatures, good mechanical properties being

obtained at temperatures as low as -196°C,

Methods of manufacture

The most common method of manufacture of the impellers

is by welding. {

1) Intemal welding: Impeller is fabricated from solid

forged discs, Depending on the size of impellers, the

vanes are formed by either milling process or by

welding separate vanes which are prebent to required

shape. The internal conventional manual welding ie

employed to join the hub with vanes and shroud. As the

welding is carried out by manual process, special care

ia to be taken in the following areas.

1, To have homogeneity of the properties of both hub’

ang shroud, both the forgings are drawn from the

sane melt.

2, The heat treatment of the impellers in an inert

atmosphere to control the scale formation due to the

oxidation.

‘3. Proper sequence of welding and uniformity of the

weld fillet deposited,

™

27 Oy, REFINERY ENGINEERING centrifugal

1 38: -

Ls SCHOOL OF TRAINING peagbe!

i en eeS cire

3.2

3.3

4. Continuous monitoring of the weld quality during

the process of manufacture by liquid dye penetrant

test at various stages. i

Spark erosion:

Spark erosion method ie used when the conventional

internal welding cannot be carried out because of narrower

passages of the impeller channels. The procedure allows

manufacture of impellers for compressors handling

capacities as low as 100 m*/hr. The impellers made

with this procedure have mechanical/ thermodynamic

characteristics better than those made by other method.

The process essentially consists of forming the shape

of the channel of the impellers by removing the material

by spark erosion, The electrode is made of pure copper

machined to the exact shape of channel.

Impellers with channels as small as 3m can be manufactured

with this method,

Bxternal welding:

For hendling very low volumetric flows and higher heads,

new series of inpellera are developed and the

characteristics of such impellers are very low outlet

vane angles (15° to 18°) and lower radii of curvature.

These characteristics result in a very long channel

passage and the Conventional welding becomes impossible.

External welding process has been specially developed

to overcome this manufacturing constraint. Following

are the salient features of thie manufacturing process:

-Manufacture hub with blind grooves with corresponding

vanes on shroud.

=Match the grooves with vanes.

3.4

3.5

e206 centrifugal

», REFINERY ENGINEERING

Saag Compressors ~

SCHOOL OF TRAINING Methods of

Manufacture

-Welding of root of groove by TI@ automatic

process with pulsed current, The material at

the bottom of the groove 1s fused to the vane

arranged exactly beneath the grodve without filler

material. :

~Subsequent layers of welding by TIG welding with

‘filler material.

-Suitable heat treatment process to achieve desired

mechanical properties.

-Pinish machining.

Advantages: 1) The external welding process does not

E have the weld deposit in the internal

as passages and hence smoother gas

passages are obtained.

2) he entire process is automatic and

the quality of welding is consistent.

Balancing drum: On an impeller stage in a centrifugal

compressor there exists an axial thrust equal to the

difference of thrust between suction and delivery sides

of the impeller, This thrust adds up in a compressor

for the number of impellers provided in a stage and it

ie too high to be taken by the thrust bearing all by

itself. én equalising drum is fitted on the shaft both

sidesof which are subjected to a differential pressure.

The size is so selected that 90% of the thrust load

due to the gas is compensated by the drum and the

residual thrust is supported by the thrust bearing.

2 40 + Compressors =

= ;

& ¥ REFINERY ENGINEERING Centrifugal

Aub / so00. OF TRAINING Methods of

Manufacture

3.6

3.7

3.8

Spacer Slesves: Spacer sleeves positioned in between

the impellers have two functions.

1) fo protect the shaft from corrosive fluids.

2) To establish the relative position of the impellers

on the rotor. The spacer outer profile also guides

the gas into the suction of the impeller.

Generally sleeves are made from 13% Or steels with

less carbon content. The spacers are mounted under

interference to ensure their positioning during

running. i

Bushes under 011 seals: The bushes positioned on the

shaft under 011 seals protect the shaft from the wearing

action of high flow of seal oil.

These bushes are made by an overlay of hardened material

(Colmonoy 6) of 600 BEN. For high pressure compressors

colmonoy is unsuitable because of very high inter=

ferences required and hardened low alloy steels are

used.

Bearings: The journal ani thrust bearings are of

white metalled type with force feed lubrication. These

are housed outside the compressor casing and they can

be accessed without dismantling the complete machine.

a) Lemon type or elliptical type of bearings are

generally employed for low speed and heavily

loaded rotors and for high speed machines, to have

better damping characteristics, tilting pad

bearings are used.

The selection of the bearing mainly depends on

“the rotor lateral behavior evaluated in critical

speed analysis,

centrifugal

2°39, nesineny ENGINEERING

a eeHagtee Compressors -

Ag A scuoo TRAINS Methods of

Manufacture

Thrust bearings are of tilting pad type with self-

equalising features. Thrust bearings are lubricated

by forced feed lubrication, Oil film between the

collar and the shaft supports the rotor.

4 fundamental parameter while choosing these

bearings is the product of specific load and peripheral

speed. This parameter has to be contained within

Certain limits based on method . of lubrication and

materials of bearing and shaft.

Improvements in the Design:

Periodical review of the design is made for achieving

more reliable efficient and trouble free operation of

compressors at site, The research and development

at collaborator's works and at BHEL enables modification

of existing design or adoption of new design philosophy.

Also based on the feed-back from various sites,

improvements in design are caryied out in the existing

design.

") REFINERY ENGINEERING = 5 yn,

OL OF TRAINING CENERIFUGAL COMPRESSORS ~ i

PRINCIPLES OF OPERATION

4.0 PRINCIPLES OF OPERATION OF A CENTRIFUGAL COMPRESSOR

As already mentioned a centrifugal compressor confers

a certain quantity of energy to increase the discharge

pressure and delivers a particular quantity of fluid

depending on the thermodynamic characteristics. :

In general the fluid is directed to the inlet flange :

with a velocity of about 30m/sec., when it undergoes

a slight initial expansion to beyond 60m/sec., to the ;

eye of the first impeller to which corresponds the initial

conditions of compression indicated by Vo, Po and to.

Such conditions are easily determined on the basis of

the reduction in enthalpy and temperatures in the above

mentioned initial expansion given respectively byt- :

2

2

cy? - cg :

Hos and t= Ang, ;

29427

C, * Velocity at inlet of 1st Impeller.

= Velocity at inlet of suction flange.

9.81 M/ec.”

a

4

At this point the fluid enters the first impeller, which

‘confers a certain quantity of energy to it, bringing it

to the final condition v1, Py and T1, volume, pressure,

temperature at inlet,

According to the theory of Euler the energy given to a

unit weight of fluid passing through the channel between

the two vanes of the impeller is equal to the change of

its momentum.’

ee See eee

Centrifugal

REFINERY ENGINEERING Compressors =

ete Principles of

101 Tr D-

|L_ OF TRAINING Operation.

Am ot (uz¢2 cos o¢2 - 1 wy cos &x 4)

Notation -

Wy, W, = Relative velocity 2, blade

at suction, delivery, angie at

outlet.

C1 Cy = Absolute Velocity

at suction, delivery.

C2 U = Horiz. Comp. of Abs.

velocity at discharge,

I" = Radial

C2 e ~ Regt yefockepeae °F

discharge. :

U4 U, * Tip speed of blade at

2 inlet & outlet.

Since in general O¢ ,90 (radial inlet) the expression iz

becomes: 7

Aw sh c2 u, cos

uu 7) 2 eS

For convenience’ the co-efficient of head may be defined:

v 2 cosO<. 2 Cou

a" 25 = :

u2 U2

Therefore: :

: 1 2 Tinde

vead = Anu = > U2 where u, = Zo 7 de = ext. dia of

Impeller

\ The quantity of energy per unit weight is called effective

‘head (i eff) and does not take into account the losses in the

suction and discharge passages.

The co-efficient of head “U2 is a function of the geometry of

"the vanes and of the capacity as can be seen from the diagram:

Centrifugal

Compressors =

a 44 63 Principles of

Operation

In the diagram is also.shown qualitatively the trend of the

polytropic efficiency y, that takes account of the abrasion,

the impact and the turbulance, of the real fluid on the

channels and vanes.

The polytropic head that the gas can utilize is only a

Proportion of the effective and is given by: i

2

Hp = “Up Hege = T2 “Up 9/9

=Z, RP, K fr K-1 107

1 ger “p (Perv as Y

Wherer

‘ 7a universal gas constant : °

11" Suction Temperature 7 - -

»- = molecular weight of the gas

‘p= potytropic efficiency.

2m*= average compressibility of the gas

K = cp/ey (Specific heat at constant pressure)

Specific heat at constant volume

Pressure ratio p

=

et ‘Oy REFINERY ENGINEERIN Centrifugal

Compressors -

gj, J sacon or anus a 45 5 Principles of

Operation

The polytropic head takes account of the thermodynamic

properties of the gas.

In point 2 of the preceeding diagram, corresponding to the

maximum polytrépic efficiency, one has a capacity for which

the fluid flow to the inlet of the impeller has a greater

angle of incidence to the vane. At this point, the polytropic

head which is proportional to the product V/2"\p is less than

the surge limit where it assumes the maximum value.

It can be seen that the thermodynamic characteristics of the

gas can be changed at the outlet as a function of the inlet

conditions,

Suppose only the molecular weight (/t) is changed maintaining

the volumetric capacity and the speed (rpm), If in the

formula for the polytropic head AA is increased, this diminish

the constant R of the gas and hence ought to augment the ——)

of the term in brackets, given that the other parameters do not!

depend on At. The consequence is that with the same head the

pressure ratio is increased therefore the greater the gas

density (weight) the easier it is to compress.

If instead the suction temperature is increased this diminishes

the term in brackets of the polytropic head formula and there-

fore the pressure ratio diminishes as a consequence, in order

to maintain the head for a given fluid with the same volumetric

capacity and the same speed (rpm) the pressure ratio increases

with reduction in the suction temperature and vice versa.

On the contrary, notwithstanding what 4s said about the

pressure ratio, this does not depend on the suction pressure

Po because in such a case the product PoVo = RTo ramains

constant and from the polytropic head formula it is seen that

not changing other parameters (within certain limits) it will

not vary.

o Hi

} &

+ 46 ¢

ti CHOOL OF TRAININ Principles of

Operation

| eo Centrifugal

REFU

”, REFINERY ENGINEERING Compressors =

The influence of K (ratio of specific heads) on the

pressure ratio ia not great since this appears twice in

the formula once upside down which compensates to some

measure.

Inetead the variation in the average compressibility of

gas (%j) influences the compression ratio more in

particular to an increase of Zm corresponds to a decrease

of and vice versa,

If the number of impellers increases, to see how the

thermodynamic characteristics of the aspirated gas :

influences the discharge for example, 2 stages of compression

carried qut with impellers having the same characteristics,

it is necessary to examine what will happen in the case

of a gas having a small molecular weight, In this case

the intake and delivery volumes differ slightly and are:

Qo = GVo} a

xq

zg

<

7 ~

4

»,

”y, REFINERY ENGINEERING Centrifugal

Compressors -

eg? SCHOOL CF TRAINING Seals & Sealing

ms Systems

4

« I.

° i

o H

S H.

a

oO

2

O,

: = :

a Sy REFINERY ENGINEERING sees ‘|

eh Pi CENTRIFUGAL, COMPRESSORS - PLOW CHART

: Sone eee eee

j OF QUALITY ASSURANCE CHECKS

CENTRIFUGAL COMPRESSOR MANUFACTURE.

ce | | Bi al

ome Centrifugal Compressors-|

4 REFINERY ENGINEERING.

Je’ lists in Centrifugal

UL) sacasormae + 625 Compressor Manufacture

(ol aiaae Tears: ee

1 IMPELLER OVERSPEEDING

* Bach impator of

individually overaped

vale of 115% of Maximum continuous 3

spad impetiors lor any

permanent delormations and microcracks a

the wolds.

‘Spin last equipment tor compressor impallors.

5 paLanoina

J Ezchimpate is palance before Is ove sped

telco ite tsanbiod on he eh Hse

ope Dancing and it eases refer

“one to he accuses spa

ie Schenck 50 VB Dynamic Balancing Machine.

(W)_NO-LOAD MECHANICAL AUN TEST:

(Mechanica un ta is cated out 19 verily the yernal cubs

jeial condition of Ihe unit assembly and help i onic

‘Riecientey gh saya we ee econ

{ost is carried ayt under casing evacus

condition.

a {ube and seat oil channels in ihe compressor

casing.

find smooth-running at Maximum

‘Broadly, the following verifications ava carried out ed for a period al four hours,

nabbecbistiuns . f al overspeed ar trip speed (110% of

§ Rotor balance 18 minutes.

© Bearing atignmont, clearance and adequacy of,

lubrication

© Clearances at inter-stage tabyrinth seals and

tiquid fitm shalt seals

(TANDEM MECHANICAL RUN TEST:

During this test, shop driver. shop tube oil

compressor

ings of the 1rain ave arranged

st Is carried out as

sbove. The train componer

iy Ie checked during this (ust

Tandem Mechanical Aun Test

Quality Assurances, Check|’

Centrifugal Compressors

REFINERY ENGINEERING

IEEINERY ENGINEERIN' Quality Assurances, dheck

lists in Centrifugal

SCHOOL OF TRAINING Compressor Manufacture

TD) STaNG MECHANICAL RUN TENT.

In case of stsing mochanieal running tes! the job

‘drat is used proterably on its own base

‘and with ariginal piping within the cont

[EL_ THERMODYNAMIC PERFORMANCE TEST

‘Thus test is carried oul (0 establish the nd temperature, oi

thermodynamic performance ol the machine with ‘ge of ofl rough

ecied gas of known properties under

‘specified conditions.

‘A.comprossor can be testod with a suitable test

‘Gee whose physical and thermodynamic

Bropertion are well known and the results aro ry elfort is made to to

Converted into expecied performance of ine same 4 ge. The perlormance

‘compressor for lis design or specilied ges under ressuro falio vs. tow,

lis design operating condition. pow ‘head vs. tow, flow vs.

‘ASME PTO-10 and BS standards stipul ceeains pel sante

‘arlous types of leale for dfteront types ol gases. A permanent closed ioop piping system, wilh he

: ‘@xchangars, piping, valves otc. wilh suitable t

Niner sconpncr iawn napecind oe Siete Ah ls it tw aoe

nd eect orn usted at por pa loop lt designed for 15 aig. and high pressure

(Oa) the teat a tocmed as Ciase-t leon Gesloaea fee

For conducting performance tests and static seats

‘Class It and Ciass ib tests are conducted when fests, a diaphvagm compressor of 600 kg/cm?

tha compretscr tn ee anniy condi It id pressure rating Is installed with the nitrogen gas:

sai! teats, the Jsulls ave to be converted: peeen trom ano

riormance dats oxpected for ho speciliod

{nfunger specilied conaiione using he parlect dation to Ihe existing lacs

us lawn, Power tos! codes spociy ihe lint of

Giterence tor maximum and minimum

‘comprossiblty functions (x8) for tho test and

Spocité pasos hese limits are excoeded

Giaserlll tot caleulavons shail be adopted, The

‘Conversion offer results to specified conditions

emade using teal gas equations In case of

Gisss=it tate.

‘The compressor and the complete systom 1s

checked for alr/ gas leaks.

(008 is acmitied al iow

parameters and purged lil the purity i achieved.

‘After the gas analysis ls satistactory tl

‘Compressor fe started and slowly brought to the

feat speed. After oblaining the test parametors —

such as Inlel pressure, temperature low and

speed — the diacharge pressure paral

(F_STATIC SEALS TEST

‘Aller completing the mechanical run test, liquid

film (shai and) soals are assembled in postion.

‘The compfessor is pressurised to operating

‘by an inert gas sucr as nilrogen. A

remial pressure of 0.5 Kg/em is maintained

‘between the seal oil jnlel and the gas inside (ie

falerence gas). The leakage seal oil across the HP

teal fs mansured for known period while the shalt

is under manual rotation. Wath this i is possible

{0 judge the sour ol leakage and the fitness o he

seal,

Liquid Film Shatt Soals under “Static Soals Tost”

0,

@% A &y REFINERY ENGINEERING

La SCHOOL OF TRAINING

fugal Compressor

Manufacture

Centrifugal Compressors

= Quality Assurances,

64 Check lists in Centri-

the HP soal rings ar

LP seal ring ‘cloarancs

‘enlarged to auit the tow pressure gas conditions,

of ine fas, Sometimes tho roducod numb

the sour (HP) oll

for a specitieg pe

Generally his test is conducted at low pressure

and at ow speeds

LUBE OIL CONSOLES:

Lube Oli Conpoles for compressors and their

‘drive turbines are functionally tested as per APL

814, The functional test includes checking the

performance of motor/ turbine. pump sets,

onto! valves, relia! valves, accumulator, coolers

and fillers. The test also includes the simulal

‘of change-over of pumps, coolers and lilters. THe

following operations are eneured duting the test

1. The operation of control valves at set pressuros

and lows, m

4. Automatic takeover of pumps,

5. Alarm and tep settings of pressure switches,

6. Cleantiness af ine aystem,

INSTRUMENTATION FOR TESTS:

Highly sophisticated and precision instruments

are available for measuring various parameters

‘during machanical run tests a6 par API 612, 614,

617 and perlormance tests as per ASME-PTC -6,

PTC-10. Calibration of these instruments is

carried out at works belora and alter tho lest. The

following are come of tho important insteuments,

available with us.

MICRO PROCESSOR-COMPUTER/SYSTEM CONTROLLER

{in tune with the modern trandi in the evolution of

Mechanical and 11

{CADAS) is not only

‘with full graphics fa

1) Relay Multiplexer Assembly with Thermocouple

islion and low inermal relay,

‘muliploxer for T.O-s.

by Pressures and ai I pressure. measuring

facility on relay muliplaxer assemblies,

(6) Speed & Froquoncy Measurements on high

requency reciprocel counter assembly,

4) Pulue Measurements for Turbine Flow Meters,

#) Stain Moafuroment.

) Current O/A Converter.

{9)High Voltage Actuation (220 V) for process

‘controlling.

During the performance twst, the dats is acqui

by Autom ‘Acquisitions ang Control Uni

(HP. 9054) trom various sensors such as pressure

transducers, differential pressure transduce

rexstance thormal detectors and thermocouples,

flow meters and various magnatic

Instrumentation and contcoi Pano!

bs

Bo 2 65

7 Rd REFINERY ENGINEERING CENTRIFUGAL COMPRESSORS

Ag / scuoou OFTRAINING SURGE AND ITS CONTROL

Surge can be dofined as the expneity below which

the centrifugal compressor performance becomes unstable. The

surging conditions occur when the inlet capucity is reduced

below s particular limit, Thia consists because of the

collapse of the prescure developing capability of the machine,

At a given speed, ap the inlet capacity is reduced, the

discharge pressure of the wachine goor on incrcusing. When

surging occurs, the high prossure cao at the discharge of the

machine flows back through the compressor in a complete

reversal of the normal direction of flow. Once the discharge

pressure is dissipated cuffictently, the conditions causing

+ the collapse of pressure no longer cxist snd the compressor

rogumos normal flow and discharge prescure. If the discha

‘conditiona on the’machine have not changed, the collapse of

preseuro ‘producing ability will repeat and cycle through the

sane sequonce, The percontago flow rt which the surge occurs

Pap m ceutritugal compressor depends upon the scrodynamte

design, gas propertios, stability of flow, system

gyaracteriatica, stage companonta deaign otc.

The above surging 16 formed’as overall machine

surging. But in certain occagions, the flow components of

stage may have a mild surging with the flow reversals within

ite geometric domaine without causing tho overall curging of

the machine, or without hampering the overall pressure

producing capability of the machine. Such mild surging cannot

have sudible noise or pressure fluctuations which can be felt

externally. Most often, tho mild surging of individual

componen ta creates enoygh flow fluctuations that the adjacent

epmponents byeak dpwy dye to spotability and the overal]

“‘machine goog into pur,

» |, Al} necensary procautions during installation of the

machine in & syatem shall be taken to prevent surging for th?

fojlowing reasona, Surging condition imposes transient

‘ zi : contd. Pagt

You might also like

- Fundamentals of Kobelco-Screw CompressorNo ratings yetFundamentals of Kobelco-Screw Compressor4 pages

- Multi-Stage Centrifugal Compressors OverviewNo ratings yetMulti-Stage Centrifugal Compressors Overview32 pages

- Reciprocating Compressor Overview and Parts100% (4)Reciprocating Compressor Overview and Parts59 pages

- API Standard 617 - Axial and Centrifugal and Expander-Compressors For Petroleum, Chemical and Gas Industry ServicesNo ratings yetAPI Standard 617 - Axial and Centrifugal and Expander-Compressors For Petroleum, Chemical and Gas Industry Services4 pages

- Centrifugal & Axial Compressor - Construction100% (3)Centrifugal & Axial Compressor - Construction16 pages