Professional Documents

Culture Documents

Distillation Tower Piping Training File of UHDE, Germany

Distillation Tower Piping Training File of UHDE, Germany

Uploaded by

Wael Mansour0 ratings0% found this document useful (0 votes)

35 views52 pagesOriginal Title

Distillation tower piping training file of UHDE, Germany

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views52 pagesDistillation Tower Piping Training File of UHDE, Germany

Distillation Tower Piping Training File of UHDE, Germany

Uploaded by

Wael MansourCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 52

ELE

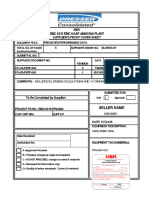

TRAINING MANUAL- PIPING

DOC No. : 29040-PI-UPS-1003

Dato:

PIPING STUDY et

Uhde India Limited COLUMN PIPING Page 1

CONTENTS

Page

09 Cover Sheet 1

List of drawings 2-3

1.0, Introduction 4

20 Distitation 4-6

30 Required Information 6-7

| 40 Sequence of column Pining Study 79

50 Nozzle Orientation and Level 9-10

6.0 Access and Maintenance Facility 10

7.0 Platfotms and Ladders "

“Fiest Edition: RO

Prepared: AKB Checked: TNG

Date:

Date:

‘Sorver:

“File Name: LB1003.—— PUNE:

"| Approved: RUD

Date:

KO: KUMUS 205

:: KUMUS 207

TRAINING MANUAL- PIPING DOC No. : 29040-PLUPS-10

CEE

PIPING STUDY Fev. _:R0

Unde India Limited COLUMN PIPING Page: 2

LIST OF ILLUSTRATIONS

SRNO. PWG.NO. DESCRIPTION

cory ISCHEMATIC- PROCESS OF DISTILLATION TOWER

2 TeLP2 [RUDE DISTILLATION OF PRODUCTS — ACROSS)

___HTEMPERATURE RANGE

3 fours FLOW DIAGRAM OF ABSORPTIONSTRIPPING SYSTEM)

FOR HYDROCARBON RECOVERY FROM GASEOUS,

IMOXTURE

= [errs

5 Ps

je jeLre ITRAVED TOWER

je pers PRAYED Tos

7 err PACKED TOWER |

3 (crs ICOUNTER FLOW (SIEVE & VALVE PLATE DISPERSORS) |

[79 joLPo —|eROSS FLOW-TRAYDETALS SOS

[70 joLPi0 TRAV TYPES BY LIQUID PATHS

11 CLPIt " [PROCESS FLOW DIAGRAM IN TOWER AREA

42 (CLP12 SAMPLE PIPING AND INSTRUMENTATION” DIAGRAW|

___[AROUND a coLuMN ie

3 |CUPIg- EVALUATION. OF THE FLOW DIAGRAM FOR” A

lDIsTLATION COLUMN. TO VISUALISE AN. ORDERLY|

[ARRANGEMENT OF PIPING °

14 CLPi@ TYPICAL PIPIERACK CROSS-SECTION OF A TO

AREA

75 cLPis CAL NOZZLE LOCATION AND PLATFORM

Balls ELEVATIONS

76 (CLPi6 PLATFORM WIDTH REQUIREMENTS

47 (CLP? |TYPICAL PLATFORM ORIENTATION

18 |CLPi@ DETAILS OF CIRCULAR PLATFORM BRACKET SPACINGS

19 |oLPia TOWER PLATFORM AND LADDER ELEVATION]

___ REQUIREMENTS — |

20 |CLP20 TYPICAL PLATFORM ARRANGEMENT

21 |CLP2t DETAILS OF A TYPICAL DISTILLATION COLUMN

2 |CLP22 DETAILS OF TOWER SKIRT Sa

2S |CLP23_TYPICAL_TOWER AREA DWV VARIOUS}

| | Facutes

24 ocPa# ~~ TYBIGAL TOWER PIPING SUPPORT

25 |CLP25 [TYPICAL ARRANGEMENT OF EXTERNAL PIPING AROUND|

~ | coLumn eee

26 |GLP26- [TYPICAL RELIEF VALVE SYSTEM OPEN AND CLOSED)

- IsysTeM

27 |CLP27 PIPING G.A. FOR COLUMN REBOILER PUN

28 |CLP26 NOTES FOR PIPING GA FOR COLUNIN REBOILER PUMP

TRAINING MANUAL- PIPING DOC No. : 29040-PI-UPS-1003

TEES PIPING STUDY Ren) Bo

Uhde India Limited COLUMN PIPING Page 3

'SR.NO. DWG.NO. DESCRIPTION

2)_|GLP29___ |TYPIGAL OPERATOR ACCESS

30 |CLP30 NET POSITIVE SUCTION HEAD (NPSH) OF BOTTONG|

"pup nie

31 |GLP31 TYPICAL TOWER PIPING ARRANGEMENT

@2_|OLP32____TYPIGAL PLAN AND ELEVATION VIEW OF TOWER AREA

33 ~«(CLP33— REBOILER CONNECTION — |

34 |CLP34. ARRANGEMENT FOR KETTLE REBOILERS ~

36 (CLP35. [TYPICAL INSTRUMENT VESSEL =

36 [6LP36 [TYPICAL ARRANGEMENT FOR LEVEL INSTRUMENT]

37 |OLP37 TYPICAL TEMPERATURE AND PRESSURE INSTRUMENT

i INozzLE LOCATION -

| "38 [CLP8 TYPICAL TEMPERATURE AND PRESSURE INSTRUMENT

_|ARRANGEMENTS —_|

39 |GLP30— TYPICAL COMMON — BRIDLE-LEVEL INSTRUMENT]

_|aRANGEMENT

40 |CLP40 TYPICAL TOWER DAVIT ARRANGEMENT

#1 |GLPa?_[TVPIGAL TOWER TROLLEY BEAM ARRANGEMENT —

Uhde India L

TRAINING MANUAL- PIPING DOG No. :29040-P-UPS-1008 |

PIPING STUDY Rov, 3R0

ited COLUMN PIPING Page: 4

190

14

20

INTRODUCTION

Piping study for the column should start after complete understanding of the following

document:

2) Technical specification of the column

») PaID

¢) Unit Plot Plan

4) Basic Engineering document highlighting the specific process requirement, platform

requirement and guidelines for the general arrangement of piping around the column,

@) Details of internal arrangements e.g

for packed type - the packing height, packing support and manhole / hand hole focations,

and for tray type - the nos. of tray, type of tray, downcomer location, manhole location ete.

Instrument data sheet,

@) Line list with operating / design conditions of the fluid

Some understanding of the process function wil faciltate the piping study to meet the

requirements of operation, maintenance, safety and the aesthetics. Various types of column

with their varying functions are in use for refinery and Petrochemical industry.

Generally they are distinguished based on the specific operation for mass transfer viz.

Distilation, Absorption - stripping or Fractionation ete.

DISTILLATION

The distillation is separation of the constituents of a liquid mixture via partial vaporisation of the

‘mixture and separate recovery of vapour and residue.

Various kinds of devices called plates or trays are used to bring the two phases into intimate

contact. The trays are stacked one above the other and enclosed in a cylindrical shell to form a

column,

‘The feed material, which is to be separated into fractions, is introduced at one or more points

along the column shell. Due to difference in gravity between liquid and vapour phases, the

liquid runs down the column, cascading from tray to tray, while vapour goes up the column

contacting the liquid at each tray.

The liquid reaching the bottom of the column is partially vaporised in a heated reboiler to

provide reboll vapour, which is sent back up the column. The remainder ofthe bottom liquid is.

Withdrawn as the bottom product.

‘The vapour reaching the top of column is cooled and condensed to a liquid in the overhead

condenser. Part of this liquid is returned to the column as reflux to provide liquld overflow and

to control the temperature of the fluids in the upper portion of the tower. The remainder of the

overhead stream is withdrawn as the overhead or distilate product,

The Typical distillation process tower is illustrated In Fig.CLP-1 and crude

products across temperature range is illustrated in Fig.CLP-2.

istilation of

o

TRAINING MANUAL- PIPING DOC No. : 29040-PI-UPS-1003,

Unde tndia Limited COLUMN PIPING Poge fs

2.1 ABSORPTION AND STRIPPING

Many operations in petrochemical plants require the absorption of components from gas

streams into lean olls or solvents, The resultant rich oil is then stripped or denuded of the

‘absorbed materials. The greatest use of this operation utlises hydrocarbon materials, but the

principles are applicable to other systems provided adequate equilibrium data is available.

‘A typical flow diagram of absorption-stripping system for hydrocarbon recovery from gaseous

‘mixture is ilustrated in Fig. CLP-3.

2.2 FRACTIONATION

A fractionation column is a type of stil. A simple sill starts with mixed liquids, such as alcoho!

and water produced by fermenting grain etc. and by boiling produces a distilate in which the

concentration of alcohol is many times higher than in feed. In petroleum industry, mixtures of

‘not only two but a lot many components are dealt with. Crude oll is a typical feed for a

fractionation column and from it, the column can form simultaneously several distillates such as

wax distilate, gas ol, eating ol, naptha and fuel gas. These fractions are termed cus

The feed is heated in a furnace before it enters the column, As the feed enters the column,

Quantities of vapour are given off by flashing due to release of pressure on the feed.

As the vapours rise up the column, they come into intimate contact with down flowing liquid,

During this contact, some of the heavier components of the vapour are condensed and some of

the higher components of the down flowing liquid are vaporised. This process is termed

refluxing.

If the composition of the feed remains the same and the column is kept in steady operation, a

temperature distribution establishes in the column. The temperature at any tray Is the boling

Point ofthe liquid on the tray. ‘Cuts’ are not taken from every tray. The P&ID will show cuts that

are to be made, including alternatives. Nozzles on selected trays are piped and nozzles for

alternate operation are provided with line blinds or valves,

‘The fractionator tower is ilustrated in Fig.CPL-4,

‘The typical vacuum tower and stripper is illustrated in Fig.CLP-5. Stripper is used to strip

lighter materials from bottom of a main or a vacuum tower distiling crude bottom residue under

23 INTERNALS

Columns based on internal details are often called as either Plato Columns or Packed

Columns,

Plate Column:

The lighter hydrocarbons vaporise and flow up through the holes in the tray plate, making

contact with the liquids on that tray.

Tray types are: Bubble Cap trays, Valve trays, Sieve trays

Bubble Cap Trays: Bubbling action effects contact. Vapour rises up through ‘risers’ into

bubbie cap, out through slots as bubbles into surrounding liquid on tray. Liquid flow over caps,

‘outlet weir and downcomer to tray below.

TRAINING MANUAL- PIPING DOC No. : 29040-PL-UPS-1003

GEES pe sruby en Ro

COLUMN PIPING Page 56

Unde Indi

Valve Trays: Commonly used valve trays are stamped out by big press and these trays come

with small valves attached to them which allow vapour traffic.

Sieve Trays: Sieve trays are perforated flat plates. They are inexpensive for small diameter

vessels but large diameter towers must have extensive supports for these trays, Sieve trays

are used for heavy hydrocarbon fractionation,

All trays have foam on top of liquid. The height of the foam will vary with the process. Fosm

may rise a foot or more above the tray liquid.

Liquid-gas contacting is made effective through the above trays by cross-flow or counter flow.

In counter flow plates, liquid and gas utilise the same openings for flow, thus there are no

downcomers.

Perforated plate with liquid cross flow (sieve plate) is the commonly specified tray.

These two types of flow is illustrated in Fig.CLP - 8

‘The two most commonly used types of tower viz. the trayed and packed arrangements are

llustrated in Fig.CLP-6 and Fig.CLP-7 respectively

3.0 REQUIRED INFORMATION

‘The basic document listed in Cl.1.0 shall be studied thoroughly for conceptual arrangement of

piping around a column,

3.1 The basic layout and general engineering specifications describe

The minimum access, walkways, platforms width and headroom requirements.

Handling facilities for tower internals, manhole covers, line blinds, relief valves,

Maximum rise of ladders.

Pipe-system requirements, such as open or closed relieving systems,

Minimum tine-size and required hose-stations.

‘Access to valves and instruments.

3.2. Design Standards show:

+ Details of ladder dimensions

+ Ladder and platform position (Step through or side step landings)

+ Toe-plate, handrail and safety-gate details.

3.3 PID and Technical specification of column provide

+ Process data showing interconnected equipment and piping,

+ Pipe sizes and pipeline components.

+ Steam tracing and insulation thickness.

+ Tower elevations and differences in related equipment levels,

3.4 Plot Plan gives:

+The physical location of a column and its relationship to other equipment.

+ Main access.

* Main pipe run o pipe rack,

‘+ Location of pumps.

‘A typical cross-section of a piperack running through the tower area of a refinery type plant is

illustrated in Fig.CLP-14,

CEE Senaeney Ren RO

‘Uhde India Limited COLUMN PIPING Pogo 7

TRAINING MANUAL- PIPING DOC No.

35

36

49

44

42

43

44

45

46

47

48

‘A typical plan of equipments located in the refinery type of plants highlighting the maintenance

access is illustrated in Fig.CLP-32.

Instrument standard shows:

* The location of instrument connections to tower for gauges, level controllers and level

alarms.

* Location of pressure and temperature connections without orientation.

* The instrumentation systems around the tower are depicted in the P&ID.

Fabrication drawing / detail dimensional drg. of column provides

‘+ Diameter and height of column.

Details and dimensions of internals.

Manhole

Process-piping connections in elevation (without orientation)

Drum, pump, exchanger drawings giving details of adjacent process equipment or

equipment supported on column itself

‘An integrated piping study should be developed from the above information,

The piping study should take care of all the general recommendations of piping arrangement

around the column and its related equipment and facilities as illustrated in Fig.CLP-25

"Typical arrangement of external piping around column"

SEQUENCE OF COLUMN PIPING STUDY

All available information / data from Equipment specification and P&ID shall be written on the

‘lovation view of the column as ilustrated in Fig.CLP-12, CLP-13 & CLP-15,

‘The designer now starts thinking about the proper orientation of nozzles and provisions for

access to the points of operation and maintenance.

Considerations of the pipeline leaving the tower area and the adjacent piping shall be

visualised.

‘The first step is to orient the manholes preferably all in same directions, Normally, manholes

shall be oriented towards dropout area within a 30° segment of column as this facitates the

lowering of tower internals to the main access way. The manhole segment of platform should

not be occupied by any piperack.

A break in ladder rise (normal 5m, maximum 7m) will occupy another segment of column for

platform.

‘The levels of platforms are to be decided on the elevation view based on the manholes and

access to relief valves, instrument for viewing,

Al platform levels in the proper segments of the tower with ladder location should be drawn on

plan view. The manhole shall be shown in proper segment with the angle of orientation, and

the space for the swing of manhole cover taking davit hinge as centre.

Layout should be started from the top of the column with the designer visualising the layout as a

whole. There will be no difficulty in dropping large overhead line straight down the side of a

column, and leaves the column at a high level and crosses directly to the condenser. This

clears a segment at lower elevations for piping or for a ladder from grade level to the first

platform.

CEE pie sto Ren Ro

Uhde India Limited COLUMN PIPING Page: 8

49° Flexibility and thermal load connected with the large-dia overhead lines to the condenser at

grade level or higher level shall be considered. The relief valve protecting the tower is usually

connected to the overhead line. A relief valve discharging to atmosphere should be located on

the highest tower platform,

In a closed relief-line system, the relief-valve should be located on the lowest tower platform

above the relief -systern header. This will result in the shortest relief-valve discharge leads to

the flare header. The entire relietline system should be self-draining,

4.10 From layout point of view, itis preferable to space the platform brackets on the tower equally

and to align the brackets over each other for the entire length of the tower. This will minimise

interferences between piping and structural members.

4.11 Nozzles and piping must mest process requirements while platforms must satisly maintenance

and operating needs. Access for tower piping, valves and instruments influence placement of

ladders.

4.12. In routing pipelines, the problem is faced to interconnected tower nozzles with other remote

points. The tentative orientation of a given tower nozzle is on the line belween tower centre and

the point to which the line is supposed to run. Segments for piping going to equipment at grade

8.9. condenser and reboiler lines are available between ladders and both sides of manhole,

See the Fig. CLP-21 / 31 for overall orientation of a distillation column,

Line approaching the yard/piperack can tum loft or right depending on the overall arrangement

Of the plant. The respective segments of these lines are between the ladders and 180°. The

segment at 180° is convenient for lines without valves and instruments, because this is the

point farthest from manhole platforms,

The sequence of lines around the tower is influenced by conditions at grade level. Piping

arrangements without lines crossing over each other give a neat appearance and usually a

more convenient installation.

4.13 The correct relationship between process nozzles and tower internals is very important. An

angle is usually chosen between the radial centroline of internals and tower-shell centrelines,

By proper choice of this angle (usually 45° or 90° to the piperack) many hours of work and

future inconvenience can be saved. Tower piping, simplicity of internal piping and manholes

access into the tower are affected by this angle. After this, the information produced by the

designer results in selecting the correct orientation of tower nozzles.

4.14 A davit usually handles heavy equiment such as large-size relief valves and large-diameter

blinds. If the davit is at the top of the tower, it can also serve for lifting and lowering tower

internals to grade.

Clearance for the lifting tackle to all points from which handling is required, and good access

should be provided,

4.15. Very often, interpretation of process requirements inside a tower is more exact than for exterior

piping design. The location of an internal part determines, within strict physical limits, the

location of tower nozzles, instruments, piping and the steshvork. The layout designer have to

concentrate on a large-scale drawing of tower-internal detalls and arrangement of process

piping to finalise the piping study.

4.16 Access, whether internal or extemal is very important. This includes accessibility of

connections from ladders and platforms and internal accessibility through shell manholes,

handholes or removable sections of trays. A manhole openings must not be obstructed by

intemal piping

TRAINING MANUAL- PIPING DOC No. : 29040-P-UPS-1003

TRAINING MANUAL- PIPING DOC No. : 29040-PI-UPS-1003,

PIPING STUDY Fey =

Unde India Limited COLUMN PIPING Poe 48

47

418

50

64

62

53

Reboiler-line elevations are determined by the draw off and retumn nozzles and the'r orientation

Is influenced by thermal flexibility considerations, Reboller lines and the overhead lines should

be as simple and direct as possible.

Fig.CLP-23 shows the segments of tower circumference allotted to piping, nozzles, manholes,

platform brackets and ladders as normally recommended to develop a well-designed layout,

NOZZLE ORIENTATION AND LEVEL

Nozzles are located at various levels on the tower to meet the process and intstrumentation

requirements.

MANHOLES

Nozzles are to be oriented Keeping provision for maintenance and operation neads.

Manholes are usually located at bottom, top and intermediate sections of tower. These

access nozzles must not be located at the downcomer sections of the tower or the seal pot

sections of the tower.

Where internal piping is arranged over a tray, manhole shall be provided but it should be

‘ensured that the internals do not block the maintenance access through the manhole,

Possible location of manhole and handholes within the angular limits of b* are illustrated in

dotal-2 of Fig.CLP-21

REBOILER CONNECTIONS

Reboiler connections are normally located at the bottom section of the tower. Detail-1 of

.CLP-21 shows reboiler draw-off connections for single-low tray. This connection can be

very important for arranging tray orientation, The simplest, most economical location for

reboller connections with the alternative location within the angular limits of a° is shown. The

angle a depends on the size of reboiler draw off nozzle and the width of the boot

(dimension b) at the tray down flow.

The return connection from the thermosyphon reboilers is shown in detall-1 of Fig.CLP-21

‘These lines should be as simple and as direct as possible, consistant with the requirements of

thermal flexibility,

For horizontally mounted thermosyphon reboiler, the draw off nozzle is located just below the

bottom tray and for vertically mounted recirculating thermosyphon reboiler, the draw off

nozzle is located at the bottom head. For both the systems, the return nozzles are located

just above the liquid level as shown in Fig.CLP-33,

REFLUX CONNECTIONS

Reflux nozzles are provided with internal pipes that discharge the liquid into the sealpot of the

tray below. Detail 3 of Fig.CLP-21 shows the reflux connactions. Care must be taken that

the horizontal leg of the intemal pipe clears the tops of bubble caps or weirs. It must be

ensured that the internal pipe can be fabricated for easy removal through a manhole or can

be fabricated inside the tower shell

ChE

TRAINING MANUAL- PIPING DOC No. : 29040-PI-UPS-1003,

PIPING STUDY ny ene

Unde India Limited COLUMN PIPING Pope: 10

54

65

56

60

64

62

63

OVERHEAD CONNECTIONS

‘The vapour outlet nozzle is usually a vertical nozzie on the top head of tower. In addition, the

vent and relief valve could be located on the top head with a typical platform arrangement for

access to vent, instrument connections and top manhole. In a closed relief line system, relief

valve should be located on the lowest tower platform above the relief system header. This will

result in the shortest relief valve discharge leads. The entire reli ine system should be self

draining.

BOTTOM CONNECTIONS

“The liquid outlet is located on the bottom head of the tower. If the tower is supported on skirt,

the nozzle is routed outside the skirt as shown in Fig.CLP-22. The elevation and orientation

Of this line is generally dictated by the pump NPSH requirement and the pump suction line

flexibility. (see Fig.CLP-30)

VEL INST!

‘The temperature and pressure instrument connections are located throughout the tower. The

temperature probe must be located in a liquid space and the pressure connection in a vapour

space as shown in Fig.CLP 37.

‘The level instruments are located in the liquid section of the tower usually atthe bottom. Tho

elevation of the nozzles is decided by the amount of liquid being éontfolled or measured and

by standard controller and guage glass lengths. Level controllers must be operable from

grade or platform and level guages / switches may be from a ladder if no platform is available.

Fig.CLP-35, 36, 37, 38, 39 lusirates a few instrument connections on tower.

ACCESS AND MAINTENANCE FACILITY

‘Access whether internal or extemal is very important, This includes accessibility of

connections from ladders and platforms and internal accessibility through shell manholes,

handholes or removable sections of trays.

Tower maintenance is usualy limited to removal of exterior items (e.g. relief or control valves)

and interior components (e.9. trays or packing rings) Handling of these items is achieved by

fixed devices (e.g. davits or trolley beams) or by mobile equipment (e.g. cranes). When

davits or beams are used, they are located at the top of the tower. accessible from a platform

and designed to lower the heaviest removable item to a specific drop out area at grade level.

When mobile equipment is used, a clear space must be provided at the back (side opposite to

piperack) ofthe tower that is accessible from plant auxiliary road.

CLP-16, 25, 29, 32 illustrates the access and maintenance facies to be considered in

the piping arrangement around a tower.

(On free-standing columns, access for major maintenance to insulation or painting will usually

require the erection of temporary scaffolding. Space for scaffolding at grade level and

provision of cleats on the shell to facilitate scaffold erection should be considered.

Ustity stations of two services viz. steam and air are usually provided on maintenance platforms.

Steam and air risers should be located during piping study to keep adequate cleats for support.

(see Fig.CLP-20)

TRAINING MANUAL- PIPING DOC No. : 29040-PI-UPS-1003,

CoE fon

PIPING STUDY

Unde tndia Limited COLUNN PIPING Poe: ul

7.0 PLATFORMS AND LADDERS

7.4 Platforms on towers are required for access to valves, instruments, blinds and maintenance

accesses. Platforms are normally circular and supported by brackets attached to the side of

the tower. Generally, access to platforms is by ladder. Fig.CLP-19 illustrates the platform

roquirements,

7.2 Platform elevations for towers are set by the items that require operation and maintenance.

‘The maximum ladder run should not exceed 7m.

7.3. Platform widths are dictated by operator access. The clear space on platform width shall be

‘min. 900mm.

For platforms with control stations, the width of platform shall be 800mm plus the width of

control station.

‘The platform for manholes and maintenance access, adequate space for swing the cover

flange flange must be provided.

7.4. Top-head platforms for access to vents, instruments and relief valves are supported on head

by trunions,

7.5 Recess between towers may be connected by common platforming.

7.6 tis preferrable to space platform brackets on tower equally and to align brackets over each

‘other over the entire length of shell. This minimises the structural design and interferences.

ftom piping,

7.7 On very wide platforms or those that support heavy piping loads, knee bracing is required in

addition fo the usual platform steel. The potential obstruction immediately under the knee.

brace must be kept in mind during platform design.

7.8 Fig.CLP 15, 16, 17, 18, 19, 20 ilustrates a few platform considerations.

TE

Unde India Limited

TRAINING MANUAL - PIPING DOC NO. : 29040-P1-UPS-1003

Rev. :RO

PIPING STUDY

COLUMN PIPING Page :10F1

DWG:NO. CPE

[DISTILLATION

SCHEMATIC PROCESS OF DISTILLATION TOWER |

RECTIACATION

SECTION

“STRIPPING

SECTION:

— | —_2 —-

DIRECT STEAM TO

BorroNs Pa

‘CONDENSER

n

REFLUX

‘VAPOUR PRODUCT

iv ue RECEIVER ORUM

DISTILLATE PRODUCT

___Feep TRAY

REBOWLER

a BOTTOMS PRODUCT

‘BOTTOMS PUMP

Tor

Unde India Limited

TRAINING MANUAL - PIPING Doc No.

PIPING STUDY

COLUMN PIPING

Rev.

Page

29040-PLUPS. 1003

Ro

10F1

CRUDE DISTILLATION OF PRODUCTS ACROSS

2 CRUDE OL

TEMPERATURE RANGE

oo BUTANE AND

a LIGHTER GAS

80°F.200 STRAIGHT RUN,

(ECOG) GASOLINE

20076215 __NAPHTHA.

(o4"G-167°6)

S1SF-450°F KEROSENE

(srexT oy

450°F-650°F __uGHT GAS

(eres) OL

HEAVY GAS.

OL

00" STRAIGHT RUN

(are RESIDUE

DWG.NO. -GLP2

\WITH WE RISE IN TEMPERATURE OF CRUDE OI, INITIAL BOILING PONT IS REACHED.

‘THE LIGHTEST MATERIAL, BUTANE PRODUCED FIRST, JUST BELOW T00"F (28°C)

‘THE HEAVIEST MATERIALS ARE PRODUCED BELOW 800° (427°C)

‘THE DISTRIBUTION OF THE DIFFERENT PRODUCTS AT VARIOUS TEMPERATURE RANGES

ARE SHOWN ABOVE.

TRAINING MANUAL - PIPING boc No,

29040-P/LUPS-1003

Ro

PIPING STUDY

Ubde India Limited COLUMN PIPING Pege 31 0F1

(WG.NO, 7 LPS

ABSORPTION &

STRIPPING

FLOW DIAGRAM OF ABSORPTION-STRIPPING SYSTEM FOR

HYDROCARBON RECOVERY FROM GASEOUS MIXTURE

OFFA

zo

a PREHEATER

(CONDENSOR

IBSORAER, ‘COOLER RAW GASOLINE

id

pac on

:

Lee

[—stRippinc STEAM

TRAINING MANUAL - PIPING DOC NO, : 29040-PLUPS-1003

JUHDE} fen

PIPING STUDY

Ubde India Limited COLUMN PIPING Page 1 0F1

DWG.NO. : CLP

FRACTIONATION

SCHEMATIC PROCESS OF FRACTIONATION TOWER

oF

‘sms a

‘STU 00°F

sma iF Conoenser

‘sTuL2

wor

aoe

ose

ove

REFLUX RETURN LINE

eo

REE L YHyyy LY

Yj

gZ Lill”

PRopucr

BorroMs SOFC)

fr

de India

imiced

TRAINING MANUAL - PIPING DOC No.

Rev.

PIPING STUDY

COLUMN PIPING Page

VACUUM TOWER & STRIPPER

T

lela

|

f vacuum Towen

|

| L

~ 1

| L oa

21 I?

t Pine

I As

4 9 9

—-

| © a 9|

El | I

q : '

JLo) JL lol

|

|

{

29040-PLUPS-1003,

UHDE|

TRAINING MANUAL - PIPING

DOC NO. :29040-PLUPS-1003

Fev RO

PIPING STUDY

Uhde India Limited COLUMN PIPING Page 10F1

On Wo Tee

TRAYED TOWER

oN

ed }:

| sux

ray

MAINTENANCE -] “

recess Hep ormnorr ,

— exer

reeo— +—e

fenouen

RerOnt

~ Leven

ements

Tors

TRAINING MANUAL - PIPING DOC NO, : 29040-Pi-UPS-1003

Rev, -RO

PIPING STUDY

Uhde India Limited COLUMN PIPING Poge 1 0F1

DWGNO CPF

PACKED TOWER

Sc

teva. wsmeuvenrs C-|

QUID DISTRIBUTOR

PACKING

F-}-+— MAINTENANCE ACCESS (TYP)

casinter —_--]

au ourter

TRAINING MANUAL - PIPING DOC NO. :29040-PLUPS-1003

PIPING STUDY

Ubde India Limited COLUMN PIPING Page :10F1

DWG.NO. guste coma |

Te

|

ie

|

fearon TT =

t

1

ELEVATION

TRAINING MANUAL - PIPING

PoE nen Fo

PIPING STUDY

‘Unde India Limited COLUMN PIPING Page 91 0F1

DOG NO. : 29040-P1-UPS.

in| evo arroras wy

Fife DAT FEO TH RESUFEVENTS

|

jt =

L | Lanne

|

|

—

(CONGESTED PLATFORM WIDTH REQUIREMENTS

Larronu mom ARE DEDIDED AG PER OPERATOR AGGEGS FOR RATEROM WTI GONTADLSLDGATEO AT

She SE OF PLATFOn Te MDTHIAIST BE Soa PLUS THE WOTHOF THe CONTROLS ORPRO SECTIONS

One MANTENACE baw

Resource

sasorneens _f |

MAINTENANCE ACCESS ARRANGEMENTS.

AT Manire44CE ACCESS PLATFORM ADEQUATE SPACE TO SWING INE ACCESS COVER FLANGE TOBE PROVIDED.

‘TopeAD MANTENANGE ACCESS MUST BE FREE FROM THREE IDES

firs

PIPING STUD’

TRAINING MANUAL - PIPING DOC NO. : 29040-P1-UPS-1003

Unde India Limited COLUMN PIPING Page :10F 1

Rey. :RO

YY

DWG.NO.:CLPIT

TYPICAL PLATFORM ORIENTATION

PLATEORM

EC ooo"

PLATFORM EL.109-0" TO 139-0"

102.740 111.890,

PLATFORM

aL e5:0"

PLATFORM EL.169-0" TO 178'

121.030 123.800

PLATFORM

ali

PLATFORM EL.139-0" TO 169-0"

114.890 121.030

TRAINING MANUAL - PIPING DOC NO, 25040-2-UPS-1003

Crs Rew

PIPING STUDY “

‘Unde India Limited COLUMN PIPING Page 10F1

Dwo-WO cure

DETAILS OF CIRCULAR PLATFORM

BRACKET SPACINGS

2

eMaNHOLE.

INSIDE,

a0,

srTose

ecient

[ugg exer ater

wee [ele]

sup To 7m Tae | ae

TRAINING MANUAL - PIPING DOC NO. :29040-PLUPS-1003

PIPING STUDY

Unde Inia Limited COLUMN PIPING Page :10F1

DWE.NO. :cLPIa

TOWER PLATFORM AND.

LADDER ELEVATION REQUIREMENTS

[MAINTENANCE ACCESS PLATFORMS WITH

[MINIMUM CLEARANCE INDICATED,

‘TOP HEAD PLATFORM

VENT ACCESS

ancrenoce

Senos

Ls eel in

PLATFORM,

aye)

I

- | rewrerature &

va PRESSURE POINT ACCESS BY

I ADDER OR PLATFORM

ines

[e607 2020)

LapoeR:

NO ACCESS REQUIRED

MAINTENANCE &

VALVE ACCESS

(S0°T0 5.0"

INTERMEDIATE PLATFORM

‘Tosurr wound

TRODER RUN

ALTERNATE VALVE.

‘AGcESS WTH OF

{WITHOUT STEM EXTENSION

|

i

BIR enna

{—conTRou NsTRUMENT &

aT iaINTENANCE ACCESS

#-0" (300)

TaN

eve, Gause access ——~ if

‘BY {ADDER OR PLATFORM DRAIN VALVE ACCESS

‘PROM GRADE

Fors

Unde India Limited

TRAINING MANUAL - PIPING OC NO. : 29040-PL-UPS-1003

PLATEORM

eLors"

‘0270

Rev. RO

PIPING STUDY

COLUMN PIPING Pago :40F1

DWG.NO. .cLPeO

TYPICAL PLATFORM ARRANGEMENT

PLATFORMS ARE REQUIRED ON TOWERS FOR ACCESS TOVALVES,

INSTRUMENTS, BLINDS AND MAINTENANCE ACCESS. PLATFORWS ARE

USUALLY CIRCULAR AND SUPPORTED BY BRACKETS ATTACHED TO

"THE TOWER. ACCESS TO PLATFORM IS GENERALLY BY LADOER.

— PREFERRED LOCATION

PING ‘ACCESS NOT REQUIRED

PAST STANDPIPE

‘BINGTRUMENTS

LEVELINSTRUMENTS,

— tanner To

UPPERLEVEL

LADDER CAGE

—— PLATFORM supPoRT

BRACKETS,

MAINTENANCE ACCESS

TRAINING MANUAL - PIPING DO NO. :29040-P-UPS.

Rev. 2

PIPING STUDY

Unde India Limited COLUMN PIPING _ Ps 1OF1

DETAILS OF A TYPICAL DISTILLATION COLUMN

omenrarion

rane

(morrays ar frozueo

TeePncnG) svapourour

E @

*| bs. I ‘8, SIMPLEST REFLUX PIPE b, REFLUX PIPE MUST CLEAR

— [BUBBLE CAPS AND Wr

* PS ETALS [DETAIL 3 : REFLUX CONNECTIONS

| @ SEE DETAL 28 im > .

t

al I

t M7

“et tf © ‘SIMILIAR TO DETAIL-3 TRAY AREAS _-f =j

Fp cn : ZI

E J oumnowarer |” ILO

a ou.

Se ! ©. I | sce pera LL " Y scauroraren NO

is

© | Ad !

—y 4 SINGLE FLOW TRAY ».00UBLE FLOW TRAY

»| DETAIL 2 : MANHOLE LOCATIONS

| °| 8" REBOILER ORAWOFF

| 1 DRAN =, 7

wef oH

a \— Secor Wy

‘uQuD

tae, ,

® orton tray ——. —#

|

@emwoes — Tesorromout ' Ie AREROILER DRANOFF

sesouenserumn | | -tRarour oor

Nowe

SINGLE LOW TRAY

DETAIL 1 : REBOILER CONNECTIONS

TRAINING MANUAL - PIPING DOC NO. : 29040-P1.UPS-1003

FEET a

PIPING STUDY

Uhde India Limited COLUMN PIPING Page OFT

Owe. NO. LPH

DETAILS OF TOWER SKIRT

jee

‘00

wor ohare rons 18708 |

ancenr une [| | | Los

eo mmone ; 4} ‘esis

NE OpeNING l + vent hoe

el? L

SE somou - i = ton Riamasa

one 7

a aes

K 7 i __ SKIRT ACCESS OPENING

hs A een

| Soeare | :

se | omge |

ae : socrwoues

| 7\ | co j é STFFENING ANG

ft f SASE RNG

I ‘VE et 100-0"

- te

OF SUPPORT

wore

‘8000

EET

Uhde India Limited

TRAINING MANUAL - PIPING

PIPING STUDY

COLUMN PIPING

DOC NO. :29040-PI-UPS-1008

Rev.

Page

Ro

1081

TYPICAL TOWER AREA DIVISION

FOR VARIOUS FACILITIES

PREFERRED AREAS FOR PIPING, PLATFORMING AND

LADDERS TO BE LOCATED IN CONJUCTION WITH

"TRAY, NOZZLE AND PLATFORM ORIENTATION,

DWG.NO, -C1Pz

PIPE RACK

fo} — -— -—-— fp

EA

|

|

|

#

VERTICAL PIPING AREA

Ha} — - —-—-— 4+]

PLATFORM OPERATING &

WAINTENANCE AREA

for

Unde India Limited

TRAINING MANUAL - PIPING

PIPING STUDY

COLUMN PIPING

DOG NO. ; 29040-P1-UPS-1003

Rev, RO.

Page 21 0F4

DAG NO CuPea

TYPICAL TOWER PIPING SUPPORT

"ADEQUATE SPACE BETWEEN BACK OF PIPING AND

‘TOWER SHELL TO FACILITATE INSTALLATION OF

PIPE SUPPORTS,

£1400 MALE

{FINSULATION

SH

1200

‘COMMON BoP

TOEATED PIPING.

\

RADIAL LOCATED

4 BING

se

f Untiry Princ

> «1100

OVERHEAD

YabOUR

UNE

S]_h, 9 -— rrurwon

| iA supose

| 4

7

—vesser

ce

cue

TES

‘Unde India Limited

TRAINING MANUAL - PIPING:

PIPING STUDY

COLUMN PIPING

DOG NO. : 29040-P1-UPS-1003

Rev.

Page

RO

10F1

TYPICAL ARRANGEMENT OF EXTERNAL PIPING AROUND COLUMN | ONS “A

ouraronioouis

a?

saver never vaive:

INDPRESSURE)

wee ——l —

——

| NEAR FRACTIONS)

joer

‘MANHOLE (FOR, f

sae

KI —™™ HEAVY CUT

Lise

mI

oe |

SikxouiN) }

saute on ET.

‘Unde India Limited

TRAINING MANUAL - PIPING

PIPING STUDY

COLUMN PIPING

ferwaresocanen

TYPICAL RELIEF VALVE SYSTEM

OPEN AND CLOSED SYSTEM

(OPEN TO ATMOSPHERE RELIEF VALVE SYSTEM LOCATED ON

‘THE TOP OF TOWER CLOSED RELIEF VALVE SYSTEM TOBE.

LOCATED AT A MINIMUM DISTANCE ABOVE THE RELIEF HEADER,

DISTANCE

ATMOSPHERIC RELIEF VALVE

PREFERRED LOCATION

tapoer

ve)

PLATFORM —

(ne)

OVERHEAD UNE

‘CLOSED SYSTEM RELIEF

VALVE PREFERRED LOCATION

(CLOSEST AVAILABLE PLATFORM

‘ABOVE RELIEF VALVE HEADER)

|

| ety rer ve

| Tobe

| |

TRAINING MANUAL - PIPING DOC NO. : 29040-P1-UPS-1003

CES Ren 80

PIPING STUDY

‘Unde India Limited COLUMN PIPING Page :10F1

DWO.NO.ciPz

PIPING GA. FOR COLUMN-REBOLER PUMP

rons oars

Soiree tar

cen ATEN

EE

‘Unde India Limited

TRAINING MANUAL - PIPING

PIPING STUDY

COLUMN PIPING Page :10F1

DOC NO. : 29040-PL-UPS-1003.

Rev. :RO

1DWG.NO..cLPam

‘GA. FOR COLUMVREBOUER

21 moe ont aU usc oc no Toman ACTON

Pt noe eon sus SCE

rouse manna oaruaese ove,

TRAINING MANUAL - PIPING DOC NO. : 29040-P-UPS-1003

Tors fen 0

PIPING STUDY

‘Unde India Limited COLUMN PIPING Page :10F1

DWO.NO, CLP

TYPICAL OPERATOR ACCESS

‘TYPICAL MAINTENANCE ACCESS

“THE CLEARANCES FOR TE OPERATOR ACCESS |

dno iuinrehanee Access cancoMe Ines, Be

{THE OUDELINES FOR TOWER BOTTOM ELEVATION j

EGET

Unde India Limited

TRAINING MANUAL - PIPING DOC NO. :29040.P-UPS-1003

Rev

PIPING STUDY

COLUMN PIPING Page

Ro

10F1

NET POSITIVE SUCTION HEAD (NPSH) OF BOTTOM PUMPS

‘Min NPSH REQUIREMENT IS A EY FAGTOR

IN DECIDING THE ELEVATION OF THE TOWER.

WG. NO,

iP

TRAINING MANUAL - PIPING DOC NO. : 29040-F1-UPS-1003

UHDE} Ree no

PIPING STUDY

‘Unde India Limited COLUMN PIPING Page 10F1

DW.NO. cima

TYPICAL TOWER PIPING ARRANGEMENT

THE PIPING ARRANGEVENT ARE TO BE DESIGNED BASED OW

PROCESS VESSEL SKETCH, TRAY OSTAKS, NOZZLE ELEVATION.

|

ova g ah

(COWNCOMER: oT

pea ,

guapoer/ -

ae

4

a; contmot stant

sa CERSPKCENT

clea fy recur oruntoie

PLAN EL.169-0" TO 178-1"

100.000 117.89, 111.890 127.030

NOTE : REF.CLP12 FOR TYPICAL P&l DIAGRAM.

TRAINING MANUAL - PIPING DOC NO. : 29040-PI-UPS-1003

PIPING STUDY

COLUMN PIPING Pege 1 0F1

Uhde India Li

DWG.RO GPR

TYPICAL PLAN AND ELEVATION VIEW OF TOWER AREA

oversea.

Sonbencens

ul [

ye lam cootens:

aa

|

| 7

| 2 2

ELEVATION

PIPE RACK

MAINTENANCE

‘ACCESS WAY jprereicononen

; ———— sy

®

: a q 4

t t f

1 + I

sorrous Puues!

REFLUX PUPS.

TRAINING MANUAL - PIPING DOC NO. : 29040-P-UPS-1003,

Re RO

PIPING STUDY

COLUMN PIPING Page 101

DWG.NO, -CLPIS

REBOILER CONNECTION —

a HORIZONTAL REBOILER |

Hic

tauio

LeveL ALTERNATE {=f

segs

etic

q

CZ essai

TOWER

| a.vermicat Resour |

vowncouen

se

sce

fet

tse hes wat car

ORAWOFF

rE

TRAINING MANUAL - PIPING Doc NO,

Rov Ro

PIPING STUDY

Uhde COLUMN PIPING 1

| PIPING G.A. FOR COLUMN-REBOILER PUMP |

oven,

eNsTH

ovens

c — WEIR HEIGHT APPRX.

icon SSO RESOUER

paren ‘SURGE VOLUME BY PROCESS,

[-800 san (SHOWN ON DATA SHEET)

ao vapor 4

5} ‘ALTERNATE LOCATIONS OF NOZZLES

q Sn. ae srecieoey nyernocess

3| Bisneceeee ant

as (Shown on onra SHEET)

a ne

Fema. inoue

g|

5

g

-OUNOATION:

HIGH PowT OF

FINSHED SURFACE

ee Meoiuw our

THERMOWELL

TEMP INDICATOR \PUMP AND OR COOLER

POSSIBLY BETWEEN REBOLER

[AND CONTROL VALVE

DIAGRAMMATIC ELEVATION

(FOR USUAL ARRANGEMENT SEE PLAN BELOW)

NOTES:

‘THIS ARRANGEMENT FOR KETTLE REBOILERS, WICH I THE TYPE MOST

‘COMMONLY USED, HAS MIEMIUM LIQUID HELD IN COLUMN AND

‘OPERATING SURGE IS IN KETTLE

1) SET KETTLE AT MIN, ELEV. TO SUIT PRODUCT LINE PRESSURE DROP

(OR PUMP SUCTION REQUIREMENTS,

2) WEIR HEIGHT DEPENDS ON REBOILER SELECTION.

'3) HEAD EQUALS NORMAL PRESSURE OROP FOR LINES AND REBOILER.

4) HEAD AT MAX. LEVEL GIVES 100% SAFETY OVER NORMAL,

5) USUALLY TRAY SPACING + 1SOMMM, PROCESS WILL SPECIFY,

6) PROCESS WL SET DIMENSION,

7) LGAND LC NOT REQUIRED ON COLUMN FOR THIS HOOKUP.

8) SET SKIRT HEIGHT TO SATISFY NOTES 1.2AND 3.

8) ANCHOR LOCATION DEPENDS ON RELATIONSHIP OF RESOILER WITH

‘COLUMN ANCHOR ONE END ONLY.

10) SURGE VOLUME IS NORMALLY A MIN. OF 2BUNUTES.

11) IF THIS THE COLUMN DRAM, PIPE TO DRAIN FUNNEL.

TRAINING MANUAL - PIPING DOC No.

Rev.

PIPING STUDY

COLUMN PIPING Page

29040-PLUPS-1003,

Ro

10F1

DWG.NO. :CLPR5

‘TYPICAL INSTRUMENT VESSEL SKETCH

Ths TANGENT UNE

‘THD= THREADED

RE RAISED FACE

Joy

2S,

suet

UHDE}

Uhde India Limited

TRAINING MANUAL - PIPING DOC NO.» 29040-PLUPS-1003,

Rev. Ro

PIPING STUDY

COLUMN PIPING Page :10F1

WG WO, /CLP36

TYPICAL ARRANGEMENT FOR LEVEL INSTRUMENT

(COVER SWING AREA

PLAN

LeveL swires

PLAN

LeveL CONTROLLER

GISHTHAND

env oR@2 —

so" 10 6-9"

300 TO 2080

ELEVATION

SINGLE MOUNTED LEVEL CONTROLLER

ELEVATION

‘SINGLE MOUNTED LEVEL GAUGE AND SWITCH

TRAINING MANUAL - PIPING

Tr PIPING STUDY

Ubde India Limited COLUMN PIPING

DOC NO, : 28040-P-UPS-1003

Rev, RO

Pago 1 0F1

DAG NO. / CUPS?

TYPICAL TEMPERATURE & PRESSURE INSTRUMENT NOZZLE LOCATIONS.

PRESSURE.

SPACE

PRESSURE INSTRUMENT

— Neate SeerATONS

ORIENTATIONS

TRAINING MANUAL - PIPING DOC NO. : 29040-PI-UPS-1003

PIPING STUDY

Ubde India Limited COLUMN PIPING Page: 10F1

L ‘TYPICAL TEMPERATURE AND PRESSURE INSTRUMENT ARRANGEMENTS:

DOMINCOMER AREA

\" PRESSURE GAUGES

Loewy wousten

‘iA THERMOMETER

tae _t t

mr)

Prone

WHEN oR ENING

TEMPERATURE NOZZLES: iam

heck FoR ADEQUATE Boaro MoureD

GlEgmance oF Prove SRemnccoune = conpurr

Wir DOWNCOMER WALL,

TRAINING MANUAL - PIPING

PIPING STUDY

COLUMN PIPING

DOC NO. : 29040-PI-UPS-1003,

Rev. RO

Page :10F1

TYPICAL COMMON BRIDLE-LEVEL INSTRUMENT ARRANGEMENT

5" STANDPIPE:

DWG.NO. 1 UPS

TRAINING MANUAL - PIPING DOC NO. | 29040-P/-UPS-1003

oavir

Rev. :RO

PIPING STUDY

‘Unde Inds Limited COLUMN PIPING Page :10F1

DWO.NO.

TYPICAL TOWER DAVIT ARRANGEMENT

ALTERNATIVE DAVITLOCATION

‘SUPPORTED FROM PLATFORM

Be 10.08"

avir supPORT

Fromvesse. —}

ELEVATION

Carr

Uhde India Limited

TRAINING MANUAL - PIPING OG NO. : 29040-P-UPS-1003

Rev: RO

PIPING STUDY

COLUMN PIPING Page 1OF1

DG. WO, “GPT

TYPICAL TOWER TROLLEY BEAM ARRANGEMENT

Troueveea

lz

%

eon

‘TRouey

BEAM SUPPORTS

i

ELEVATION

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design and Analysis of Asme Boiler and Pressure VesselDocument229 pagesDesign and Analysis of Asme Boiler and Pressure VesselWael MansourNo ratings yet

- Noise Survey in WorkshopDocument1 pageNoise Survey in WorkshopWael MansourNo ratings yet

- Cladding in Heat Exchanger - BaherDocument3 pagesCladding in Heat Exchanger - BaherWael MansourNo ratings yet

- Safurex WPSDocument5 pagesSafurex WPSWael MansourNo ratings yet

- Opinion FormDocument1 pageOpinion FormWael MansourNo ratings yet

- Cylinders Certificates 2-2024Document5 pagesCylinders Certificates 2-2024Wael MansourNo ratings yet

- 19-3 Cable-Plug 01Document3 pages19-3 Cable-Plug 01Wael MansourNo ratings yet

- Xerox Scan - 25022024082933Document1 pageXerox Scan - 25022024082933Wael MansourNo ratings yet

- PRV NH1034Document5 pagesPRV NH1034Wael MansourNo ratings yet

- Stamicarbon SafurexDocument32 pagesStamicarbon SafurexWael MansourNo ratings yet

- Piping ClassDocument42 pagesPiping ClassWael MansourNo ratings yet