Professional Documents

Culture Documents

Taller 2 J. Tixe

Taller 2 J. Tixe

Uploaded by

Leo YugchaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taller 2 J. Tixe

Taller 2 J. Tixe

Uploaded by

Leo YugchaCopyright:

Available Formats

UNIVERSIDAD TÉCNICA DE AMBATO

FACULTAD DE INGENIERÍA CIVIL Y

MECÁNICA

Diseño Mecánico Avanzado

Nombre: Joel Tixe

Curso: 7mo "B"

Fecha: 8/11/2022

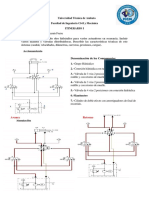

Determine las matrices de rigidez y de flexibilidad de una lámina de tejido de vidrio E

genérica y resina de poliéster con 27.41% en volumen orientada a 0 y 92 ° respecto al eje 1.

además determinar la deformación de la lámina si esta sometida a un esfuerzo biaxial de 10

MPA, espesor de cada lamina h ≔ 0.001 m

1.- DATOS ( Ver en ficha técnica)

Tipo de fibra : T ≔ “U”

Fracción de volumen de la fibra de vidrio: Vf ≔ 0.7259

Módulo de elasticidad de la fibra de vidrio: Ef ≔ 81.2 GPa

Coeficiente de Poisson de la fibra: vf ≔ 0.21

Módulo de corte de la fibra: Gf ≔ 0.07 GPa

Módulo de elasticidad del epoxi: Em ≔ 4.3 GPa

Módulo de corte del epoxi: Gm ≔ 4.3 GPa

Coeficiente de Poisson de la resina poliéster: vm ≔ 0.44

2.- CÁLCULOS DE MÓDULO DE ELASTICIDAD

E1 ≔ ‖ if T = “U” | | = 60.122 GPa

‖ ‖ ||

‖ ‖ Ef ⋅ Vf + Em ⋅ ⎛⎝1 - Vf⎞⎠ | |

‖ ||

‖ else if T = “W” ||

‖ ‖ ⎛ Ef 3 ⋅ Em ⎞ ||

‖ ‖ Vf ⋅ ⎜― + ――⎟ + Em | |

‖‖ ‖‖ ⎝ 2 2 ⎠ | ||

E2 ≔ ‖ if T = “U” | | = 14.971 GPa

‖ ‖ ||

‖ ‖ Em ||

‖ ‖ ――――――――

⎛ 2 ⎞ ⎛ 2 ⎞ ||

‖ ‖ ⎝1 - vm ⎠ ⋅ ⎝1 + 0.85 ⋅ Vf ⎠ | |

‖ ‖ ――――――――― Em ||

‖ |

E2 ≔ ‖ if T = “U” | | = 14.971 GPa

‖ ‖ ||

‖ ‖ Em ||

‖ ‖ ――――――――

⎛ 2 ⎞ ⎛ 2 ⎞ ||

‖ ‖ ⎝1 - vm ⎠ ⋅ ⎝1 + 0.85 ⋅ Vf ⎠ | |

‖ ‖ ――――――――― Em ||

‖ ‖ ―― ⋅ Vf ||

‖ ‖ E f ||

‖ ‖ ⎛⎝1 - Vf⎞⎠ + ――――

1.25

⎛1 - v ⎞ | |

2

‖ ‖ ⎝ m ⎠ ||

‖ else if T = “W” ||

‖ ‖ ||

‖ ‖ E1 | ||

‖

3.- CÁLCULO DE MÓDULO CORTANTE

G12 ≔ ‖ if T = “U” | | = 5.915 GPa

‖ ‖ ||

‖ ‖ Gm ⋅ ⎛⎝1 + 0.6 ⋅ Vf 0.5⎞⎠ | |

‖ ‖ ――――――― ||

‖ ‖⎛ Vf

⎞ 1.25 ||

‖ ‖ ⎝1 - Vf⎠ + ――― 1 - vm 2 ||

‖ ‖ ||

‖ else if T = “W” ||

‖ ‖ ||

‖ ‖ ―――3 ⋅ Em

||

‖ ‖ 4 ⋅ Vf + 1 || |

‖ ‖ |

4.- CÁLCULO DE COEFICIENTE DE POISSON

v12 ≔ ‖ if T = “U” | | = 0.273

‖ ‖ ||

‖ ‖ vf ⋅ Vf + vm ⋅ ⎛⎝1 - Vf⎞⎠ | |

‖ ||

‖ else if T = “W” ||

‖ ‖ G12 ||

‖ ‖ ―― || v12 ⋅ E2

‖‖ ‖‖ E1 | || v21 ≔ ――― = 0.068

E1

5.- COMPONENTE DE LA MATRIZ DE RIGIDEZ

E1

Q11 ≔ ―――― = 61.259 GPa

⎛⎝1 - v12 ⋅ v21⎞⎠

Cualquiera de las 2 formas funcionan

v12 ⋅ E2 v21 ⋅ E1

Q12 ≔ ―――― = 4.165 GPa Q12 ≔ ―――― = 4.165 GPa

⎛⎝1 - v12 ⋅ v21⎞⎠ ⎛⎝1 - v12 ⋅ v21⎞⎠

E2

Q22 ≔ ―――― = 15.254 GPa

⎛⎝1 - v12 ⋅ v21⎞⎠

Q66 ≔ G12 = 5.915 GPa

Q66 ≔ G12 = 5.915 GPa

6.- MATRIZ DE RIGIDEZ

⎡ Q11 Q12 0 ⎤ ⎡ 61.259 4.165 0 ⎤

⎢ ⎥ ⎢ ⎥ GPa

Q ≔ Q12 Q22 0 = 4.165 15.254 0

⎢ ⎥ ⎢ ⎥

⎢⎣ 0 0 Q66 ⎥⎦ ⎣ 0 0 5.915 ⎦

7.- MATRIZ DE FLEXIBILIDAD

⎡ 0.016633 -0.004542 0 ⎤

-1 ⎢ 1

⎥ ――

S ≔ Q = -0.004542 0.066796 0

⎢ ⎥

⎣ 0 0 0.169048 ⎦ GPa

8.- CÁLCULO DE m Y n

ϕ1 ≔ 0 ° ϕ2 ≔ 20 °

m ≔ ⎡⎣ cos ⎛⎝ϕ1⎞⎠ cos ⎛⎝ϕ2⎞⎠ ⎤⎦ = [[ 1 0.94 ]] n ≔ ⎡⎣ sin ⎛⎝ϕ1⎞⎠ sin ⎛⎝ϕ2⎞⎠ ⎤⎦ = [[ 0 0.342 ]]

9.- CÁLCULO DE Q' A 0 °

i≔1

4 2 2 4

Q'11 ≔ m ⋅ Q11 + 2 ⋅ m ⋅n ⋅ ⎛⎝Q12 + 2 ⋅ Q66⎞⎠ + n ⋅ Q22 = 61.259 GPa

1,i 1,i 1,i 1,i

Q'12 ≔ m 2

⋅n 2

⋅ ⎛⎝Q11 + Q22 - 4 ⋅ Q66⎞⎠ + ⎛m 4 + n 4 ⎞ ⋅ Q12 = 4.165 GPa

1,i 1,i ⎜⎝ 1 , i 1,i ⎟

⎠

Q'21 ≔ Q'12 = 4.165 GPa

4 2 2 4

Q'22 ≔ n ⋅ Q11 + 2 ⋅ m ⋅n ⋅ ⎛⎝Q12 + 2 ⋅ Q66⎞⎠ + m ⋅ Q22 = 15.254 GPa

1,i 1,i 1,i 1,i

Q'16 ≔ m 3

⋅n ⋅ ⎛⎝Q11 - Q12⎞⎠ + m ⋅n 3

⋅ ⎛m 2 - n 2 ⎞ ⋅ Q66 = 0 GPa

⋅ ⎛⎝Q12 - Q22⎞⎠ - 2 ⋅ m ⋅n

1,i 1,i 1,i 1,i ⎜⎝ 1 , i 1,i ⎟

⎠ 1,i 1,i

Q'26 ≔ m ⋅ n 3 ⋅ ⎛⎝Q11 - Q12⎞⎠ + m 3 ⋅ n ⋅ ⎛⎝Q12 - Q22⎞⎠ + 2 ⋅ m ⋅ n ⋅ ⎛m 2 - n 2 ⎞ ⋅ Q66 = 0 GPa

1,i 1,i 1,i 1,i 1,i 1,i ⎜ ⎝ 1,i 1,i ⎟

⎠

Q'66 ≔ m 2

⋅n 2

⋅ ⎛⎝Q11 + Q22 - 2 ⋅ Q12 - 2 ⋅ Q66⎞⎠ + ⎛m 4

+n 4 ⎞ ⋅ Q = 5.915 GPa

66

1,i 1,i ⎜⎝ 1 , i 1,i ⎟⎠

10.- MATRIZ DE RIGIDEZ A 0 °

⎡ Q'11 Q'12 Q'16 ⎤ ⎡ 61.259 4.165 0 ⎤

⎢ ⎥ ⎢ ⎥ GPa

Q0 ≔ Q'12 Q'22 Q'26 = 4.165 15.254 0

⎢ ⎥ ⎢ ⎥

⎢⎣ Q'16 Q'26 Q'66 ⎥⎦ ⎣ 0 0 5.915 ⎦

11.- MATRIZ DE FLEXIBILIDAD A 0 °

11.- MATRIZ DE FLEXIBILIDAD A 0 °

⎡ 0.017 -0.005 0 ⎤

1

S30 ≔ Q0 -1 = ⎢ -0.005 0.067 0 ⎥ ――

⎢ ⎥ GPa

⎣ 0 0 0.169 ⎦

12.- CÁLCULO DE Q' A 20 °

i≔2

4 2 2 4

Q'11 ≔ m ⋅ Q11 + 2 ⋅ m ⋅n ⋅ ⎛⎝Q12 + 2 ⋅ Q66⎞⎠ + n ⋅ Q22 = 51.279 GPa

1,i 1,i 1,i 1,i

Q'12 ≔ m 2

⋅n 2

⋅ ⎛⎝Q11 + Q22 - 4 ⋅ Q66⎞⎠ + ⎛m 4 + n 4 ⎞ ⋅ Q12 = 8.764 GPa

1,i 1,i ⎜⎝ 1 , i 1,i ⎟

⎠

Q'21 ≔ Q'12 = 8.764 GPa

4 2 2 4

Q'22 ≔ n ⋅ Q11 + 2 ⋅ m ⋅n ⋅ ⎛⎝Q12 + 2 ⋅ Q66⎞⎠ + m ⋅ Q22 = 16.037 GPa

1,i 1,i 1,i 1,i

Q'16 ≔ m 3

⋅n ⋅ ⎛⎝Q11 - Q12⎞⎠ + m ⋅n ⋅ ⎛m 2 - n 2 ⎞ ⋅ Q66 = 12.873 GPa

3

⋅ ⎛⎝Q12 - Q22⎞⎠ - 2 ⋅ m ⋅n

1,i 1,i 1,i 1,i ⎜⎝ 1 , i 1,i ⎟⎠ 1,i 1,i

Q'26 ≔ m ⋅ n 3

⋅ ⎛⎝Q11 - Q12⎞⎠ + m 3

⋅ n ⋅ ⎛⎝Q12 - Q22⎞⎠ + 2 ⋅ m ⋅ n ⋅ ⎛m 2

-n 2 ⎞ ⋅ Q = 1.912 GPa

66

1,i 1,i 1,i 1,i 1,i 1,i ⎜ ⎝ 1,i 1,i ⎟⎠

Q'66 ≔ m 2 ⋅ n 2 ⋅ ⎛⎝Q11 + Q22 - 2 ⋅ Q12 - 2 ⋅ Q66⎞⎠ + ⎛m 4 + n 4 ⎞ ⋅ Q66 = 10.514 GPa

1,i 1,i ⎜⎝ 1 , i 1,i ⎟

⎠

13.- MATRIZ DE FLEXIBILIDAD A 20 °

⎡ Q'11 Q'12 Q'16 ⎤ ⎡ 51.279 8.764 12.873 ⎤

⎢ ⎥

Q20 ≔ Q'12 Q'22 Q'26 = ⎢ 8.764 16.037 1.912 ⎥ GPa

⎢ ⎥ ⎢ ⎥

⎢⎣ Q'16 Q'26 Q'66 ⎥⎦ ⎣ 12.873 1.912 10.514 ⎦

14.- MATRIZ DE FLEXIBILIDAD A 0 °

⎡ 0.0304 -0.0124 -0.035 ⎤

1

S20 ≔ Q20 -1 = ⎢ -0.0124 0.0688 0.0027 ⎥ ――

⎢ ⎥ GPa

⎣ -0.035 0.0027 0.1374 ⎦

15.- CALCULO DE DEFORMACIONES DE LA LÁMINA A EN DIRECCIÓN DEL EJE X

⎡ 10 ⎤ ⎡ 1.209 ⋅ 10 -4 ⎤

⎢ ⎥

σ ≔ ⎢ 10 ⎥ MPa ε ≔ S ⋅ σ = ⎢ 6.225 ⋅ 10 -4 ⎥

⎢ ⎥

⎣ 0 ⎦ ⎣0 ⎦

16.- CÁLCULO DE LA MATRIZ DE TRANSFORMACIÓN A 0 °

16.- CÁLCULO DE LA MATRIZ DE TRANSFORMACIÓN A 0 °

i≔1

⎡ m 2 n 2 2⋅m ⋅n ⎤

⎢ 1 , i 1,i 1,i 1,i ⎥ ⎡1 0 0⎤

T≔⎢ n 2 m 2 -2 ⋅ m ⋅ n ⎥ = ⎢ 0 1 0 ⎥

⎢ 1,i 1,i 1,i 1,i⎥ ⎢ ⎥

⎢ 2 2 ⎥

⎣0 0 1⎦

-m ⋅ n m ⋅n m -n

⎢⎣ 1,i 1,i 1,i 1,i 1,i 1,i ⎥⎦

⎡ m 2 n 2 m ⋅n ⎤

⎢ 1 , i 1,i 1,i 1,i ⎥ ⎡1 0 0⎤

F≔⎢ n 2

m 2

-m ⋅ n ⎥=⎢0 1 0⎥

⎢ 1,i 1,i 1,i 1,i ⎥ ⎢ ⎥

⎢ 2 ⎥ ⎣0 0 1⎦

-2 ⋅ m ⋅ n 2⋅m ⋅n m -n 2

⎢⎣ 1,i 1,i 1,i 1,i 1,i 1,i ⎥⎦

17.-CÁLCULO DE DEFORMACIES DE LAMINAS A 20 °

⎡ 1.209 ⋅ 10 -4 ⎤

⎢ ⎥

ε ≔ F -1 ⋅ S ⋅ T ⋅ σ = ⎢ 6.225 ⋅ 10 -4 ⎥

⎣0 ⎦

18.- CÁLCULO DE LA MATRIZ DE TRANSFORMACION A 20 °

i≔2

⎡ m 2 n 2 2⋅m ⋅n ⎤

⎢ 1 , i 1,i 1,i 1,i ⎥ ⎡ 0.883 0.117 0.643 ⎤

T≔ ⎢ n 2

m 2

-2 ⋅ m ⋅ n ⎥ = ⎢ 0.117 0.883 -0.643 ⎥

⎢ 1,i 1,i 1,i 1,i⎥ ⎢ ⎥

⎢ 2 2 ⎥

⎣ -0.321 0.321 0.766 ⎦

-m ⋅ n m ⋅n m -n

⎢⎣ 1,i 1,i 1,i 1,i 1,i 1,i ⎥⎦

⎡ m 2 n 2 m ⋅n ⎤

⎢ 1 , i 1,i 1,i 1,i ⎥ ⎡ 0.883 0.117 0.321 ⎤

F≔⎢ n 2

m 2

-m ⋅ n ⎥ = ⎢ 0.117 0.883 -0.321 ⎥

⎢ 1,i 1,i 1,i 1,i ⎥ ⎢ ⎥

⎢ 2 ⎥ ⎣ -0.643 0.643 0.766 ⎦

-2 ⋅ m ⋅ n 2⋅m ⋅n m -n 2

⎢⎣ 1,i 1,i 1,i 1,i 1,i 1,i ⎥⎦

19.-CÁLCULO DE DEFORMACIES DE LAMINAS A 20 °

⎡ 3.282 ⋅ 10 -4 ⎤

⎢ ⎥

ε ≔ F -1 ⋅ S20 ⋅ T ⋅ σ = ⎢ 4.153 ⋅ 10 -4 ⎥

⎢⎣ -4.94 ⋅ 10 -4 ⎥⎦

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mantenimiento Programado Vs No Programado (1) - CompressedDocument10 pagesMantenimiento Programado Vs No Programado (1) - CompressedLeo YugchaNo ratings yet

- Problemas de ArmadurasDocument14 pagesProblemas de ArmadurasLeo YugchaNo ratings yet

- Facultad de Ingeniería Civil y MecánicaDocument5 pagesFacultad de Ingeniería Civil y MecánicaLeo YugchaNo ratings yet

- Simulación Circuito OleohidráulicoDocument5 pagesSimulación Circuito OleohidráulicoLeo YugchaNo ratings yet

- Universidad Técnica de Ambato Facultad de Ingeniería Civil Y Mecánica Carrera de MecánicaDocument7 pagesUniversidad Técnica de Ambato Facultad de Ingeniería Civil Y Mecánica Carrera de MecánicaLeo YugchaNo ratings yet

- Cuestionario 1 de Tecnología Del MantenimientoDocument6 pagesCuestionario 1 de Tecnología Del MantenimientoLeo YugchaNo ratings yet